Injection Molding Production Management Made Easy

ELK GROVE VILLAGE, IL, June 4, 2021 - Does your injection molding machine offer easy to use onboard production management tools?

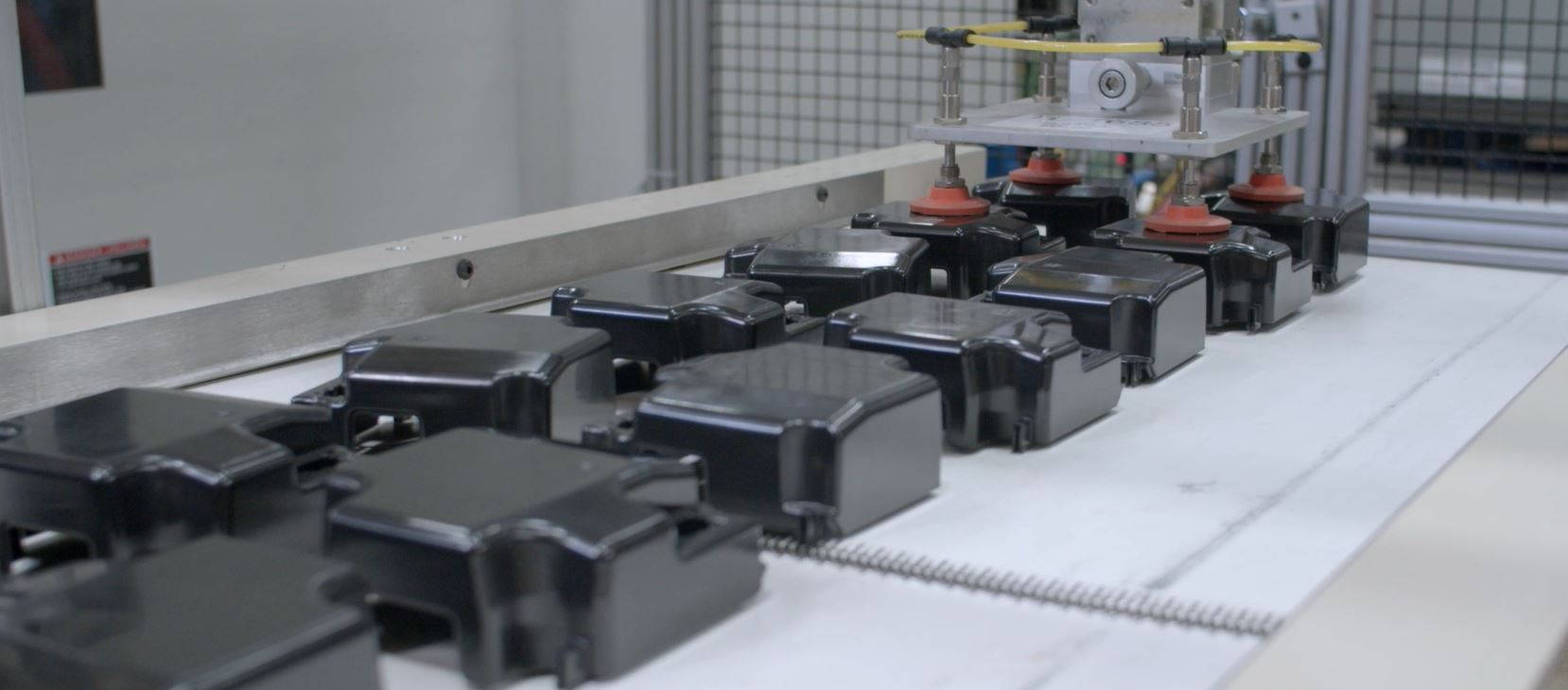

Many injection molding machines lack user-friendly onboard production management functions. A quality production management tool should be efficient- not requiring a ton of data, but just the crucially important data going instantly from machine to manager. It should ultimately boost injection molding productivity and efficiency.

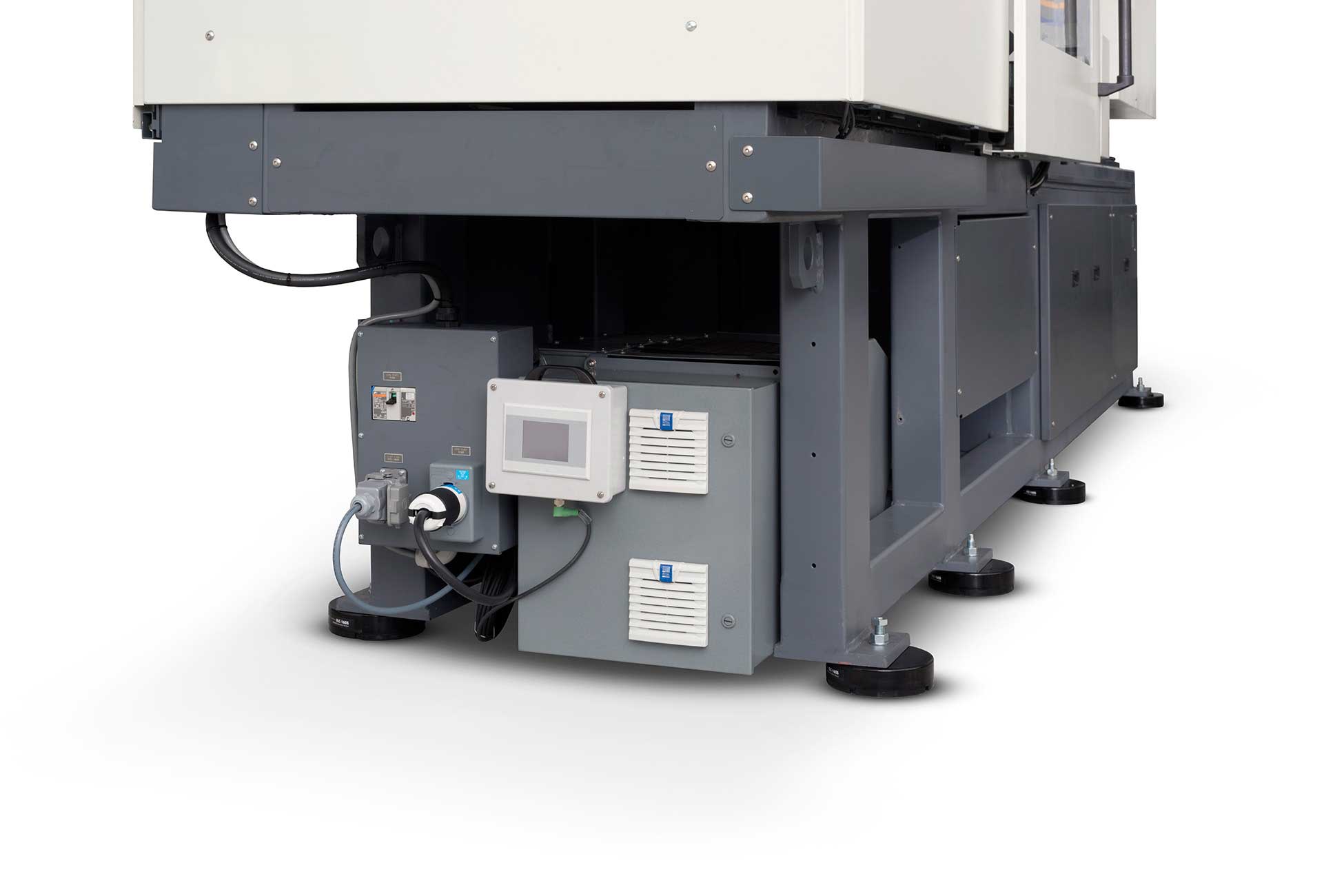

V70 Controller Includes Intuitive Production Management Tools

Shibaura Machine’s V70 controller offers production management functions that are adapted for highly quality-conscious companies that aim for systematic analysis and optimization of their processes. It is a good choice for manufacturers that focus on the transparency of their injection molding processes and comprehensive documentation of component quality. Our V70 production management tools enable users to:

- Enter in shot weight, part weight, number of cavities, required number of parts, and container capacity;

- Track resin usage, production completion ratio, good parts vs. suspect parts, run ratio, container usage;

- Drag and drop icons to configure automatic shut-down and start-up sequences. At the end of production, the machine can automatically shut down, purge material, and load the next mold set-up. After mold change, the operator can initiate an auto-start up sequence including a “soft start” feature. This “soft start” feature allows the machine to inject at a reduced speed, pressure, and shot size for a predetermined number of shots to avoid overpacking the tool.

Optimize Your Injection Molding Process

Shibaura Machine is committed to offering customers the most innovative ways to cut costs permanently.

The production management functionality on the V70 controller allows for optimal monitoring and analysis of the injection molding process. You can continually measure and track the production of your parts: shot-to-shot, each and every part. This easy to use production management system offers a clear view of your data within the machine controller allowing you to efficiently manage production.

Contact the injection molding machine team below to learn more.

Contact us today to learn how our on-board production management tools can benefit your injection molding operation!

Related Articles View All Articles

Reducing Cycle Times in Injection Molding: How All-Electric Has Changed the Game

ELK GROVE VILLAGE, IL, May 27, 2021 - Why is reducing cycle times such a popular topic in injection molding? Largely because from both a time and cost standpoint the effects of even a few seconds improvement on your cycle time can have a major impact on yo...

Read moreStandard Pneumatic Features Maximize Your Injection Molding Machine Investment

ELK GROVE VILLAGE, IL, May 19, 2021 - Have you ever gone shopping for a car? The answer for most of us is probably yes. You know you’re making an investment in a vehicle that you will likely have for years to come and want it to be just so. While many feat...

Read moreUsing Programmable Outputs to Improve Injection Molding Productivity

ELK GROVE VILLAGE, IL, May 12, 2021 - The demand for quality parts quickly continues to grow. Shop floors are working to meet customer requirements and being able to boost efficiency in production is key. Having the flexibility of connecting auxiliary equi...

Read moreShibaura Machine Makes Core Pull on All Electric Injection Molding Machines Simple

ELK GROVE VILLAGE, IL, May 5, 2021 - Many molds rely on core pull in order to produce their final product successfully. Whether it’s a hollowed out container, unscrewing features in the tool, or ejecting parts- the core pull feature provides shops a way to...

Read moreIntroducing Injection Molding “Tech Talk Thursday” Webinar Series

ELK GROVE VILLAGE, IL, April 22, 2021 – Profitability and competitive advantage. These are two things factories strive for when it comes to their injection molding operation. Owners and operators alike are continually working to be as efficient as possible...

Read moreServices to Keep Your Injection Molding Machines Running Efficiently

ELK GROVE VILLAGE, IL, April 14, 2021 – High quality parts come from high quality machinery. In order to keep your injection molding machines running efficiently with minimal downtime it's important to have the backing of a strong service team. Most moldin...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools