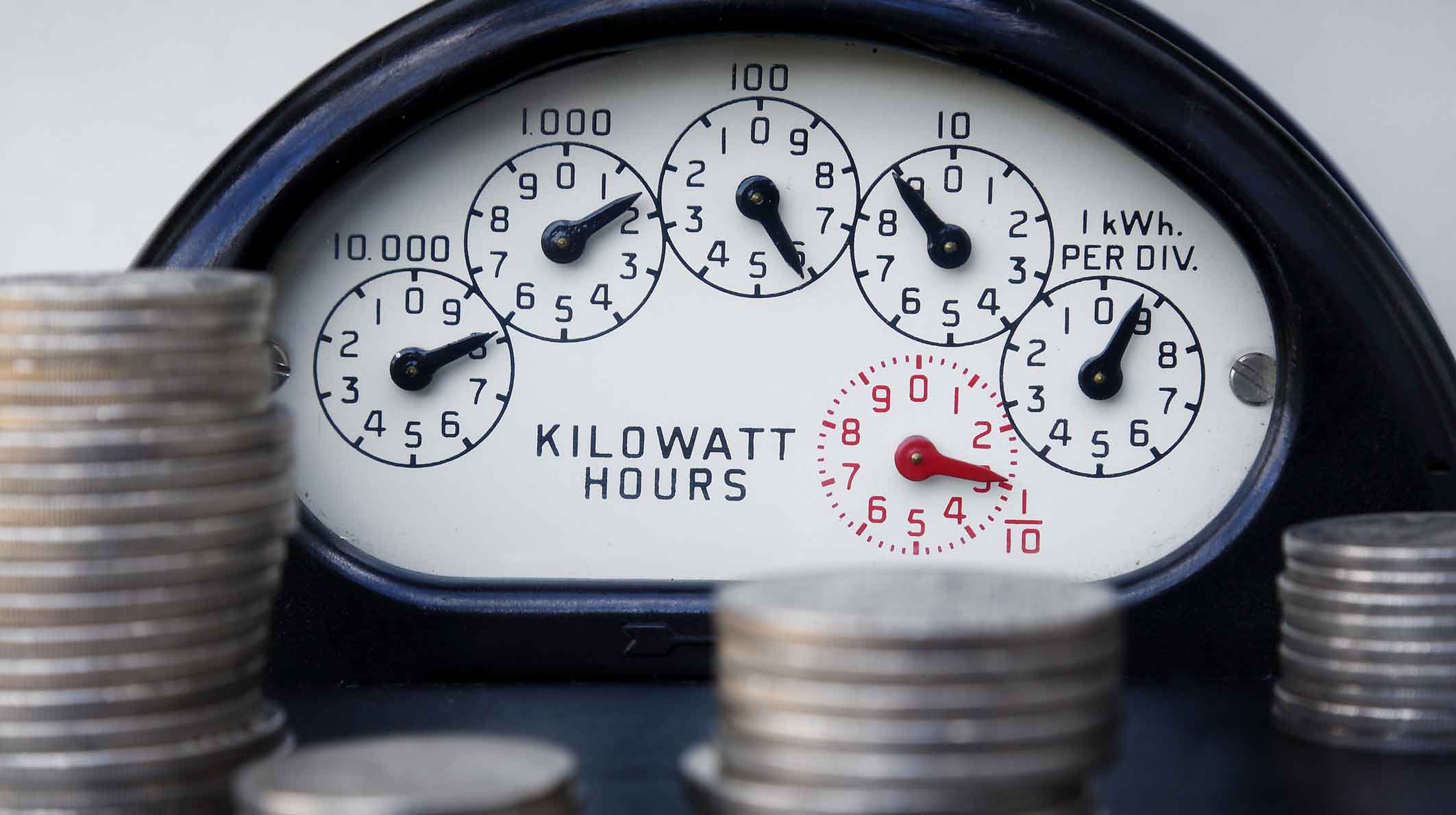

Injection Molding Energy Consumption At a Glance

ELK GROVE VILLAGE, IL, July 28, 2021 - From energy hogs forty years ago to the efficient all-electric options of today, injection molding machines have made quite the evolution.

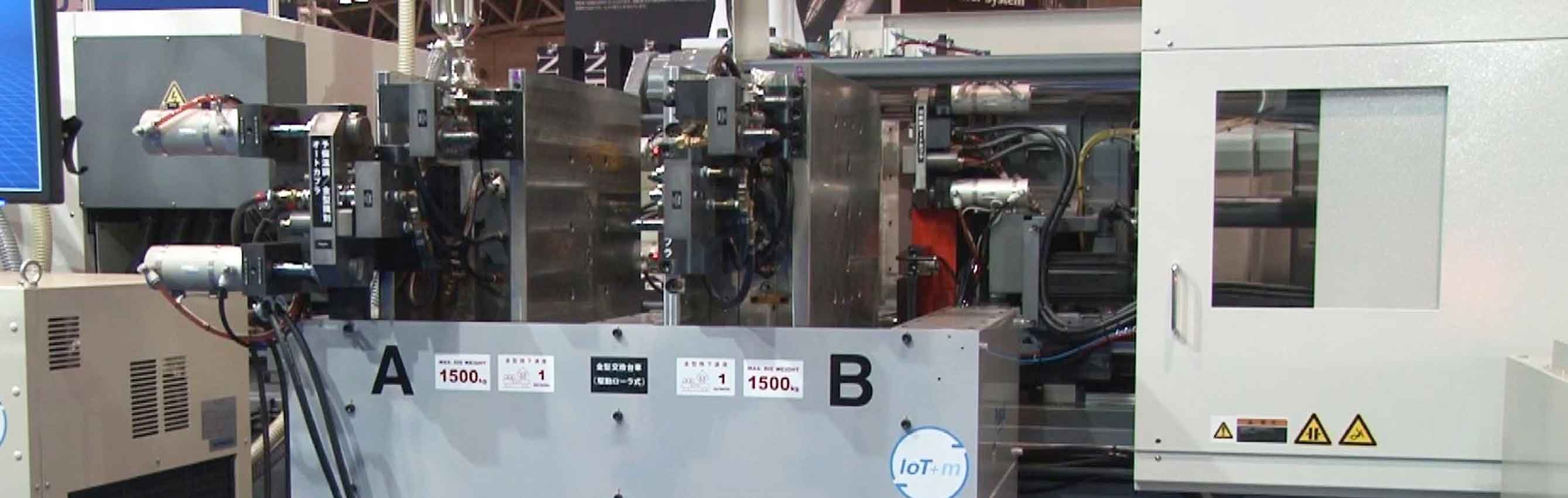

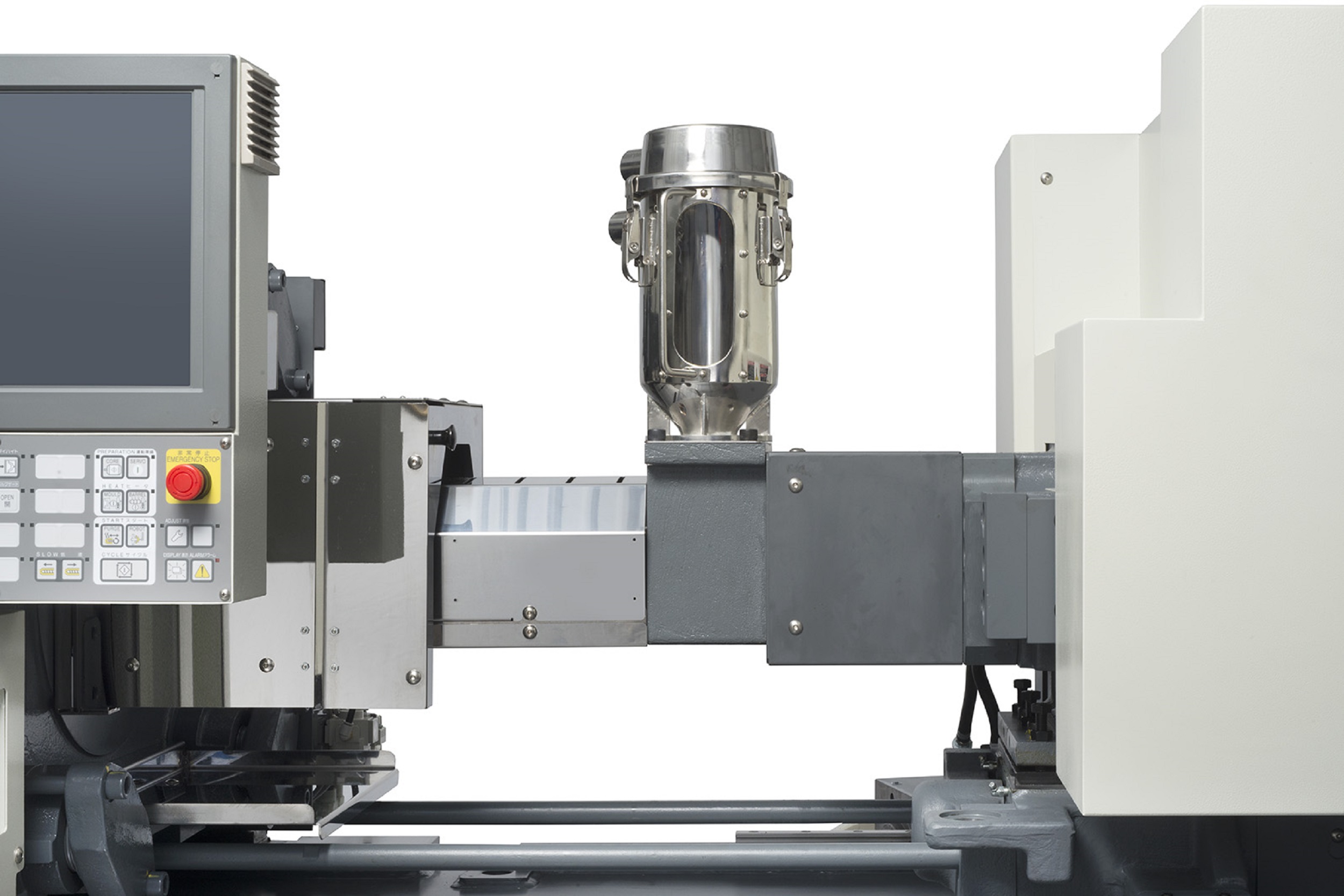

While injection molding is still an energy intensive process, the all-electric injection molding machines introduced in the 1980’s allowed factories the ability to accomplish the same tasks of years ago, but with greater efficiency by only consuming power when needed while still offering tremendous capability. Flash forward to present and Shibaura Machine has taken the technology a step further by offering an easy-to-use interface to better understand and monitor your injection molding machine’s energy consumption.

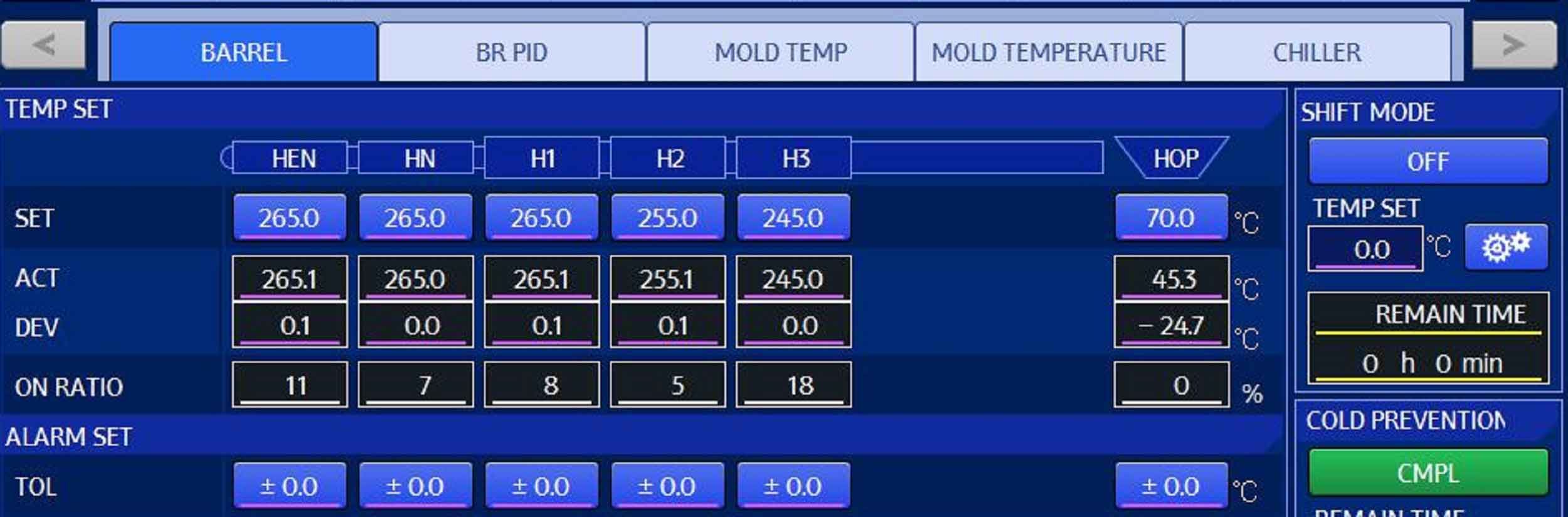

Start Understanding Your Energy Consumption

Having a clear understanding of your energy usage allows you to spend time and effort where the returns will be the greatest. The energy consumption monitor on the Shibaura Machine V70 controller shows not only estimated consumption value, but electricity rate allowing you to make important decisions that can save time and money.

Data on the energy consumption tab includes:

- Electricity consumption estimated value and electricity rates with power usage broken down by servo motors and barrel heaters

- The average electric power usage of 1 shot per cycle – updated each cycle

- Shows energy consumption of each of the 4 servo motors (inject, charge, clamp and eject) as well as heater band energy usage

- Shows energy usage broken down to minutes, days, and months

- Ability to input your actual kw cost per hour and the machine will calculate the rest

- Displays real time energy usage graphs

- Energy studies can be displayed and downloaded for future reference

Start Saving on Energy Costs

It pays to make use of the new machinery developments of today. As energy prices increase, so will the operating cost gap of machines- eventually putting those with older technology at a disadvantage to competitors. By running the all-electric SXIII injection molding machine and using the energy consumption monitor features you will be able to better understand your usage and create a valuable energy management process that will save time and money long-term.

Contact us today to learn how our ECSXIII series can help reduce your energy costs!

Related Articles View All Articles

Shibaura Machine Simplifies Lights-Out Molding

ELK GROVE VILLAGE, IL, July 21, 2021 - Amid a shortage of skilled labor and increasingly high offshoring costs, lights-out technology has become a popular topic of conversation amongst injection molding manufacturers. Lights-out injection molding has impac...

Read more5 Ways to Reduce Injection Molding Start-Up Scrap with Shibaura Machine’s ECSXIII Series

ELK GROVE VILLAGE, IL, July 15, 2021 - When it comes to improving your injection molding process, reducing scrap at machine start-up is one of the more effective ways to increase efficiency. With costs rising on materials and shortages throughout the indus...

Read moreFrom One Product to the Next- Improving Set-up Efficiency in Injection Molding with SMED and the SXIII

ELK GROVE VILLAGE, IL, July 7, 2021 - Reducing the changeover time for your operations is critical to maintain a competitive advantage and improve profitability in the manufacturing industry today.That’s where the concept of single-minute exchange of die, ...

Read moreGain Control Over Your Barrel Temperature with Shibaura Machine’s V70 Controller

ELK GROVE VILLAGE, IL, June 25, 2021 - Errors in temperature control result in a large part of rejects in the injection molding world. If a molder wants to ensure a stable molding cycle and high quality product, having a temperature control process is esse...

Read moreUsing Auto-Purge to Improve Injection Molding Efficiency

ELK GROVE VILLAGE, IL, June 23, 2021 - Molders today are always looking for a way to minimize their losses. So while purging is often necessary, it makes many molders cringe because this process often means costly waste and lost production time- defeating...

Read moreMold Recipe Management: Saving Time and Money in Injection Molding

ELK GROVE VILLAGE, IL, June 9, 2021 - Think of a chef on a Friday night at a popular restaurant. They are tasked with switching from one recipe to the next in a single night. Not only that, they need to make sure they use the correct measurements, with qui...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools