Why Automate and Integrate Your Die Casting Sprayer Solution? Read This.

ELK GROVE VILLAGE, IL, April 7, 2022 -

Would you fry an egg without applying oil to the pan first? Any chef knows the answer to that question is no. However, too much or too little oil can cause less than ideal results. Using just the right amount of oil ensures the egg doesn’t stick to the pan and can be easily released to flip, with the end result being a delicious breakfast.

The same goes for spraying lubricant in the die casting process. Any operator knows that to ensure a high-quality manufactured part, the film formation and wetting on the mold surface from the lubricant is required to act as a release agent and for cooling purposes. But just like applying oil to the pan, you don’t want to over or under-apply the lubricant because in doing so the result could be a poor finish with other quality issues.

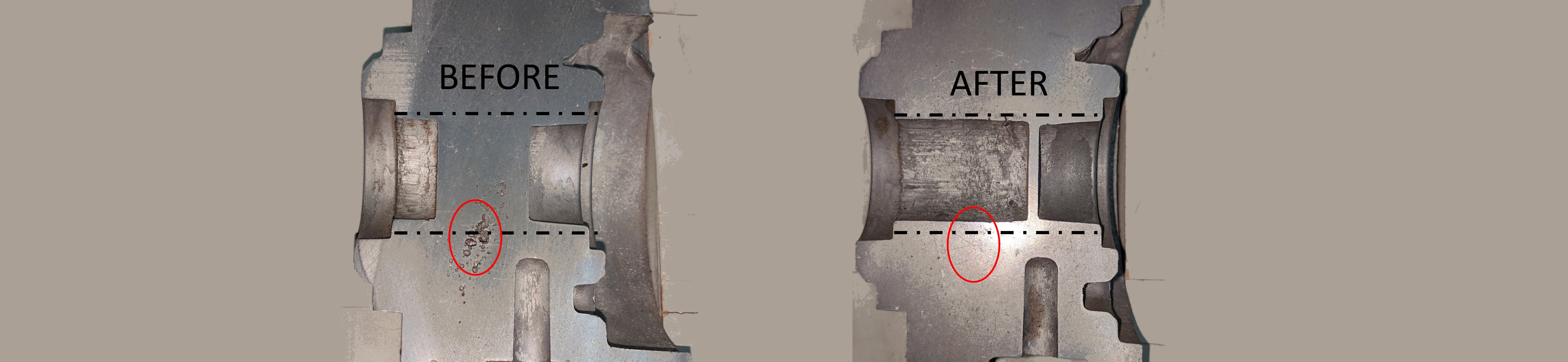

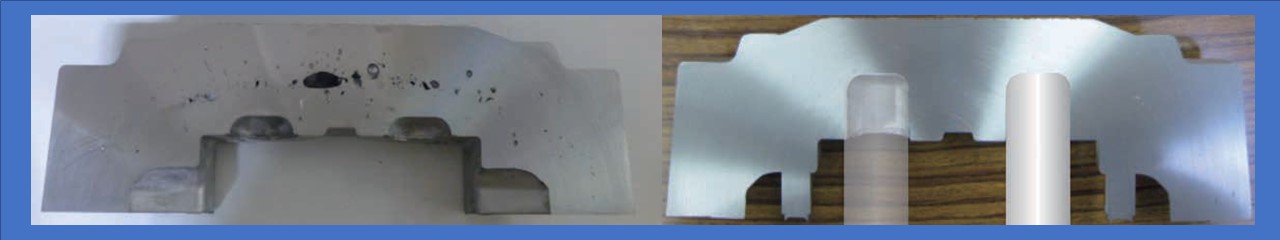

So the question remains, how can your factory become more exacting in lubrication spraying? Not enough lubricant means the casting won’t properly release which causes overheating, defects, or even serious die damage. On the flip side, dies with an excess lubricant are more likely to blister, leave castings with porosity, and over-cool which can cause the metal to pre-maturely freeze off. The answer to improving your spraying process is through automation and direct integration with your die casting machine. In doing so, your sprayer solution can improve the repeatability of clean and defect-free high-quality castings.

Automate and Integrate

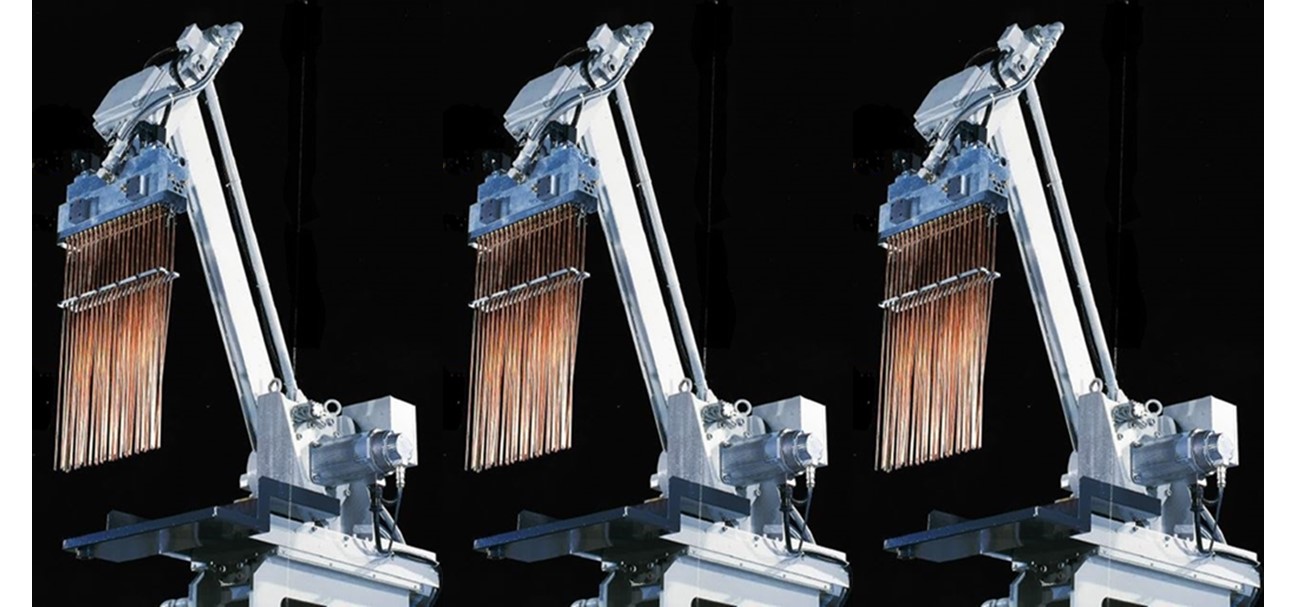

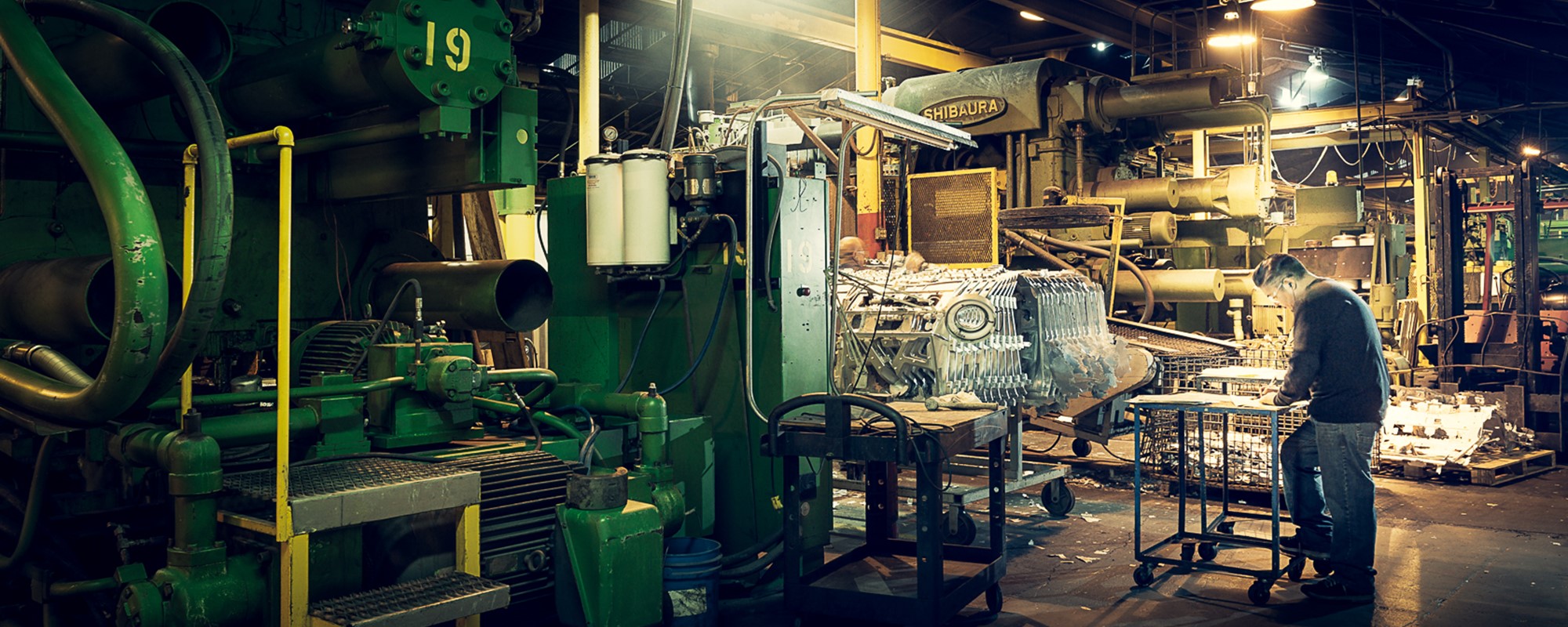

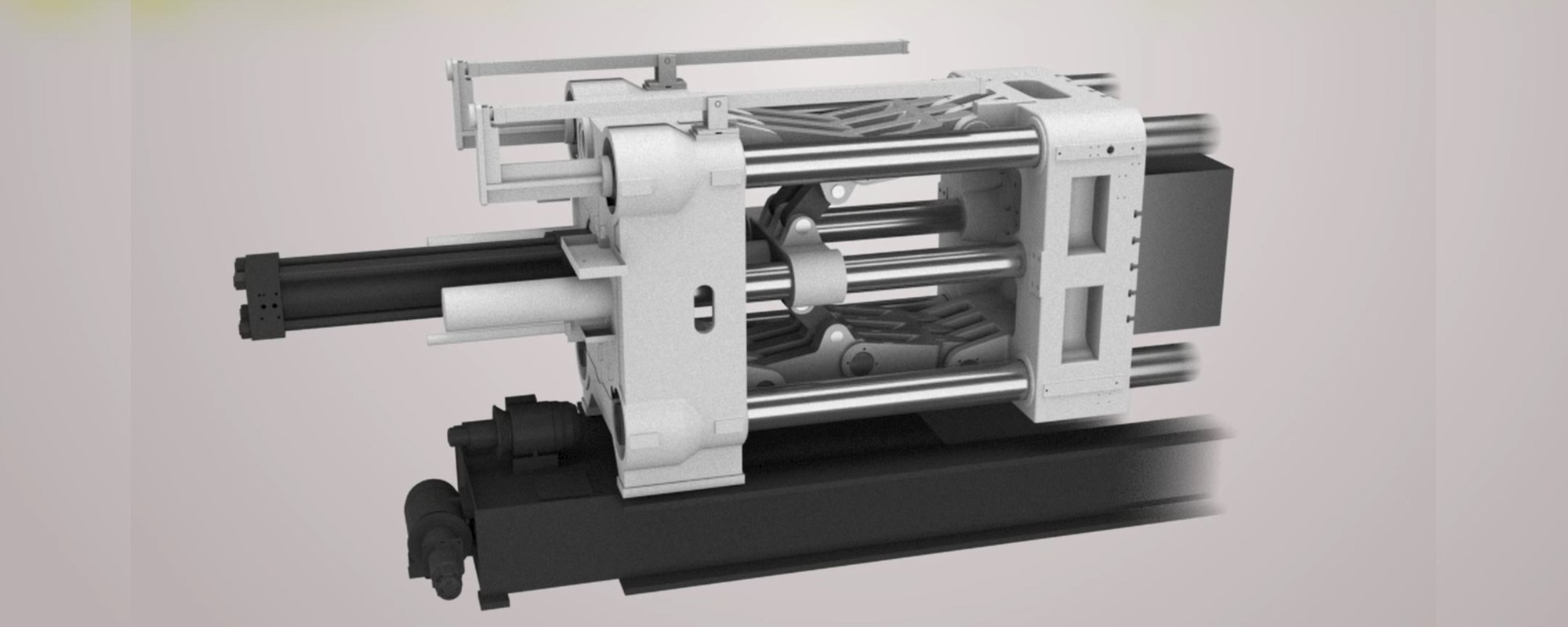

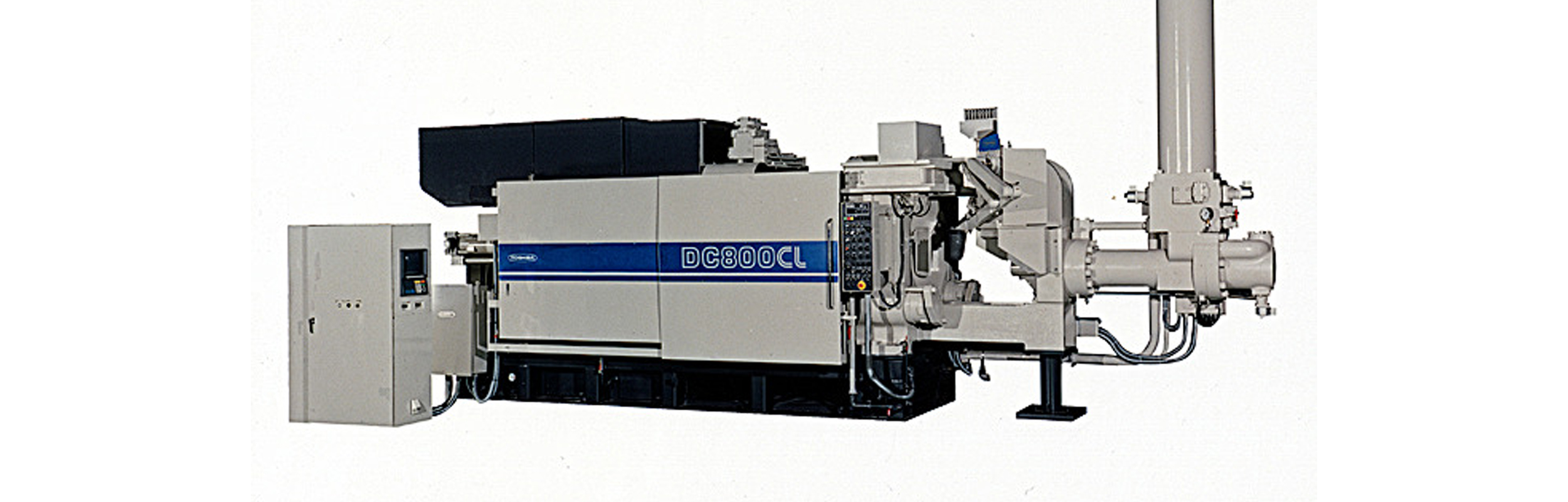

Being able to spray evenly across the die area can be easier said than done. Particular parts with irregular shapes and varying wall thickness can be a challenge for spray applications. Shibaura Machine’s spray system provides factories with a highly flexible modular spray system that integrates directly with their TOSCAST controller for improved ease of use.

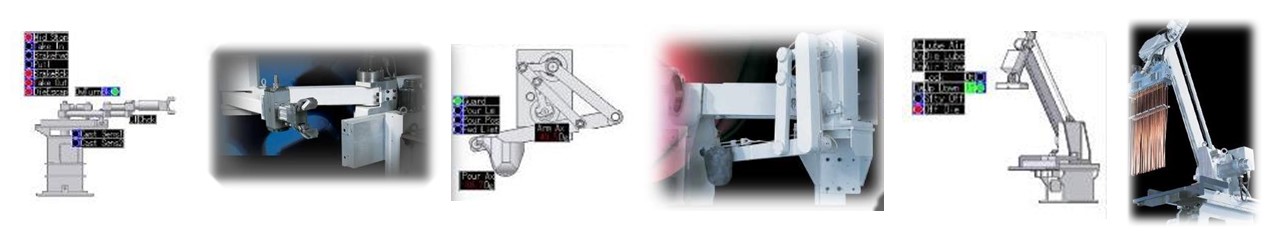

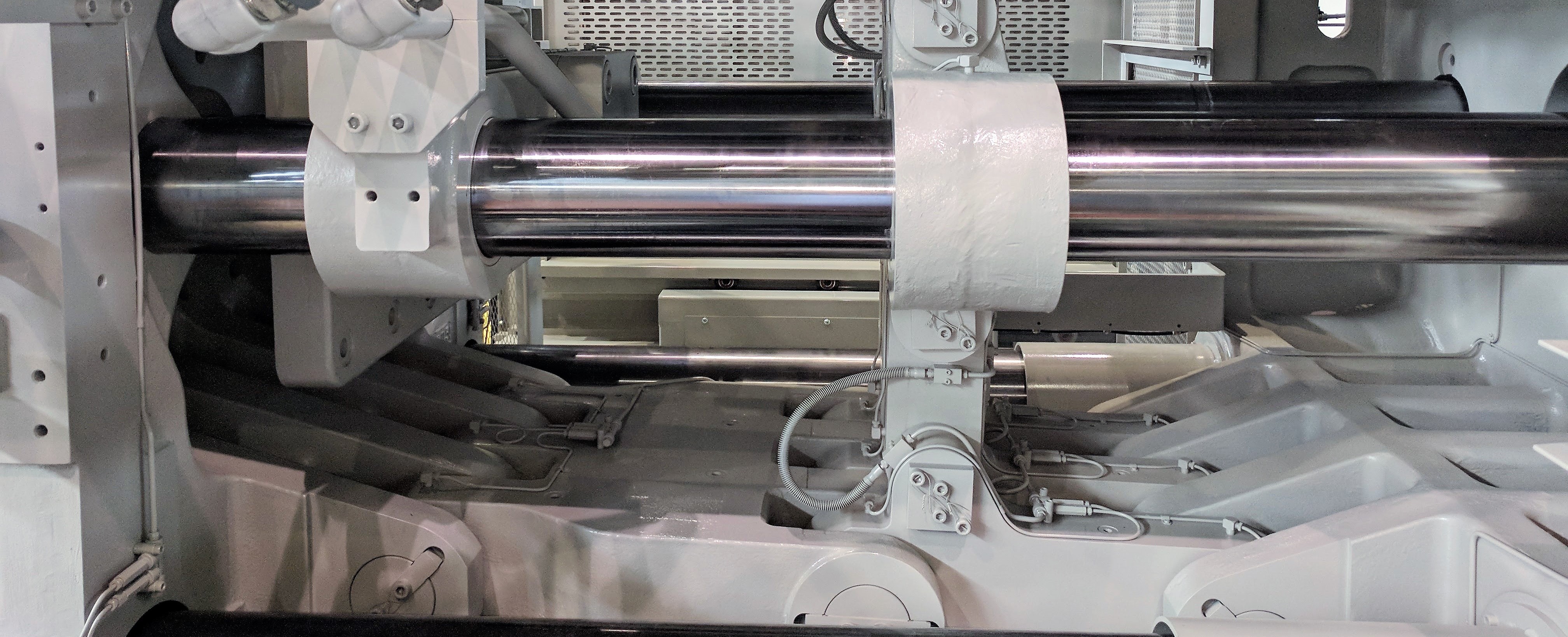

The spray system brings consistency and repeatability to the factory. The operator is allowed to provide exact direction on where the copper tubing will spray the flow and to what amount. Tubes can be individually turned off, meaning the lubricant only goes where it is needed. The fluid spraying contains release agents so the material doesn’t stick to the tool steel and the volume helps to control the heat. High-pressure air is also used to further clean and prepare the mold surface. Customers can choose to tailor the spray module attached to the spray system based on their needs with various spray nozzles, configurations, and flood tubes.

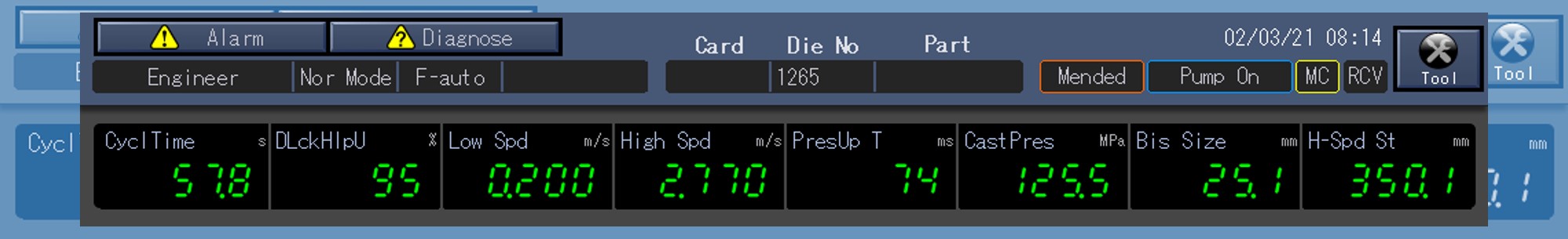

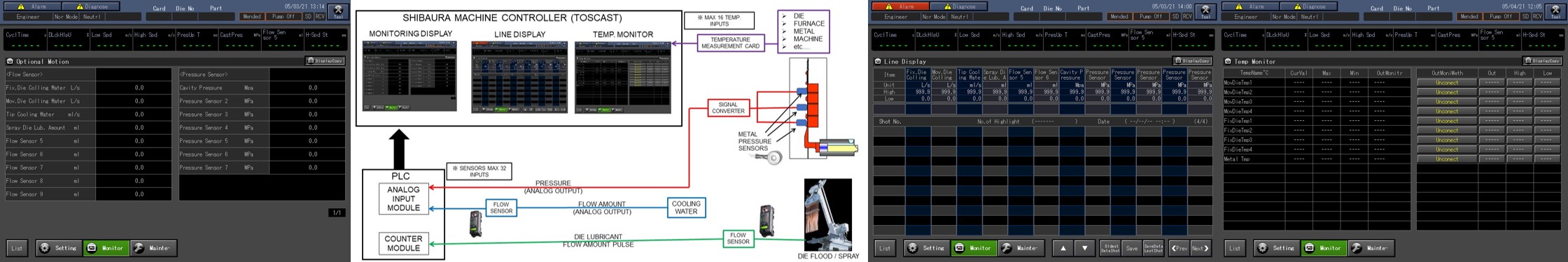

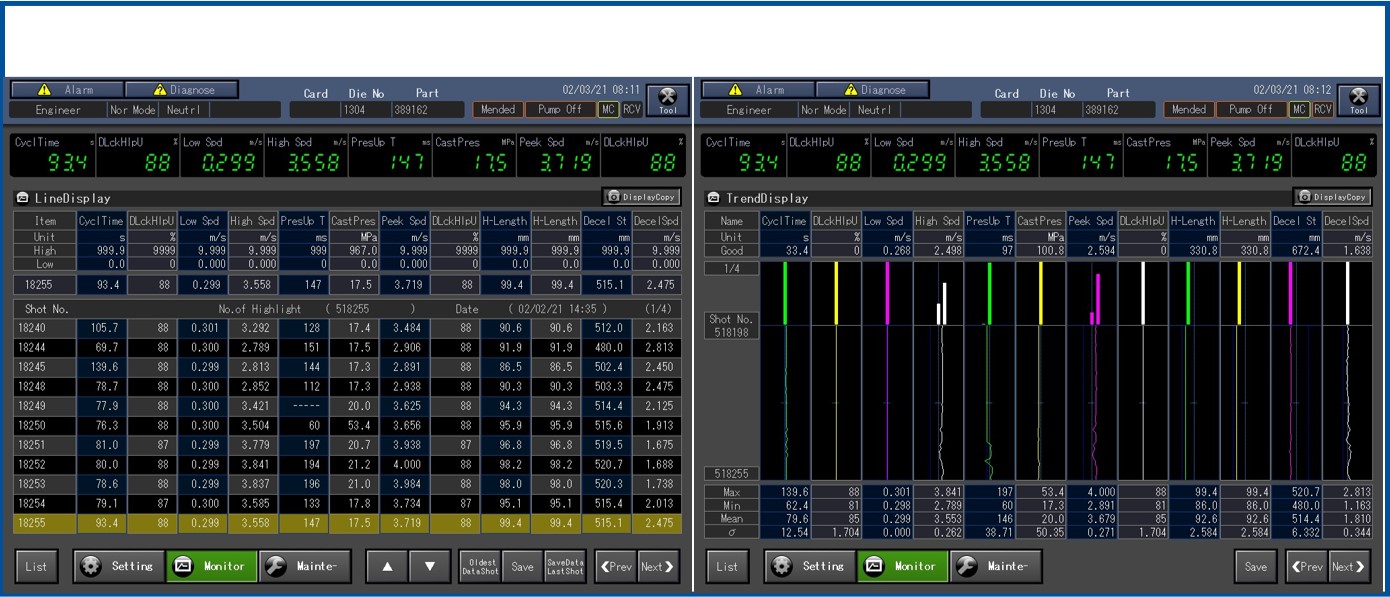

The integration between TOSCAST and the spray system allows the operator to work directly on a single controlling system with no additional HMI. Through TOSCAST the operator can set the positions and speeds of the sprayer's motion, along with the rest of your die cast machine. Since the sprayer is integrated with the TOSCAST, all the maintenance and monitoring functions are also controlled on the same single screen as the machine operations. Being able to control the sprayer with ease and accuracy helps improve the consistency and repeatability, key contributors to the efficiency of your production and bottom line.

Learn More

Proper, precise spraying is critical, along with adjustability – to ensure intense spraying in hot areas versus low-temperature areas. Contact the Die Cast Team to learn more about how the spray system controlled with the TOSCAST can start improving your factory productivity.

Contact the Die Casting Team to learn more about how the integration spray system can improve your manufacturing capabilities.

- Phone: (888) 593-1616

- Email: dc-sales@shibaura-machine.com

Related Articles View All Articles

Why Automate and Integrate Your Die Casting Sprayer Solution? Read This.

ELK GROVE VILLAGE, IL, April 7, 2022 -Would you fry an egg without applying oil to the pan first? Any chef knows the answer to that question is no. However, too much or too little oil can cause less than ideal results. Using just the right amount of oil en...

Read moreReduce Targeted Porosity in Your Die Casting with Shibaura Machine’s Squeeze Master

ELK GROVE VILLAGE, IL, March 24, 2022 -One of the great advantages of die casting is that without multiple operations, complex shapes can be achieved with minimal waste and scrap in an efficient way. However, certain geometries and features are impossible ...

Read moreImprove Your Vacuum System and Reduce Porosity with TOSCAST Monitoring

ELK GROVE VILLAGE, IL, March 10, 2022 -When low porosity, high quality castings are required, using a vacuum system is an excellent option.Vacuum pressure die casting allows factories to produce parts with predictable and repeatable mechanical properties b...

Read moreReduce Porosity with Shibaura Machine’s Advanced Die Casting Shot Control

ELK GROVE VILLAGE, IL, February 26, 2022 -Porosity in die casting can not only affect the esthetic of castings, but also impact the structural integrity and functionality of the casting- something manufacturers want to prevent, especially when producing hi...

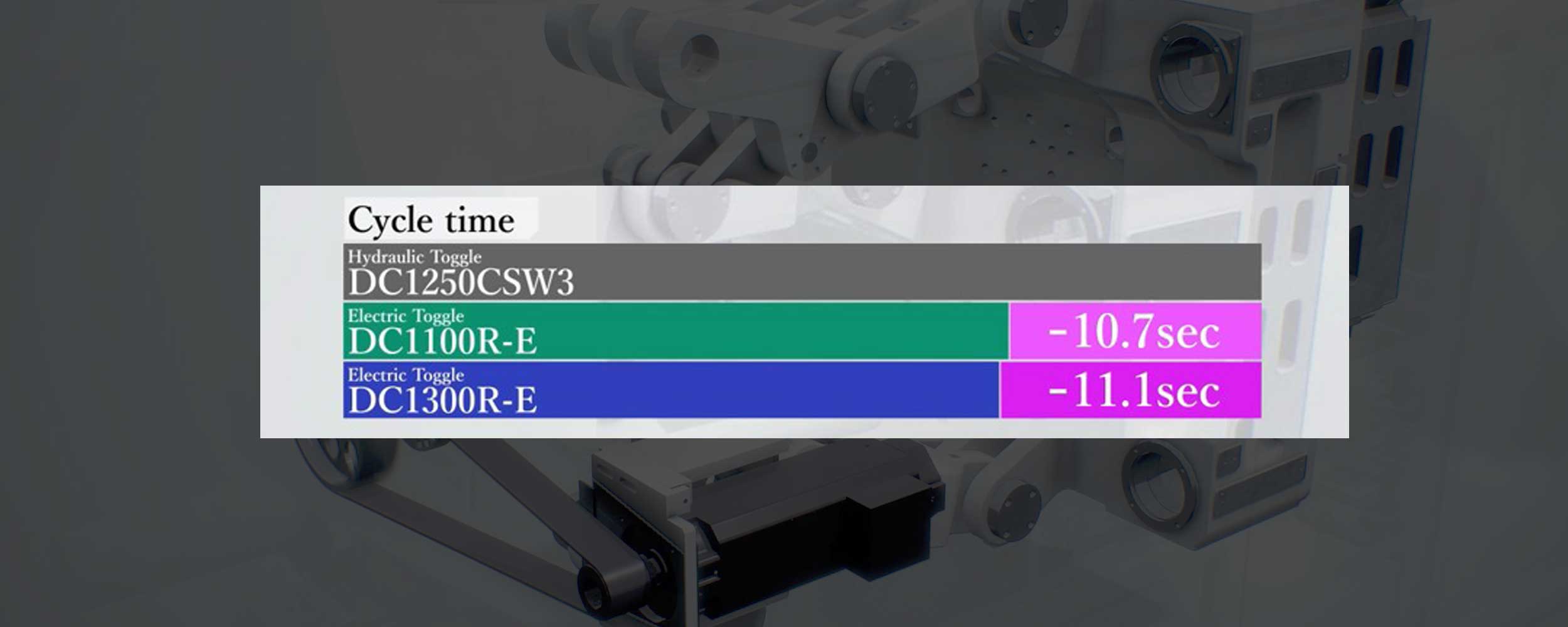

Read moreHow the Electric Servo Motor is Saving Cycle, Space, and Maintenance in the Die Casting World

ELK GROVE VILLAGE, IL, January 19, 2022 - The die casting world continues to evolve and with that comes improved technology. Electric servo motor driven machines continue to become increasingly popular because they Save cycle time, Save space requirements ...

Read moreDie Casting Virtual Training Makes Learning Easy

ELK GROVE VILLAGE, IL, January 5, 2022 - With die casting equipment, turning the wrong knob can have serious consequences. And while the industry is still facing skilled labor shortages, that means straightforward training is more important than ever to pr...

Read moreOur Die Casting Parts Department Commitment to You

ELK GROVE VILLAGE, IL, December 16, 2021 - Even with Shibaura Machine’s robust and reliable die casting machines, we know with heavy usage over time even the most well-maintained machines will inevitably need parts support. And when that time comes, every ...

Read moreHow Shibaura Machine’s Die Casting Parts Department Minimizes Downtime

ELK GROVE VILLAGE, IL, December 6, 2021 - Uptime, efficiency, quality. At Shibaura Machine we strive to offer our customers the highest performance and best return on their die casting machine investment in the industry. Our vertically integrated philosoph...

Read moreControl Porosity in Die Casting Easier with Shibaura Machine

ELK GROVE VILLAGE, IL, November 18, 2021 - The tiny pockets of air and small voids found in parts that we call porosity can quickly turn into a manufacturer's worst nightmare. Porosity in parts can not only harm a component's structural integrity, but al...

Read moreNever Be Left Wondering in Die Casting With TOSCAST Monitoring System

ELK GROVE VILLAGE, IL, November 4, 2021 - What goes on between one operator and the die casting machine should never be left a surprise to the next shift operator. While most factories have a process in place to record what took place the shift before, som...

Read moreShibaura Machine’s New Electric Toggle Die Clamping Machines Provide the Industry a More Efficient Solution

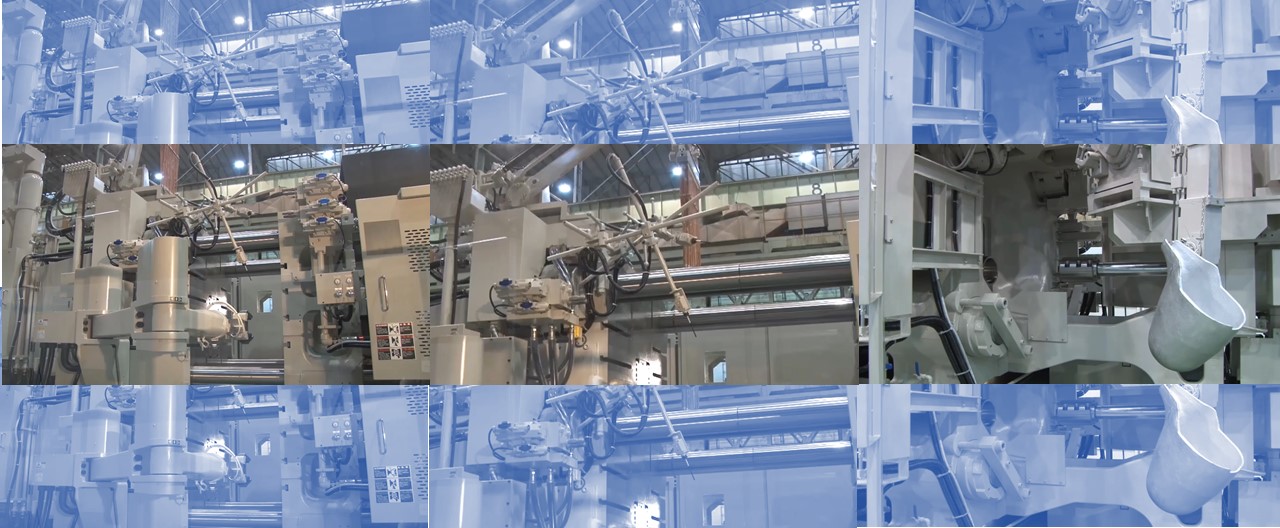

ELK GROVE VILLAGE, IL, October 21, 2021 - As the automotive industry evolves from internal combustion engines to electric vehicles, so must other industries to reduce carbon footprint. From automotive and agriculture to aerospace and consumer goods, implem...

Read moreShibaura Machine Makes it Simple to Match the Die to the Machine

ELK GROVE VILLAGE, IL, September 7, 2021 - Being successful in die casting is a combination of efficiency and productivity. Being able to be a step ahead of where your competition is at and exceed customer expectations requires it. One way to gain an advan...

Read moreImproving Efficiency in Die Casting with Shibaura Machine's Integrated Cell Management Solution

ELK GROVE VILLAGE, IL, Aug 19, 2021 - Die casting is a complex process. In the early days that meant dividing all the tasks into separate rooms, but as technology advancements have been made the entire process often happens under one small section of floor...

Read moreThe Importance of Details in Die Casting

ELK GROVE VILLAGE, IL, Aug 5, 2021 - At a busy foundry it can be easy to let small details become an oversight. From tasks like checking the alloy, temperature, and even ladle cup size- this can seem time consuming in the moment. However, those details are...

Read moreWhy Reliable Temperature Control is Critical to Your Die Casting Success

ELK GROVE VILLAGE, IL, July 22, 2021 - What does temperature have to do with it?If you’re involved in die casting production then you know it's everything. Even a slight fluctuation in temperature can mean major damage and defects. Ensuring a well-controll...

Read moreWhen is Waste Not Truly Waste in Die Casting?

ELK GROVE VILLAGE, IL, July 08, 2021 - The green movement is more important than ever before. No industry is overlooked, and it is every company’s duty to make changes to support the environment. In die casting that often means eliminating excess productio...

Read moreExtend Your Die Casting Equipment’s Lifespan

ELK GROVE VILLAGE, IL, June 17, 2021 - Die casting equipment: it’s one of the biggest investments you’ll make in your business. It begs the question then, how long will the equipment last? Shibaura Machine has been designing die casting machines that meet ...

Read moreHow Evolved is Your Die Casting Machines Construction?

ELK GROVE VILLAGE, IL, June 3, 2021 - We can talk about cycle times, repeatability, and user-friendly controls, but if your die casting machine is not running then you’re not working. Design factors that affect die casting machine durability are often smal...

Read moreMonitor, Control, and Manage Your Die Casting Process More Efficiently

ELK GROVE VILLAGE, IL, May 20, 2021 - Does your die casting machine realize the world around it? At the end of the day, the answer is not as much as it probably should. While it is surrounded by auxiliary equipment that monitors temperature, flow, and pres...

Read moreShot Cylinder Construction is More Important Than One Would Think

ELK GROVE VILLAGE, IL, April 15, 2021 - Have you ever heard the saying that too many cooks in the kitchen spoil the broth? This expression can also be applied to die casting machine shot cylinder design. Consider early generation and many current-day die c...

Read moreDie Casting Factory Accessory Integration Improves Productivity

ELK GROVE VILLAGE, IL, April 2, 2021 - Die casting has evolved a lot over the past one hundred years. At the beginning it was run solely by what a person could accomplish. Workers were expected to be the timers, electronics, and robots that we now have tod...

Read moreMonitoring Repeatability in Die Casting

ELK GROVE VILLAGE, IL, March 18, 2021 - The precision in die casting offers high quality, repeatability shot after shot. This repeatable accuracy offers a lower cost of operation and consistency, two things that are important when looking at improving prof...

Read moreDie Casting Machine - Ease of Use: The TOSCAST controller provides easy visibility of real-time machine status

ELK GROVE VILLAGE, IL, February 19, 2021 Die casting still proves to be the most accurate option when it comes to complex cast metal products. However, it is complex process that involves molten metal, high pressures, critical temperature control, and a v...

Read moreIntroducing a More Environmentally Friendly & Energy Efficient Die Casting Machine

ELK GROVE VILLAGE, IL, February 4, 2021 - Imagine having the option to turn on and off your die casting hydraulic pump motor instead of having it continuously running. What would that mean to your overall energy consumption and the environmental footprint...

Read moreTailor TOSCAST to Improve Your Die Casting Productivity

ELK GROVE VILLAGE, IL, January 20, 2021 For years, die casting machines have offered digital control options making operators more efficient and improving throughput, but a gap still exists. These machines can only do so much before a human needs to step ...

Read moreConsiderations for Reducing Die Casting Cycle Time

ELK GROVE VILLAGE, IL, January 5, 2021 When it comes to die casting, cycle time optimization is more than just moving quickly. At first thought, the time required to complete castings should be as short as possible because more money can be made if you pr...

Read moreOur Commitment to Keep Our Die Casting Customers Up and Running

ELK GROVE VILLAGE, IL, December 16, 2020 When the die casting machine is down costs go up.Avoiding costly downtimes and keeping quality levels high starts with choosing the right machine partner. The right partner will not only provide you with a quality d...

Read moreWorking Together to Make Sure Your Die Casting Equipment is Optimally Operating

ELK GROVE VILLAGE, IL, December 8, 2020 - As a Die Caster, are You Up To Date on the Latest Developments?In an industry that is continually evolving with technology developments, it can be difficult to keep up with the demands of the industry. However, by ...

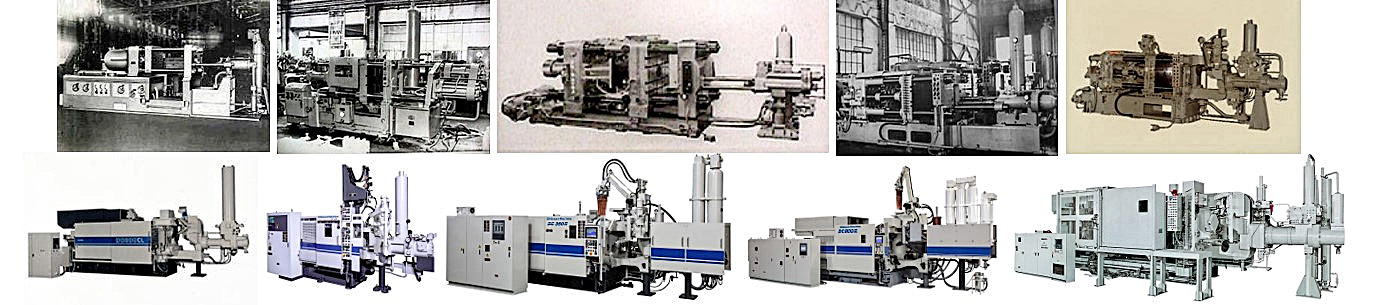

Read moreShibaura Machine has almost 50 years in the United States

ELK GROVE VILLAGE, IL, June 6, 2020 Shibaura Machine has been manufacturing Die Casting Machines since 1953! Established an office in the United States in 1974! Currently with over 17,000 die-casting machines worldwide! Our team averages almost 25 year...

Read moreShibaura Machine Die Casting Offers Used Machine History Reporting Service

ELK GROVE VILLAGE, IL, July 10, 2020 The purchase of a used machine comes with risks! Help mitigate these risks by requesting a free machine history report. Contact us at dc-MachineFacts@shibaura-machine.com before you consider purchasing a used die casti...

Read moreAvoid damage to your machine caused by extended downtime

ELK GROVE VILLAGE, IL, July 10, 2020 If your die casting machines are not under power for an extended period, You must read the following:The below recommendations will help keep your machines in good running condition and minimize unplanned downtime:KEEP...

Read moreHow Shibaura Machine’s Die Casting Parts Department Minimizes Downtime

ELK GROVE VILLAGE, IL, December 6, 2021 - Uptime, efficiency, quality. At Shibaura Machine we strive to offer our customers the highest performance and best return on their die casting machine investment in the industry. Our vertically integrated philosoph...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools