Achieving Injection Molding Excellence with Integrated Auxiliary Equipment

ELK GROVE VILLAGE, IL, June 21, 2023 - Staying ahead of the competition in manufacturing requires adopting innovative solutions that enhance productivity and efficiency. Auxiliary equipment offers a way to enable precise and automated handling of materials, streamlined production workflows, and real-time monitoring of key performance indicators.

Taking it a step further, Shibaura Machine provides seamless integration of auxiliary equipment with its injection molding machines. This allows businesses the opportunity to unlock new levels of productivity and efficiency by enabling manufacturers to optimize various aspects of their operations and improve overall operational performance.

Streamlined Workflow

Traditionally, auxiliary equipment such as robots, mold temperature controllers, chillers, dryers, and hot runner systems operated as separate entities with their own controllers. Shibaura Machine enables seamless communication between its injection molding machine and these auxiliary equipment controllers through VNC (Virtual Network Computing).

This integrated control and monitoring system provides a comprehensive view of the production cell from one control panel, improving management of the molding process and ensuring a smoother production flow. For example, customers can directly integrate robot controls into the Shibaura Machine V70 controller. Through the VNC robot link feature, manufacturers can set up, program, and control leading robot brands, including Sepro, Star Automation, and Yushin, from the main V70 controller.

Shibaura Machine's injection molding machines are also designed to recall setup information of various auxiliary equipment, reducing the need to change programs on independent HMIs. In these cases, the settings can be saved as part of the mold recipe. As a result, operators can switch between different setups without the time-consuming task of reprogramming independent HMIs. This time-saving feature is particularly useful for manufacturers with multiple accessories, further enhancing productivity and operational efficiency.

Enhanced Automation and Error Handling

Integrating auxiliary equipment with Shibaura Machine's injection molding solutions also enables programmable inputs that respond to alarm or error signals generated by the auxiliary equipment.

For instance, if the mold temperature controller detects an out-of-tolerance water temperature, the machine can be programmed to take appropriate action. It can continue running while diverting suspect parts and providing a visual or audible notification to alert the operator. Alternatively, the machine can stop, back up the injection unit, and initiate an auto purge while notifying plant personnel of the issue. This integration prevents the production of potentially defective parts due to auxiliary equipment malfunctions, improving overall productivity.

Optimize Your Production Process

Shibaura Machine's integration approach fosters connectivity and communication between the different pieces of equipment needed to maintain a competitive edge. By integrating the auxiliary equipment with the injection molding machine, these devices become part of a unified solution allowing manufacturers to meet the evolving demands of the industry.

Contact the Injection Molding team to learn more about integrating your auxiliary equipment.

Tel: (888) 593-1616

Email: im-success@shibaura-machine.com

Related Articles View All Articles

Driving Sustainable Development: The Rise of All-Electric Injection Molding Machines

ELK GROVE VILLAGE, IL, June 7, 2023 - As sustainability becomes an increasingly important focus worldwide, industries are seeking innovative solutions to align their operations with the United Nations' Sustainable Development Goals (SDGs). In the world of ...

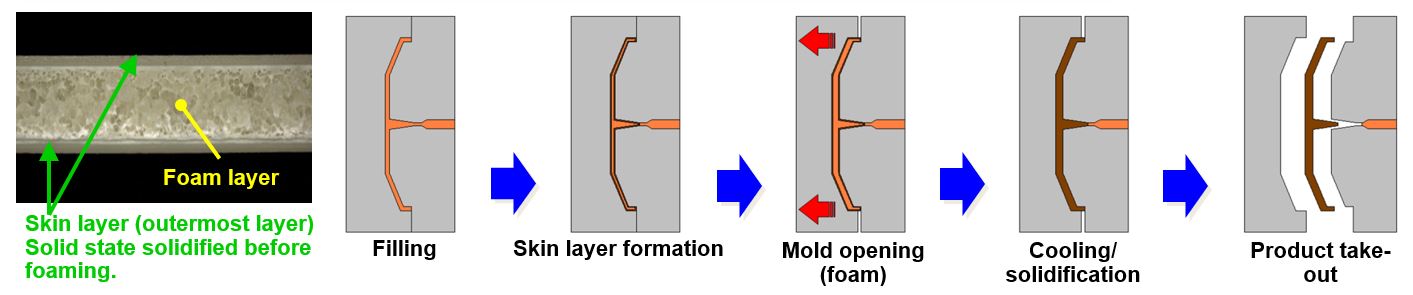

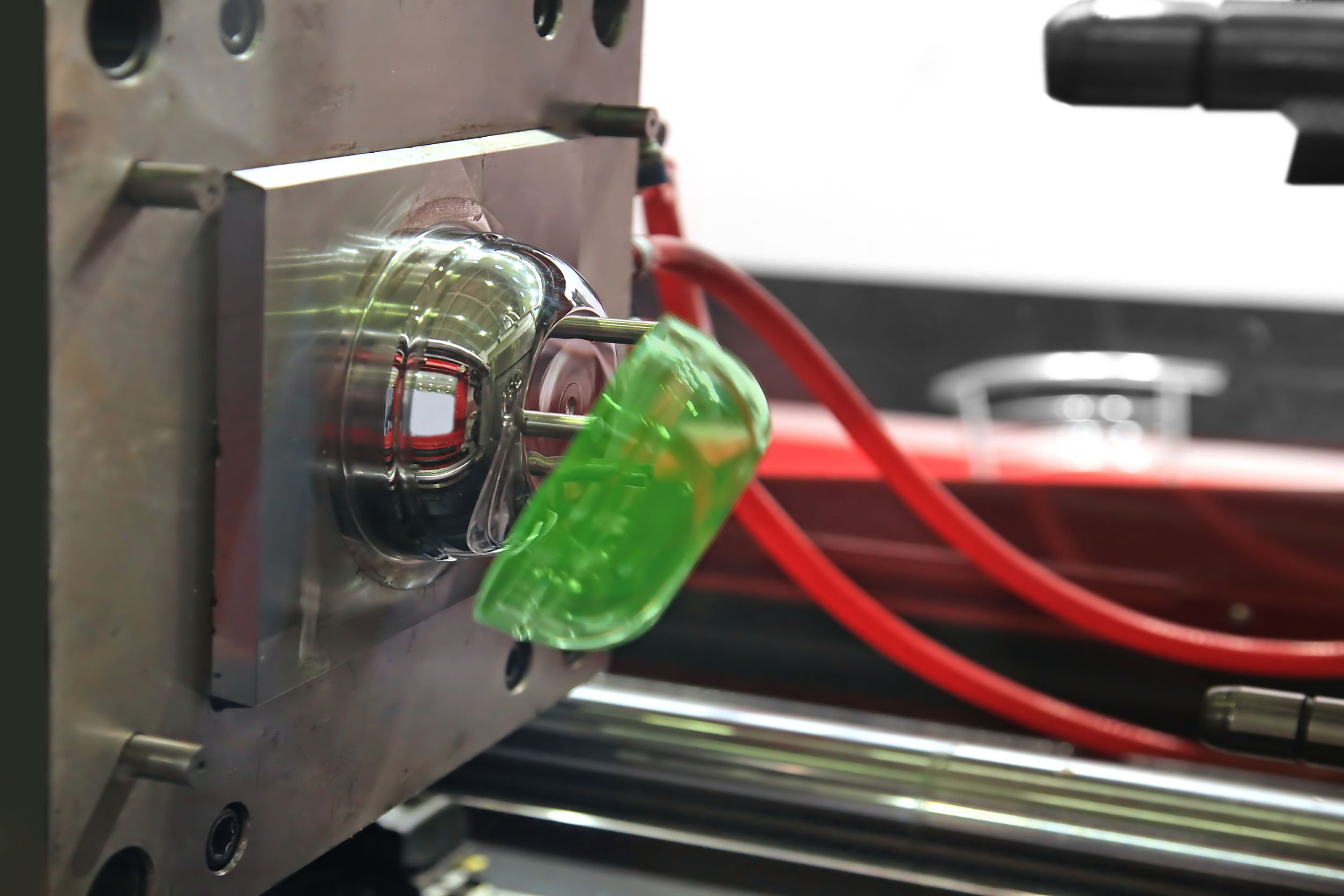

Read moreAchieve Weight Reduction and Precise Control with Core Back Foam Molding

ELK GROVE VILLAGE, IL, May 24, 2023 - Foam molding has emerged as a highly popular and versatile technique in the plastics industry. This method offers a plethora of advantages, ranging from significant part weight reduction and improved shock absorption t...

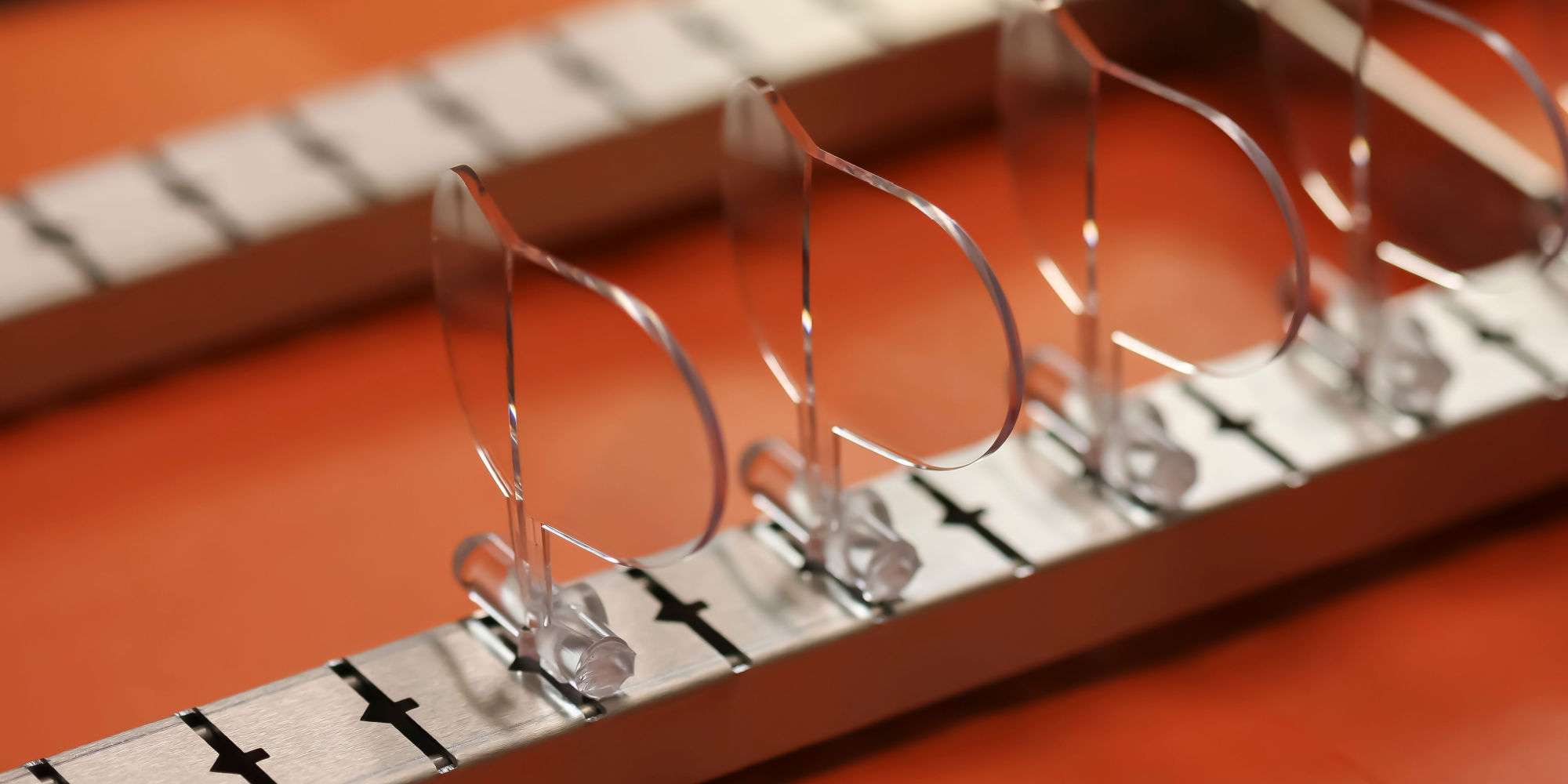

Read morePrecision Optics and Thin-Wall Molding Made Easier with PRESTROL

ELK GROVE VILLAGE, IL, May 10, 2023 - In order to produce high-quality parts with consistent properties and dimensions, it's important to achieve uniform distribution of material within the mold cavity during the injection process. However, this continues ...

Read moreHow Electric Ejectors Improve Injection Molding Performance

ELK GROVE VILLAGE, IL, November 16, 2022 - An electric ejector system can be a huge competitive differentiator compared to its hydraulic counterparts. The electric ejectors provide molders the ability to view torque giving better insight to allow for impro...

Read moreGive Your Injection Molding Parts Quality a Boost With Moldlyzer

ELK GROVE VILLAGE, IL, November 16, 2022 - The goal of any injection molding operation is 100% quality. Part of that process includes ensuring the injection pressure is right where it needs to be every time, in every stage of the operation. Without the rig...

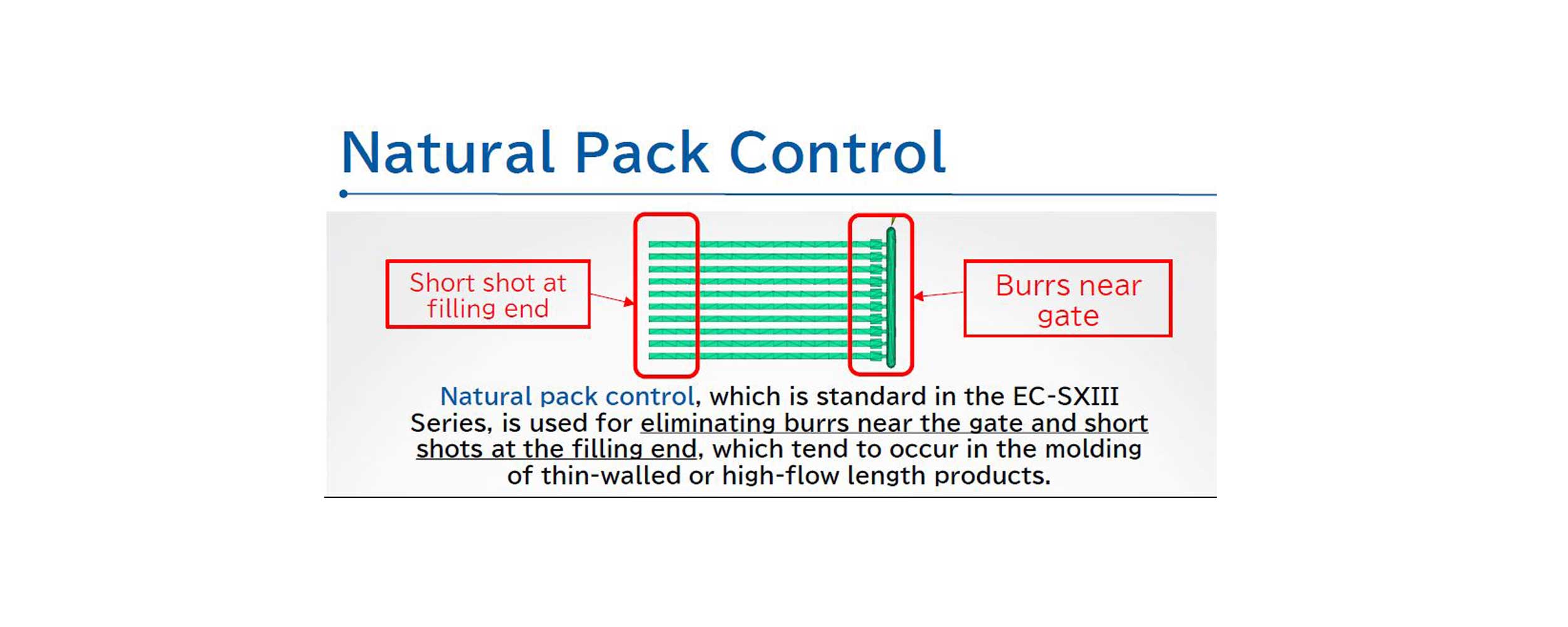

Read moreExploring the Natural Pack Feature on the V70 Controller to Improve Injection Molding Processing

ELK GROVE VILLAGE, IL, November 9, 2022 - Manufacturers molding thin and/or long flow length parts are always looking for ways to reduce part defects. With high peak cavity pressure these applications can be particularly challenging. By being able to maxim...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools