Better Management of Chip and Coolant in the Machining Process

ELK GROVE VILLAGE, IL, October 31, 2022 -

Given the accumulation of coolant and chips in the machining process this topic continues to draw attention as shops look for innovative solutions to meet their needs. Keeping the work zone clear of coolant and chips not only serves in the companies best interest because it provides a safer work environment, but when these materials are well managed it also provides a more productive environment.

A well-designed machine enclosure has become one of the most popular options to keep your shop clean, protect employees from flying particles, and keep production safe. Different machine tools require varying designs of enclosures- some with side access, top access, access doors, or all three. All enclosures will essentially serve as barriers between workers and the materials like chips and coolants traveling from a machine tool, often at high speeds, during cutting operations.

Chip Management With Added Benefits

Poor chip management can create a serious bottleneck in your manufacturing process, ultimately hurting productivity.

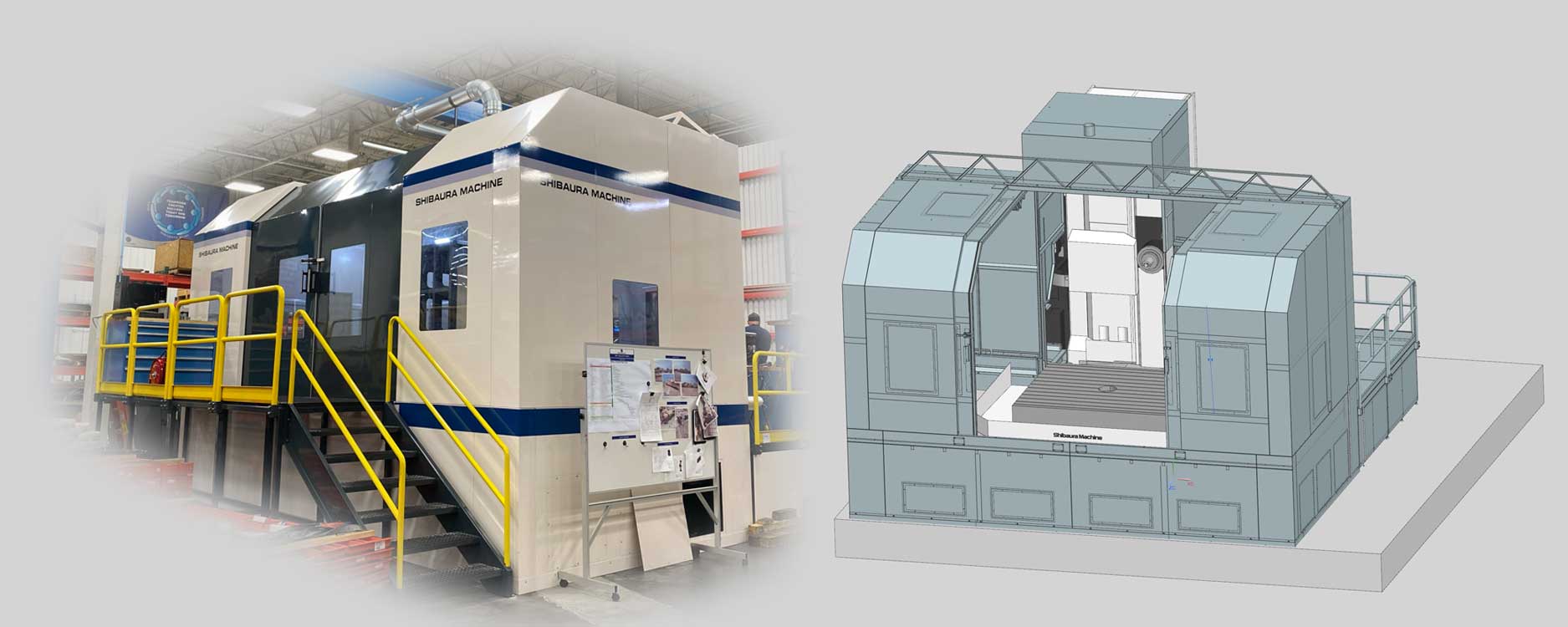

The enclosure for your machine tool will depend on several factors. One of the biggest is the axis of travel and swing clearance your machine tool offers. Shibaura Machine offers a variety of enclosures for our machine tools that are all designed with rigidity, aesthetic appeal, and coolant and chip control in mind.

For example, the new top cover for our TUE series of vertical turning machines is an integrated enclosure that provides quick and easy access to the machine tool while preventing chips and coolant from exiting the machine tool work zone.

The line of machine tool enclosure options from Shibaura Machine include:

- Horizontal boring machines – From full enclosure to work zone enclosure

- Vertical turning machines – Perimeter enclosure and new, optional top cover (TUE series)

- Double column machines – From full enclosure to half enclosure

- Horizontal machining centers – Full enclosure

Start Increasing Productivity Today

Ultimately, being able to manage your chip and coolant with a machine tool enclosure comes with more than one advantage. From protecting workers to ensuring the investment of valuable machinery, chip management with machine tool enclosures makes sense.

Work with Shibaura Machine to select a machine tool enclosure to ensure it meets all of your requirements. From workpiece access and conveyor openings we have a variety of cost-effective and functional enclosures to choose from.

Related Articles View All Machine Tools Articles

Improve Efficiency and Grow Opportunity with a Multi-tasking Machine Tool

ELK GROVE VILLAGE, IL, October 24, 2022 - Being able to combine functions in a single machine tool has long allowed us to save time, save money, and increase efficiency. Everything from smartphones to printers, even gym equipment, has been transformed to p...

Read moreConsiderations when using large cutting tools

ELK GROVE VILLAGE, IL, October 18, 2022 - When searching for the appropriate tooling for your machining application there are many different factors that should be considered. From speeds and feeds to workpiece shape and material, and even how much power d...

Read moreIs High Feed Machining Right for My Shop?

ELK GROVE VILLAGE, IL, October 04, 2022 - Getting parts out the door with the highest efficiency and lowest cost has remained a constant productivity marker for machine tool shops. High feed machining is a process that has been around for a while and when ...

Read moreShibaura Machine is Bringing Service and Support Teams Into Your Shop

ELK GROVE VILLAGE, IL, September 30, 2022 - With machine tools performing constant repetitive tasks maintenance is to be expected, but to what extent? Being able to better plan for preventative maintenance and control downtime can make a huge impact on you...

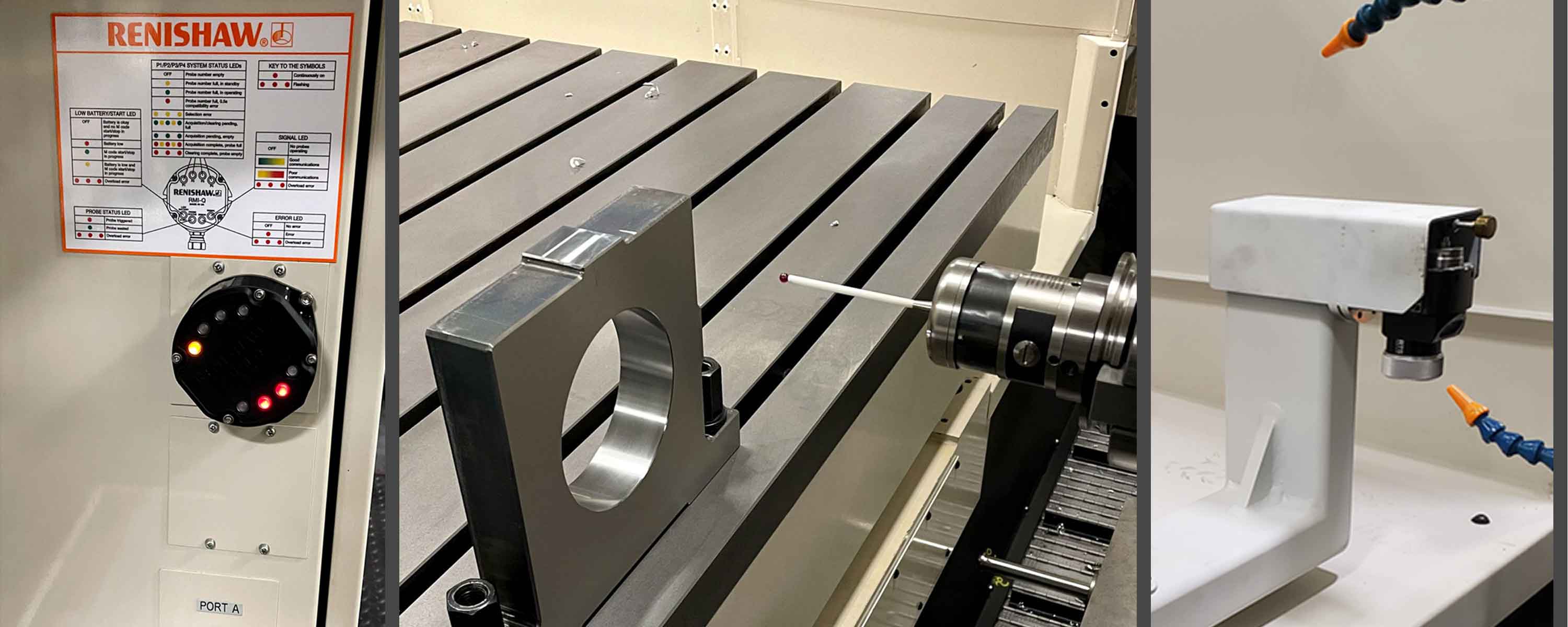

Read moreExploring The Benefits of On-Machine Measuring with Machine Tools

ELK GROVE VILLAGE, IL, September 9, 2022 - Incorporating on-machine measurement on machine tools has increasingly become a way for shops to drastically reduce the time required to measure parts and reduce production lead time. As technology has evolved, it...

Read moreSee How machiNetCloud IIoT Solution is Improving Machine Tool OEE at IMTS 2022

ELK GROVE VILLAGE, IL, September 2, 2022 - As the Industrial Internet of Things (IIoT) continues to grow and evolve, shops can more accurately and easily create leaner operations. Shibaura Machine’s IIoT solution, machiNetCloud, will be on display and avai...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools