Invest in Your Success: Shibaura Machine's Training Programs for Injection Molding Professionals

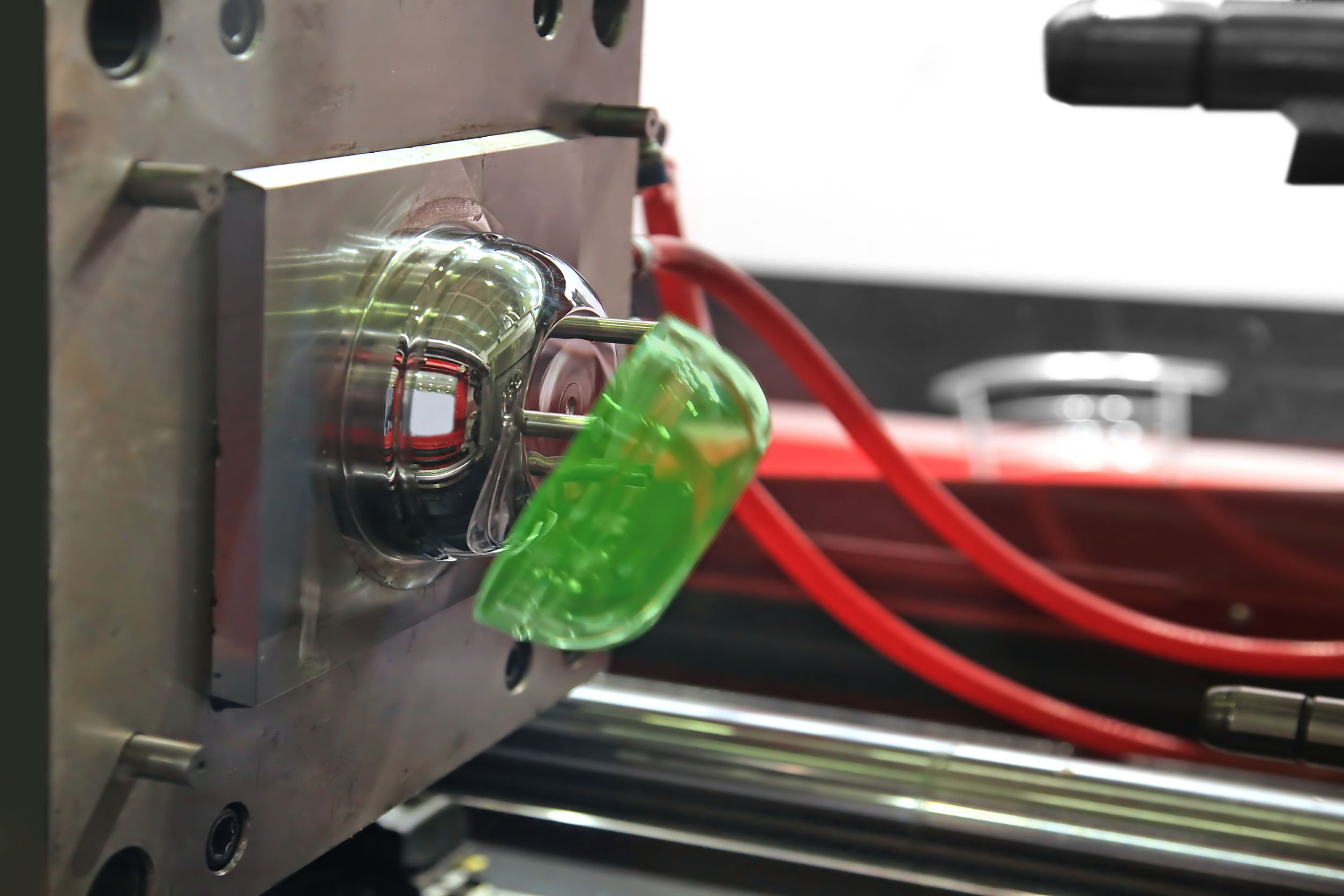

ELK GROVE VILLAGE, IL, July 5, 2023 - When it comes to injection molding, having a well-trained team is crucial for maximizing machine performance and achieving optimal results. Training ensures that all personnel understand not only the machine's capabilities, but also the requirements of the injection molding process. Whether a novice or coming with years of experience, a single training session can help reduce the risk of costly errors, while also ensuring that the process runs as efficiently and cost-effectively as possible.

Shibaura Machine offers a range of training options tailored to manufacturers at different stages of their injection molding journey. Our training programs are designed to equip operators and maintenance personnel with the necessary skills and knowledge to excel in their roles.

Offering a Diverse Set of Training Classes

Each class is tailored to the individual's goals and needs, and our instructors are highly experienced experts in the field. Among the most popular training classes are:

- V70 Controller: This class focuses on the operation and programming of the V70 controller, enabling participants to effectively navigate and utilize its features for optimal machine control.

- Maintenance: The maintenance class is designed to provide participants with the knowledge and skills required to perform routine maintenance tasks, ensuring the longevity and reliability of their injection molding machines.

- Basic Processing: This class covers the fundamentals of injection molding process parameters, including material selection, machine setup, mold preparation, and troubleshooting. Participants will gain a solid understanding of the key aspects involved in achieving consistent and high-quality molding.

- Advanced Processing (Molding 360): Our new Molding 360 - Advanced Processing class takes participants beyond the basics and dives deeper into advanced molding techniques, process optimization, calculations, and troubleshooting. This class is ideal for manufacturers looking to refine their molding processes and enhance overall productivity.

Partner Classes and Locations

In addition to our in-house training programs, we also collaborate with industry-leading training providers, including RJG and Paulson, to offer a wider range of classes and expertise. By partnering with these reputable organizations, we ensure that manufacturers have access to comprehensive training resources that cover a broad spectrum of injection molding topics.

Most of our training classes are conducted at our North American Technical Centers, strategically located in Elk Grove Village, IL; Charlotte, NC; Markham, ON, Canada; and Rancho Cucamonga, CA. These state-of-the-art facilities provide a conducive learning environment equipped with the latest machinery and technology. However, we understand that onsite training may be more suitable for some manufacturers. Upon request, we can arrange customized training sessions at your facility to meet your specific needs.

Ready to Elevate Your Molding Skills?

Shibaura Machine's training programs are designed to take your injection molding skills to the next level. Our classes combine classroom presentations, machine demonstrations, and hands-on learning to ensure a comprehensive and immersive training experience. Whether you are new to injection molding or seeking to enhance your advanced processing techniques, our training programs can help you gain the knowledge and confidence to excel in your role.

Invest in your team's skills and expertise with Shibaura Machine's training programs and maximize the full potential of your injection molding operations. For more information and a full schedule of classes Click Here.

Still have questions? Feel free to reach out to our team.

Tel: (888) 593-1616

Email: im-success@shibaura-machine.com

Related Articles View All Articles

Achieving Injection Molding Excellence with Integrated Auxiliary Equipment

ELK GROVE VILLAGE, IL, June 21, 2023 - Staying ahead of the competition in manufacturing requires adopting innovative solutions that enhance productivity and efficiency. Auxiliary equipment offers a way to enable precise and automated handling of materials...

Read moreDriving Sustainable Development: The Rise of All-Electric Injection Molding Machines

ELK GROVE VILLAGE, IL, June 7, 2023 - As sustainability becomes an increasingly important focus worldwide, industries are seeking innovative solutions to align their operations with the United Nations' Sustainable Development Goals (SDGs). In the world of ...

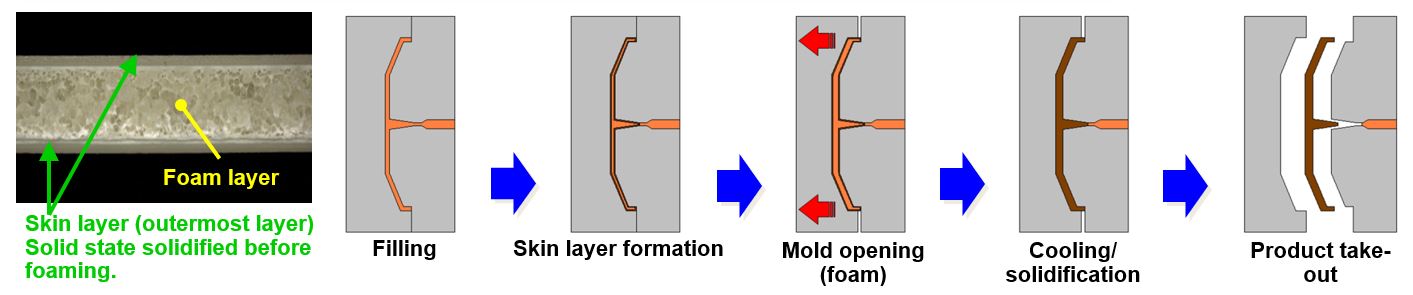

Read moreAchieve Weight Reduction and Precise Control with Core Back Foam Molding

ELK GROVE VILLAGE, IL, May 24, 2023 - Foam molding has emerged as a highly popular and versatile technique in the plastics industry. This method offers a plethora of advantages, ranging from significant part weight reduction and improved shock absorption t...

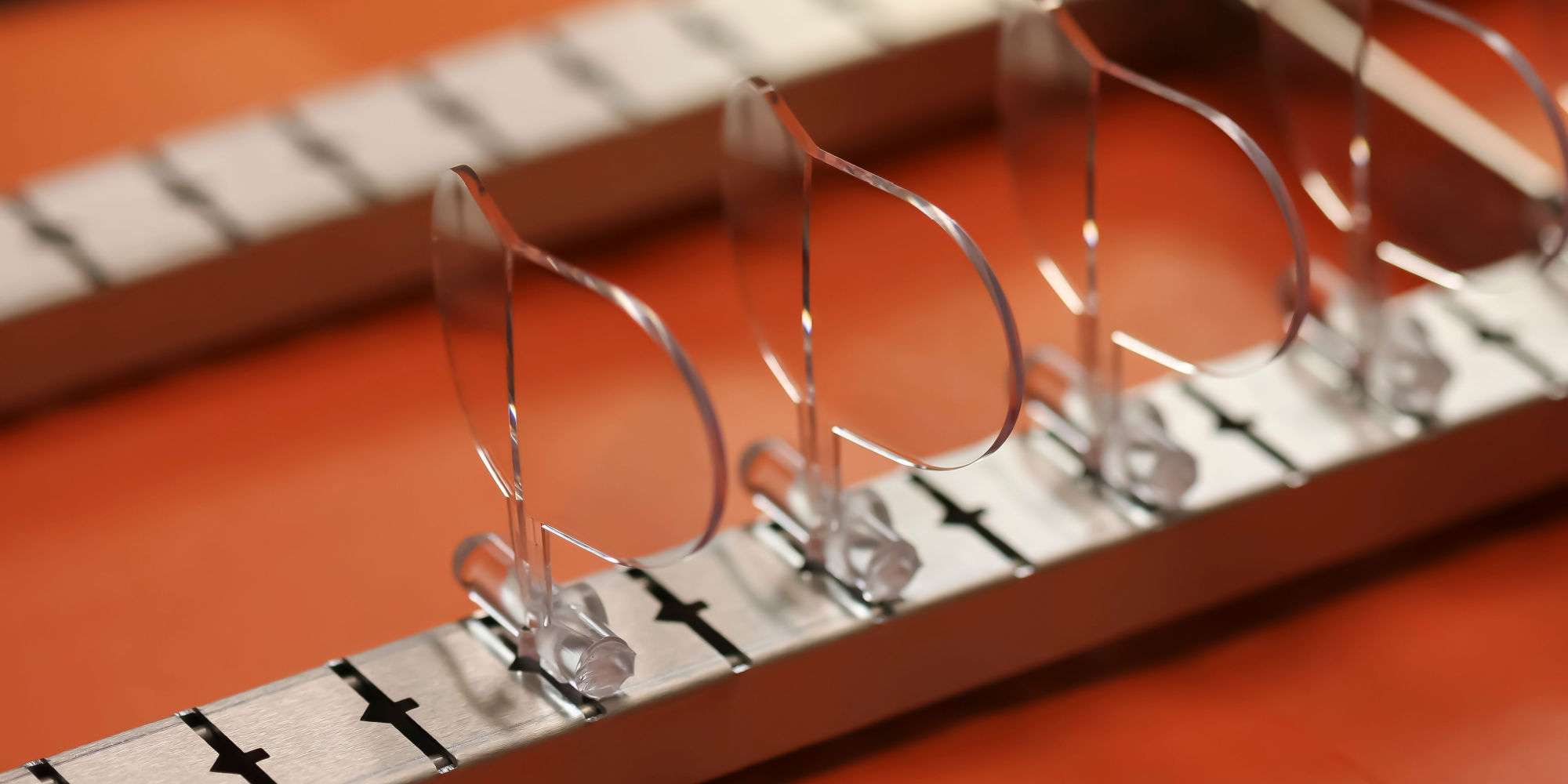

Read morePrecision Optics and Thin-Wall Molding Made Easier with PRESTROL

ELK GROVE VILLAGE, IL, May 10, 2023 - In order to produce high-quality parts with consistent properties and dimensions, it's important to achieve uniform distribution of material within the mold cavity during the injection process. However, this continues ...

Read moreHow Electric Ejectors Improve Injection Molding Performance

ELK GROVE VILLAGE, IL, November 16, 2022 - An electric ejector system can be a huge competitive differentiator compared to its hydraulic counterparts. The electric ejectors provide molders the ability to view torque giving better insight to allow for impro...

Read moreGive Your Injection Molding Parts Quality a Boost With Moldlyzer

ELK GROVE VILLAGE, IL, November 16, 2022 - The goal of any injection molding operation is 100% quality. Part of that process includes ensuring the injection pressure is right where it needs to be every time, in every stage of the operation. Without the rig...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools