Improve Product Quality with Better Screw Speed and Back Pressure Control

ELK GROVE VILLAGE, IL, March 9, 2022 - When it comes to improving part quality and cycle times, don’t underestimate the power of proper control of back pressure and screw rotation. Together, these two functions have a major influence on an injection molding company’s overall throughput goals.

Shibaura Machine’s V70 controller provides the injection molding processor with precise control of both screw rotation speed and back pressure at their fingertips. The Screw Speed Rotation Program and Back Pressure Program found on the V70 controller means processors can profile their screw rotation speeds and back pressure which in turn produces a more mechanically and thermally balanced part, time after time.

Easy Control of Screw Rotation Speed and Back Pressure

The close relationship between screw rotation speed, back pressure and product quality make them key parameters in the injection molding process.

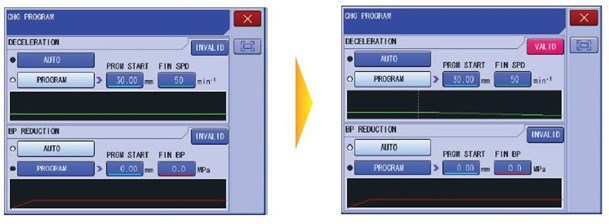

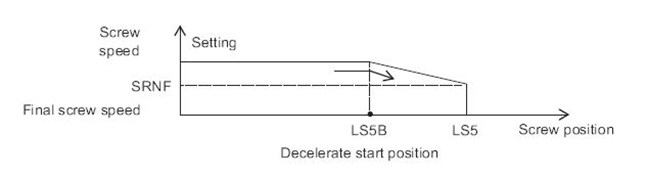

Screw Rotation Speed Program

Creating a stable melt and realizing a smooth transition from one set point to another can be produced by controlling the screw rotation speed. The Screw Rotation Speed Program allows the operator to control the speed during charging so that it accelerates or decelerates before the charge complete position. Operators can also set the screw rotation speed, decelerate start position, and final screw speed.

Being able to control this process via the V70 controller allows for improved melt, mixing, and recovery.

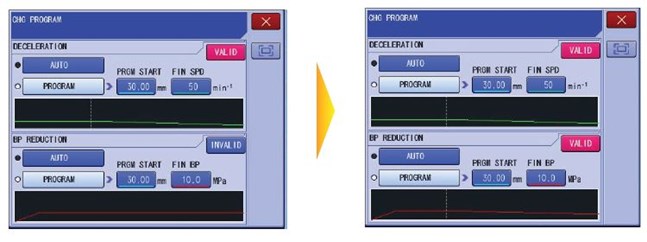

Screw Back Pressure Program

Back pressure is a controllable process parameter that is often mistakenly overlooked. Material melting and color mixing can be improved with controlled back pressure. Being able to use the V70 controller to input the settings offers an easy and efficient way for the operator to minimize pressurizing the runner system during recovery, which will also help eliminate drooling into the mold during mold open.

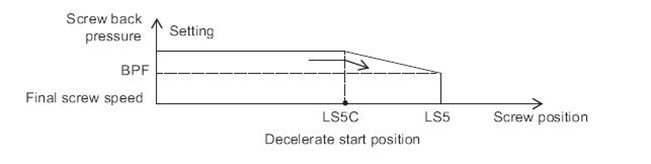

The program allows the operator to control the screw back pressure during charging so that it increases or decreases pressure before the charge complete position.

Improve Your Part Quality

Contact the Injection Molding Team to learn more about the easy-to-use Screw Rotation Speed and Back Pressure Programs found on the V70 controller to start improving your shop's part quality.

Tel: (888) 593-1616

Contact us today to learn how our unique screw speed and back pressure control can help improve your molding process!

Related Articles View All Articles

Improve Injection Molding Part Weight Stability with Plastrol

ELK GROVE VILLAGE, IL, March 2, 2022 - Many manufacturers are facing increased supply chain hiccups, especially when it comes to resin. Pair that with increases in demand for everything from medical devices to semiconductor components and this leaves littl...

Read moreMinimize Your Footprint and Bring Precise Control with Hot Runner Integration

ELK GROVE VILLAGE, IL, February 23, 2022 - Hot runner technology has revolutionized the injection molding process since it was introduced over 50 years ago. With it, manufacturers have seen improved molded part quality, operational efficiency, and reduced ...

Read moreMonitor Injection Molding Energy Consumption Easily on the SXIII Series

ELK GROVE VILLAGE, IL, February 16, 2022 - Plastic injection molding machine drive technology has evolved dramatically over the decades. One of the most significant changes is the all-electric servo drive design in comparison to traditional hydraulic machi...

Read moreSimplify Injection Molding Machine Maintenance with the V70 Controller

ELK GROVE VILLAGE, IL, February 9, 2022 - Performing preventative maintenance is necessary to ensure your injection molding machine longevity and process stability. However, when it comes to tight deadlines and the choice is between machine preventative ma...

Read moreReduce Cooling Water Load with All-Electric Machines

ELK GROVE VILLAGE, IL, February 2, 2022 - Water cooling systems have long been used in hydraulic injection molding machines in order to keep the machine running smoothly. But imagine being able to reduce cooling water load requirements- it will allow you t...

Read moreImproving OEE with All-Electric Machines

ELK GROVE VILLAGE, IL, January 31, 2022 - Stops in production, whether planned or not, create Availability Loss on the factory floor. While it isn’t always possible to eliminate changeover time, being able to significantly reduce it along with unplanned do...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools