Precision Optics and Thin-Wall Molding Made Easier with PRESTROL

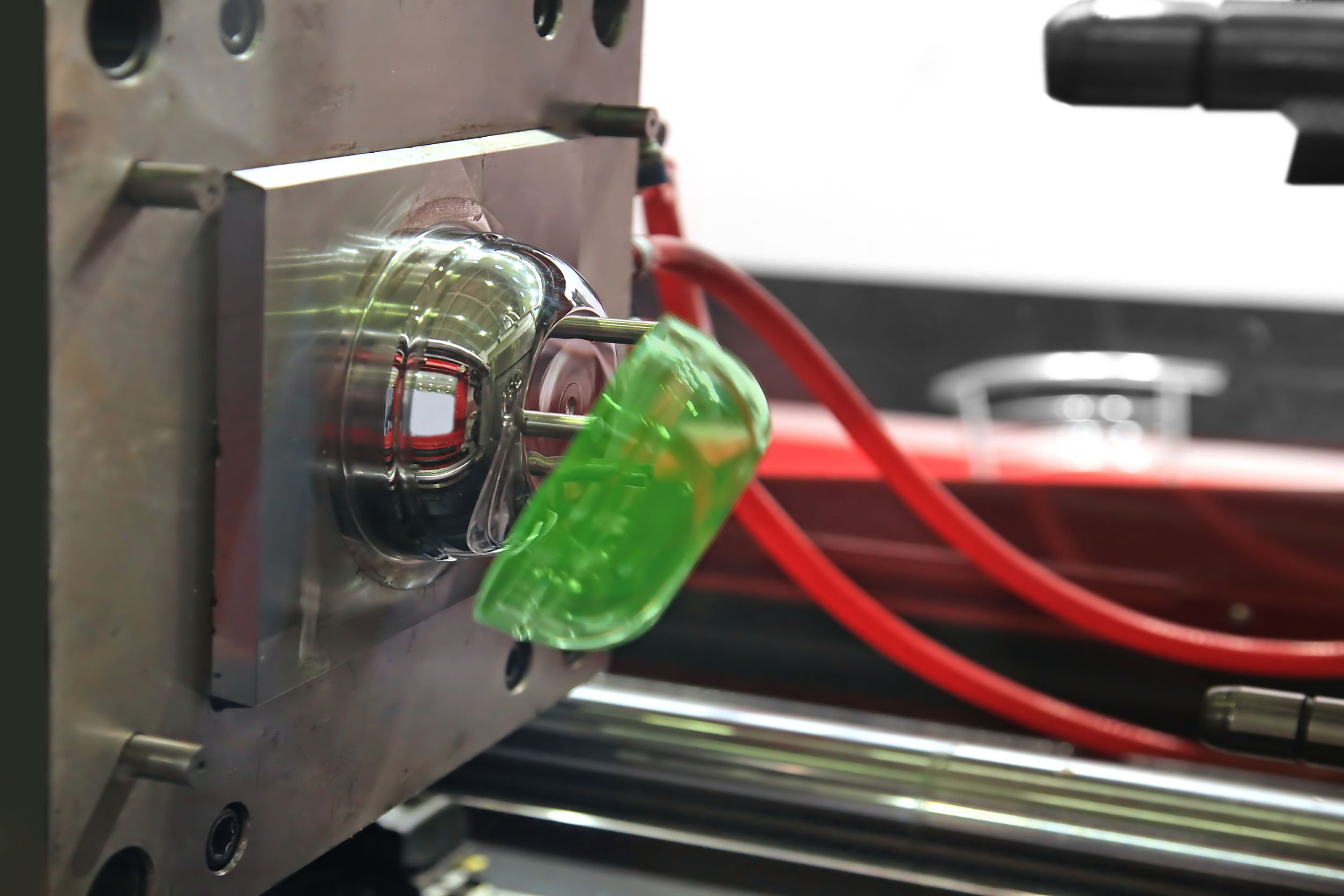

ELK GROVE VILLAGE, IL, May 10, 2023 - In order to produce high-quality parts with consistent properties and dimensions, it's important to achieve uniform distribution of material within the mold cavity during the injection process. However, this continues to be a top challenge for molders, particularly on parts with large projected areas and thin walls because they are more prone to variations in material flow and cooling rates.

To overcome this challenge, a variety of techniques and technologies have been introduced over time. By carefully controlling variables, injection molders can improve the quality and consistency of the parts they produce, even for those with large projected areas and thin walls.

With the voice of the customer in mind, the PRESTROL function on the V70 controller optimizes the filling and packing phases of the injection molding process, allowing for the consistent material distribution needed to reduce part defects.

Improving Precision Optics and Thin-Wall Molding Quality

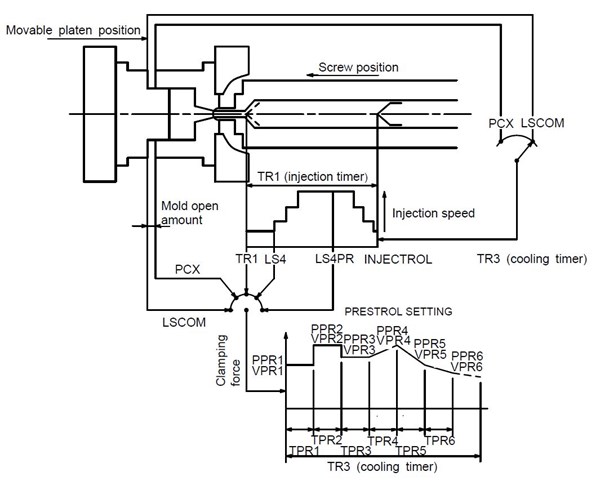

PRESTROL is a circuit that achieves compression operation in conjunction with injection operation through controlling the clamping force using a multistage program. By using the function, strain near the gate can be reduced, and pressure can reach outer areas of the mold cavity even with high-speed filling. This option allows molders to achieve high-quality parts with consistent properties and dimensions.

Elimination of warpage, sink marks, and internal stress

By achieving compression operation with clamping force, it not only shortens the pressure transmission path in the resin but also distributes uniform force over a wide area. This results in the elimination of warpage, sink marks, and internal stress.

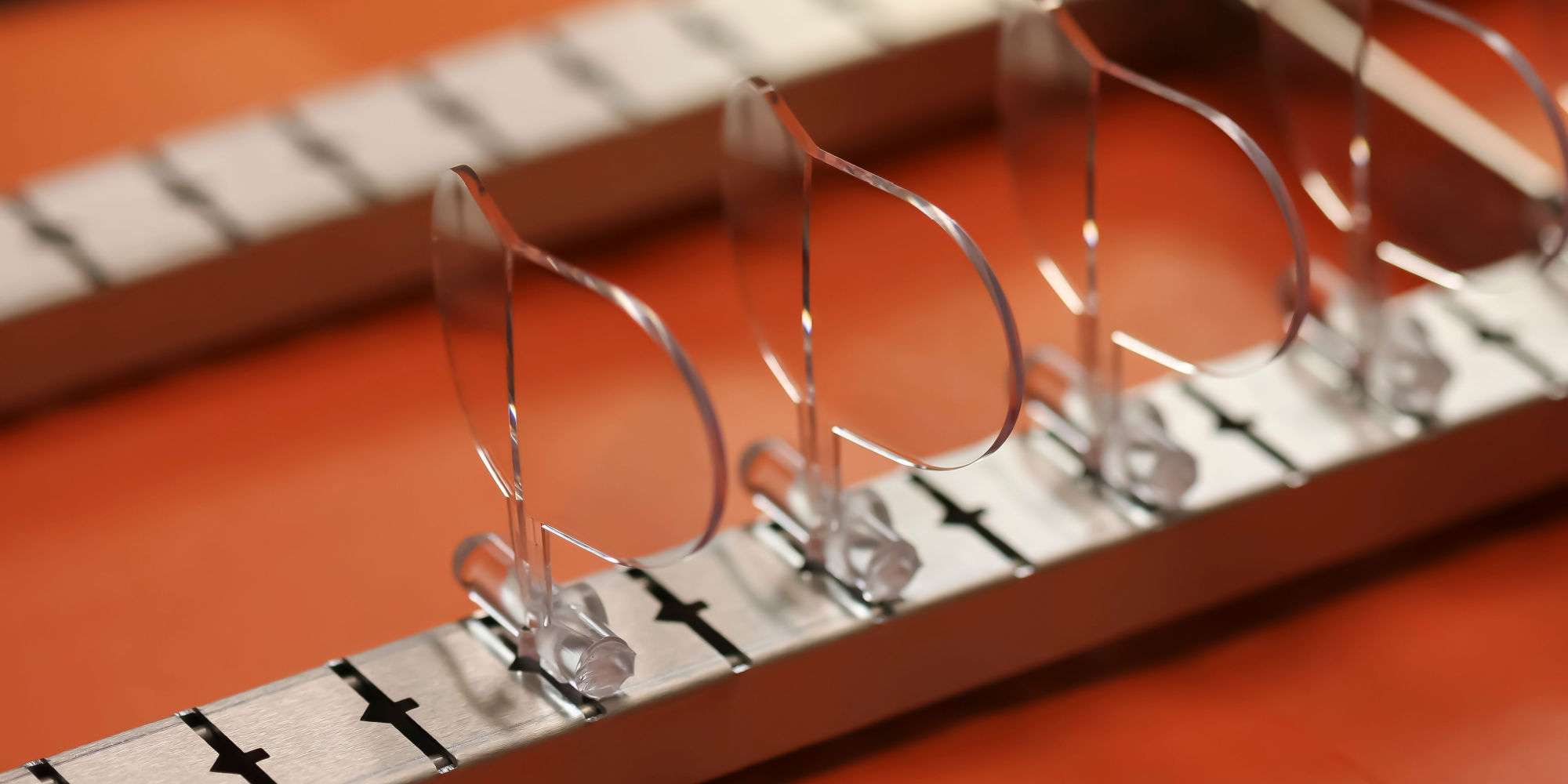

Improved transferability

Enable high transferability in molding of precision optics products such as lenses, discs, and products with large projected areas and thin walls.

Programmability

The clamping force PPR1 to PPR6 and the compression speed VPR1 to VPR6 for compression operation can be programmed. The setting pattern of clamping force and compression speed for compression operation is represented graphically and can be easily visually-checked. Setting data of the function can be saved in and loaded from the internal memory.

Precision

The precision of the movable mold position of the function is 0.01 mm, and the precision of the clamping force time is 0.01 seconds.

Flexibility

On the PRESTROL function, speed control (VPR1 to VPR6) can be set individually for each compression operation clamping force (PPR1 to PPR6). This control allows for increasing or decreasing speed of clamping force, allowing the user to profile the clamping function for their specific application.

Upgrade Your Injection Molding Process

Injection molders face numerous challenges when it comes to achieving uniform material distribution in the mold cavity during the injection molding process, especially for parts with large projected areas and thin walls. However, with the addition of the PRESTROL function it can significantly improve the quality and consistency of the parts produced.

Contact the Injection Molding team to learn how the PRESTROL function can serve as a powerful tool to enhance the performance and efficiency of your Shibaura Machine injection molding machine and further improve quality for even the most difficult to produce parts.

Tel: (888)593-1616

Email: im-success@shibaura-machine.com

Related Articles View All Articles

How Electric Ejectors Improve Injection Molding Performance

ELK GROVE VILLAGE, IL, November 16, 2022 - An electric ejector system can be a huge competitive differentiator compared to its hydraulic counterparts. The electric ejectors provide molders the ability to view torque giving better insight to allow for impro...

Read moreGive Your Injection Molding Parts Quality a Boost With Moldlyzer

ELK GROVE VILLAGE, IL, November 16, 2022 - The goal of any injection molding operation is 100% quality. Part of that process includes ensuring the injection pressure is right where it needs to be every time, in every stage of the operation. Without the rig...

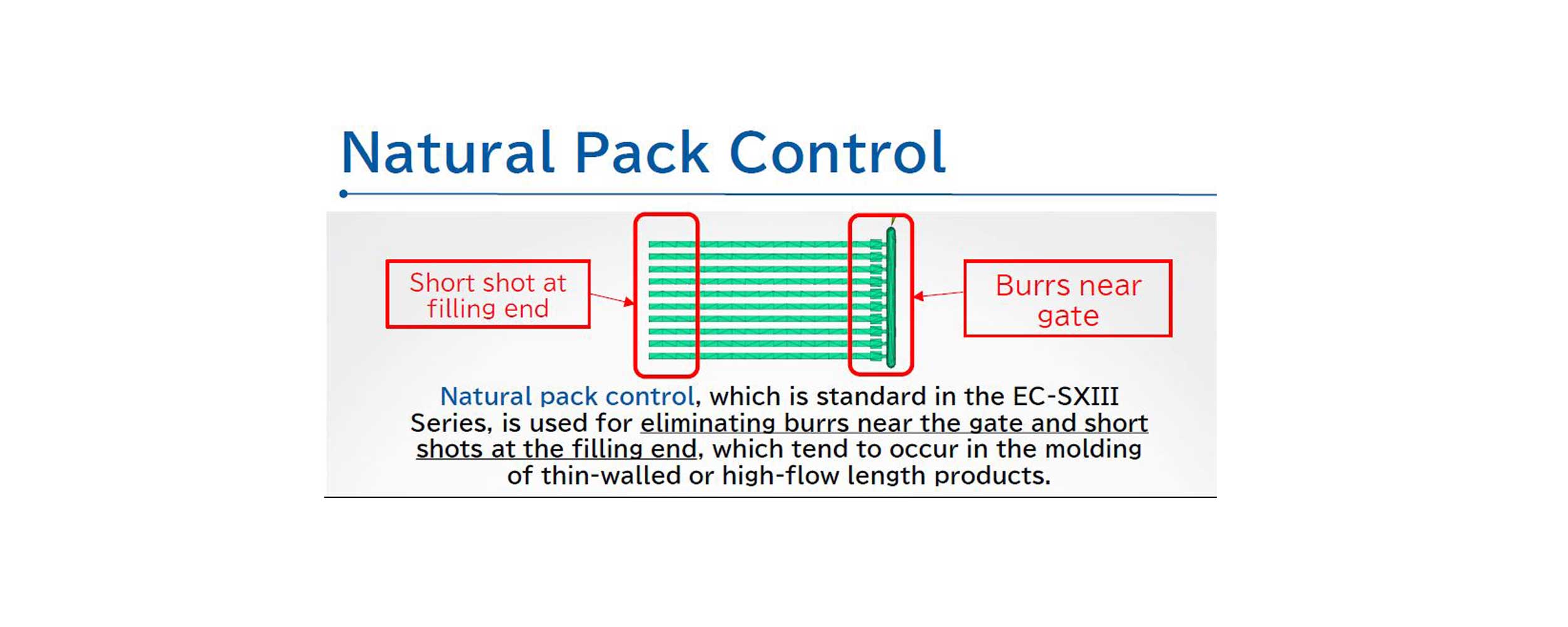

Read moreExploring the Natural Pack Feature on the V70 Controller to Improve Injection Molding Processing

ELK GROVE VILLAGE, IL, November 9, 2022 - Manufacturers molding thin and/or long flow length parts are always looking for ways to reduce part defects. With high peak cavity pressure these applications can be particularly challenging. By being able to maxim...

Read moreBring Real-Time Quality Monitoring to the Injection Molding Floor with Shibaura Machine

ELK GROVE VILLAGE, IL, November 2, 2022 - How efficiently and effectively are you able to control your quality processes? When quality management is running smoothly it not only maintains quality but is focused on maximizing productivity creating the best ...

Read moreNow Enrolling for In-Person Injection Molding Training Courses

ELK GROVE VILLAGE, IL, August 3, 2022 - Shibaura Machine is pleased to announce our popular in-person injection molding training courses are resuming for the remainder of 2022. Customers can join us at our tech centers in Elk Grove Village, IL, Charlotte, ...

Read moreRobot Integration Simplified With Shibaura Machine

ELK GROVE VILLAGE, IL, June 29, 2022 - Automating tasks with robots has become an increasingly popular option for injection molding manufacturers. From placing inserts into molds to moving parts through post-mold processes, robots provide process stability...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools