Is High Feed Machining Right for My Shop?

ELK GROVE VILLAGE, IL, October 04, 2022 -

Getting parts out the door with the highest efficiency and lowest cost has remained a constant productivity marker for machine tool shops. High feed machining is a process that has been around for a while and when applied properly can open the door for shops to gain new business opportunities with increased productivity and improved machining time.

Using a high feed machining strategy, the machine tool works with low depth of cuts and high feed per revolution to improve metal removal rates. It helps to not only keep the chip load low, but optimize the heat generation and dissipation of heat through the chips formed. In order to properly apply the high feed machining process it is important your machine tool is up to the challenge and the correct cutting application is applied.

Evaluating Your Machine Tool for High Feed Machining

High feed machining (HFM) requires a rigid and highly capable machine tool. Using a smaller depth of cut this process produces a thinner chip that carries the heat away from the cutting edge. The cutter runs at extremely high feeds, which require the machine and the control to be able to keep up. Compared to conventional machining it is not uncommon to run at up to five times higher feed per tooth.

To accomplish a HFM strategy and increase metal removal rates not only does the machine itself need to be engineered to certain standards, but the CNC control and CAM software will also need to be evaluated. The CNC control should have a higher processor speed in order to handle significantly more lines of program data to maintain machine accuracy. Secondly, the CAM system should be able to handle tool path smoothing strategies, which require a dynamic tool path option.

While newer machine tools provide an easy path to applying HFM, it is possible to use an older machine tool and still work at a high speed achieving reliable results, provided the CNC control has the necessary capabilities.

Is HFM Right For My Shop?

HFM is a great process to achieve high metal removal rates, improving productivity and machining time when applied correctly. It allows your shop to take full advantage of machine tools and the benefits can significantly outweigh the challenges.

If you are considering a HFM strategy contact the Machine Tool Team to help guide your shop to success.

Related Articles View All Machine Tools Articles

Shibaura Machine is Bringing Service and Support Teams Into Your Shop

ELK GROVE VILLAGE, IL, September 30, 2022 - With machine tools performing constant repetitive tasks maintenance is to be expected, but to what extent? Being able to better plan for preventative maintenance and control downtime can make a huge impact on you...

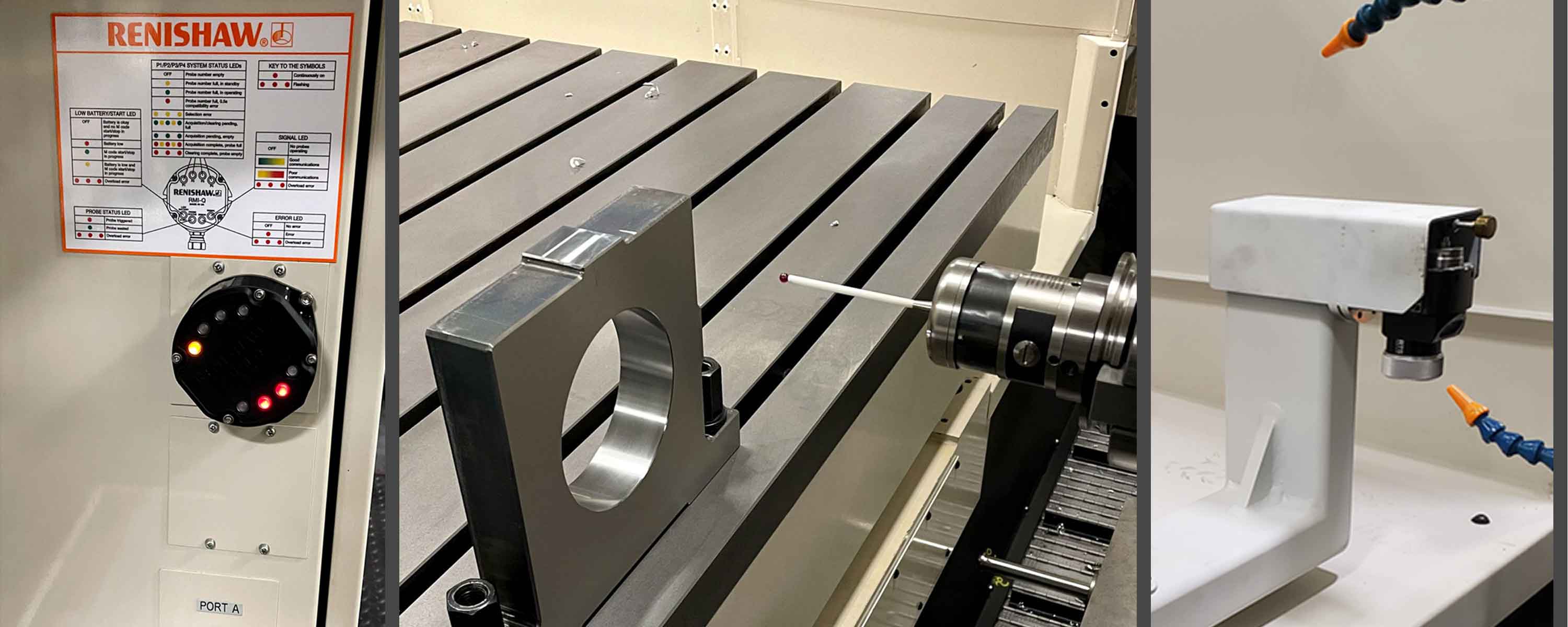

Read moreExploring The Benefits of On-Machine Measuring with Machine Tools

ELK GROVE VILLAGE, IL, September 9, 2022 - Incorporating on-machine measurement on machine tools has increasingly become a way for shops to drastically reduce the time required to measure parts and reduce production lead time. As technology has evolved, it...

Read moreSee How machiNetCloud IIoT Solution is Improving Machine Tool OEE at IMTS 2022

ELK GROVE VILLAGE, IL, September 2, 2022 - As the Industrial Internet of Things (IIoT) continues to grow and evolve, shops can more accurately and easily create leaner operations. Shibaura Machine’s IIoT solution, machiNetCloud, will be on display and avai...

Read moreIMTS 2022 Special Financing Opportunity for the BTH-130.R24 Horizontal Boring Machine

ELK GROVE VILLAGE, IL, August 26, 2022 - With the International Manufacturing Technology Show (IMTS 2022) less than a month away (September 12-17 in Chicago), Shibaura Machine Company, America is gearing up to meet the attendees. Booth 339430 in the South ...

Read moreShibaura Machine Showcases the TUE-200(S) Extended Column and Ram Travel at IMTS 2022

ELK GROVE VILLAGE, IL, August 18, 2022 - The upcoming International Manufacturing and Technology Show will showcase the latest machining technologies and processes. Shops looking to streamline their CNC machining processes are invited to visit us at Booth ...

Read moreOptimize Your Shops Macro Programs to Boost Productivity

ELK GROVE VILLAGE, IL, August 18, 2022 - When talking about machine tool maintenance the first thing that comes to mind is often the mechanical aspects. From adjusting accuracy, changing oil and filters, and even cleaning the machine. With most machine too...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools