Understanding the Design Principals of Machine Enclosures

ELK GROVE VILLAGE, IL, May 9, 2022 -

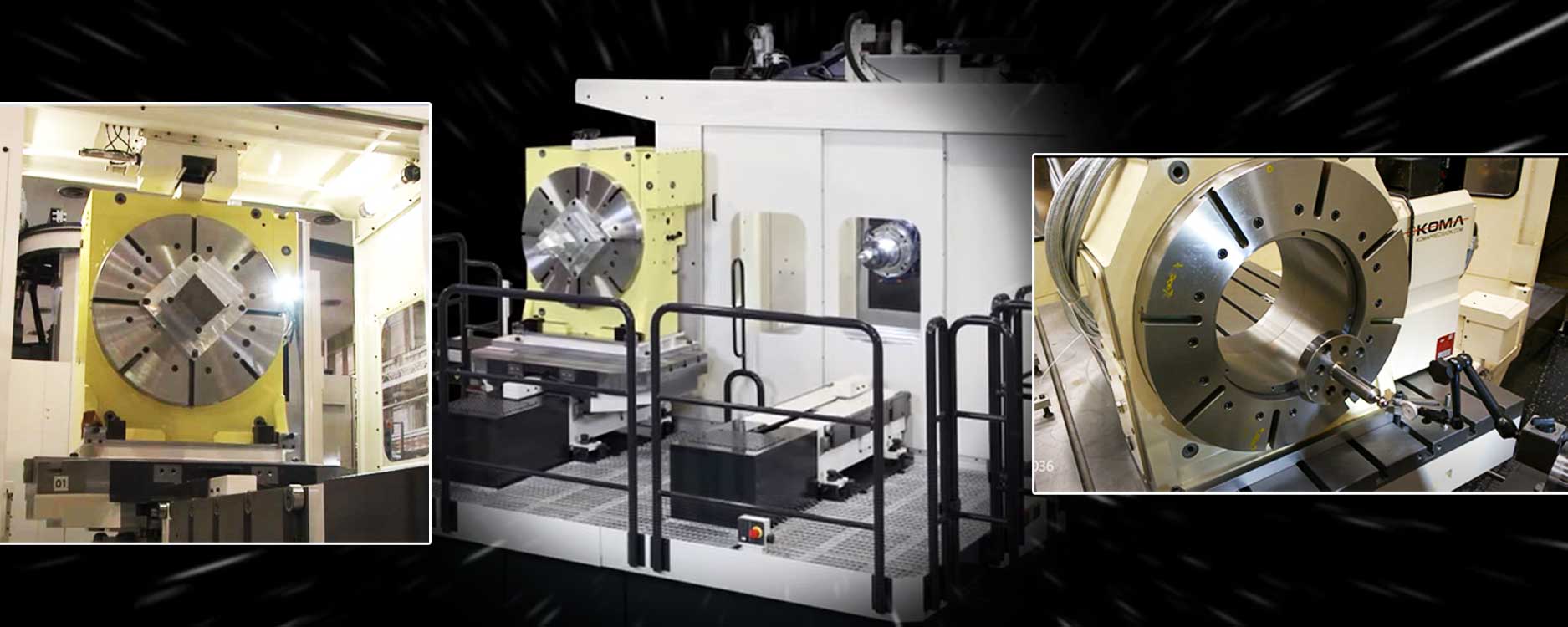

Machine enclosures have quickly become mainstream as a way to ensure your machine is operating as efficiently as possible and improve your work zone environment. The enclosure not only contains chip and coolant but determines the overall outer esthetic appearance of the machine tool.

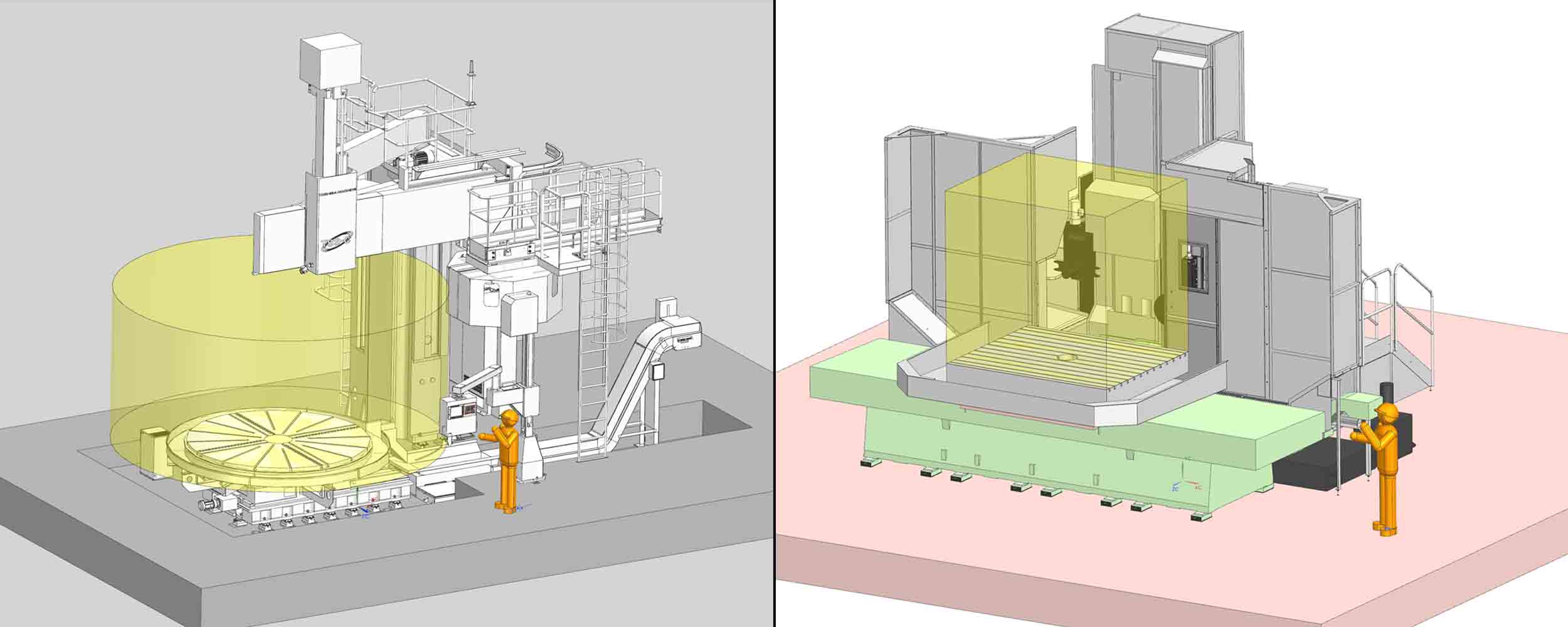

The type of machine enclosure utilized can vary. It largely depends on the axis of travel and swing clearance offered by the machine tool. The factors that go into play for the design of an enclosure are numerous, but a few design principles remain constant. Some that are commonly considered are rigidity, coolant control, esthetic considerations, and overall cost.

Consider These Design Principles

In addition to the design principles mentioned above, Shibaura Machine takes the characteristics below into consideration during the design phase to ensure a machine enclosure is designed to meet its current and future needs.

Flexibility/Modularity

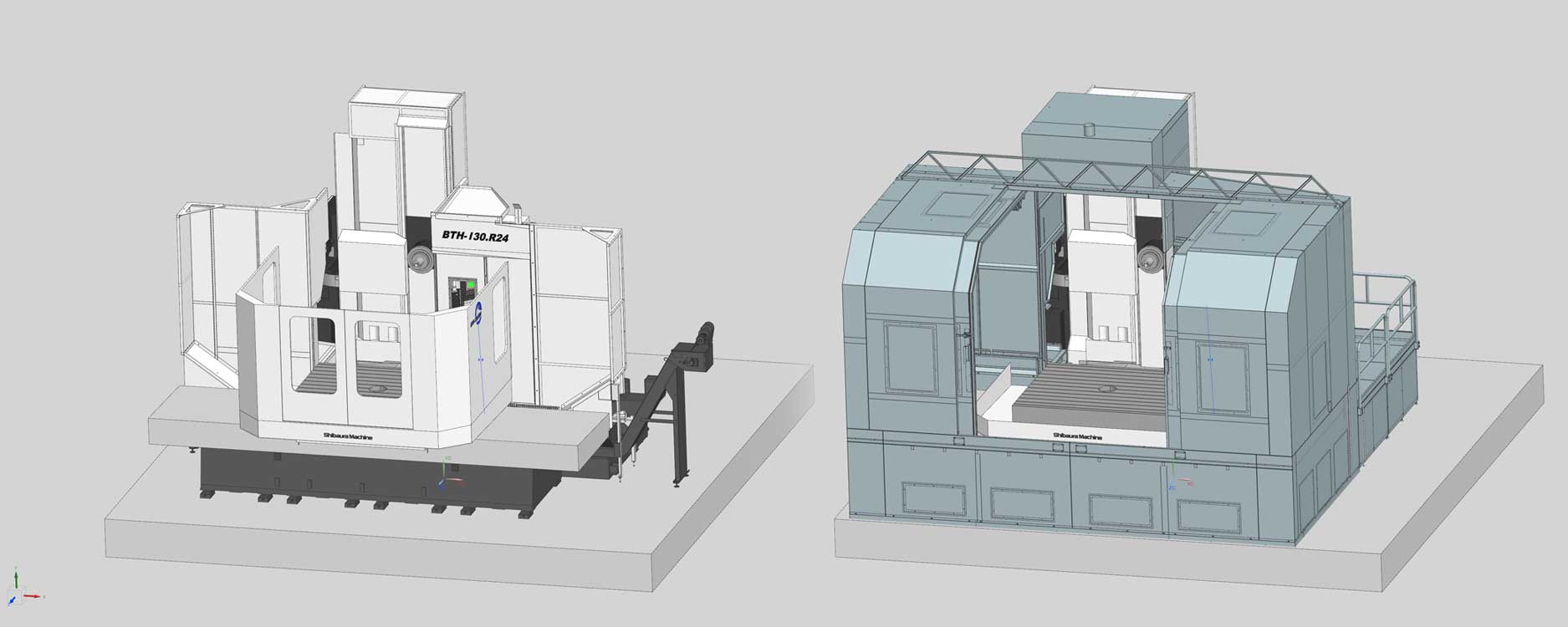

With machines today being more modular, a similar enclosure design makes sense. Enclosures designed with the ability to scale can save time and money. This allows the factory to standardize its machine tool enclosure design.

Esthetic Appearance

The outside of the enclosure needs to look seamless and clean, while the interior should present a clean look as well.

Functionality

Consider factors such as windows for work zone visibility and internal panels to protect components. Shibaura Machine enclosures may also contain an access door to provide access to the work zone without having to open the full enclosure.

Partner With Shibaura Machine

Enclosures play a vital role in the protection and performance of your machinery and the management of your shop environment. Careful consideration during the design phase will increase your machine efficiency and help you in producing a cost-effective, functional, and esthetically pleasing enclosure.

Related Articles View All Machine Tools Articles

The Future of Machining in the EV Market

ELK GROVE VILLAGE, IL, May 2, 2022 - The Electric Vehicle (EV) market continues to shake up the entire supply chain of the automotive industry with its unprecedented growth rates. Between 2020 and 2026, the size of the global EV market is expected to incre...

Read moreExpand Capabilities with Horizontal Boring Mill Table on Table Configuration

ELK GROVE VILLAGE, IL, April 18, 2022 - A typical Horizontal Boring Machine (HBM) excels at machining two bores in perfect parallelism. While the name indicates boring, these machines can be used for many different machining applications. With the addition...

Read moreImprove Your Approach to Machine Tool Maintenance

ELK GROVE VILLAGE, IL, April 13, 2022 - With machine availability being a key metric to the production capability of your factory it leaves us asking, is there a better way to maintain and reduce downtime of your machine tool? The answer is YesDepending on...

Read moreVersatility Meets High Performance With the TSS VTL Table Slide Mechanism

ELK GROVE VILLAGE, IL, April 4, 2022 - The power to multi-task in shops is increasingly becoming a valuable tool and competitive differentiator. With the right multi-tasking machines, manufacturers are able to reduce cycle times by offering a single setup,...

Read moreIncrease Double-Column Machine Capabilities With These Attachments

ELK GROVE VILLAGE, IL, March 28, 2022 - When it comes to choosing a double-column machine there are several considerations you’ll want to take. Is it high-performance, does it provide the stability and power required to deliver uninterrupted precision? Can...

Read moreMachining Large and Complex Workpieces? Consider These Machine Specs.

ELK GROVE VILLAGE, IL, March 21, 2022 - When it comes to machining large workpieces you need an equally large machine tool. While that might seem obvious, there are also a couple of other less than obvious factors to consider when choosing your next large ...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools