The Future of Manufacturing in America: Reshoring, Automation, and Innovation

ELK GROVE VILLAGE, IL, November 28, 2023 -

Global manufacturing is experiencing a significant shift. The Reshoring Initiative, a movement to bring manufacturing jobs and operations back to the United States, is not just reshaping our business strategies but also redefining American manufacturing as a whole. This initiative is more than a mere economic trend; it represents a strategic pivot crucial for American manufacturing revitalization.

The Evolution of Offshoring

A report by Kearney's Reshoring Index showed a dramatic shift in the past few years. This moved the initiative from a strategic possibility to a viable market reality. Our industry's journey from offshoring to reshoring is marked by evolving economic landscapes and shifting market demands. Five key drivers fuel the reshoring movement:

1. The Total Cost of Ownership

The total cost of ownership (TCO) model reveals that hidden costs associated with offshoring often outweigh apparent cost benefits. Reshoring can reduce shipping and warehousing costs, lower inventory levels, and improve customer responsiveness.

2. Technological Innovations

The U.S.'s leadership in advanced manufacturing technologies, particularly in automation and AI, reduces the labor cost gap, making domestic production increasingly viable.

3. Quality Control

Proximity to manufacturing facilities enhances quality control and regulatory compliance, aspects we value highly.

4. Government Policies

Initiatives like the Made in America Tax Credit encourage companies to bring manufacturing jobs back to the United States.

5. Consumer Trends

The growing preference for 'Made in the USA' products aligns with our commitment to quality standards.

Embracing Automation and Advanced Technologies in US Manufacturing Reshoring

The reshoring trend in American manufacturing marks a pivotal shift towards superior operational efficiency and heightened market responsiveness. Central to this movement are advancements in automation and cutting-edge technologies, which redefine the manufacturing sector. Key among these are state-of-the-art CNC machine tools, which bring several transformative benefits:

Unmatched Precision and Consistency

CNC machines excel in producing parts with exceptionally tight tolerances, ensuring unparalleled quality and uniformity. This level of precision is vital for sustaining a competitive edge in the global marketplace.

Elevated Efficiency and Productivity

CNC machining drastically cuts production times, which increases productivity. This is crucial to keeping pace with today's dynamic market demands.

Flexible Manufacturing Capabilities

Today's CNC machines, particularly those equipped with multitasking features, can seamlessly transition between various production tasks. Flexibility is key to responding to fluctuating customer needs and market shifts. The introduction of multitasking machine tools, such as Shibaura Machine’s MP-U Series, which combine functions like milling, turning, and drilling in one setup, has revolutionized the manufacturing process. This has reduced processing time and improved workflow efficiency.

Minimized Waste and Cost

CNC machining's high precision reduces material waste. By crafting parts more accurately and with fewer resources, manufacturers realize substantial cost savings over time. This efficiency is advantageous not only in terms of material costs but also in reducing environmental impact.

Optimized Skilled Labor

While CNC operations demand skilled personnel, they also enable more strategic employment of labor. Workers can concentrate on high-level tasks and innovation, managing and refining complex operations of advanced CNC machinery, rather than engaging in monotonous, manual labor.

Integrating IIoT in Manufacturing

The incorporation of the Industrial Internet of Things (IIoT), exemplified by systems like machiNetCloud from Shibaura Machine, is revolutionizing the manufacturing landscape. IIoT introduces a plethora of capabilities, primarily through real-time data analytics.

This technology offers critical insights into machine performance, production rates, and maintenance schedules, empowering manufacturers to make proactive, informed decisions. IIoT provides a cohesive link between different manufacturing stages, from CNC machinery to assembly lines. This integration not only heightens efficiency but also significantly reduces downtime, streamlining the entire production process.

The Future Landscape of American Manufacturing

The Reshoring Initiative is not just about bringing jobs back; it's about fostering a resilient, innovative, and competitive manufacturing sector in the U.S. It's expected to strengthen the economy, create jobs, and restore the U.S.'s position in global manufacturing.

To learn more about the machine tools and technologies that are redefining the capabilities and competitiveness of American manufacturing on the global stage, contact the Machine Tool team. We partner with companies to navigate a strategic approach that ensures the long-term success and sustainability of the reshoring movement.

Related Articles View All Machine Tools Articles

Navigating the Electric Vehicle Shift: Advanced Machine Tools for Modern Automotive Production

ELK GROVE VILLAGE, IL, November 21, 2023 - As the automotive industry evolves, multitasking machine tools play an increasingly important role. With these tools, cycle times can be reduced and efficiency can be enhanced across applications for both electric...

Read moreView the Future with You: Highlights from Shibaura Machine Group's 2023 Solutions Fair

ELK GROVE VILLAGE, IL, November 7, 2023 - The Shibaura Machine Group held its much-anticipated Solutions Fair last week from October 31st to November 2nd. The event showcased a blend of cutting-edge technology and rich cultural heritage of their Numazu and...

Read moreMachine Tool Industry Focus: Oil and Gas

ELK GROVE VILLAGE, IL, October 31, 2023 - The oil and gas industry is experiencing a revival, with capital investments reaching new heights. According to the International Energy Forum, oil and gas upstream capital expenditures increased by 39% in 2022 to ...

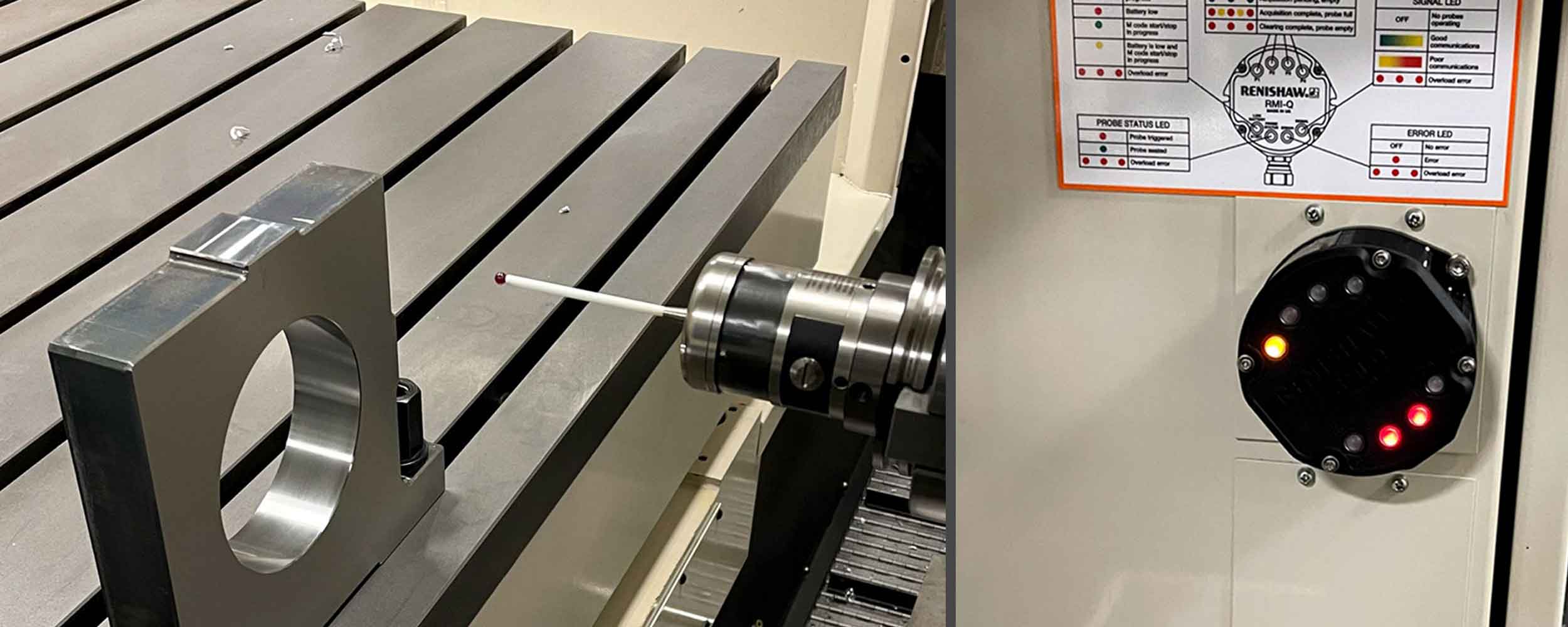

Read moreConsidering On-Machine Measurement for Large Workpieces? Read this first.

ELK GROVE VILLAGE, IL, October 24, 2023 - In the fast-paced world of manufacturing, the need for precision and efficiency has never been greater. As workpieces grow in size and complexity, traditional methods of measurement are proving to be increasingly i...

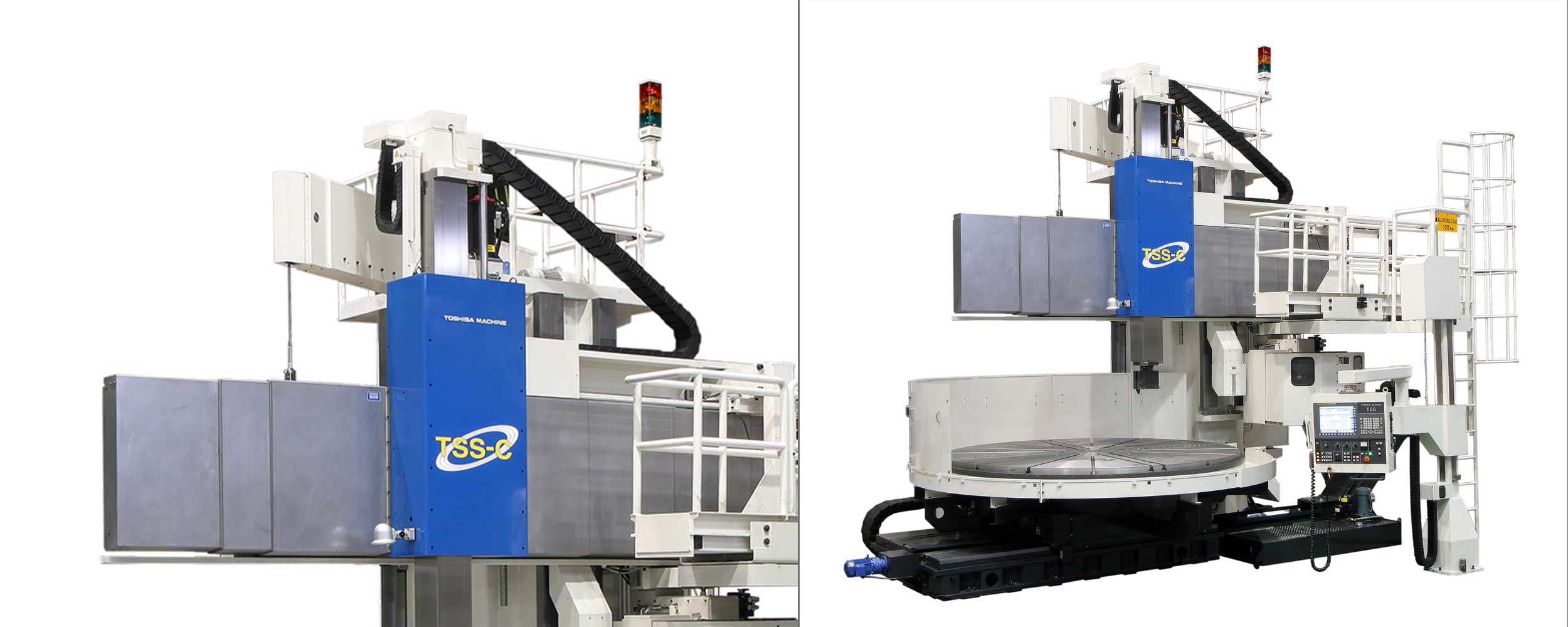

Read moreHow Shibaura Machine is Solving X-Axis Straightness of Motion on the TSS Series

ELK GROVE VILLAGE, IL, October 3, 2023 - In precision machining, even the slightest misalignment can lead to significant errors in the final product. While advancements in technology have made it easier to achieve high levels of accuracy, certain challenge...

Read moreHow Smart Factories Are Transforming Modern Manufacturing

ELK GROVE VILLAGE, IL, September 26, 2023 - In an era defined by digital transformation, the future of manufacturing is significantly influenced by the concept of the Smart Factory. This modern manufacturing approach leverages advanced technologies to crea...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools