Optimize Part Weight Consistency with the Shibaura Machine Plastrol Function

ELK GROVE VILLAGE, IL, September 2, 2021 - Part weight variations due to inconsistent check ring response can cause unwanted fluctuations and endanger a stable injection molding process. When we look for ways to stabilize the process and improve shot-to-shot repeatability, Shibaura Machine’s Plastrol function can do a lot.

Stabilizing the shot size and optimizing check ring response of the screw tip can be accomplished with the Plastrol function. This function allows for the part weight and filling pressure to be stable which is especially important when running small shot sizes.

How does the Plastrol function operate?

With four special operation types, the user can control the screw’s special operation after charging completes. These operations can be performed individually or combined.

Four Operation Types:

- Pre injection after charge: Injecting resin at low pressure after charging allows the auxiliary compression of that resin and regulates its density. The effect is stabilization of plasticization resin quantity.

- Pre-injection after decompression: Advances the screw after decompression completes and closes the check ring, stabilizing it.

- Screw inversion in decompression: Reversing the screw during decompression lowers the resin pressure between the check ring and spacer, stabilizing the check ring response.

- Screw inversion before injection: Reversing the screw operation before starting injection lowers the resin pressure between the check ring and spacer, stabilizing the check ring response.

What are the benefits of this function?

The real benefit of the Plastrol function is better shot weight repeatability and more consistent parts. Using this function thoughtfully can stabilize and optimize the overall injection molding process. Contact our injection molding team to learn more about the Plastrol function and our SXIII series.

Contact us today to see if Plastrol can benefit your molding operation!

Related Articles View All Articles

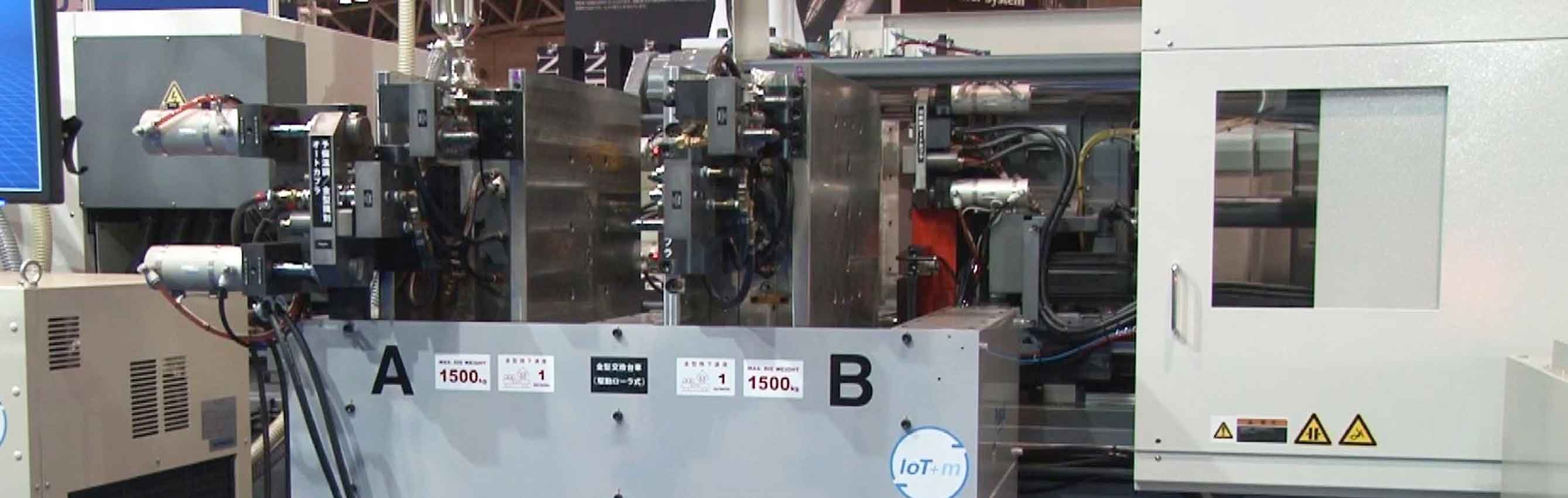

Shibaura Machine’s New Smart Factory Highlights IoT Solutions Paired With All-Electric Injection Molding Technology

ELK GROVE VILLAGE, IL, August 27, 2021 - Shibaura Machine will be launching its new Smart Factory with an open house at their Elk Grove Village, Illinois tech center in the Fall, 2021. This manufacturing cell will further support customers to fully leverag...

Read moreTaking LSR Molding to a Higher Level with All-Electric Technology

ELK GROVE VILLAGE, IL, August 20, 2021 -Liquid silicone rubber molding is experiencing demand growth like never before in North America. While many manufacturers are considering whether to invest in a dedicated liquid silicone rubber (LSR) molding machine...

Read moreTwo-Shot Molding: Any Machine, Any Time with Shibaura Machine

ELK GROVE VILLAGE, IL, August 6, 2021 - Two-shot molding is one of the most efficient processes for manufacturers creating products using plastics. By allowing operators to create multi-material or multi-colored parts without adding extra assembly steps it...

Read moreInjection Molding Energy Consumption At a Glance

ELK GROVE VILLAGE, IL, July 28, 2021 - From energy hogs forty years ago to the efficient all-electric options of today, injection molding machines have made quite the evolution. While injection molding is still an energy intensive process, the all-electric...

Read moreFrom One Product to the Next- Improving Set-up Efficiency in Injection Molding with SMED and the SXIII

ELK GROVE VILLAGE, IL, July 7, 2021 - Reducing the changeover time for your operations is critical to maintain a competitive advantage and improve profitability in the manufacturing industry today.That’s where the concept of single-minute exchange of die, ...

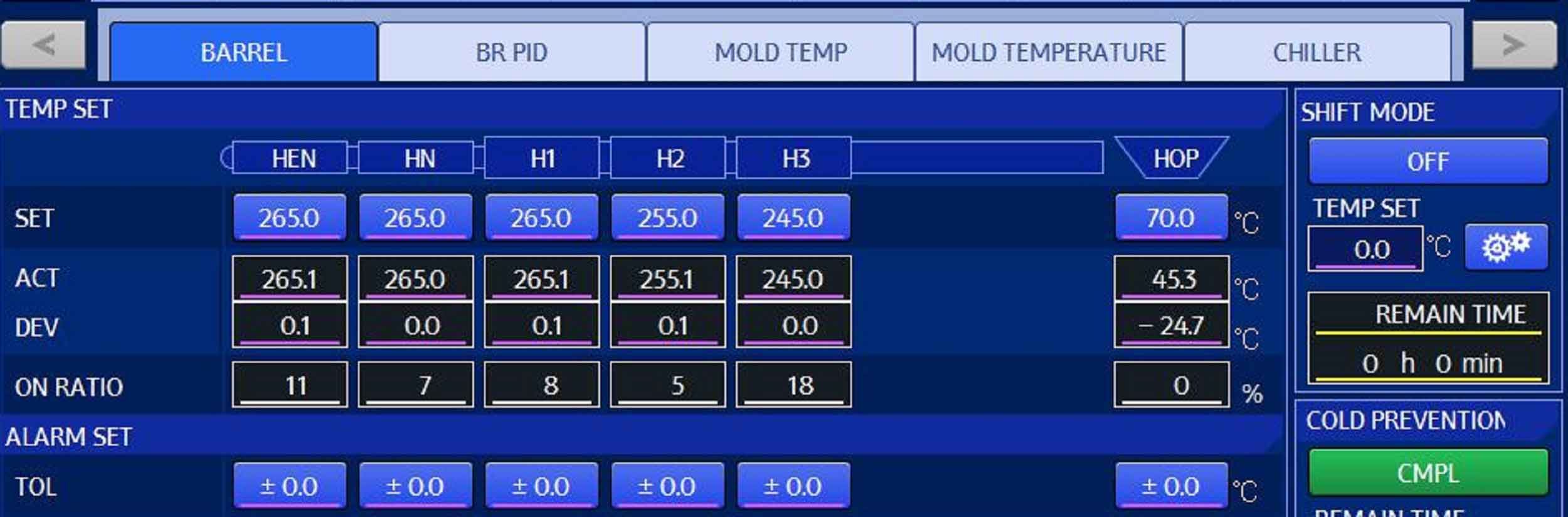

Read moreGain Control Over Your Barrel Temperature with Shibaura Machine’s V70 Controller

ELK GROVE VILLAGE, IL, June 25, 2021 - Errors in temperature control result in a large part of rejects in the injection molding world. If a molder wants to ensure a stable molding cycle and high quality product, having a temperature control process is esse...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools