5 Value Adds to Increasing Automation with the Multi-Pallet Magazine on the TMD Series

ELK GROVE VILLAGE, IL, August 22, 2023 -

In manufacturing, staying ahead requires more than just meeting current demands – it requires a proactive anticipation of tomorrow's challenges. As the drive towards automation gains momentum, manufacturers are realizing the critical importance of aligning their strategies with both present needs and future expectations.

The demand for machine tools equipped with multi-pallet specifications reflects the changing landscape of manufacturing. Multi-pallet magazines play an essential role in modern manufacturing, allowing for the rapid changeover of pallets in CNC machine tools. This technology contributes to increased efficiency and productivity, particularly in high-volume production environments.

The Shift to Automation

The concept of setting a workpiece on Friday, completing machining over the weekend, and commencing work on a new piece on Monday underscores the potential of automated multi-pallet systems to elevate productivity.

The TMD series of Vertical Boring & Turning Mills by Shibaura Machine has the option to include an integrated multi-pallet magazine, seamlessly incorporated into the machine tool design. In combination with an advanced control system and programming capabilities, shops can recognize these five value-adding features.

1. Optimized Throughput

By minimizing workpiece transition times, these systems drastically reduce idle periods between machining operations. For instance, while one pallet is undergoing machining, another can be in the process of being loaded or unloaded. This simultaneous operation ensures that the machines are engaged in productive tasks throughout their operational cycle, resulting in a significant boost to overall throughput.

2. Workpiece Flexibility

A multi-pallet magazine integrated into the TMD Series allows manufacturers to switch between pallets and accommodate varying workpiece configurations, including those with different dimensions and specifications. This allows for seamless transitions from turning to milling or from machining a large component to a smaller one without extensive setup changes. It allows resources to be utilized efficiently and production demands to be adjusted as they change.

3. Reduced Human Intervention

With automated workpiece exchanges and well-orchestrated machining processes, manufacturers can envision a scenario where machines continue their work even when human intervention isn't always available. As a result, manufacturers are able to save labor costs and reduce operating expenses. In addition, with quicker turnaround times manufacturers can produce more products at a lower cost.

4. Continuous Production

Alternating pallets makes the manufacturing process a continuous flow of production. It is possible to machine one pallet while setting up another, ensuring uninterrupted production. This cooperation of operations is a cornerstone of modern, efficient manufacturing.

5. Enhanced Efficiency

In order to automate multi-pallet processes, advanced cell controllers are essential. For instance, the cell controller ensures that the integrated pallet changer system, machines, and other components of the TMD Series work together. The cell controller seamlessly manages transitions between workpieces, tool changes, and machine-specific functions, contributing to the overall efficiency of manufacturing.

Future-Ready Manufacturing

Manufacturing technology investments should go beyond current needs and cater to future ones. The multi-pallet solutions for the TMD series of Vertical Boring & Turning Mills have been developed to meet the demands of manufacturing as they evolve.

Providing the foundation for efficient automation and integration, these systems enable manufacturers to stay ahead of the curve, well-equipped to meet the challenges and opportunities of the future. Keep an eye out for upcoming articles that will highlight how Shibaura Machines' horizontal boring and double column machines integrate multi-pallet solutions to redefine efficiency and precision.

Contact the Machine Tool team to learn more.

Related Articles View All Machine Tools Articles

Embracing the Future: Shibaura Machine's Product Innovation in Multi-Tasking Equipment

ELK GROVE VILLAGE, IL, August 8, 2023 - As manufacturers seek to optimize efficiency and expand capabilities, multi-tasking machining centers have emerged as major innovations in the industry. These advanced machines integrate various machining operations ...

Read moreNano Machines Answer the Demand for High Precision Industrial Equipment Parts Production

ELK GROVE VILLAGE, IL, July 26, 2023 - In the world of industrial equipment manufacturing the importance of product quality cannot be overstated. While parts can vary widely depending on the specific industry and application, the overall quality influences...

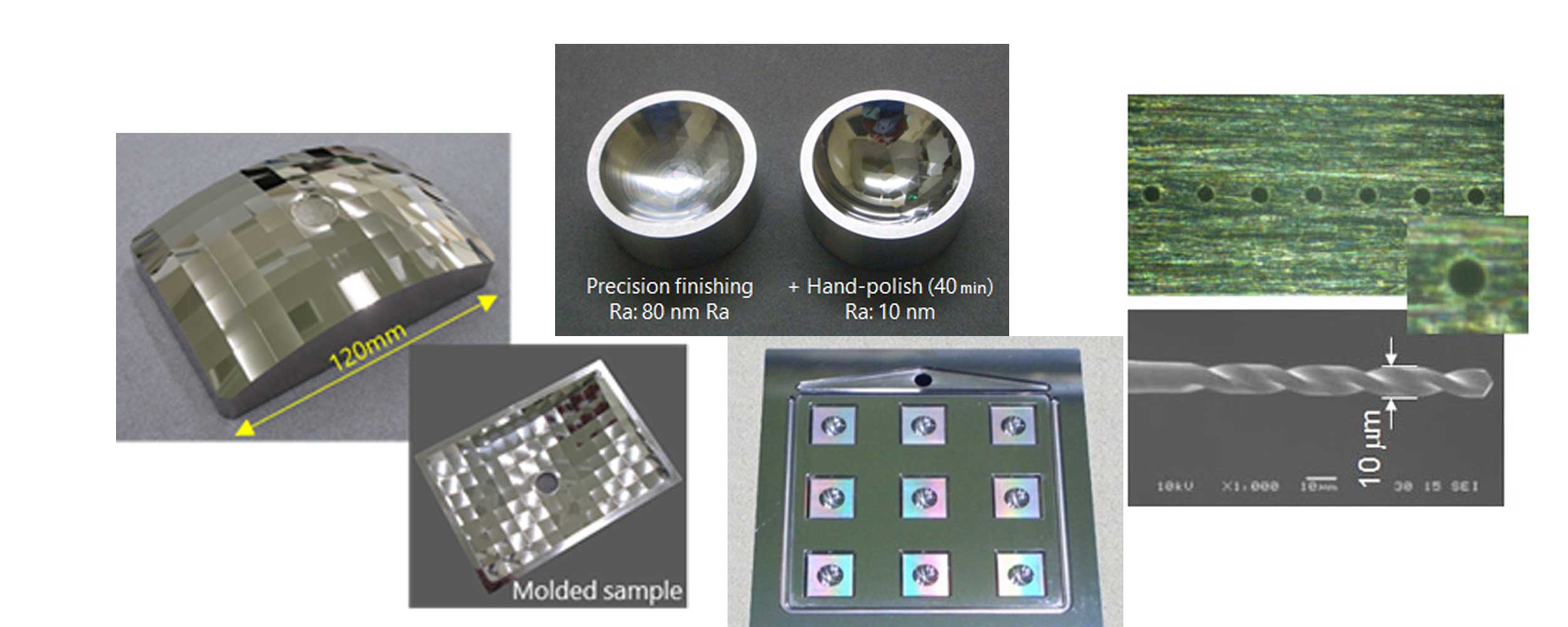

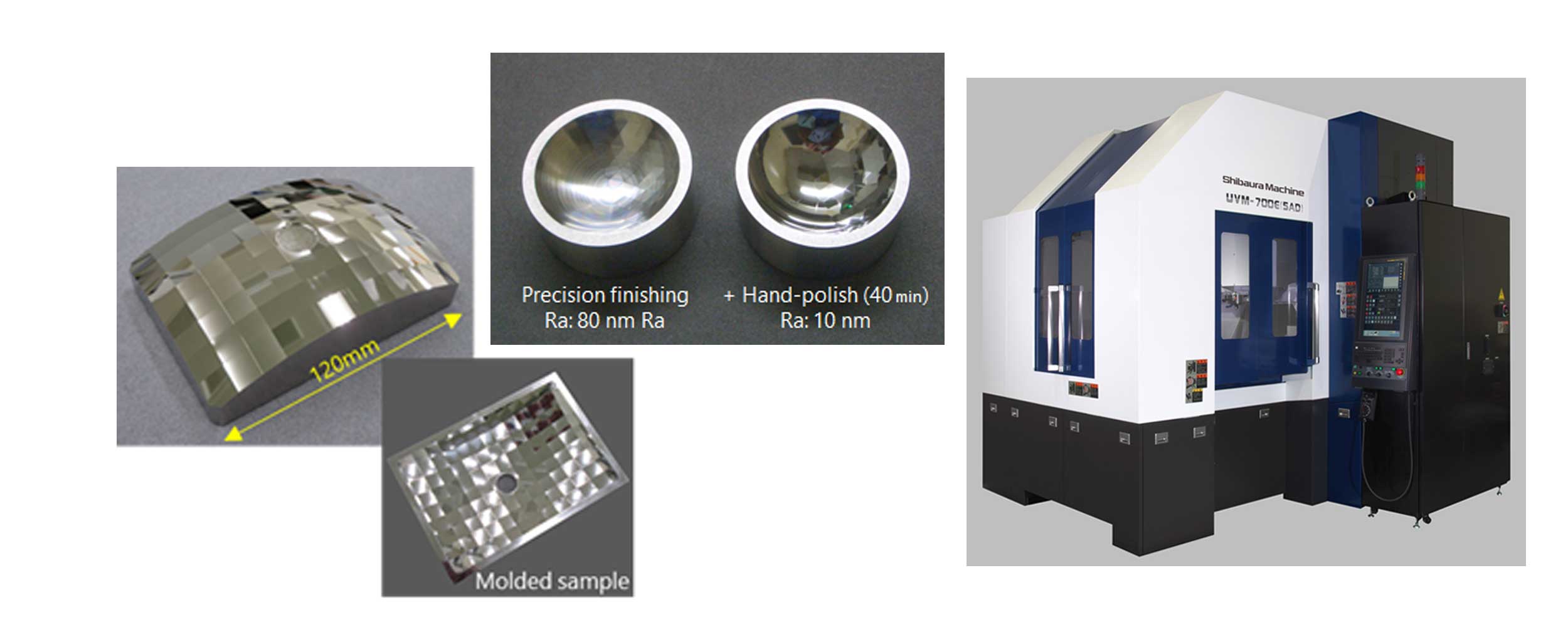

Read moreEnabling High Precision Machining with the UVM Series Nano Machines

ELK GROVE VILLAGE, IL, July 19, 2023 - Manufacturers continually seek innovative solutions to satisfy customer demands as industries increasingly require greater levels of precision, reliability, and complexity with their applications. Many are turning to ...

Read moreHow Manufacturers Can Meet the Demands of the Renewable Energy Market

ELK GROVE VILLAGE, IL, July 12, 2023 - As the world prioritizes sustainability and environmental responsibility, the renewable energy sector is undergoing a significant transformation. Countries and industries worldwide are seeking cleaner and more sustain...

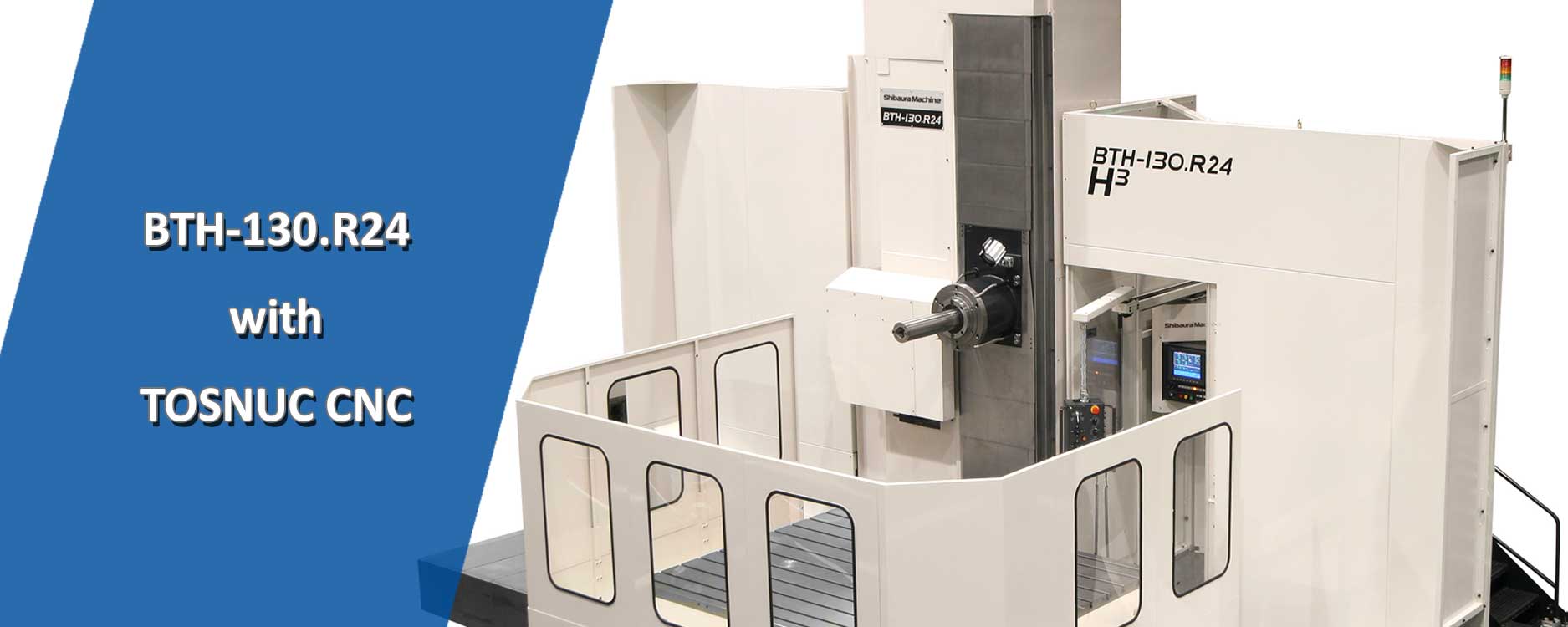

Read moreEmpowering Manufacturers: The BTH-130.R24 and TOSNUC Control System for Precision, Efficiency, and Operational Ease

ELK GROVE VILLAGE, IL, June 27, 2023 - Precision, efficiency, and ease of operation are paramount for manufacturers seeking to gain a competitive edge. Are you taking full advantage of the capabilities of your TOSNUC control system when it comes to your BT...

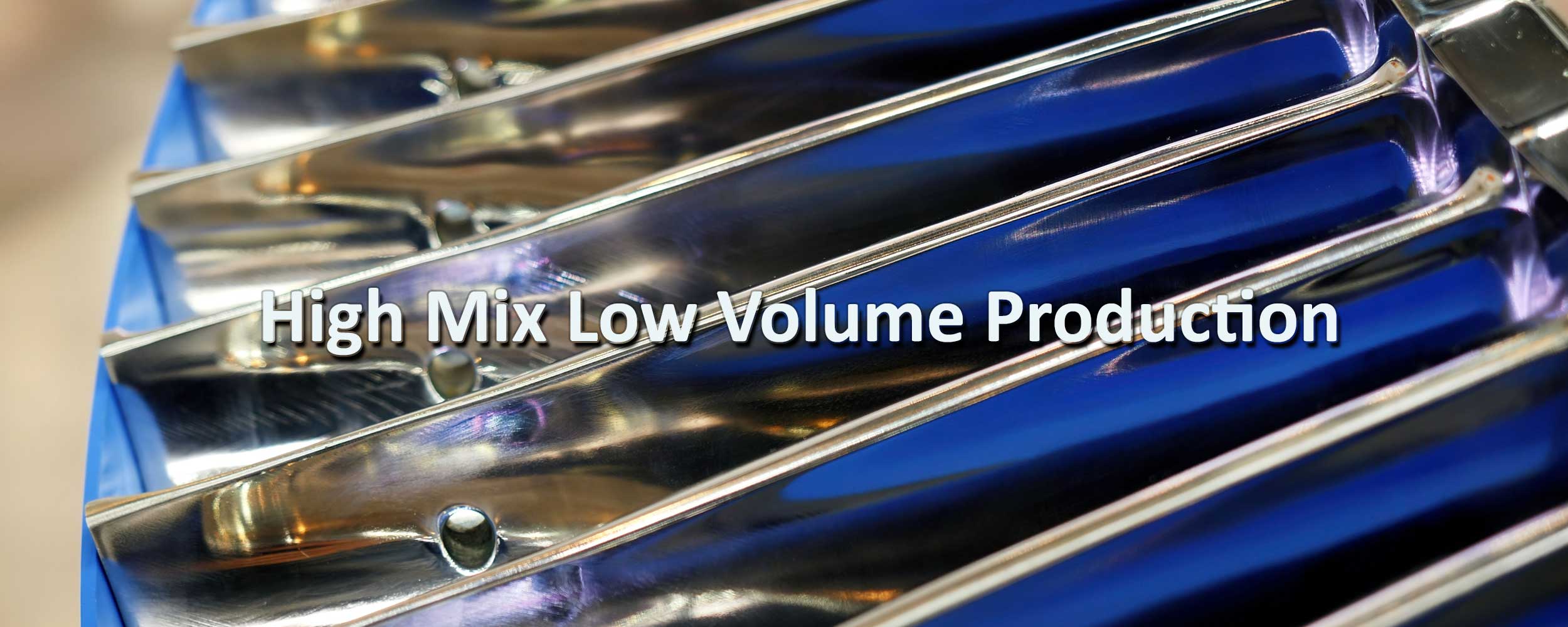

Read moreDriving Success in High Mix Low Volume Production: Multi-Tasking Machines and Attachment Changers as Key Enablers

ELK GROVE VILLAGE, IL, June 19, 2023 - In the ever-changing landscape of manufacturing, businesses face the challenge of adapting to diverse customer demands while maintaining operational efficiency. High mix low volume (HMLV) production has emerged as a g...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools