Engineering Excellence: A Closer Look at Shibaura Machine's TUE Series Tool Holders

ELK GROVE VILLAGE, IL, February 6, 2024 -

Shibaura Machine's TUE series machines are equipped with a diverse range of tool holders, each designed to maximize functionality and versatility. These tool holders are integral to the TUE series, catering to a wide array of machining operations and ensuring the highest standards of precision and performance.

A Snapshot: Machine Tool Holders

Shibaura Machine's tool holders enable the machine tools to handle a variety of operations. From intricate boring to precision turning operations, these holders adapt to diverse manufacturing requirements.

Boring Tool Holder

This includes the FMS50A-BFP type for the TUE(S) series. Available in lengths from 250mm to 400mm, they offer flexibility for various boring tasks. For example, if your shop is tasked with creating a series of engine cylinders that require precise boring to meet stringent specifications utilizing the FMS50A-BFP type holder, set at a length of 350mm, the technicians can accurately bore the cylinders to the exact dimensions required.

Turning Tool Holder

This series includes the FMS50A-ST for the TUE(S) series. Available in lengths from 160mm to 250mm, they provide robust support for squared tooling tasks. For example, if your shop specializes in aerospace components and is producing stainless steel brackets, which require meticulous turning operations to achieve the aerodynamic profiles necessary for optimal performance by employing the FMS50A-ST turning tool holder, set at a length of 200mm, the machinists can achieve unparalleled precision. The holder's ability to provide stable support for turning tooling tasks allows for the precise shaping of the brackets, ensuring that each piece meets the exacting standards of the aerospace industry.

Sandvik CAPTO Tool Holders

Shibaura Machine also offers Sandvik CAPTO holders, known for their precision and adaptability. These modular system holders come in C8 and C6 types, each tailored for specific applications within the TUE series. Known for their quick-change capabilities, they reduce setup time and enhance productivity, suitable for a range of machining applications including milling, turning, and drilling.

Access Multiple Machining Operations

Whether for detailed boring or specific turning tooling tasks, these tool holders are engineered to meet the diverse needs of modern machining operations in a variety of industries including oil & gas, energy, aerospace, and more. Their adaptability and precision ensure that each task is executed with the highest level of efficiency and accuracy.

To explore the full potential of these versatile tool holders and to get tailored solutions for your specific machining requirements, contact the Machine Tools team at Shibaura Machine. They can provide detailed specifications, pricing, and expert advice to help you make the most informed decision for your manufacturing needs.

Related Articles View All Machine Tools Articles

The Future of Machine Tool Support: Introducing Shibaura Machine's Customer Portal

ELK GROVE VILLAGE, IL, January 30, 2024 - As we get ready to launch our new Customer Service Portal for Machine Tool customers later this year, Shibaura Machine Company, America is leading the way in transforming how you access information and receive supp...

Read moreElevating Customer Support in Machine Tools: Shibaura Machine's Integration of CRM and Smart Glasses

ELK GROVE VILLAGE, IL, January 23, 2024 - In an era where digital transformation is not just a trend but a business imperative, Shibaura Machine Company, America continues to grow our virtual customer support options in the machine tool industry. Building ...

Read moreTransforming Machine Tool Maintenance: Shibaura Machine’s Remote Assist Service

ELK GROVE VILLAGE, IL, January 9, 2024 - In the face of rapidly advancing technology and ever-increasing global competition, the manufacturing industry stands at a pivotal crossroads. Shibaura Machine understands the critical need for speed, efficiency, an...

Read moreExploring the TOSNUC PX200 CNC Control: A Smart Machining Partner

ELK GROVE VILLAGE, IL, December 13, 2023 - Today's manufacturing world moves fast, and being precise, efficient, and easy to use is more important than ever. This week we're highlighting TOSNUC PX200 Controller, which is more than just a CNC control syste...

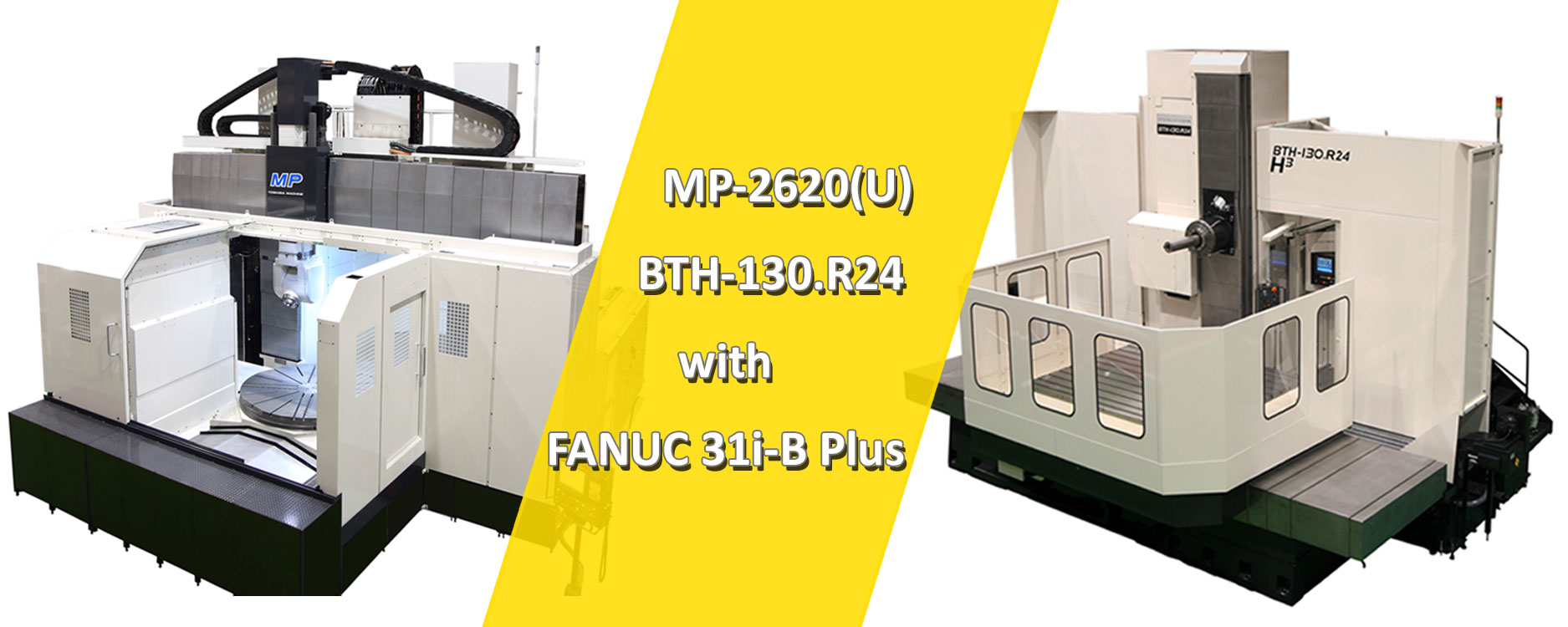

Read moreInnovation and Precision at the Center the FANUC 31i-B Plus CNC Control

ELK GROVE VILLAGE, IL, December 5, 2023 - The FANUC 31i-B Plus marks a significant advancement in machine tool CNC control technology. Known for its efficiency and exceptional features, it's designed for modern, complex machines, driving innovation in mach...

Read moreThe Future of Manufacturing in America: Reshoring, Automation, and Innovation

ELK GROVE VILLAGE, IL, November 28, 2023 - Global manufacturing is experiencing a significant shift. The Reshoring Initiative, a movement to bring manufacturing jobs and operations back to the United States, is not just reshaping our business strategies bu...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools