machiNetCloud Industrial IoT Now Included on New Injection Molding Machines

ELK GROVE VILLAGE, IL, June 22, 2022 - As the landscape in manufacturing continues to rapidly change due to digitalization, the Industrial Internet of Things (IIoT) brings a great opportunity to gain a competitive advantage in every form of production, including injection molding.

Smart manufacturing makes it easier to collect and analyze data, predict trends, and prevent problems before they arise. IIoT can provide a clear advantage in improving production efficiency, quality, and time to market.

Shibaura Machine is pleased to now provide customers purchasing new injection molding machines with a one-year Silver subscription to our IIoT solution, machiNetCloud. machiNetCloud integrates to all machines, bringing real-time monitoring, reduced downtime, secure, remote technical support, and more from anywhere in the world.

Applications Built for Industrial IoT

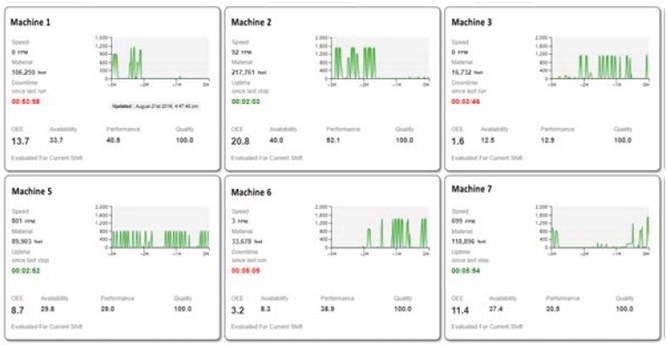

Shibaura Machine’s machiNetCloud solution provides injection molding factories the ability to save both time and money. With this new easily accessible technology and a lower barrier to entry, manufacturers can improve their overall equipment efficiency. Using machiNetCloud also provides timely, detailed data about production availability, performance, and quality.

The applications available on machiNetCloud can be accessed at the factory or the mobile app- anytime, anywhere. These applications include:

- Machine Insights*: Ongoing monitoring of equipment to access and analyze machine data and calculate your overall equipment efficiency (OEE) score.

- Production Monitoring*: Oversee your entire manufacturing process and set real-time notifications to maintain product quality, avoid delays, and loss of revenue.

- Remote Access*: Secure connectivity to technicians anywhere, anytime.

- Downtime Tracking: Easy to understand reporting of the largest downtime sources and track the reasons for stop time.

- Lifecycle Tracking: Improved predictive maintenance and machine utilization.

- Recipe/Process Management: Track, monitor, and categorize the machine parameters quickly.

- Quality Management: Track quality trends while taking a proactive approach to ISO 9000 compliance.

*Machine Insights, Production monitoring, and Remote Access are included with the Silver Tier Subscription.

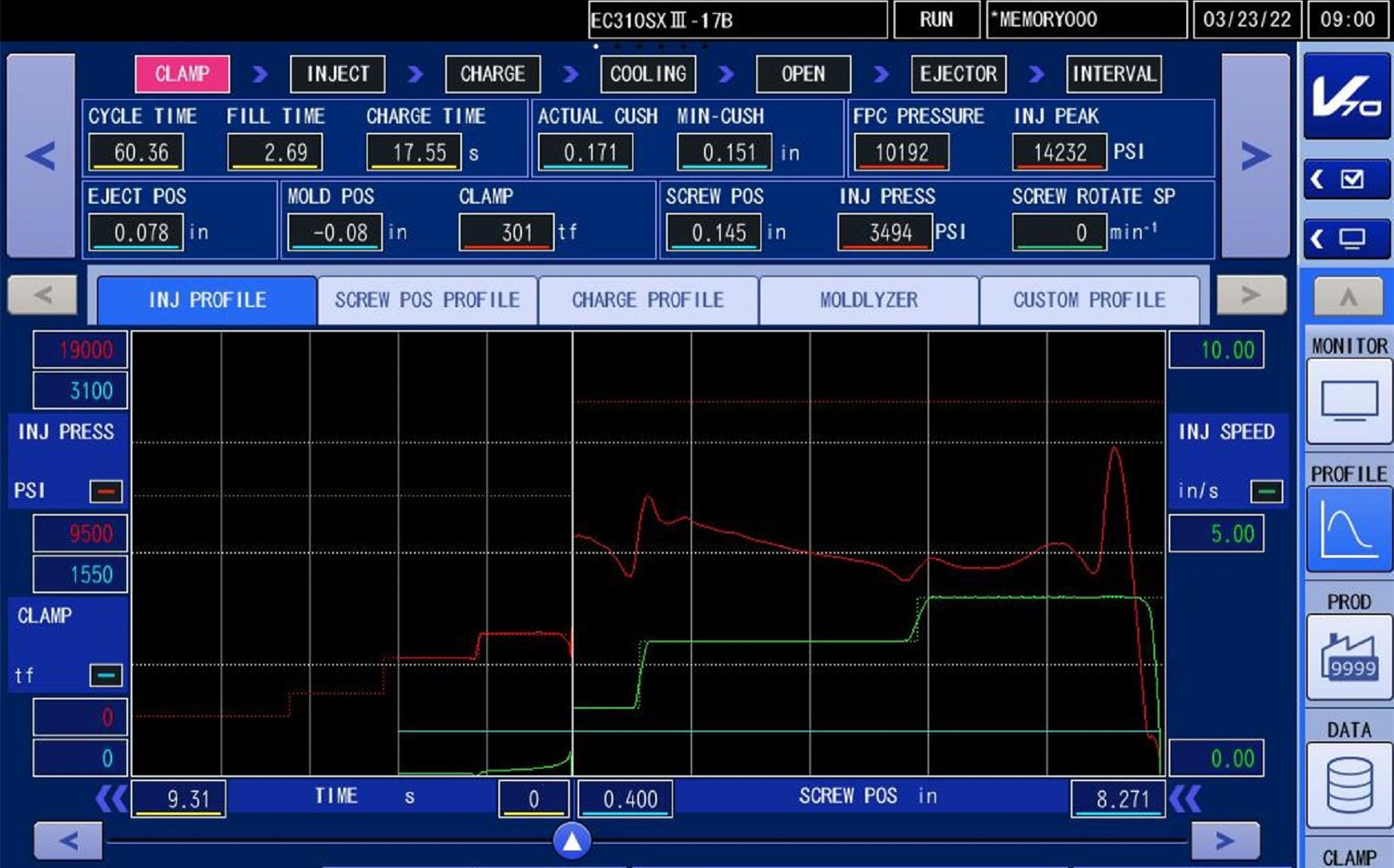

All the data that is gathered and analyzed provides a competitive advantage. For those in injection molding, the data and reporting can help ensure higher levels of repeatability in the molding process, increase quality consistency, and lower defects.

Improve Overall Equipment Efficiency

Complying with international security standards, with high-level end-to-end encryption the machiNetCloud platform provides your company with a secure solution to explore the incredible benefits of smart manufacturing. The Silver Tier subscription is now included free for one year on any new injection molding machine.

Start exploring greater manufacturing productivity and quality today by contacting the Injection Molding team today.

Tel: (888) 593-1616

Related Articles View All Articles

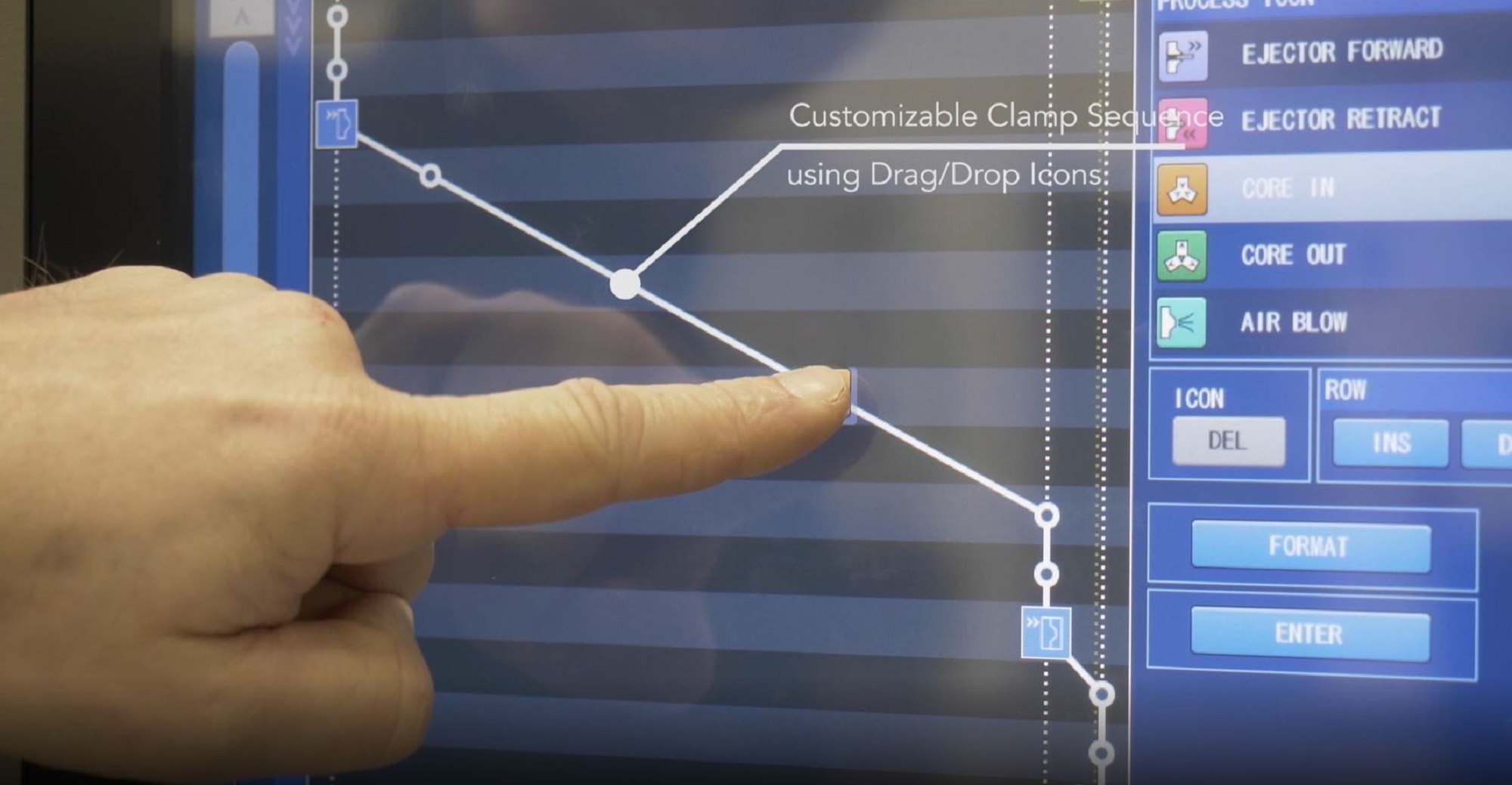

Customize Your Clamping Sequence at a Touch

ELK GROVE VILLAGE, IL, June 17, 2022 - One of the steps to get the best results from injection molding requires the operator to properly set up the clamping sequence. Without an intuitive and visual experience, setting this up can be a time-consuming and d...

Read moreRegistration is Open For Our Injection Molding Smart Factory Open House

ELK GROVE VILLAGE, IL, April 28, 2022 - Merging existing technologies with new innovations can be challenging for manufacturers. To help injection molding factories envision the future of manufacturing, Shibaura Machine has partnered with key industry part...

Read more4 Ways to Ensure Precision Filling Transfer Using Final Pack Control

ELK GROVE VILLAGE, IL, March 24, 2022 - The more you can control your production conditions in injection molding the more repeatable your results. When it comes to transfer from the filling stage to packing it might be considered the most crucial element o...

Read moreHow to Establish Optimum Fill Time with Precise Control

ELK GROVE VILLAGE, IL, March 16, 2022 - When it comes to injection molding, the filling stage is critical. Filling too fast in order to save time or reduce the process cycle can end up causing gas to become trapped in the vents. Filling too slowly or fast ...

Read moreImprove Product Quality with Better Screw Speed and Back Pressure Control

ELK GROVE VILLAGE, IL, March 9, 2022 - When it comes to improving part quality and cycle times, don’t underestimate the power of proper control of back pressure and screw rotation. Together, these two functions have a major influence on an injection moldin...

Read moreImprove Injection Molding Part Weight Stability with Plastrol

ELK GROVE VILLAGE, IL, March 2, 2022 - Many manufacturers are facing increased supply chain hiccups, especially when it comes to resin. Pair that with increases in demand for everything from medical devices to semiconductor components and this leaves littl...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools