Flexibility as a Competitive Advantage: Embracing the Latest Trends in Machine Tools

ELK GROVE VILLAGE, IL, June 5, 2023 -

Global trends in the machine tool industry are leaning towards greater flexibility, driven by the evolving needs and demands of manufacturers across various sectors. Traditionally, machine tools were designed for specific tasks and rigidly configured for a particular production process. However, the landscape is shifting towards adaptable and flexible machine tools that offer versatility and agility to accommodate diverse manufacturing requirements.

Several trends in machine tool flexibility have emerged that are here to stay. These trends are shaping the industry and enabling manufacturers to adapt to dynamic market demands, optimize production processes, and achieve higher levels of efficiency and productivity.

1. Multi-Tasking Machines

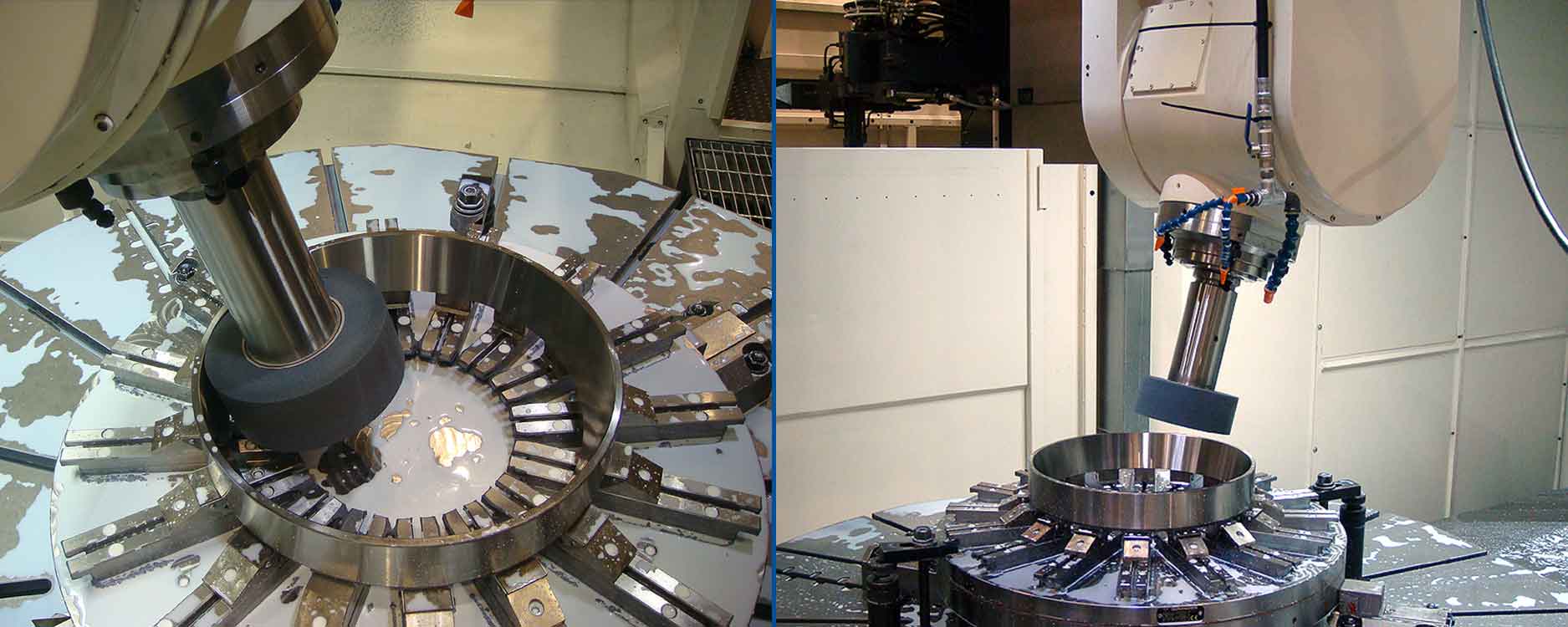

Manufacturers are increasingly opting for multi-tasking machines that can perform multiple operations in a single setup. These machines integrate different machining processes, such as milling, turning, drilling, boring, and grinding, into a single platform. By combining operations, manufacturers can optimize production efficiency, reduce setup time, improve workpiece quality, and enhance overall productivity.

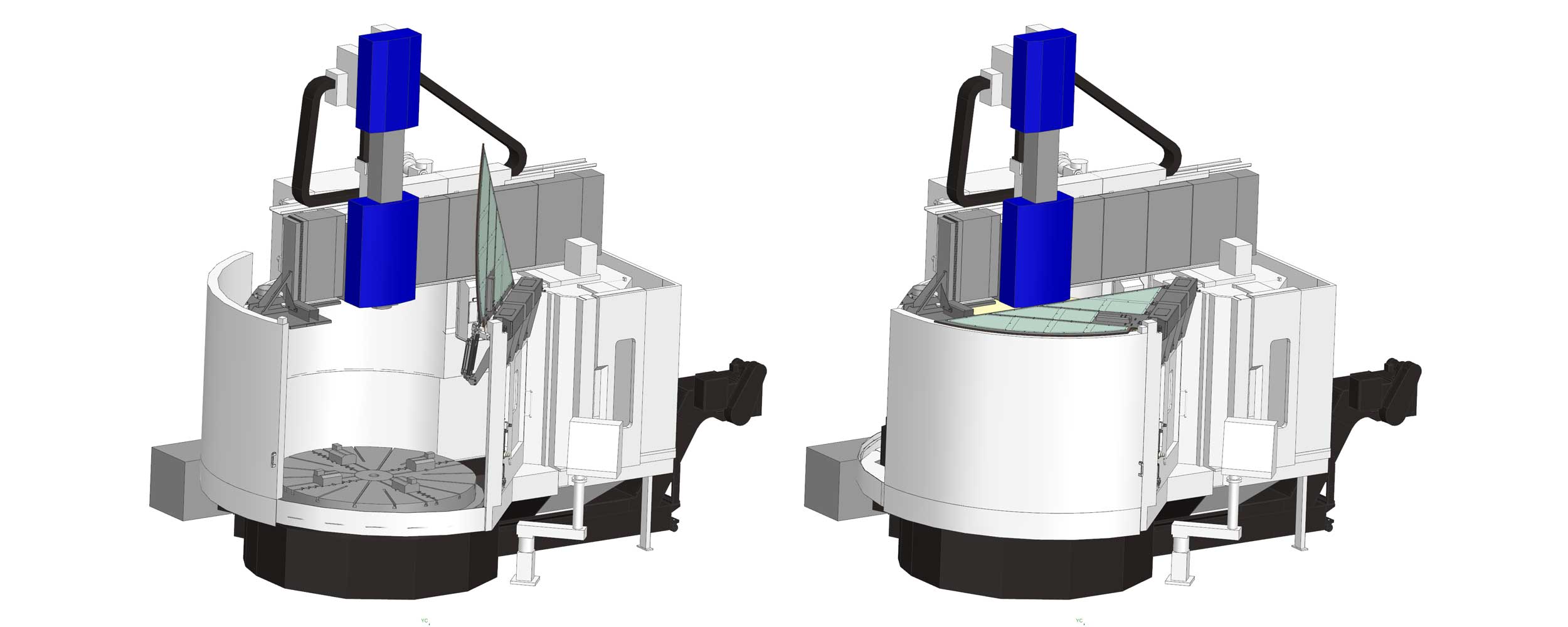

As an example, Shibaura Machine has developed a series of MP-2620(U) double-column type multi-tasking machining centers that offer enhanced capabilities for machinists. These machines seamlessly integrate turning functions and can be used as 5-axis turn-milling machining centers by incorporating attachments along with the use of the automatic attachment changer. By combining multiple functionalities within a single machine, not only does it result in reduced cycle time, but it also streamlines workpiece handling and enables efficient multi-tasking and 5-axis machining operations.

2. Automation and Robotics

The integration of automation and robotics is another key trend driving flexibility in machine tools. Automated systems, such as robotic arms and gantries, enhance the versatility of machines by automating loading and unloading of workpieces, pallet changers, tool changers, and other repetitive tasks. This not only reduces manual labor but also enables machines to handle a wider range of tasks and adapt to varying production volumes.

By embracing automation, Shibaura Machine users can enhance operational agility, reduce labor costs, and stay ahead of the curve in an increasingly automated industrial landscape. The pallet changer enables seamless transition between workpieces, minimizing downtime and maximizing workflow efficiency. Likewise, the automatic attachment changer allows for swift and automated swapping of tools, optimizing manufacturing processes. These automated options also reduce the reliance on manual intervention and enable businesses to maximize operational efficiency with minimal human resources.

3. Advanced Control Systems

The adoption of advanced control systems, such as computer numerical control (CNC), has revolutionized the flexibility of machine tools. Machinists actively seek advanced control systems for machine tools that offer seamless operation and reliable performance. With intuitive interfaces and programming languages, CNC systems empower operators to quickly switch between setups and adjust machining parameters on the fly.

To cater to the diverse needs of machinists, Shibaura Machine has developed innovative solutions that prioritize both efficiency and ease of operation. Our BTH-130.R24 horizontal boring machine, for instance, offers the option to leverage either the TOSNUC or FANUC control systems. This flexibility allows machinists to harness the full capabilities of their machine, ensuring optimal performance and productivity from the very beginning.

4. Modular Designs

Modular designs allow for easy customization and scalability. Modular machine tools consist of standardized components and modules that can be reconfigured or added as needed. This approach enables manufacturers to adapt machines to specific applications, expand capacity when required, and integrate additional functionalities seamlessly.

By incorporating modular components and subsystems, Shibaura Machine's machine tools can be easily adapted and configured for different applications, processes, and production needs. This modular design concept enables efficient customization, maintenance, and future scalability, providing customers with versatile and adaptable solutions for their machining operations.

5. Connectivity and Digitalization

Industry 4.0 and IIoT concepts including Shibaura Machine machiNetCloud connectivity and digitalization, are transforming machine tools into intelligent systems. With the integration of sensors, data analytics, and machine learning algorithms, machine tools can gather real-time data, monitor performance, and optimize processes. This data-driven approach allows manufacturers to make informed decisions, identify bottlenecks, and adjust machine settings for enhanced flexibility and productivity.

6. Adaptive Machining

Adaptive machining techniques, such as in-process monitoring and feedback control, are gaining popularity. By continuously monitoring machining conditions, such as cutting forces, temperatures, and tool wear, machine tools can make real-time adjustments to optimize performance and maintain desired tolerances. Adaptive machining ensures consistent quality, even when dealing with varying material properties or unexpected changes in the manufacturing environment.

The adaptive machining capabilities offered by Shibaura Machine not only increase productivity but also provide greater flexibility and responsiveness in the manufacturing process. By automatically adjusting machining parameters, the system can adapt to variations in material properties, tool wear, or environmental conditions, ensuring consistent and high-quality results throughout the production run.

Maintain Your Competitive Edge

The global trend towards greater flexibility in machine tools is driven by the need for manufacturers to respond quickly to changing market demands, handle diverse production requirements, and improve overall efficiency.

By embracing multi-tasking machines, advanced control systems, modular designs, automation, connectivity, and adaptive machining techniques, manufacturers can unlock new levels of flexibility and stay competitive in a rapidly evolving manufacturing landscape.

Contact the Machine Tool team to learn more.

Related Articles View All Machine Tools Articles

When Size Does Not Determine Accuracy: Breaking Stereotypes with Large Machine Tools

ELK GROVE VILLAGE, IL, May 30, 2023 - In the world of machine tools, precision is often associated with smaller workzone machines or those with limited travel or reach. It's as if the prevailing belief is that accuracy diminishes as the size and scope of t...

Read moreHow the BSF-150C Floor-Type Boring and Milling Machine Enhances Accuracy in Large Workpiece Machining

ELK GROVE VILLAGE, IL, May 23, 2023 - As the demand for high cutting performance, less downtime, and improved productivity increases for machining medium and large-sized parts, floor-type horizontal boring and milling machines have become more popular. Shi...

Read moreThe Smart Choice for Chip and Coolant Management: Introducing the TUE Series Top Cover

ELK GROVE VILLAGE, IL, May 9, 2023 - As technology continues to evolve, so do the challenges that arise in the manufacturing industry. One of the challenges that persist is managing coolant and chips in the machining process. Having a well-designed chip an...

Read moreThe Multi-tasking Capabilities of the Mill-Turn Machine Tool

ELK GROVE VILLAGE, IL, April 25, 2023 - Transitioning between machine tools is one of the biggest challenges for machinists. This can result in human errors during setup and the accumulation of processing errors. As a solution, multi-tasking tools are beco...

Read moreExploring the Versatility of Dynamic Part Probing for CNC Machine Tools

ELK GROVE VILLAGE, IL, April 19, 2023 - Dynamic part probing is a powerful tool that has transformed the way CNC machine tools operate in manufacturing. By using sensors and software to collect and analyze data in real-time during the machining process, dy...

Read morePrecise Machining on the MP-(U) for Challenging Materials with the Grinding Attachment

ELK GROVE VILLAGE, IL, April 05, 2023 - Multi-tasking machine tools have revolutionized the manufacturing industry, providing a versatile and efficient solution to various machining requirements. These machines are designed to perform several functions all...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools