Injection Molding Machines

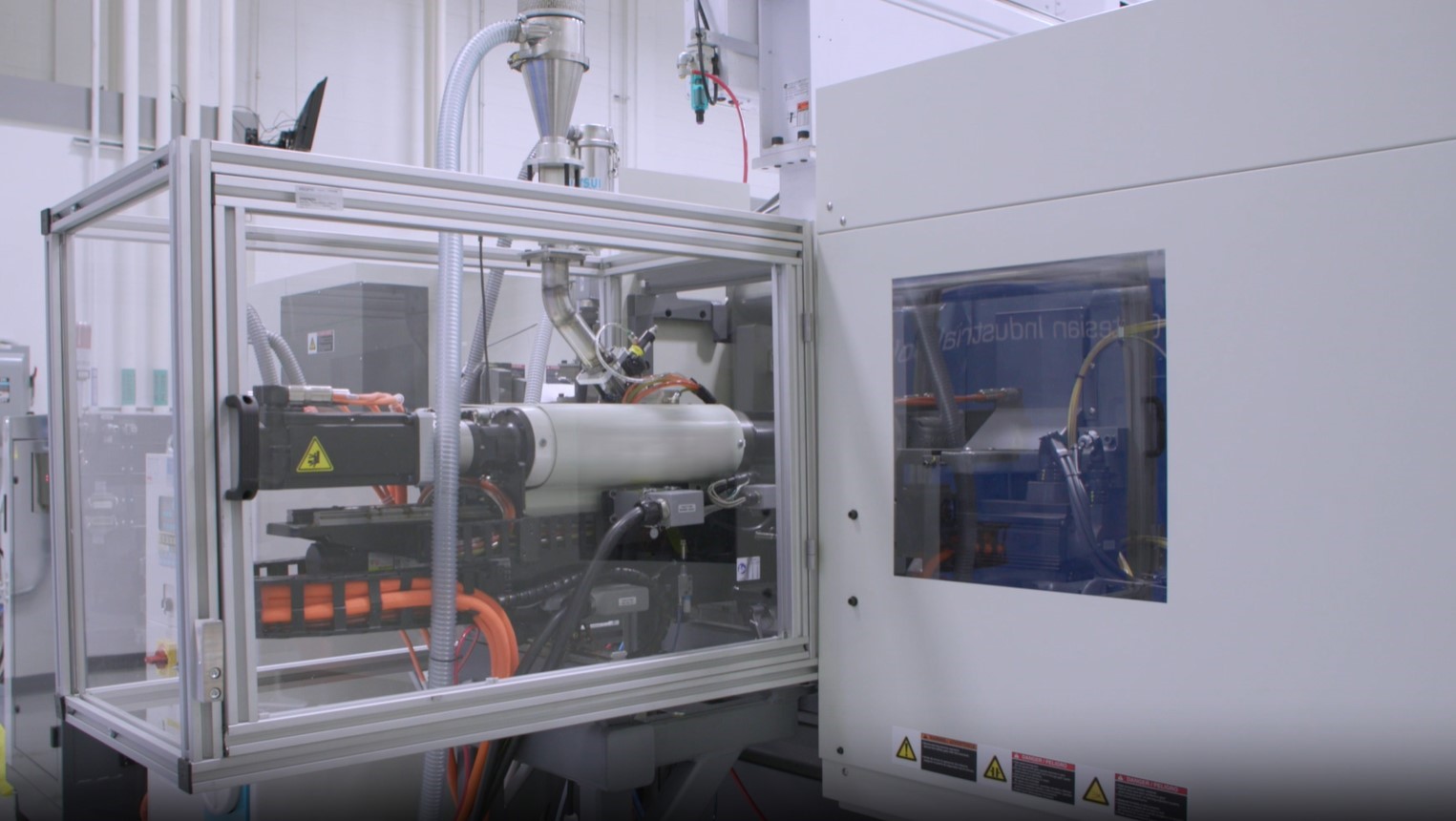

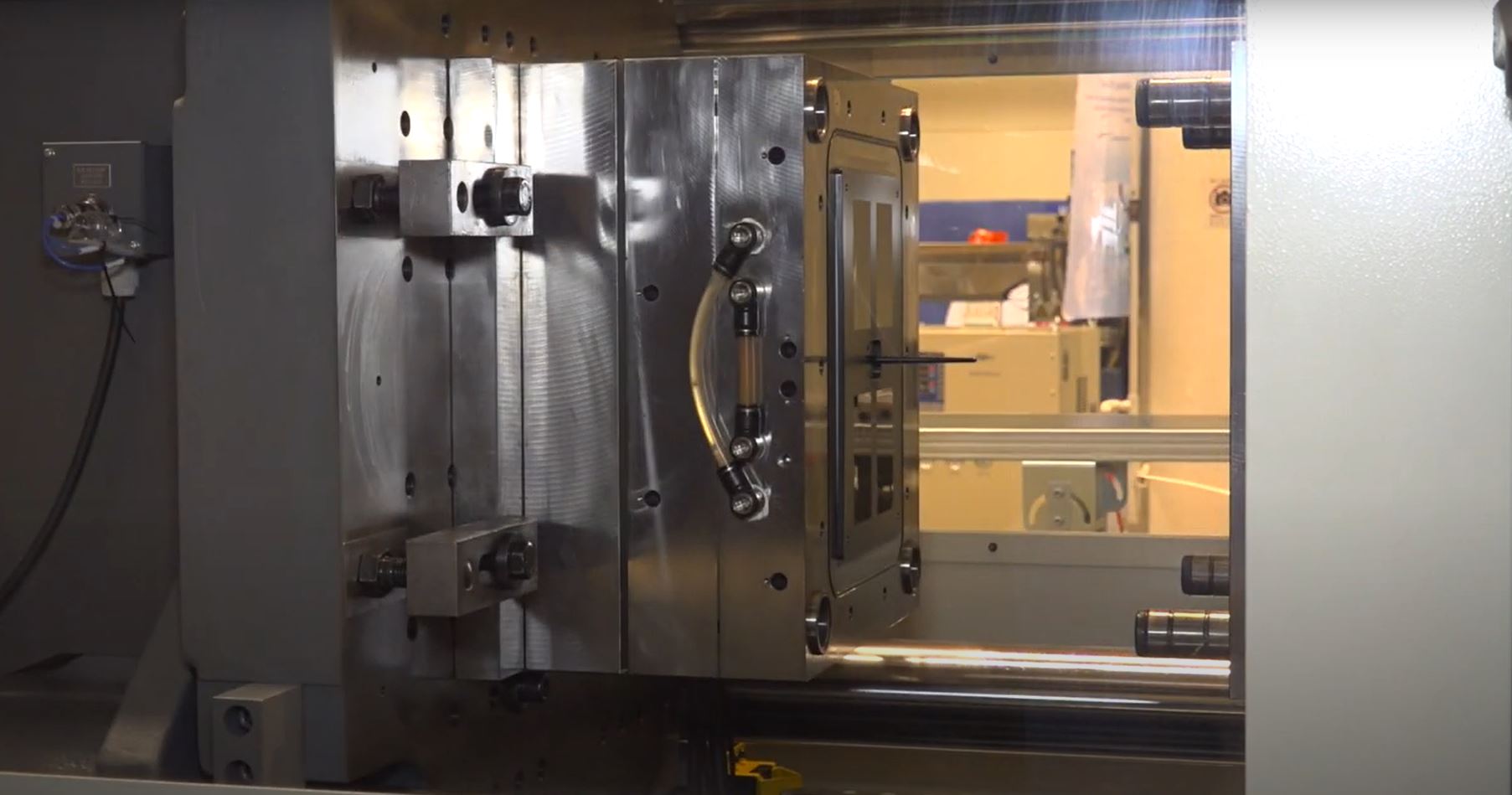

EC SXIII Series - All-Electric Injection Molding Machines

55 to 3,350 U.S. tons of clamping force

Shibaura Machine is a leading global manufacturer of high precision injection molding machines.

Our North American headquarters, centrally located in Elk Grove Village, IL, is fully equipped to support sales, service, parts, mold trials, and customer training. Our service offices in Elk Grove Village, IL, Rancho Cucamonga, CA, Charlotte, NC, and Markham, ON, Canada are staffed with experienced, professional service technicians who are fully committed to supporting the success and profitability of our customers.

Shibaura Machine generally stocks over 100 injection molding machines in our North American inventory for quick delivery. Our U.S. assembly facility allows us to quickly customize molding presses to our customer’s specifications. Capabilities include; powering up machines for test runs, installing software updates, installation of special options, and machine inspection before shipment.

We have provided precision injection molding machines to the North American market since 1974 and have an installed base of over 15,000 injection molding machines. Our global manufacturing and world-class engineering capability, along with our long heritage of industry leading innovation, reliability, and precision, continue to make us the most proven and reliable partner for your injection molding machinery needs.

Solutions

Injection molding solutions for a wide range of applications

SXIII All-Electric Series

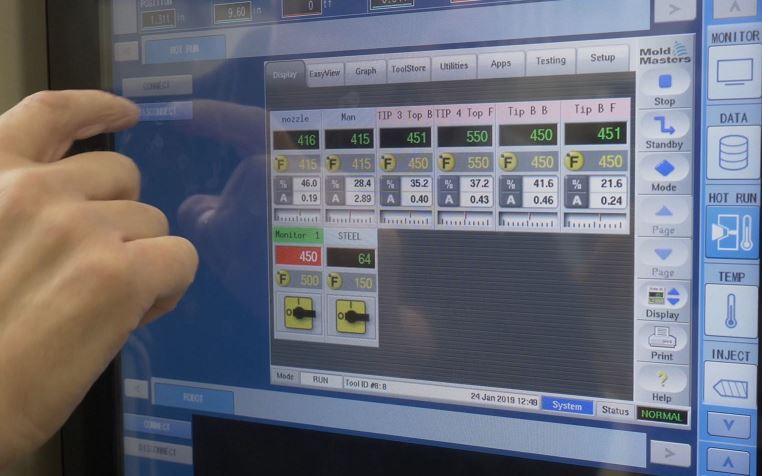

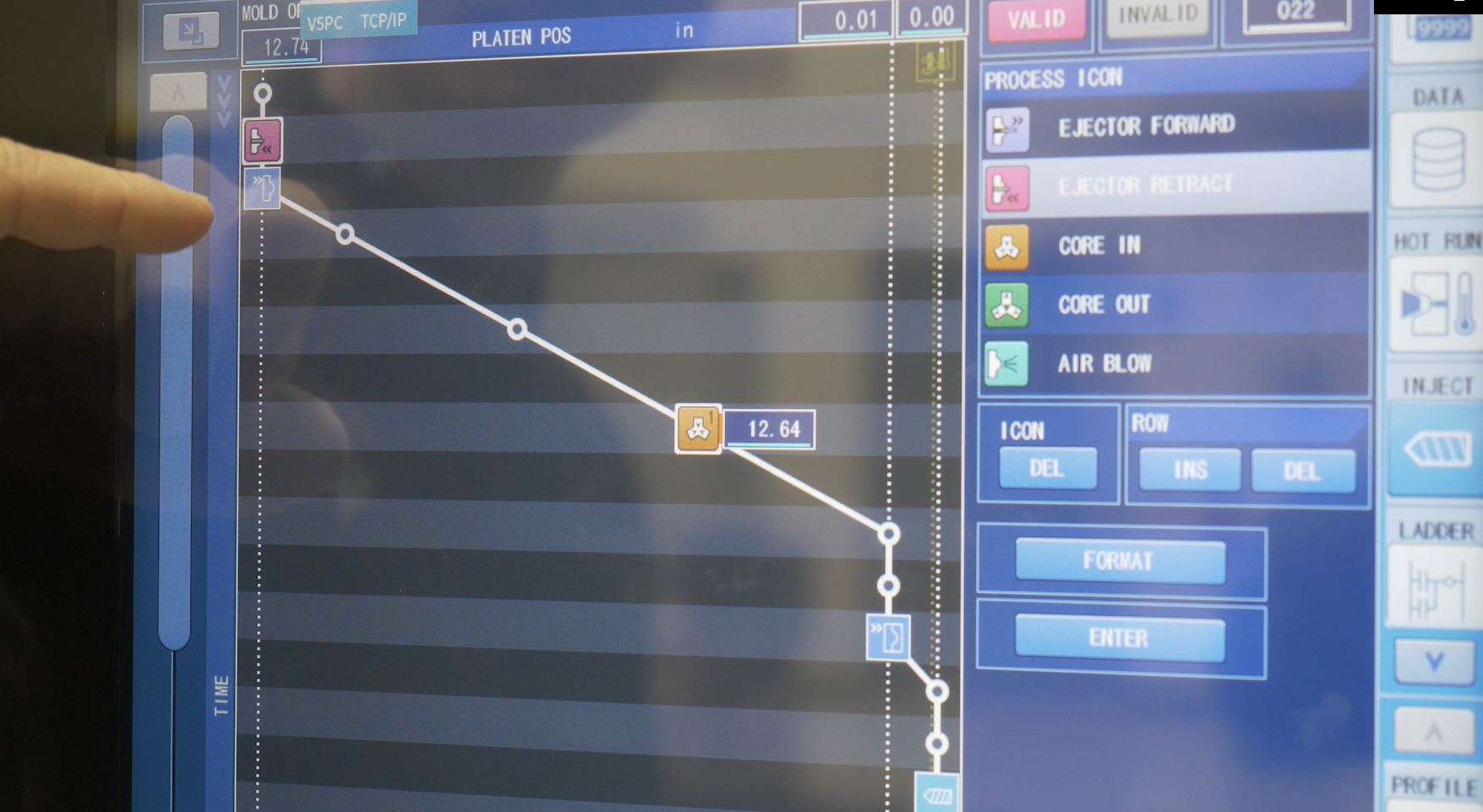

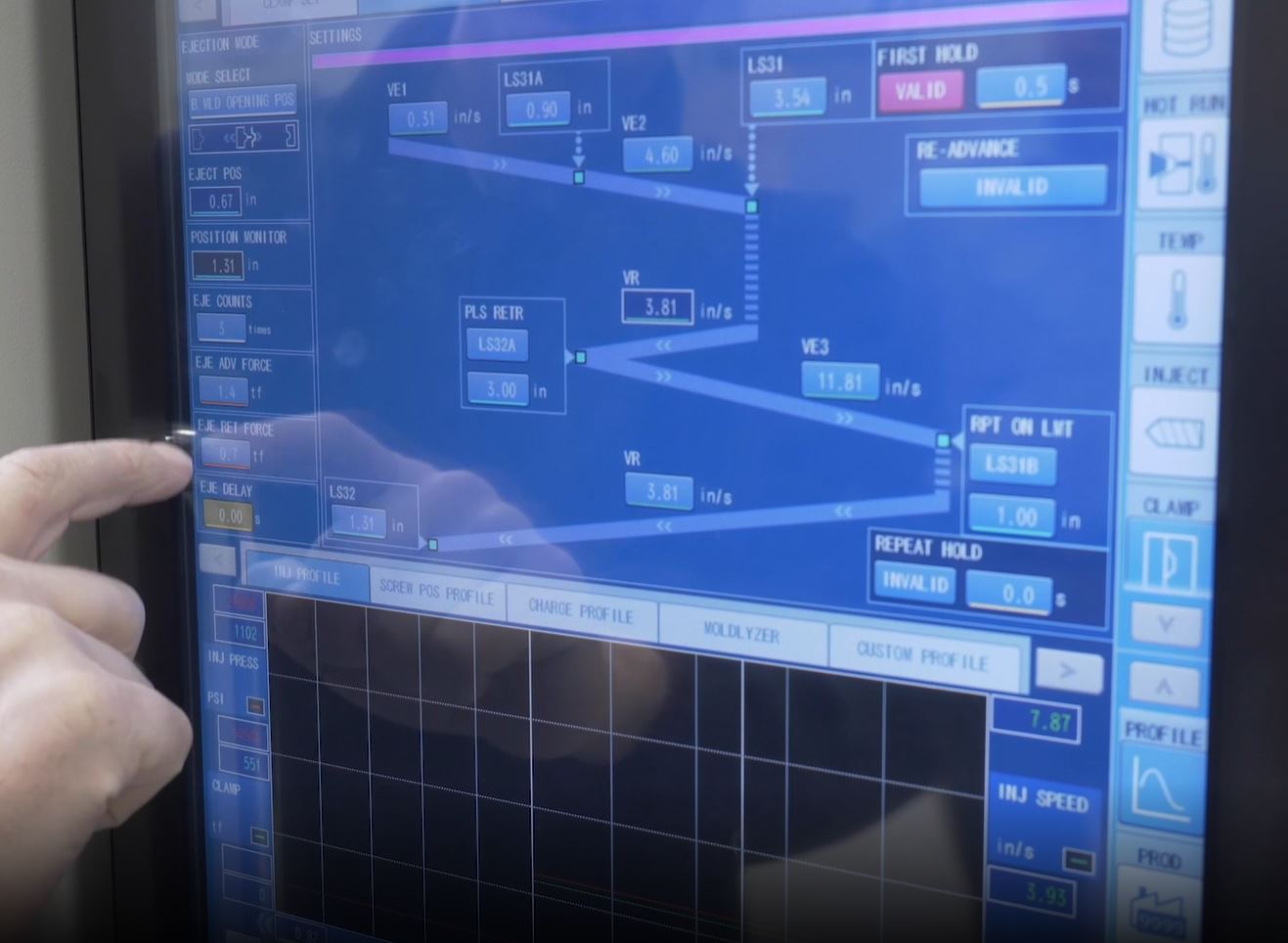

V70 Controller

Videos

Customer Care

Training

PNA - V70 Controller Training

This 1-1/2 day class will include the review of machine capabilities, the highlights of special features associated with V70 controller and our ECSXIII series all-electric machines. Students will have hands-on training on an ECSXIIIV70 machine. Click below to download the class synopsis.

PNA - EC Maintenance Training

This 1-1/2 day class will include the review of proper maintenance procedures for Shibaura electric molding machines. The attendee should have a basic understanding of Shibaura electric machines. Details of machine parameters, requirements for proper machine upkeep, and review of control functions will be presented. There will be hands-on training using a Shibaura molding machine as well as classroom training.

PNA - V70 Controller Training

This 1-1/2 day class will include the review of machine capabilities, the highlights of special features associated with V70 controller and our ECSXIII series all-electric machines. Students will have hands-on training on an ECSXIIIV70 machine. Click below to download the class synopsis.

Molding 360 - Advanced Processing

This is an intensive, 3-day injection molding processing course designed to enhance skills and provide the tools required to maximize quality, productivity, and profitability. Students will be taught how to develop a process through use of scientific molding concepts. Classroom learning is combined with hands-on learning at the machine.

EC Maintenance Training

This 1-1/2 day class will include the review of proper maintenance procedures for Shibaura electric molding machines. The attendee should have a basic understanding of Shibaura electric machines. Details of machine parameters, requirements for proper machine upkeep, and review of control functions will be presented. There will be hands-on training using a Shibaura molding machine as well as classroom training.

PNA - V70 Controller Training

This 1-1/2 day class will include the review of machine capabilities, the highlights of special features associated with V70 controller and our ECSXIII series all-electric machines. Students will have hands-on training on an ECSXIIIV70 machine. Click below to download the class synopsis.

PNA - EC Maintenance Training

This 1-1/2 day class will include the review of proper maintenance procedures for Shibaura electric molding machines. The attendee should have a basic understanding of Shibaura electric machines. Details of machine parameters, requirements for proper machine upkeep, and review of control functions will be presented. There will be hands-on training using a Shibaura molding machine as well as classroom training.

PNA - V70 Controller Training

This 1-1/2 day class will include the review of machine capabilities, the highlights of special features associated with V70 controller and our ECSXIII series all-electric machines. Students will have hands-on training on an ECSXIIIV70 machine. Click below to download the class synopsis.

EC Maintenance Training

This 1-1/2 day class will include the review of proper maintenance procedures for Shibaura electric molding machines. The attendee should have a basic understanding of Shibaura electric machines. Details of machine parameters, requirements for proper machine upkeep, and review of control functions will be presented. There will be hands-on training using a Shibaura molding machine as well as classroom training.

Articles View All Articles

Elevating Medical Injection Molding Performance

ELK GROVE VILLAGE, IL, February 23, 2024 - A leading provider of precision machinery and manufacturing solutions, Shibaura Machine announced the release of its Medical Spec injection molding machine at the 2024 Plastec West show in Anaheim, CA earlier this...

Read moreSecurity and Simplicity: The Dual Focus of the V70 Controller's User Log-in

ELK GROVE VILLAGE, IL, November 15, 2023 - In today's competitive injection molding industry, the difference between leading the pack and falling behind often comes down to the smallest details—like the user log-in experience on your injection molding mach...

Read moreHow Mold Movement During Charging Can Reduce Cycle Times in Injection Molding

ELK GROVE VILLAGE, IL, November 7, 2023 - As the injection molding industry continues to grow at a rapid pace, efficiency is paramount. The capability of simultaneously charging during mold movement has become a game-changing innovation, setting new standa...

Read moreThe Rise of All Electric LSR Injection Molding Machines

ELK GROVE VILLAGE, IL, September 29, 2023 - Are you looking for a way to produce high-quality, intricate silicone components at unprecedented speeds? You're not alone. In a manufacturing landscape where efficiency, versatility, and precision are pivotal, t...

Read moreEasily Transition to Multi-Shot Molding with Shibaura Machine

ELK GROVE VILLAGE, IL, September 13, 2023 - Two-shot molding has long captured manufacturers' interest for its ability to produce complex, multi-material components in a single cycle. With two-shot molding, designs that were once considered too intricate o...

Read moreImprove Your Injection Molding Process with Barrel Temperature Shift Mode

ELK GROVE VILLAGE, IL, August 23, 2023 - To ensure optimal product quality, consistency, and operational efficiency, precise temperature control plays a critical role in the injection molding process. One essential feature that can significantly impact inj...

Read moreCustomer Testimonials View All

Increasing plant efficiency with the help of Shibaura Machine

Founded in 1953, Hoffer Plastics has grown to become an industry leader and innovator in the custom plastic injection molding industry. Located in a 365,000 sq. ft. facility on 24 acres and employing more than 350 people, they produce more than three bill...

Achieving faster cycle times and a higher level of precision with Shibaura Machine

New Berlin Plastics was founded in 1975. After two company moves in 1976 and 1982, business continued to expand, allowing NBP to transition to a new 100,000 square foot facility in 1998. This facility is located in New Berlin, Wisconsin and serves as the...

Exceeding requirements for high-precision, tight-tolerance parts with the help of Shibaura Machine

Performance Gear Systems was founded in 1997 with the mission to be a world leader in the design, engineering, and manufacturing of high precision plastic gears and actuators. Located in Plainfield, IL, this 50,000 square foot cutting-edge facility brings ...

Meeting the demand for high-volume, precision medical devices with the help of Shibaura Machine

JunoPacific is a custom medical device design, development, manufacturing and assembly operation located near two major medical device hubs: San Jose, CA and Minneapolis, MN.Manufacturing custom plastic products for multi-national fortune 500 medical compa...

FAQ

Does Shibaura Machine offer 24/7 technical phone support?

Yes. Dial 1 (888) 593-1616 #1 for service. Outside of normal business hours, you can leave a message and an "on-call" technician will call you back.

Does Shibaura Machine stock machines for quick delivery?

Yes! We typically have over 100 machines in-stock and ready for quick delivery.

Does Shibaura Machine offer machine financing?

Yes, our in-house financing arm, TMAC offers a variety of flexible financing solutions. Click Here for more information.

What type of training does Shibaura Machine offer?

Yes, we offer a variety of training classes including Processing, Controls, and Maintenance. Classes are held in Elk Grove Village, Illinois, Ontario, California, Charlotte, North Carolina, and Markham, Ontario Canada. Click here to learn more.

Does Shibaura Machine offer an Industry 4.0 solution?

Our V70 controller supports OPC-UA communication standards. This capability along with our machiNet IoT+m platform allows machine and process data to be remotely monitored and shared with plant MES and ERP system. Contact your Shibaura Machine representative today to discuss your specific requirements.

Can your machines be integrated with auxiliary equipment?

Yes, in most cases auxiliary equipment can be integrated with our machines. Speak to your Shibaura Machine representative for more details.

What type of warranty does Shibaura Machine offer?

Our industry leading, 4-year limited warranty reflects the quality and reliability of Shibaura Machine. Click Here for more details,