Customize Your Clamping Sequence at a Touch

ELK GROVE VILLAGE, IL, June 17, 2022 - One of the steps to get the best results from injection molding requires the operator to properly set up the clamping sequence. Without an intuitive and visual experience, setting this up can be a time-consuming and difficult task.

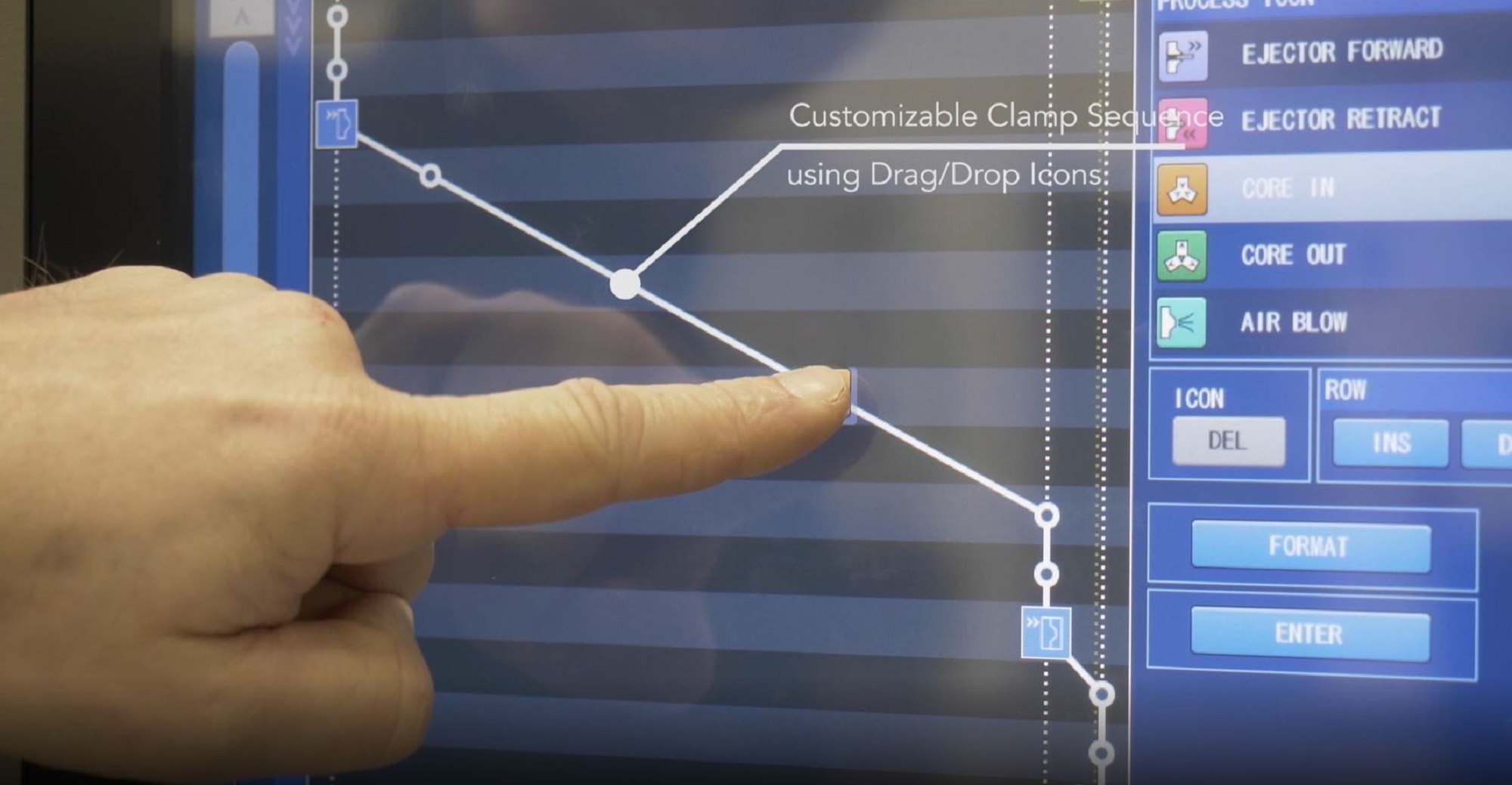

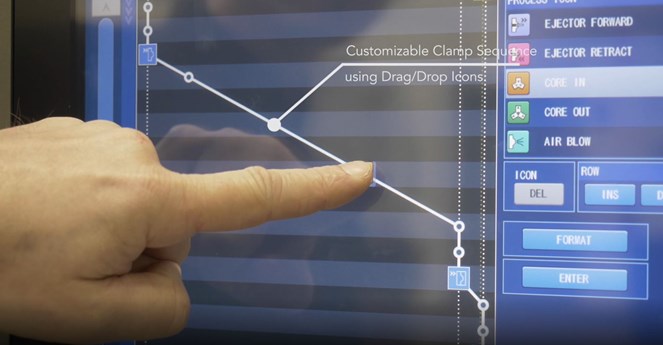

In order to address this issue, Shibaura Machine offers the Customizable Clamp Sequence feature, now available on their V70 controller. The Customizable Clamp Sequence feature provides a screen for the operator to set up their clamping sequence with easy-to-understand visual icons used in a simple drag-and-drop process. This easy interaction reduces operator error, improves productivity, and results in less mold damage.

Removing the Complexity of Clamp Sequencing

While a quick process that only lasts several seconds, clamping can be a complex thing. The basic function of the clamping unit is to open and close the mold and eject the product, however adding in additional functions such as air blow, cores, and ejectors can make it become a time-consuming task that is prone to error.

Using the Customizable Clamp Sequence feature, operators drag and drop to set up the desired sequence and can then save this data allowing them to repeat the sequence quickly in the future. Shown below, this operator is customizing a clamp sequence that can result in less machine downtime and mold damage.

The process steps that operators are able to customize into a sequence include:

- Clamp open and close

- Air blow

- Ejector actuation

- Core in and out

This feature also allows the user to make settings for special operations that otherwise are not shown on the V70 controller's main Clamp, Ejector, Core, and Air Blow screens.

Learn More

The Customizable Clamp Sequence feature is easy to use and requires no additional software or hardware to accomplish non-standard sequences. As part of the V70 controller, injection molding customers can start using it immediately as part of their process and see the benefits of gained productivity and reduced downtime.

Contact our Injection Molding team to learn more about this feature and all the benefits of the V70 controller.

Tel: (888) 593-1616

Related Articles View All Articles

Registration is Open For Our Injection Molding Smart Factory Open House

ELK GROVE VILLAGE, IL, April 28, 2022 - Merging existing technologies with new innovations can be challenging for manufacturers. To help injection molding factories envision the future of manufacturing, Shibaura Machine has partnered with key industry part...

Read more4 Ways to Ensure Precision Filling Transfer Using Final Pack Control

ELK GROVE VILLAGE, IL, March 24, 2022 - The more you can control your production conditions in injection molding the more repeatable your results. When it comes to transfer from the filling stage to packing it might be considered the most crucial element o...

Read moreHow to Establish Optimum Fill Time with Precise Control

ELK GROVE VILLAGE, IL, March 16, 2022 - When it comes to injection molding, the filling stage is critical. Filling too fast in order to save time or reduce the process cycle can end up causing gas to become trapped in the vents. Filling too slowly or fast ...

Read moreImprove Product Quality with Better Screw Speed and Back Pressure Control

ELK GROVE VILLAGE, IL, March 9, 2022 - When it comes to improving part quality and cycle times, don’t underestimate the power of proper control of back pressure and screw rotation. Together, these two functions have a major influence on an injection moldin...

Read moreImprove Injection Molding Part Weight Stability with Plastrol

ELK GROVE VILLAGE, IL, March 2, 2022 - Many manufacturers are facing increased supply chain hiccups, especially when it comes to resin. Pair that with increases in demand for everything from medical devices to semiconductor components and this leaves littl...

Read moreMinimize Your Footprint and Bring Precise Control with Hot Runner Integration

ELK GROVE VILLAGE, IL, February 23, 2022 - Hot runner technology has revolutionized the injection molding process since it was introduced over 50 years ago. With it, manufacturers have seen improved molded part quality, operational efficiency, and reduced ...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools