Using Auto-Purge to Improve Injection Molding Efficiency

ELK GROVE VILLAGE, IL, June 23, 2021 - Molders today are always looking for a way to minimize their losses. So while purging is often necessary, it makes many molders cringe because this process often means costly waste and lost production time- defeating the purpose of improving their bottom line.

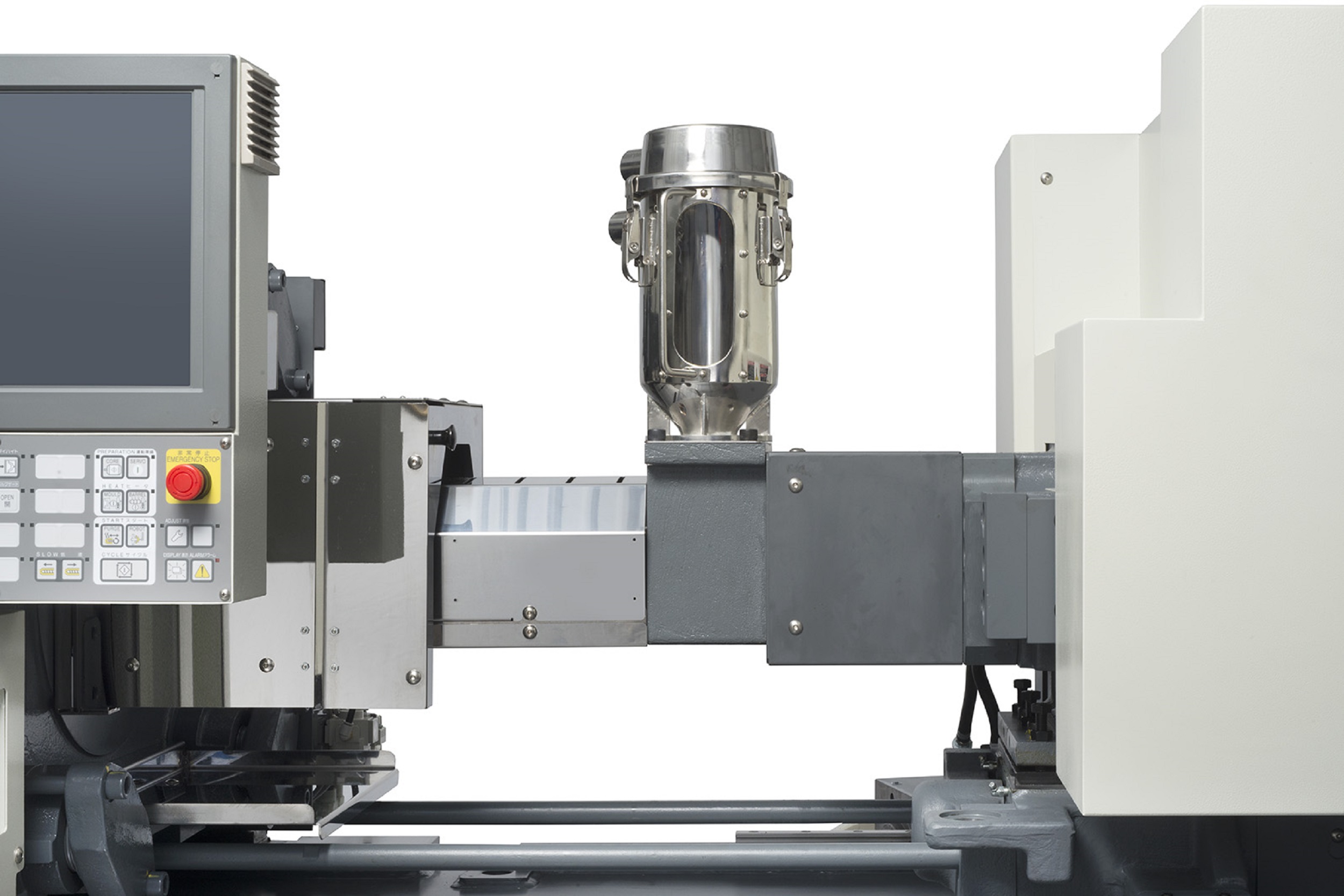

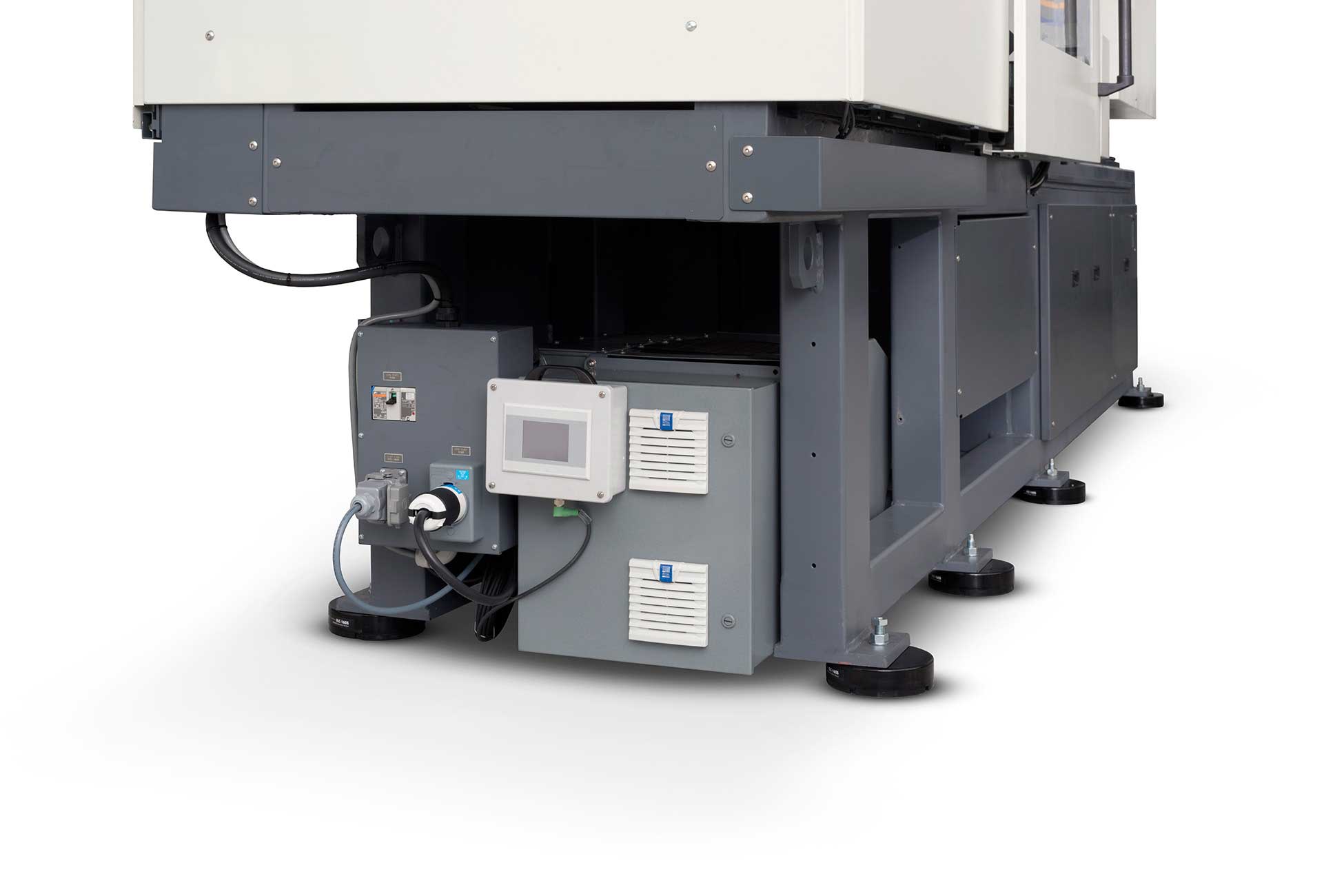

Automating the purging process can not only save time compared to conventional purging, but makes it possible to extend the time between required maintenance for the mold and improve overall efficiency. The auto purge feature on the V70 controller by Shibaura Machine plasticizes materials newly inserted into the hopper when exchanging materials in the injection molding machine, and automatically performs the operation of purging residual materials in the barrel without changing the production set-up data.

Dramatically Improve Efficiency

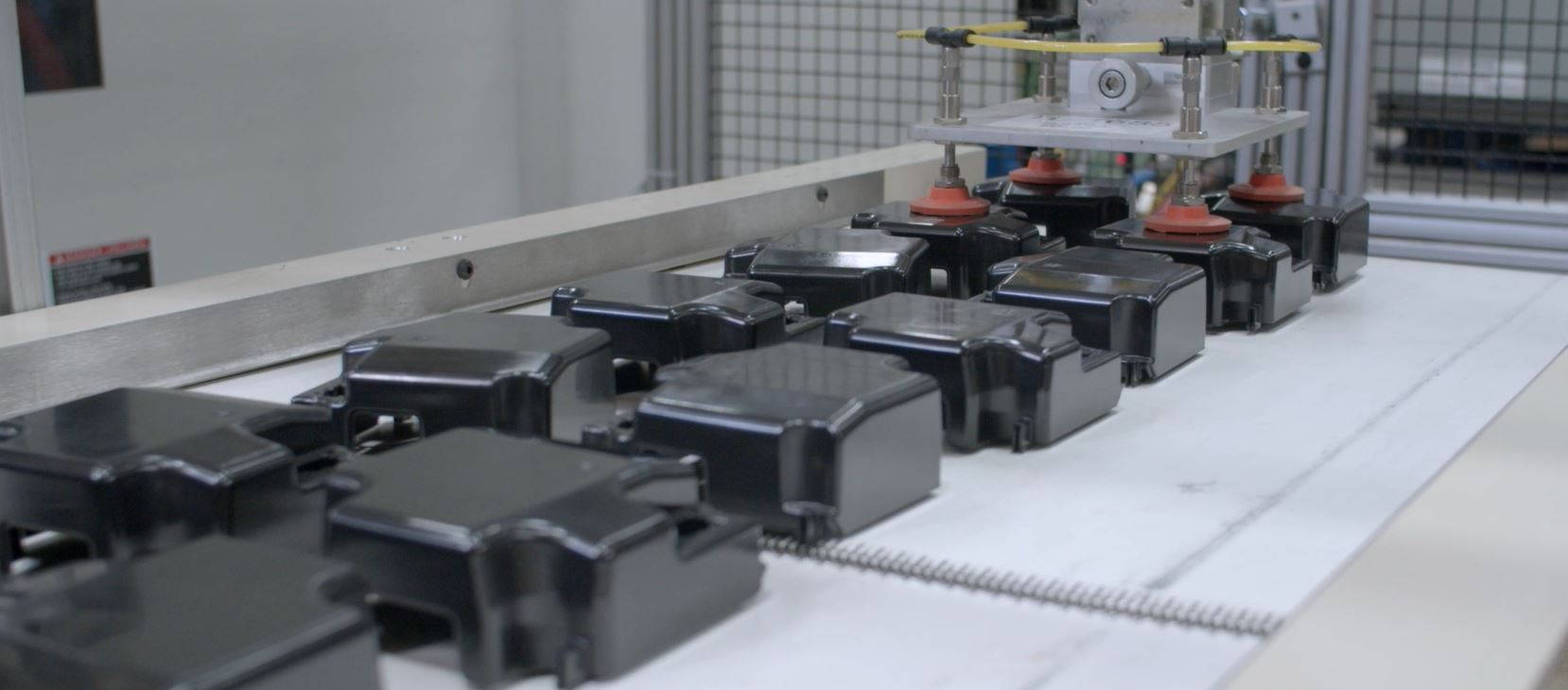

The V70 controller’s auto purge feature helps molders realize several benefits after a purge. Fewer scrap parts, less carbon build-up in the barrel, elimination of color hanging up in the tool, and reducing changeover time means not only less downtime, but a dramatic improvement in efficiency.

The auto purge feature offers three types of operations to choose from:

- Program purge mode where purging is performed according to pre-programmed settings;

- Screw speed purge mode that rotates the screw for the set time;

- Customized purge mode which is a combination of the four operations of screw advance, charging, rotating in place, and screw retract.

Additionally, the auto purge feature has several options that make it incredibly user-friendly. Molders have the ability to save up to 50 pre-saved programs that can be material specific, utilize a rotate in place feature, and choose from several modes including: cavity purge, shut off nozzle, and valve gate.

Start Optimizing Your Results Today

The injection molding experts at Shibaura Machine can help you learn more about how to leverage the auto purge feature on the V70 controller. With a properly executed purging process, coupled with the proper material, you can save thousands a year in lost production while increasing output and avoiding excess scrap. Contact our team today to learn more about the auto purge feature.

Contact us today to learn how our auto-purge feature can benefit your injection molding operation!

Related Articles View All Articles

Mold Recipe Management: Saving Time and Money in Injection Molding

ELK GROVE VILLAGE, IL, June 9, 2021 - Think of a chef on a Friday night at a popular restaurant. They are tasked with switching from one recipe to the next in a single night. Not only that, they need to make sure they use the correct measurements, with qui...

Read moreInjection Molding Production Management Made Easy

ELK GROVE VILLAGE, IL, June 4, 2021 - Does your injection molding machine offer easy to use onboard production management tools?Many injection molding machines lack user-friendly onboard production management functions. A quality production management tool...

Read moreReducing Cycle Times in Injection Molding: How All-Electric Has Changed the Game

ELK GROVE VILLAGE, IL, May 27, 2021 - Why is reducing cycle times such a popular topic in injection molding? Largely because from both a time and cost standpoint the effects of even a few seconds improvement on your cycle time can have a major impact on yo...

Read moreStandard Pneumatic Features Maximize Your Injection Molding Machine Investment

ELK GROVE VILLAGE, IL, May 19, 2021 - Have you ever gone shopping for a car? The answer for most of us is probably yes. You know you’re making an investment in a vehicle that you will likely have for years to come and want it to be just so. While many feat...

Read moreUsing Programmable Outputs to Improve Injection Molding Productivity

ELK GROVE VILLAGE, IL, May 12, 2021 - The demand for quality parts quickly continues to grow. Shop floors are working to meet customer requirements and being able to boost efficiency in production is key. Having the flexibility of connecting auxiliary equi...

Read moreShibaura Machine Makes Core Pull on All Electric Injection Molding Machines Simple

ELK GROVE VILLAGE, IL, May 5, 2021 - Many molds rely on core pull in order to produce their final product successfully. Whether it’s a hollowed out container, unscrewing features in the tool, or ejecting parts- the core pull feature provides shops a way to...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools