Understanding the Importance of Foundations for Precision Machine Tools

ELK GROVE VILLAGE, IL, May 23, 2022 -

Would a contractor ever build a house without a solid foundation? The answer is a resounding no. Without a solid foundation not only will the home be unstable, but will likely bring in unwanted outside elements. The same goes for a machine tool, with the foundation acting as a building block on which it is placed.

The performance of a machine tool largely depends on the foundation on which it sits. Just like a building needs a solid foundation for stability, the stability of the process of your machine tool is dependent on the behavior of the foundation. There can be no flaws or compromises, particularly with precision machine tools when high accuracy and specific surface finish are required.

A Key Element to Maximum Performance

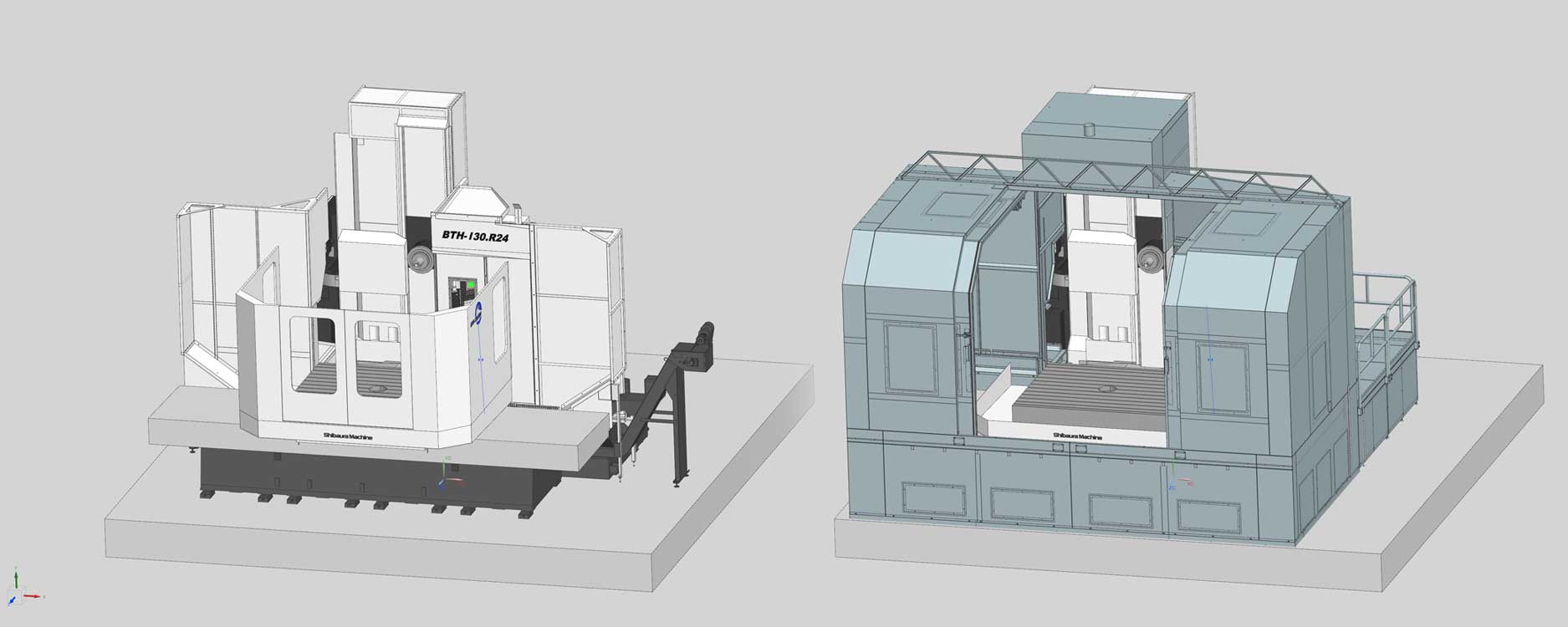

When a shop purchases a machine tool they undoubtedly have certain expectations. In order for the machine tool to meet full capabilities and deliver profits year after year, the foundation on which the machine tool sits has been documented as a key element to ensure proper accuracy and performance.

Building and designing a good foundation is critical to maintaining a consistently high-quality workpiece over a long period of time. The foundation ensures machine alignment and repeatable geometry by providing stiffness to the machine tool.

Factors to a Successful Machine Tool Foundation

The complexity of foundation design and build varies depending on machine size, type, and construction, but listed below are several key factors to consider when constructing your foundation.

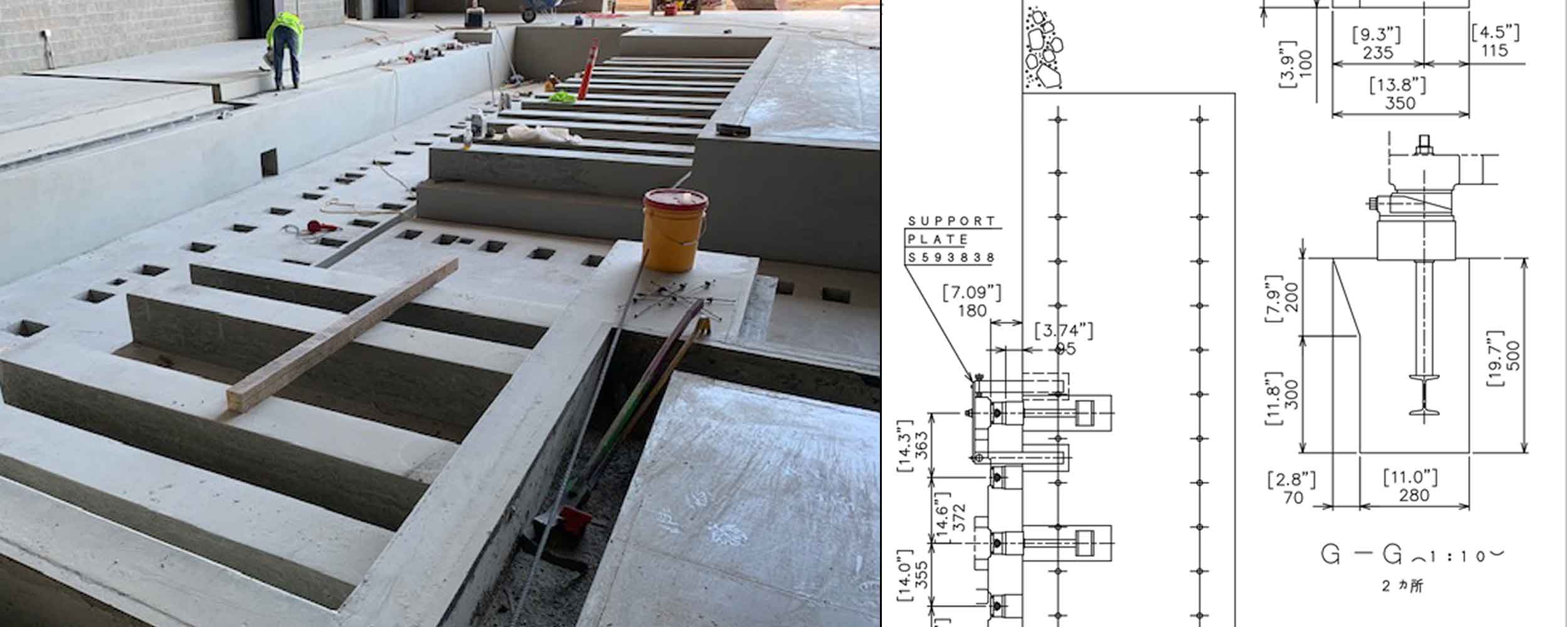

- Obtain a foundation reference drawing and guidelines from the machine tool builder

- Single pour of concrete construction

- Machine tool is appropriately anchored to the foundation (grouting)

- Proper provisions for an electrical grounding circuit

- Checklists to monitor the performance of the construction contractors

The bottom line, the foundation is integral to the success of your machine tool and the cost to do so is a fraction of the investment you make with the machine. Work with our Machine Tool Team to help understand the appropriate foundation requirements and ensure maximum performance from your investment.

Related Articles View All Machine Tools Articles

Consider High-Pressure Coolant to Improve Chip Management

ELK GROVE VILLAGE, IL, May 16, 2022 - Managing machine tool cutting variables such as feeds, speeds and depth of cut play a key role in eliminating unpredictable cutting tool wear and poor chip management. Incorporating a high pressure coolant system will ...

Read moreUnderstanding the Design Principals of Machine Enclosures

ELK GROVE VILLAGE, IL, May 9, 2022 - Machine enclosures have quickly become mainstream as a way to ensure your machine is operating as efficiently as possible and improve your work zone environment. The enclosure not only contains chip and coolant but dete...

Read moreThe Future of Machining in the EV Market

ELK GROVE VILLAGE, IL, May 2, 2022 - The Electric Vehicle (EV) market continues to shake up the entire supply chain of the automotive industry with its unprecedented growth rates. Between 2020 and 2026, the size of the global EV market is expected to incre...

Read moreExpand Capabilities with Horizontal Boring Mill Table on Table Configuration

ELK GROVE VILLAGE, IL, April 18, 2022 - A typical Horizontal Boring Machine (HBM) excels at machining two bores in perfect parallelism. While the name indicates boring, these machines can be used for many different machining applications. With the addition...

Read moreImprove Your Approach to Machine Tool Maintenance

ELK GROVE VILLAGE, IL, April 13, 2022 - With machine availability being a key metric to the production capability of your factory it leaves us asking, is there a better way to maintain and reduce downtime of your machine tool? The answer is YesDepending on...

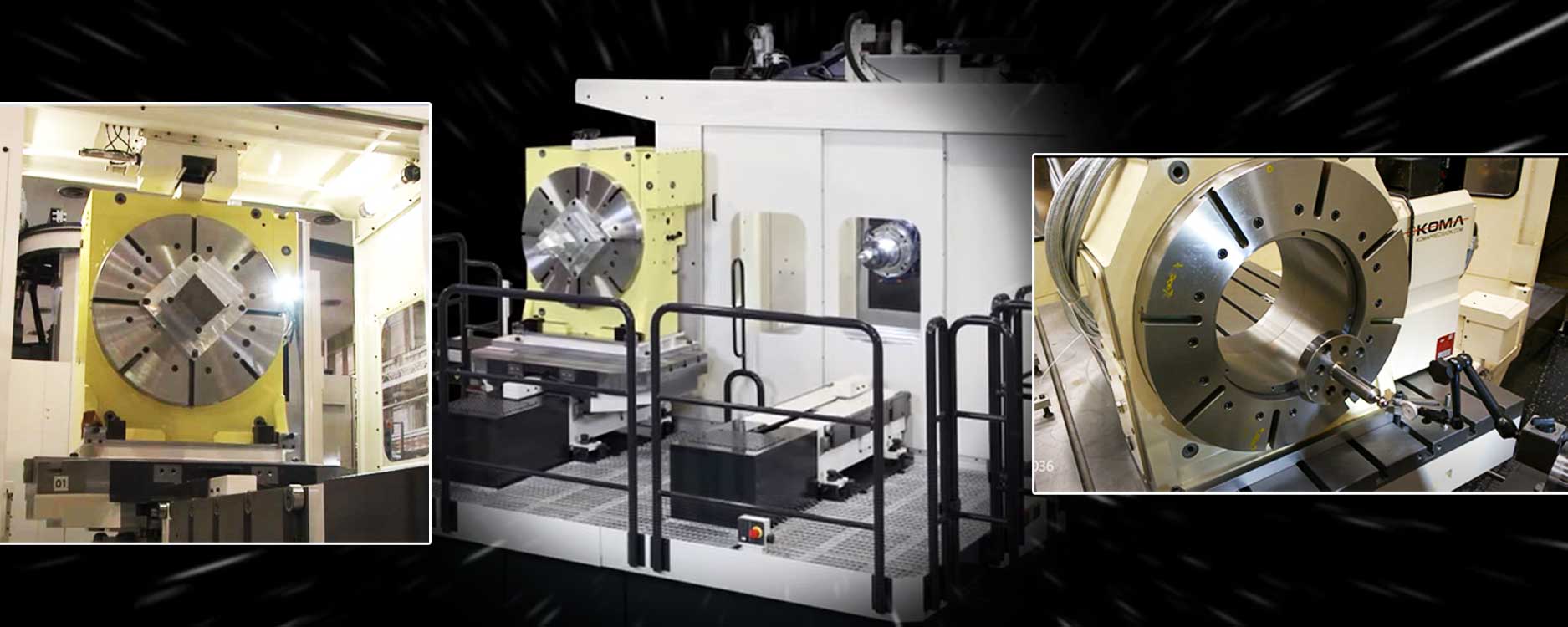

Read moreVersatility Meets High Performance With the TSS VTL Table Slide Mechanism

ELK GROVE VILLAGE, IL, April 4, 2022 - The power to multi-task in shops is increasingly becoming a valuable tool and competitive differentiator. With the right multi-tasking machines, manufacturers are able to reduce cycle times by offering a single setup,...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools