How Electric Ejectors Improve Injection Molding Performance

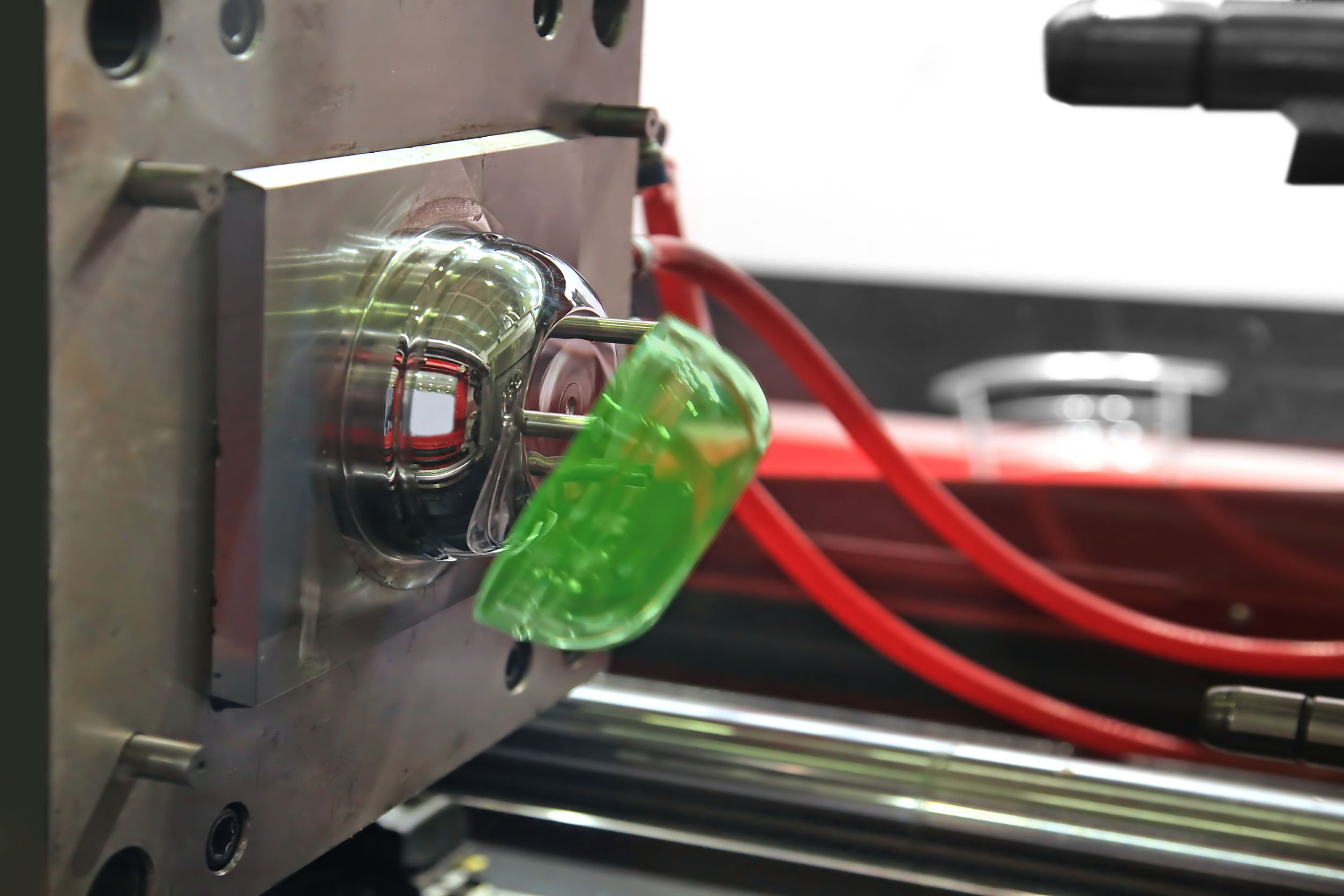

ELK GROVE VILLAGE, IL, November 16, 2022 - An electric ejector system can be a huge competitive differentiator compared to its hydraulic counterparts. The electric ejectors provide molders the ability to view torque giving better insight to allow for improved control of the cycle which prevents tooling damage and increases the life of molds by catching small issues before they create major breakage and unplanned downtime. In addition, the standard eject-on-the-fly feature on the all-electric system allows ejectors to function during mold opening, further reducing cycle time.

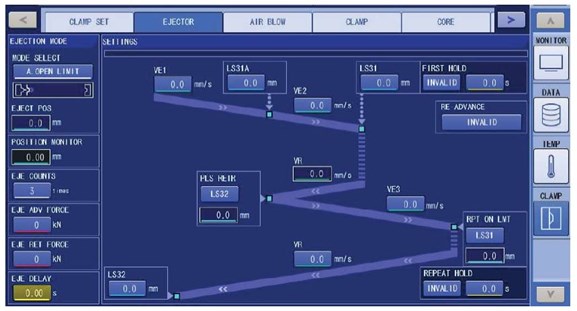

Shibaura Machine’s all-electric injection molding machines provide users real time feedback and control of the ejector force because of the electric servo motor. This ejector system provides a user-friendly interface with graphical display and is an extremely flexible tool. As a standard feature, the Ejector Monitor screen provides visibility into the instant torque on the ejector servo motor and several options to enhance your ejector monitoring capabilities.

Better Ejector Protection

By using an independent electric servo motor for ejection, the Eject Monitor feature allows users instant insight into the torque and capabilities to help prevent mold damage that hydraulic systems do not. Namely, the user can not only monitor the ejector servo motor torque during ejection, but also set a torque limit on the ejectors. In using this feature, it will help better prevent mold damage when mold components are worn or binding and can easily detect ejection error due to overpacking parts, worn ejector pins and mechanical lifters, etc. and immediately stops the ejector advance operation when an error is detected.

Additionally, operators can monitor the torque in two zones. This allows the eject operation to set limits on the retract limit and advance limit. The eject operation will stop when the detected torque in the desired monitoring zone (1 or 2) exceeds its limit settings. The zones will automatically be returned to the retract limit after eject operation is stopped due to an error detection and an alarm will display alerting the operator to what zone an ejection error has occurred.

Additional ejector functions available:

- Stroke change and eject hold options available for multi-stroke ejection;

- First ejection re-advance which stops the first eject operation at the desired position during ejection and then restarts the eject operation;

- Continuous high speed ejector circuit enables high speed operation of continuous ejection when setting multiple eject operations to speed up advance and retract operations by using the servo motor control command system

- Gate cut circuit will trigger ejection and perform gate cut after injection completes

Start Improving Machine Efficiency Today

The Ejector Torque Monitor and Eject-on-the-Fly capability on Shibaura Machine ECSXIII series all-electric machines can increase performance and efficiency. If you are not currently utilizing these features on your Shibaura Machine all-electric injection molding machine, contact our team today to get started.

Tel: (888)593-1616

Email: im-success@shibaura-machine.com

Related Articles View All Articles

Give Your Injection Molding Parts Quality a Boost With Moldlyzer

ELK GROVE VILLAGE, IL, November 16, 2022 - The goal of any injection molding operation is 100% quality. Part of that process includes ensuring the injection pressure is right where it needs to be every time, in every stage of the operation. Without the rig...

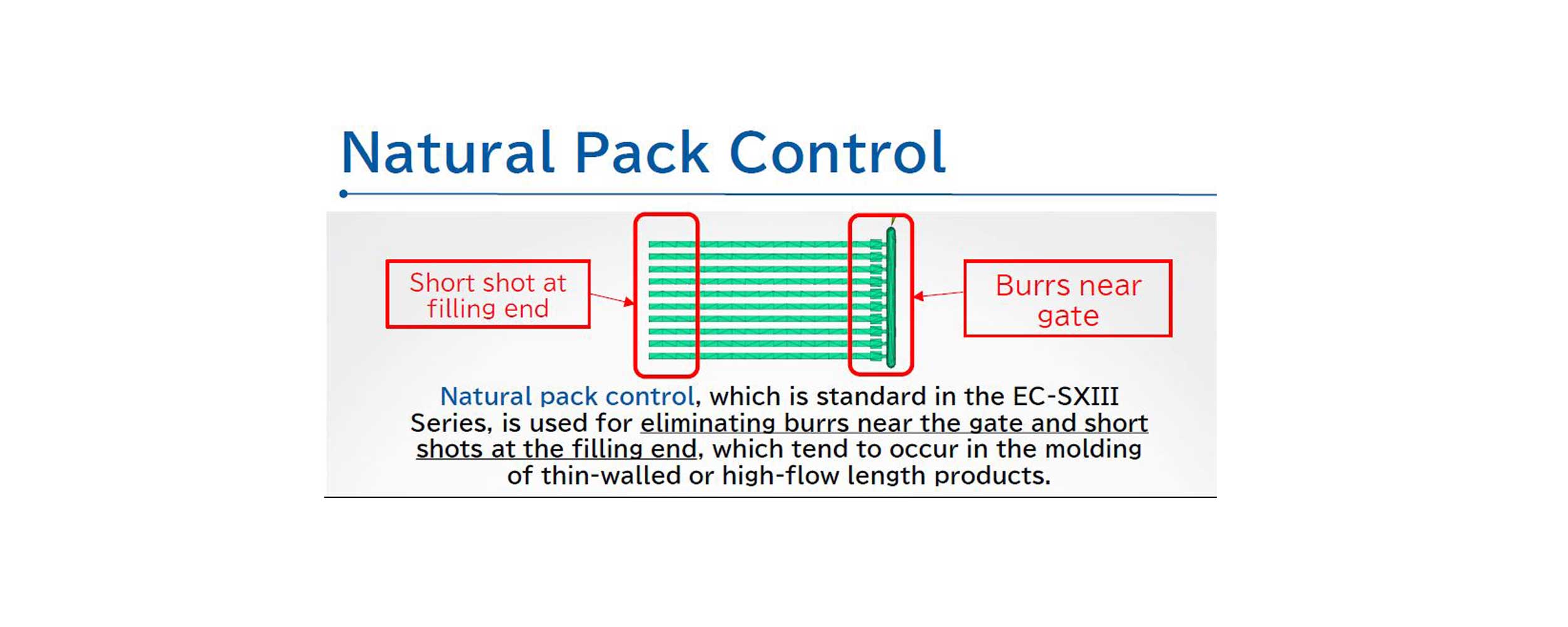

Read moreExploring the Natural Pack Feature on the V70 Controller to Improve Injection Molding Processing

ELK GROVE VILLAGE, IL, November 9, 2022 - Manufacturers molding thin and/or long flow length parts are always looking for ways to reduce part defects. With high peak cavity pressure these applications can be particularly challenging. By being able to maxim...

Read moreBring Real-Time Quality Monitoring to the Injection Molding Floor with Shibaura Machine

ELK GROVE VILLAGE, IL, November 2, 2022 - How efficiently and effectively are you able to control your quality processes? When quality management is running smoothly it not only maintains quality but is focused on maximizing productivity creating the best ...

Read moreNow Enrolling for In-Person Injection Molding Training Courses

ELK GROVE VILLAGE, IL, August 3, 2022 - Shibaura Machine is pleased to announce our popular in-person injection molding training courses are resuming for the remainder of 2022. Customers can join us at our tech centers in Elk Grove Village, IL, Charlotte, ...

Read moreRobot Integration Simplified With Shibaura Machine

ELK GROVE VILLAGE, IL, June 29, 2022 - Automating tasks with robots has become an increasingly popular option for injection molding manufacturers. From placing inserts into molds to moving parts through post-mold processes, robots provide process stability...

Read moremachiNetCloud Industrial IoT Now Included on New Injection Molding Machines

ELK GROVE VILLAGE, IL, June 22, 2022 - As the landscape in manufacturing continues to rapidly change due to digitalization, the Industrial Internet of Things (IIoT) brings a great opportunity to gain a competitive advantage in every form of production, inc...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools