How Smart Factories Are Transforming Modern Manufacturing

ELK GROVE VILLAGE, IL, September 26, 2023 -

In an era defined by digital transformation, the future of manufacturing is significantly influenced by the concept of the Smart Factory. This modern manufacturing approach leverages advanced technologies to create a more connected, efficient, and intelligent production environment.

As an industry leader with decades of experience in machine tool technology, Shibaura Machine is at the forefront of this industry transformation. We're setting the standards that will define the future of manufacturing, driving efficiency and quality to unparalleled heights. In this article, we'll explore how a Smart Factory impacts crucial aspects of manufacturers operations, from labor and quality to the pivotal metric of Overall Equipment Effectiveness (OEE).

Labor: Empowering the Workforce through Data

Unlike a traditional factory where employees rely on routine reports, a Smart Factory allows real-time tracking of metrics. This enables a proactive approach to workflow management, thereby significantly reducing human error and downtime.

Factors such as spindle speed, feed rate, and cutting force are continuously tracked, enabling automatic adjustments or instant alerts if metrics stray from predefined safe parameters. This proactive, data-driven approach significantly minimizes the chances of machine failure and costly downtime, while optimizing tool performance and throughput.

Advanced automation and real-time monitoring of machine tools free up operators to concentrate on tasks that add more value, such as fine-tuning machining processes, troubleshooting complex issues, or overseeing quality control. This reorientation of labor enriches job roles and leverages human expertise, making operations more efficient and providing a more rewarding work environment.

Operations: Precision, Efficiency, and Flexibility

In a Smart Factory, the concept of operations evolves to include continuous feedback loops powered by real-time data. The algorithms continually adjust machine tool settings, such as cutting speeds or torque, based on current performance metrics. This not only extends machine life by reducing wear and tear but also enhances operational efficiency by allowing machines to operate at their peak capabilities. The outcome is a manufacturing environment characterized by precision, flexibility, and unparalleled efficiency.

Smart Factories also tackle the issue of resource underutilization that plagues traditional manufacturing settings. Through real-time data collection and analytics, these digitally advanced facilities ensure optimal allocation of resources, from machine tools to human labor. This continuous stream of actionable insights allows for each component in the factory to operate at peak efficiency, thereby maximizing productivity and minimizing waste.

Quality: Consistency and Excellence

In a Smart Factory, quality assurance isn't a periodic checkpoint but an ongoing, real-time process. For example, consider a vertical turning and boring mill like Shibaura Machine’s TUE Series, equipped with a probe that continuously monitors dimensions and tolerances of the workpiece. If any deviations are detected, the system can either alert the operator or automatically make adjustments to bring the process back within specifications.

This level of real-time quality control drastically lowers the probability of defects making it to the final product. By weaving quality assurance into the operation, this ensures a level of consistency and excellence that traditional manufacturing environments struggle to match.

Improving Overall Equipment Effectiveness through Smart Factories

One of the many values of a Smart Factories lies in its ability to elevate OEE. Manufacturers can ensure that their machine tools are not only more efficient but also smarter and interconnected as part of an overall IIoT (Industrial Internet of Things) strategy. For example, utilizing an IIoT platform like machiNetCloud by Shibaura Machine allows for manufacturers to seamlessly integrate with existing systems to enhance operational insights.

By simultaneously optimizing uptime, performance, and quality through real-time data and algorithms, these advanced facilities create a manufacturing environment where every element operates at near-peak efficiency. This combination of technology and data-driven insights makes Smart Factories the gold standard for modern manufacturing, turning the ideal of operational excellence into a tangible reality.

Shibaura Machine is committed to helping businesses transition into this smarter, more efficient future. Together, we can lay the foundations for a new era of industrial excellence.

Contact the Machine Tool team to learn more.

Related Articles View All Machine Tools Articles

Intelligent Data Acquisition: A Look at FOCAS2 and Machine Tools

ELK GROVE VILLAGE, IL, September 19, 2023 - Data acquisition and machine maintenance are now more than just operational requirements; they are strategic imperatives for manufacturing success.Recognizing the critical role data plays, manufacturers are incre...

Read moreWhere Innovation Meets Expertise: Shibaura Machine and Manske Machinery, Inc. at WIMTS 2023

ELK GROVE VILLAGE, IL, September 6, 2023 - Shibaura Machine is excited to announce the company's participation at the 2023 Wisconsin Manufacturing & Technology Show (WIMTS), the largest manufacturing event in the state. With a history spanning over 30 year...

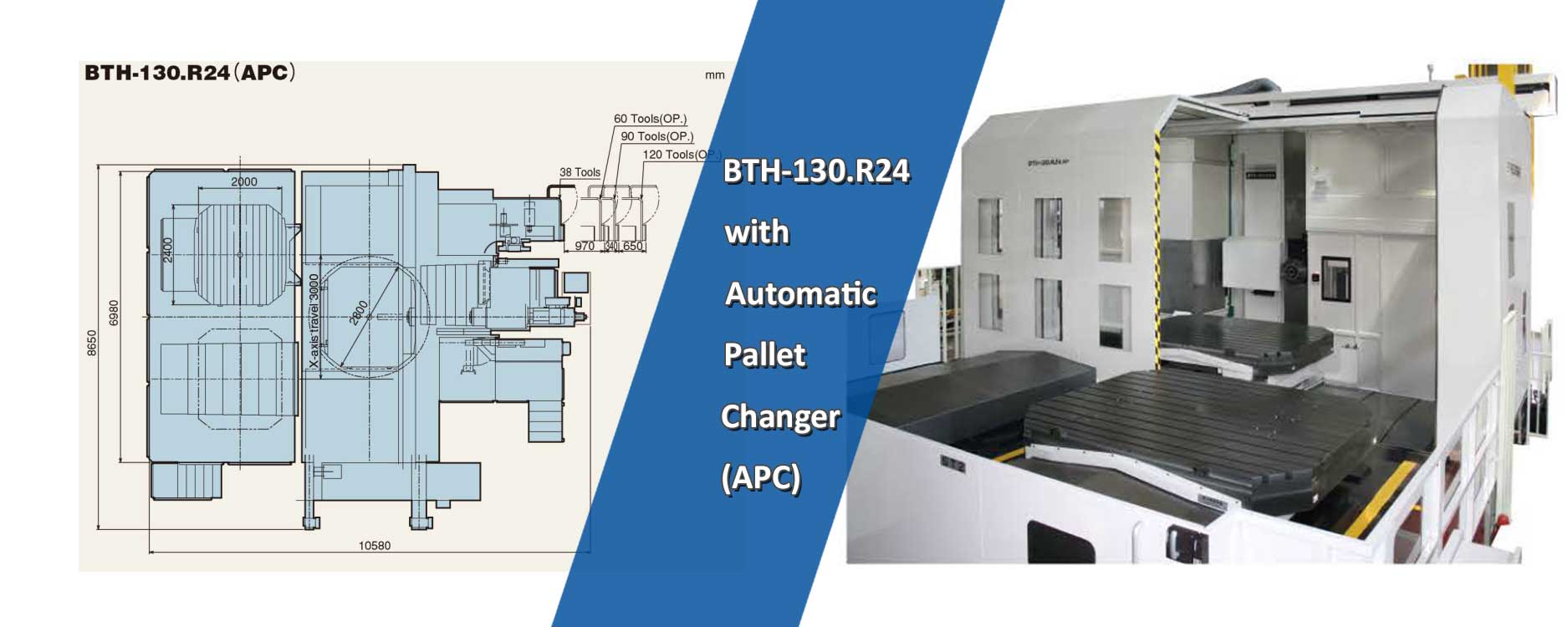

Read moreUnleashing Production Potential with Multi-Pallet Integration in BTH-Series Horizontal Boring Machines

ELK GROVE VILLAGE, IL, August 29, 2023 - In modern manufacturing, efficiency and adaptability are not just buzzwords; they're a cornerstone of success. As factories expand production mix and volume, new opportunities bring fresh challenges. A particular pa...

Read more5 Value Adds to Increasing Automation with the Multi-Pallet Magazine on the TMD Series

ELK GROVE VILLAGE, IL, August 22, 2023 - In manufacturing, staying ahead requires more than just meeting current demands – it requires a proactive anticipation of tomorrow's challenges. As the drive towards automation gains momentum, manufacturers are real...

Read moreEmbracing the Future: Shibaura Machine's Product Innovation in Multi-Tasking Equipment

ELK GROVE VILLAGE, IL, August 8, 2023 - As manufacturers seek to optimize efficiency and expand capabilities, multi-tasking machining centers have emerged as major innovations in the industry. These advanced machines integrate various machining operations ...

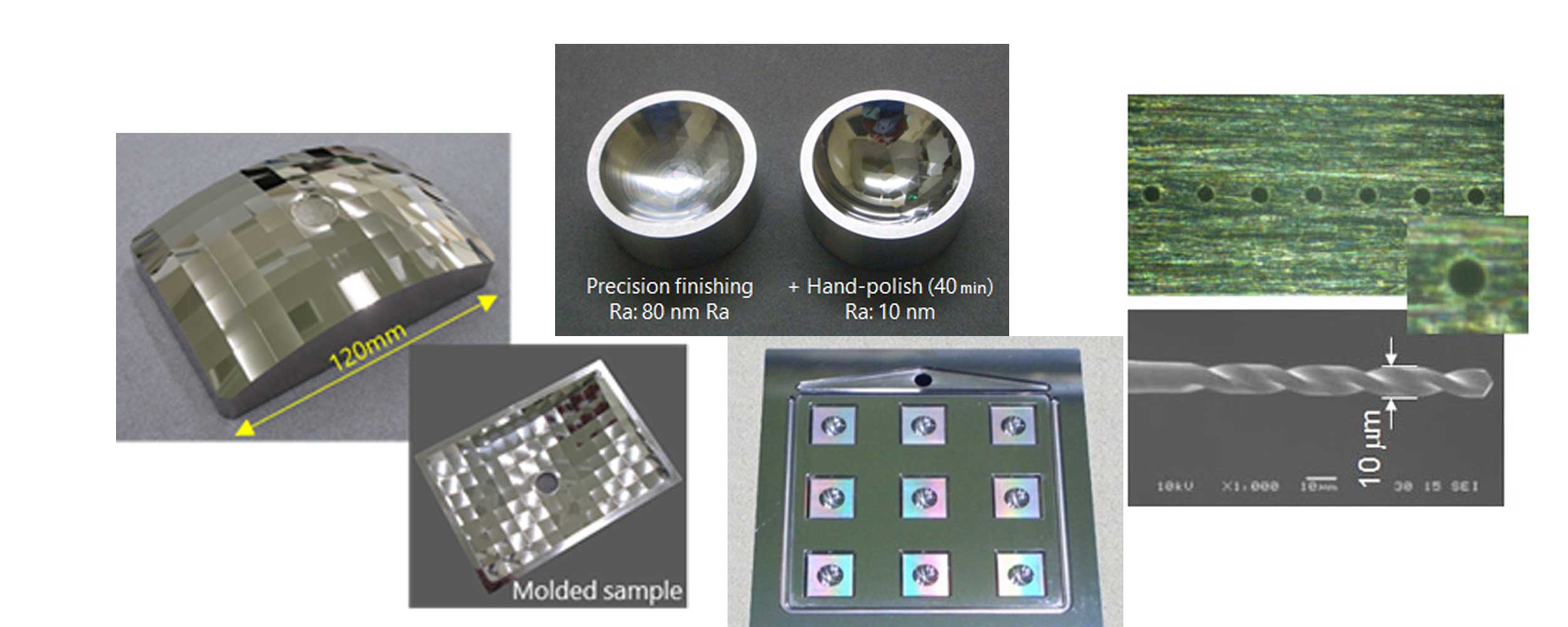

Read moreNano Machines Answer the Demand for High Precision Industrial Equipment Parts Production

ELK GROVE VILLAGE, IL, July 26, 2023 - In the world of industrial equipment manufacturing the importance of product quality cannot be overstated. While parts can vary widely depending on the specific industry and application, the overall quality influences...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools