How to Establish Optimum Fill Time with Precise Control

ELK GROVE VILLAGE, IL, March 16, 2022 - When it comes to injection molding, the filling stage is critical. Filling too fast in order to save time or reduce the process cycle can end up causing gas to become trapped in the vents. Filling too slowly or fast can lead to gaps, high levels of stress, and surface blemishes. In order to get the filling time shortened to improve molding efficiency, but not overly fast harming the mold integrity, it takes operator control and the ability to customize filling stage response times.

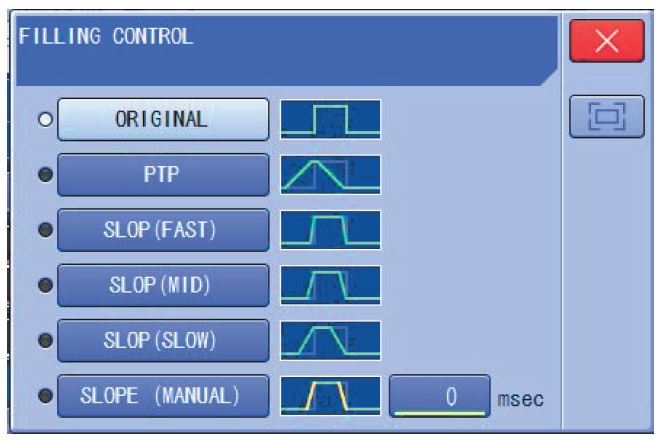

Shibaura Machine’s Filling Control function on the V70 controller allows the operator to easily select different fill patterns. Specifically, Fill Control allows the user to identify and choose how quickly they want their injection profile setpoints to be achieved during the filling stage. This function also allows users the ability to customize and control the filling stage response times.

No Guessing, Precise Control

Using Fill Control can help improve part quality, both in strength and aesthetically. The method to control the filling speed setting can be easily selected from several different patterns right at the operator's fingertips.

Standard

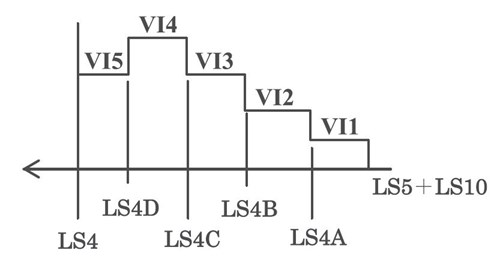

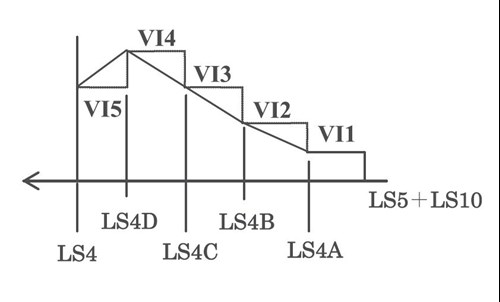

Shows the step-like response to filling speed setting changes. This example is showing how it reduces the fill rate just as the plastic reaches the end of fill point.

Slope Control (4 Options)

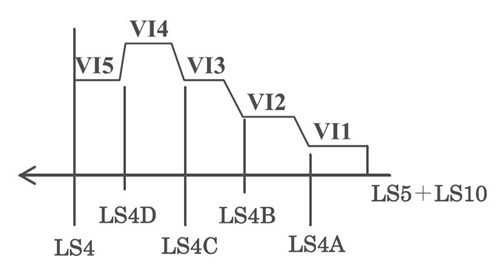

This setting allows for a slope-based response to filling speed. Users can select Fast, Middle, Slow, and Manual within the slope settings. The slope manual setting allows the user to choose the response time between injection speeds.

Point-to-Point Control

This option shows a polygonal line response to filling speed setting changes. Operators can utilize PTP Control for a smoother injection profile.

Learn More

A general rule is an operator should fill the mold as quickly as the part allows to save cycle time. Utilizing the Filling Control function allows for the operator to optimize their fill time while improving part quality.

Contact the Injection Molding Team to learn more about the Filling Control function and all the capabilities of the V70 controller to start improving your production.

Tel: (888) 593-1616

Contact us today to learn how our unique injection fill control can help improve your molding process!

Related Articles View All Articles

Improve Product Quality with Better Screw Speed and Back Pressure Control

ELK GROVE VILLAGE, IL, March 9, 2022 - When it comes to improving part quality and cycle times, don’t underestimate the power of proper control of back pressure and screw rotation. Together, these two functions have a major influence on an injection moldin...

Read moreImprove Injection Molding Part Weight Stability with Plastrol

ELK GROVE VILLAGE, IL, March 2, 2022 - Many manufacturers are facing increased supply chain hiccups, especially when it comes to resin. Pair that with increases in demand for everything from medical devices to semiconductor components and this leaves littl...

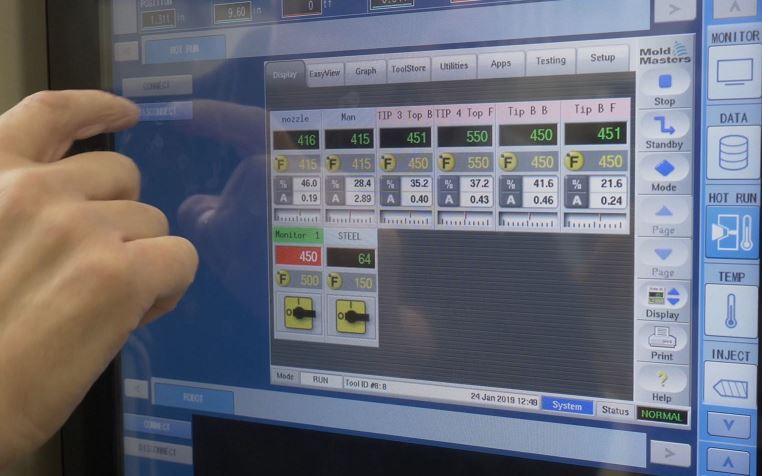

Read moreMinimize Your Footprint and Bring Precise Control with Hot Runner Integration

ELK GROVE VILLAGE, IL, February 23, 2022 - Hot runner technology has revolutionized the injection molding process since it was introduced over 50 years ago. With it, manufacturers have seen improved molded part quality, operational efficiency, and reduced ...

Read moreMonitor Injection Molding Energy Consumption Easily on the SXIII Series

ELK GROVE VILLAGE, IL, February 16, 2022 - Plastic injection molding machine drive technology has evolved dramatically over the decades. One of the most significant changes is the all-electric servo drive design in comparison to traditional hydraulic machi...

Read moreSimplify Injection Molding Machine Maintenance with the V70 Controller

ELK GROVE VILLAGE, IL, February 9, 2022 - Performing preventative maintenance is necessary to ensure your injection molding machine longevity and process stability. However, when it comes to tight deadlines and the choice is between machine preventative ma...

Read moreReduce Cooling Water Load with All-Electric Machines

ELK GROVE VILLAGE, IL, February 2, 2022 - Water cooling systems have long been used in hydraulic injection molding machines in order to keep the machine running smoothly. But imagine being able to reduce cooling water load requirements- it will allow you t...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools