Considering On-Machine Measurement for Large Workpieces? Read this first.

ELK GROVE VILLAGE, IL, October 24, 2023 -

In the fast-paced world of manufacturing, the need for precision and efficiency has never been greater. As workpieces grow in size and complexity, traditional methods of measurement are proving to be increasingly inadequate.

On-machine measurement is no longer a luxury but a necessity for modern machinists, especially when dealing with large workpieces. Below are several benefits manufacturers can expect when incorporating this method.

Accurate Data Collection

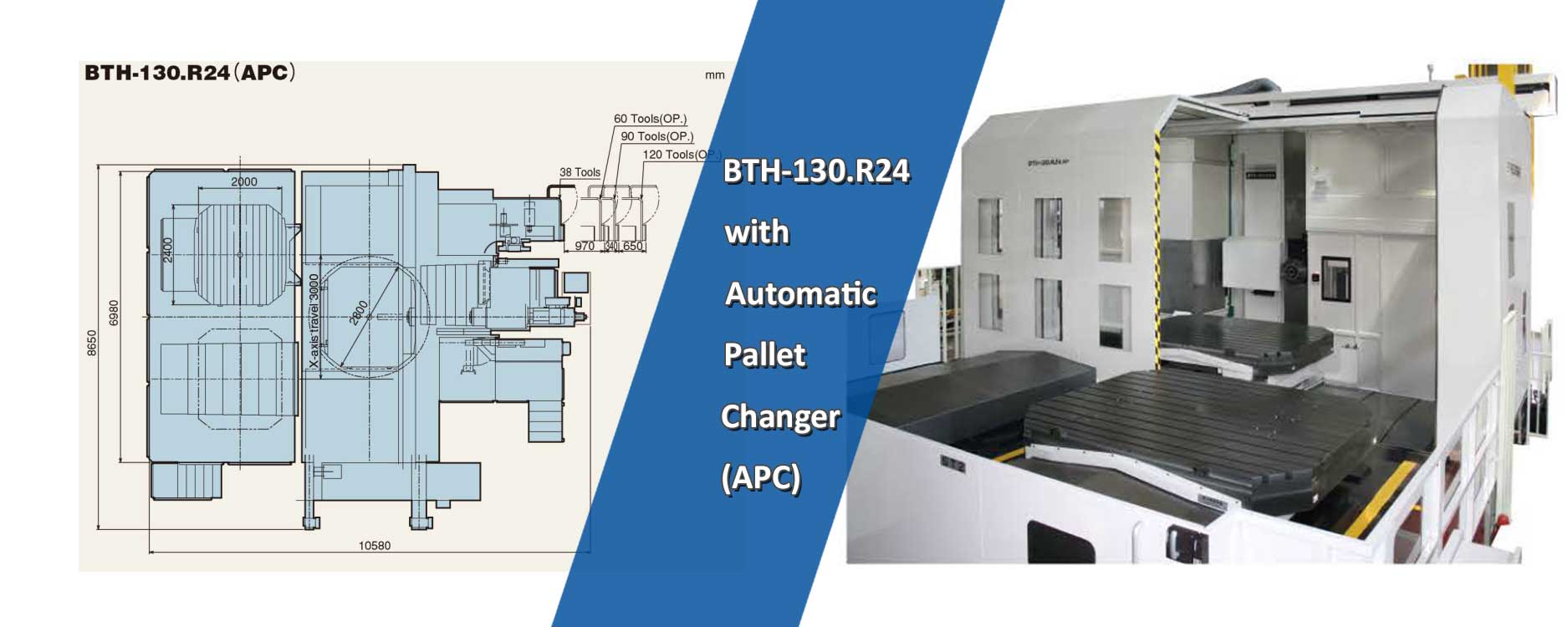

On-machine measurement allows for data collection and analysis. Traditional methods include transporting large workpieces to a separate measuring room and then back to the machine tool which can be time-consuming. The on-machine method enables machinists to make immediate adjustments, ensuring that the workpiece meets manufacturing quality standards. For example, Shibaura Machine's BTH Series of horizontal boring machines is designed to tackle these challenges effectively.

Cost-Efficiency

By integrating the measurement process into the machine tool itself, you eliminate the need for separate measuring rooms and additional labor, reducing operational costs. Moreover, by eliminating manual handling, you reduce error and safety risks.

Enhanced Productivity

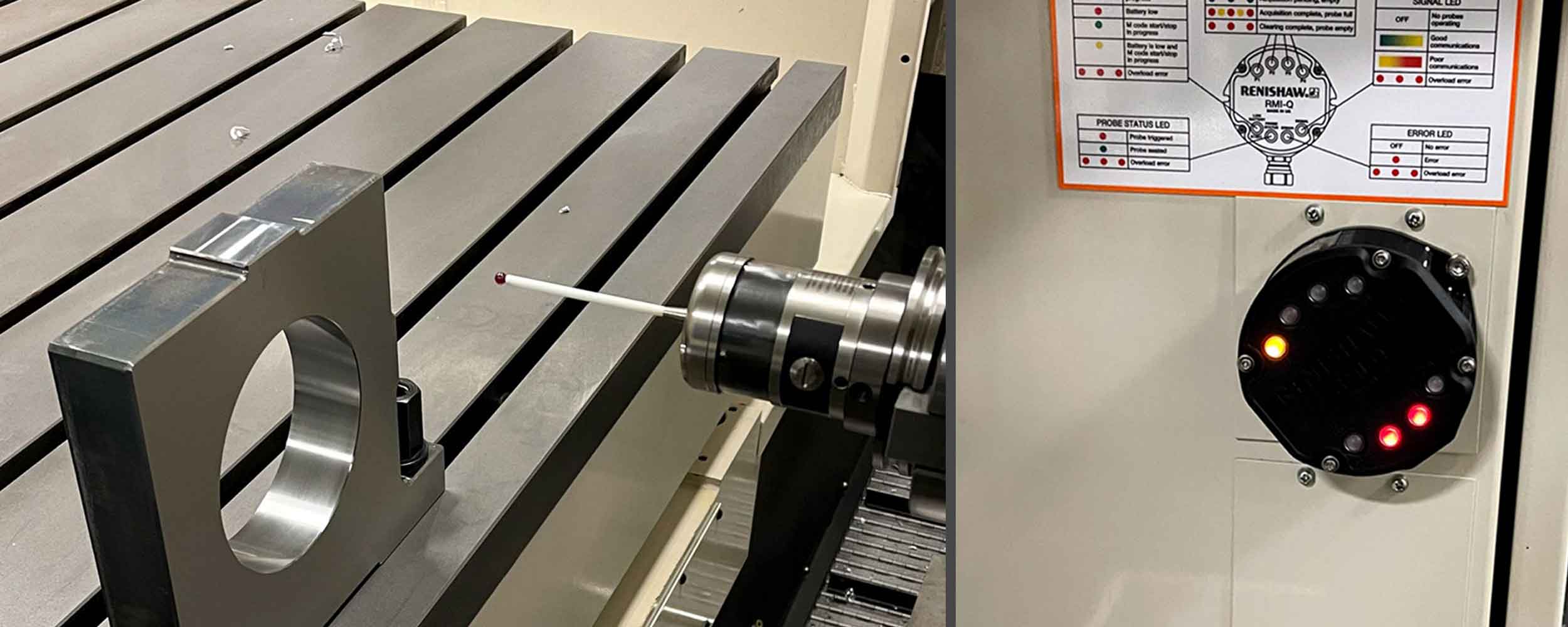

Through data collection, machinists can make quick decisions, reducing downtime and increasing productivity. Machine measuring removes the back-and-forth which can not only disrupt workflow but also tie up resources that could be better utilized elsewhere. Renishaw's probing and tool measurement systems are excellent examples of technology that can be integrated into machine tools for this purpose.

Options for On-Machine Measurement of Large Workpieces

The larger the workpiece, the more complex the measurement process becomes. This can lead to inaccuracies if not managed correctly.

Beyond Shibaura Machine’s Automatic Measurement and Automatic Tool Length Measurement Functions within the machine tools, our partnership with Metrology Resource Group (MRG) offers integration and application assistance for customers to further advance their on-machine measurement of large workpieces and address these challenges. The systems below seamlessly integrate with machine tools to offer a comprehensive and versatile system.

Advanced Measurement Techniques with Probing

The Renishaw inspection probe system RMP60 also offers a robust solution for on-machine measurement and job set-up. Utilizing a touch-trigger mechanism, this probe system provides highly accurate data points by making physical contact with the workpiece surface. This ensures that even the most intricate details are captured with the utmost accuracy. Its integration capabilities with various machine tools such as Shibaura Machine's double column MPJ-M Series make it a versatile choice for a wide range of manufacturing settings.

Modernize Large Workpiece Machining

The manufacturing landscape evolves, and so should your methods. On-machine measurement of large workpieces offers unparalleled advantages in time-efficiency, cost-saving, and most importantly, accuracy. Contact the Machine Tool team to learn more about your options for on-machine measurement with large workpieces.

Related Articles View All Machine Tools Articles

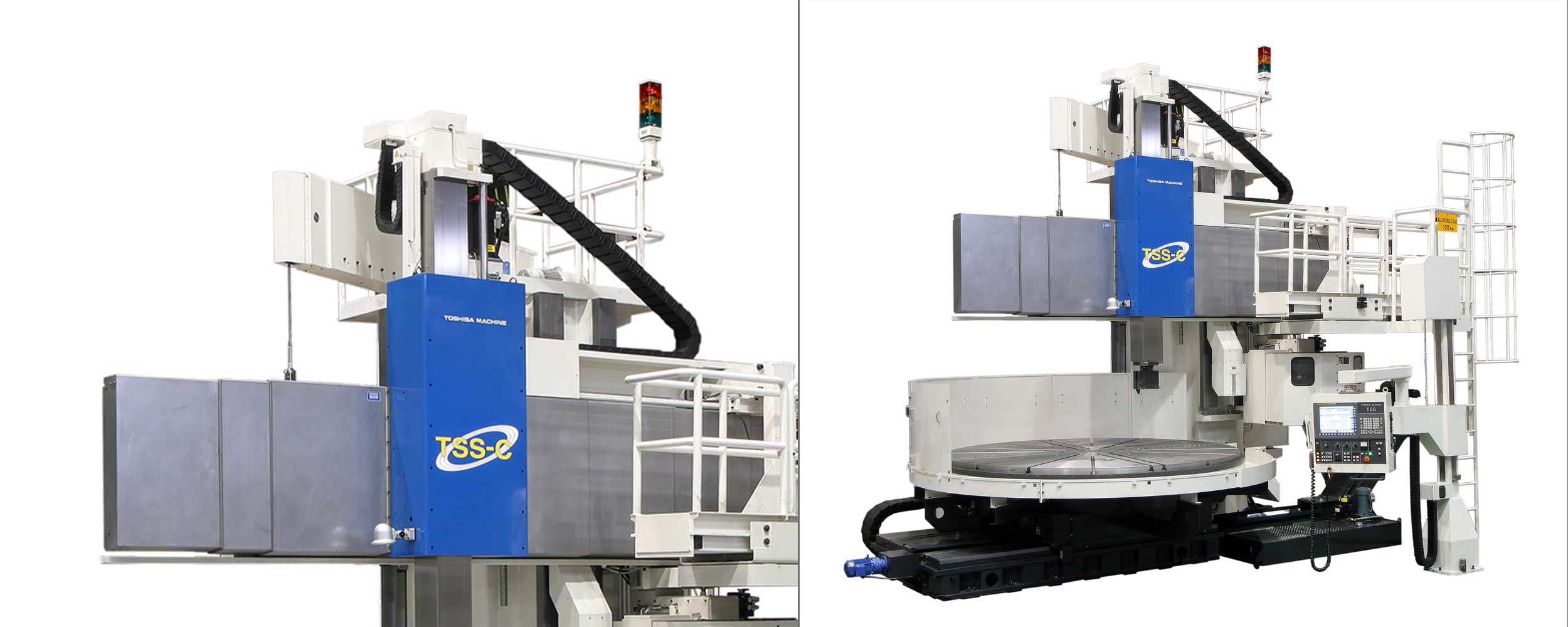

How Shibaura Machine is Solving X-Axis Straightness of Motion on the TSS Series

ELK GROVE VILLAGE, IL, October 3, 2023 - In precision machining, even the slightest misalignment can lead to significant errors in the final product. While advancements in technology have made it easier to achieve high levels of accuracy, certain challenge...

Read moreHow Smart Factories Are Transforming Modern Manufacturing

ELK GROVE VILLAGE, IL, September 26, 2023 - In an era defined by digital transformation, the future of manufacturing is significantly influenced by the concept of the Smart Factory. This modern manufacturing approach leverages advanced technologies to crea...

Read moreIntelligent Data Acquisition: A Look at FOCAS2 and Machine Tools

ELK GROVE VILLAGE, IL, September 19, 2023 - Data acquisition and machine maintenance are now more than just operational requirements; they are strategic imperatives for manufacturing success.Recognizing the critical role data plays, manufacturers are incre...

Read moreWhere Innovation Meets Expertise: Shibaura Machine and Manske Machinery, Inc. at WIMTS 2023

ELK GROVE VILLAGE, IL, September 6, 2023 - Shibaura Machine is excited to announce the company's participation at the 2023 Wisconsin Manufacturing & Technology Show (WIMTS), the largest manufacturing event in the state. With a history spanning over 30 year...

Read moreUnleashing Production Potential with Multi-Pallet Integration in BTH-Series Horizontal Boring Machines

ELK GROVE VILLAGE, IL, August 29, 2023 - In modern manufacturing, efficiency and adaptability are not just buzzwords; they're a cornerstone of success. As factories expand production mix and volume, new opportunities bring fresh challenges. A particular pa...

Read more5 Value Adds to Increasing Automation with the Multi-Pallet Magazine on the TMD Series

ELK GROVE VILLAGE, IL, August 22, 2023 - In manufacturing, staying ahead requires more than just meeting current demands – it requires a proactive anticipation of tomorrow's challenges. As the drive towards automation gains momentum, manufacturers are real...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools