Resin Viscosity Changes Affecting Your Injection Molding Process? DST-Fill Can Help!

ELK GROVE VILLAGE, IL, October 20, 2021 - Many variables can affect the injection molding process. Of these variables, resin viscosity is perhaps the most critical. Oftentimes the viscosity of materials is neither consistent nor predictable resulting in an inconsistent process.

Shibaura Machine’s all-electric SXIII series of injection molding machines features a Dynamic Self Tuning-Fill (DST-Fill) function which uses injection pressure feedback. With the DST-fill feature, the machine can automatically detect changes in material viscosity and make process changes in order to prevent part defects before they happen or stop them quickly with minimal scrap.

Easy Monitoring to Viscosity Changes

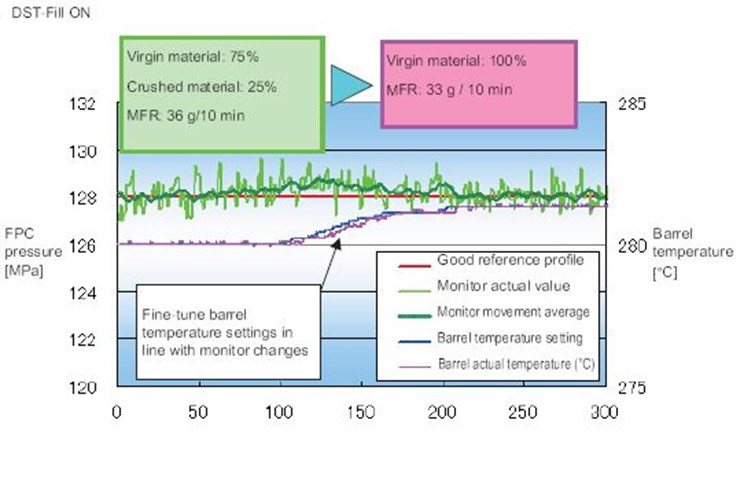

While some injection molding machines can detect changes in resin viscosity, Shibaura Machine’s DST-Fill function takes it a step further by aiming to stabilize molded article quality by automatically adjusting set up data.

By monitoring the injection pressure, DST-fill detects the monitoring data movement average during continuous molding to maintain molding stability. If the injection pressure increases over a set tolerance then the machine will increase the front zone and nozzle temp or just the front zone temp to lower or raise the viscosity of the material. The front zone by itself has the greatest affect on viscosity. This feature is able to automatically fine tune setup data when the movement average varies relative to the good article reference profile.

When To Use DST-Fill

DST-Fill can be useful for a variety of applications. We find it most appropriate to use when running high tolerance applications and when introducing regrind material mixed with virgin material. It can also be useful when the material lot changes in the middle of a production run..

Stop The Guessing

Automatically compensating for resin viscosity changes can be a vital step in solving molding issues. The DST-Fill function on the V70 controller can help stabilize your process - automatically!

Contact our team today to learn more about this feature -im-success@shibaura-machine.com

Contact us today to see if Dynamic Self Tuning (DST) - Fill can help your molding shop achieve its goals!

Related Articles View All Articles

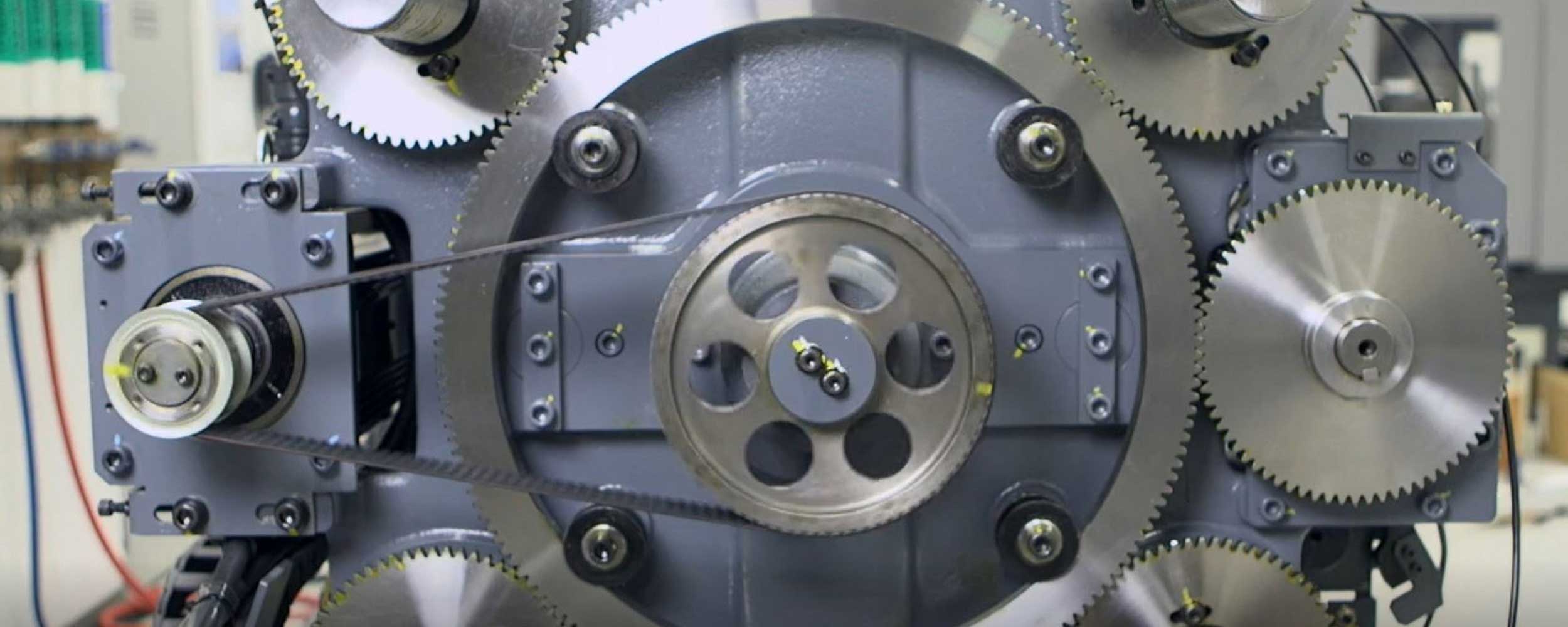

Belt Drive or Direct Drive? Shibaura Machine is Breaking Down the Differences

ELK GROVE VILLAGE, IL, September 22, 2021 - Linear motion control systems, such as direct drive and belt drive, are key in today’s motion-driven automation environment. And while both options look similar, they are fundamentally different. You will want to...

Read moreOptimize Part Weight Consistency with the Shibaura Machine Plastrol Function

ELK GROVE VILLAGE, IL, September 2, 2021 - Part weight variations due to inconsistent check ring response can cause unwanted fluctuations and endanger a stable injection molding process. When we look for ways to stabilize the process and improve shot-to-sh...

Read moreShibaura Machine’s New Smart Factory Highlights IoT Solutions Paired With All-Electric Injection Molding Technology

ELK GROVE VILLAGE, IL, August 27, 2021 - Shibaura Machine will be launching its new Smart Factory with an open house at their Elk Grove Village, Illinois tech center in the Fall, 2021. This manufacturing cell will further support customers to fully leverag...

Read moreTaking LSR Molding to a Higher Level with All-Electric Technology

ELK GROVE VILLAGE, IL, August 20, 2021 -Liquid silicone rubber molding is experiencing demand growth like never before in North America. While many manufacturers are considering whether to invest in a dedicated liquid silicone rubber (LSR) molding machine...

Read moreTwo-Shot Molding: Any Machine, Any Time with Shibaura Machine

ELK GROVE VILLAGE, IL, August 6, 2021 - Two-shot molding is one of the most efficient processes for manufacturers creating products using plastics. By allowing operators to create multi-material or multi-colored parts without adding extra assembly steps it...

Read moreInjection Molding Energy Consumption At a Glance

ELK GROVE VILLAGE, IL, July 28, 2021 - From energy hogs forty years ago to the efficient all-electric options of today, injection molding machines have made quite the evolution. While injection molding is still an energy intensive process, the all-electric...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools