Stabilize Your Injection Molding Process with Filling Impulse Transfer (F.I.T.)

ELK GROVE VILLAGE, IL, October 4, 2021 - While most modern all-electric injection machines have high levels of repeatability, molding defects can still be an issue due to material property inconsistencies. Perhaps the material lot has changed or the percentage of regrind used has been modified. The F.I.T. function on Shibaura Machine’s V70 controller works to stabilize the molded product quality by responding in real-time to these changes in material viscosity.

Automatically Adjust to Maintain Quality

Can your machine automatically compensate for changes in material properties? This is a common question injection molding machine manufacturers are asked. Shibaura Machine’s Filling Impulse Transfer (F.I.T.) control provides automatic adjustment on-the-fly, saving the operator time, guesswork, and preventing potential part quality issues.

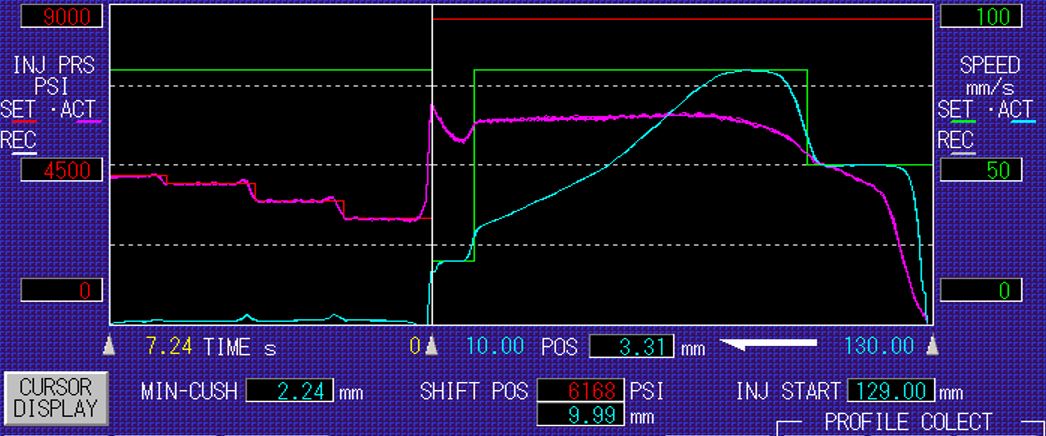

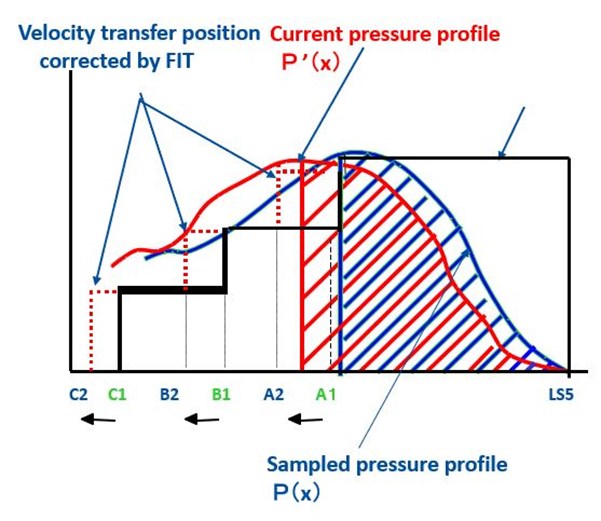

The F.I.T. control records the injection pressure profile for good molded parts and automatically adjusts the transfer-to-holding position during the filling process, so that the work amount per speed setting segment is the same as this standard. Below is an example of adjusting the section from LS4A to LS5 +LS10.

Setting up the procedure on the SXIII series all-electric injection molding machines is simple with the easy-to-use interface. Consult the operators manual for complete instructions which will walk you through setting F.I.T. control start and finish positions, collecting the reference pressure profile, and the ability to use the F.I.T. Control alarm which will alert operators when the speed shift position and pressure shift time adjustments are outside the preset tolerance.

The Shibaura V70 controller was designed with the processor in mind. Learn more about the F.I.T. control and all the features that allow for a more efficient manufacturing operation by contacting our team of experts today at im-success@shibaura-machine.com, or click the link below to request a quote.

Contact us today to see if Filling Impulse Transfer can help your molding shop achieve its goals!

Related Articles View All Articles

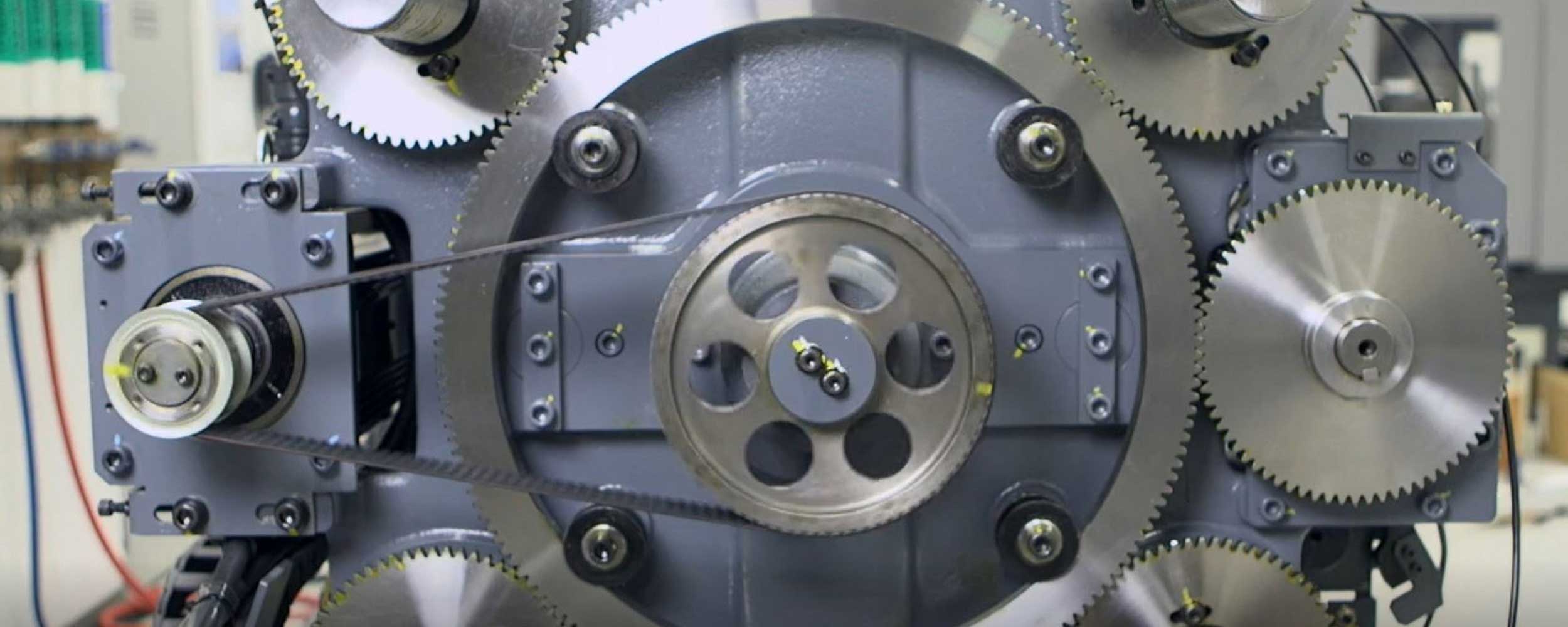

Belt Drive or Direct Drive? Shibaura Machine is Breaking Down the Differences

ELK GROVE VILLAGE, IL, September 22, 2021 - Linear motion control systems, such as direct drive and belt drive, are key in today’s motion-driven automation environment. And while both options look similar, they are fundamentally different. You will want to...

Read moreOptimize Part Weight Consistency with the Shibaura Machine Plastrol Function

ELK GROVE VILLAGE, IL, September 2, 2021 - Part weight variations due to inconsistent check ring response can cause unwanted fluctuations and endanger a stable injection molding process. When we look for ways to stabilize the process and improve shot-to-sh...

Read moreShibaura Machine’s New Smart Factory Highlights IoT Solutions Paired With All-Electric Injection Molding Technology

ELK GROVE VILLAGE, IL, August 27, 2021 - Shibaura Machine will be launching its new Smart Factory with an open house at their Elk Grove Village, Illinois tech center in the Fall, 2021. This manufacturing cell will further support customers to fully leverag...

Read moreTaking LSR Molding to a Higher Level with All-Electric Technology

ELK GROVE VILLAGE, IL, August 20, 2021 -Liquid silicone rubber molding is experiencing demand growth like never before in North America. While many manufacturers are considering whether to invest in a dedicated liquid silicone rubber (LSR) molding machine...

Read moreTwo-Shot Molding: Any Machine, Any Time with Shibaura Machine

ELK GROVE VILLAGE, IL, August 6, 2021 - Two-shot molding is one of the most efficient processes for manufacturers creating products using plastics. By allowing operators to create multi-material or multi-colored parts without adding extra assembly steps it...

Read moreInjection Molding Energy Consumption At a Glance

ELK GROVE VILLAGE, IL, July 28, 2021 - From energy hogs forty years ago to the efficient all-electric options of today, injection molding machines have made quite the evolution. While injection molding is still an energy intensive process, the all-electric...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools