Shibaura Machine's Space-Saving BTD-110S.R16 HBM with FANUC and TOSNUC Control Options at IMTS 2024

ELK GROVE VILLAGE, IL, July 23, 2024 -

In today’s competitive manufacturing landscape, facilities need compact yet powerful solutions to enhance their machining capabilities without expanding their footprint. Shibaura Machine’s BTD-110S.R16 Horizontal Boring Mill is designed to meet this demand. Built with a compact design, this machine offers rigidity and performance, making it an ideal upgrade for shops looking to boost efficiency and precision.

This state-of-the-art machine will be showcased at Shibaura Machine's booth located on Level 3 in the South Hall, #339424 at the upcoming International Manufacturing Technology Show (IMTS) 2024, providing an excellent opportunity for industry professionals to witness its capabilities firsthand.

Big Performance, Compact Engineering

Don't be fooled by its size. The BTD-110S.R16 packs a powerful punch within a space-saving design. This innovative machine delivers the performance you need to tackle demanding tasks, while its compact footprint allows you to maximize your production floor. With the flexibility to use either the FANUC or TOSNUC control systems, it ensures seamless integration into your existing workflow, enhancing both productivity and precision. Below are several key benefits and applications that make this machine tool a game-changer for manufacturers.

1. Advanced Spindle Technology

At the heart of the BTD-110S.R16 is its advanced spindle construction, designed for deep hole boring and other demanding tasks. Supported by long-span type bearings and featuring an automatic spindle end clamp, the spindle significantly increases cutting force and positioning accuracy. This innovative design minimizes thermal displacement, ensuring precision even during extended operations.

In industries where components must meet rigorous safety standards or withstand extreme conditions, the BTD-110S.R16 excels in producing high-precision parts. Its advanced spindle technology ensures that these critical parts are manufactured to the highest standards, providing the reliability and accuracy essential for demanding applications.

2. Rotary Table and B-Axis Functionality

The BTD-110S.R16 includes a 55" x 63" (1400 x 1600mm) rotary table, with an optional automatic pallet changer (APC) for enhanced productivity. The B-axis continuous indexing function allows for efficient machining of cylindrical and end surfaces, eliminating the need for an additional rotary table. This simplifies programming and operation, making complex tasks more manageable.

For instance, consider the automotive industry demands for high-quality parts for optimal performance and safety. The BTD-110S.R16 is ideal for producing complex components such as engine and transmission parts. The machine's rotary table and B-axis functionality enable faster production times and higher accuracy, directly contributing to improved vehicle performance and efficiency.

3. Automated Measuring Systems

To further enhance precision and efficiency, the BTD-110S.R16 can be equipped with Renishaw probes for automatic tool setting and workpiece measurement. These systems reduce manual intervention, maintaining high accuracy and efficiency across various operations.

Join Shibaura Machine at IMTS 2024

Join us at IMTS 2024 to discover how the BTD-110S.R16 can elevate your manufacturing capabilities and keep you at the cutting edge of technology. Don't miss the chance to explore the future of machining with Shibaura Machine.

Event Details:

- Dates: September 9-14, 2024

- Location: McCormick Place, Chicago, IL, South Building, Level 3, 339424- Metal Removal

Registration: Open to the public at IMTS 2024 Registration

Related Articles View All Machine Tools Articles

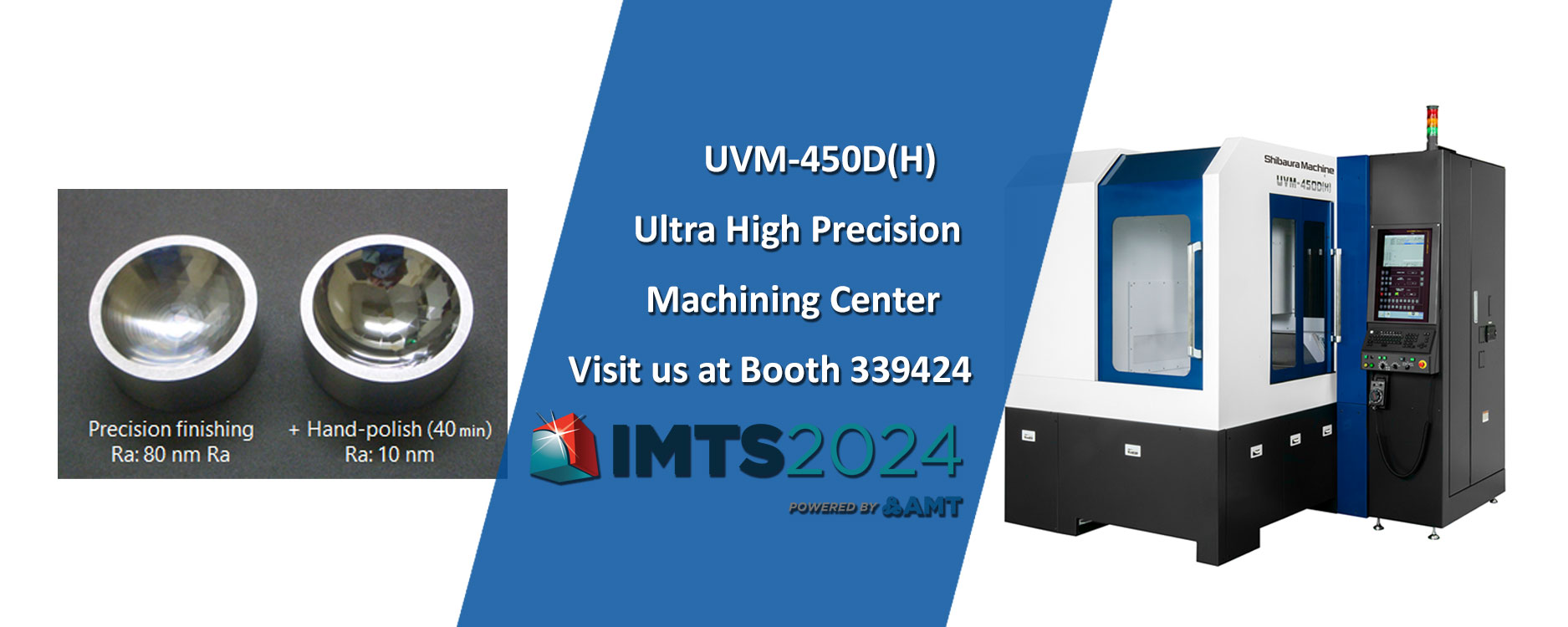

Meet the Future of Nano Machining: Shibaura Machine's UVM-450D(H) High Precision Machining Center at IMTS 2024

ELK GROVE VILLAGE, IL, July 16, 2024 - As industries evolve, the demand for precision at the nano level has become increasingly vital. Micro machining, characterized by its ability to deliver exceptional accuracy and intricate detailing, is revolutionizing...

Read moreMachining Excellence: Shibaura Machine's TUE-200(S) Vertical Boring and Turning Mill on Display at IMTS 2024

ELK GROVE VILLAGE, IL, July 9, 2024 - As the manufacturing industry continuously advances, the demand for versatile, efficient, and precise machinery grows stronger than ever. Shibaura Machine, America is thrilled to announce that the TUE-200(S) Vertical B...

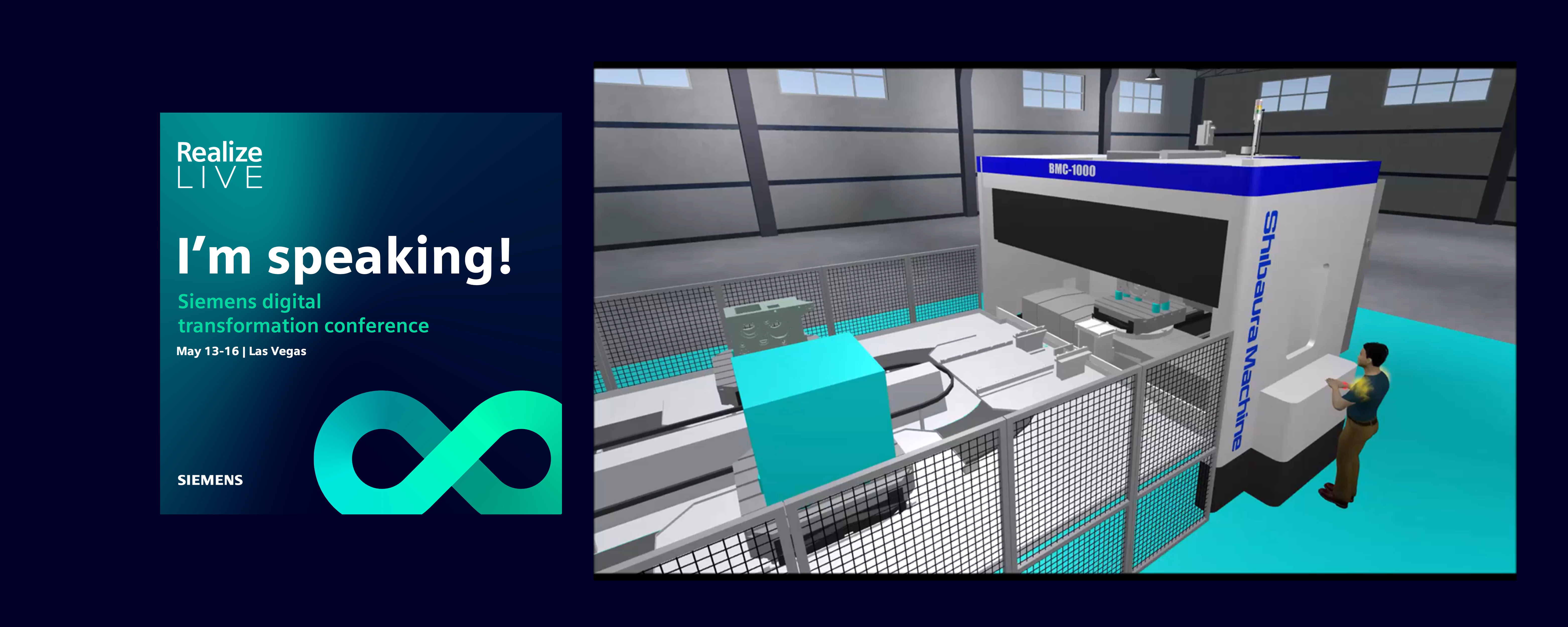

Read moreSiemens Realize Live 2024 Recap on Shibaura Machine’s Digital Twins and Virtual Reality

ELK GROVE VILLAGE, IL, May 28, 2024 - At the recent Siemens Realize LIVE 2024 event, Shibaura Machine Company, America presented on the transformative potential of digital twins and virtual reality (VR) to further collaborative user engagement and optimize...

Read moreExplore Collaborative VR and Digital Twins with Shibaura Machine at Siemens Realize Live 2024

ELK GROVE VILLAGE, IL, April 23, 2024 - Join Shibaura Machine at the much-anticipated Siemens Realize LIVE 2024, held at Mandalay Bay Convention Center, Resort and Casino in Las Vegas, Nevada from May 13-16, where we’ll be showcasing how we’re harnessing S...

Read moreThe Foundation of Manufacturing Excellence: A Strong Machine Tool Factory Presence

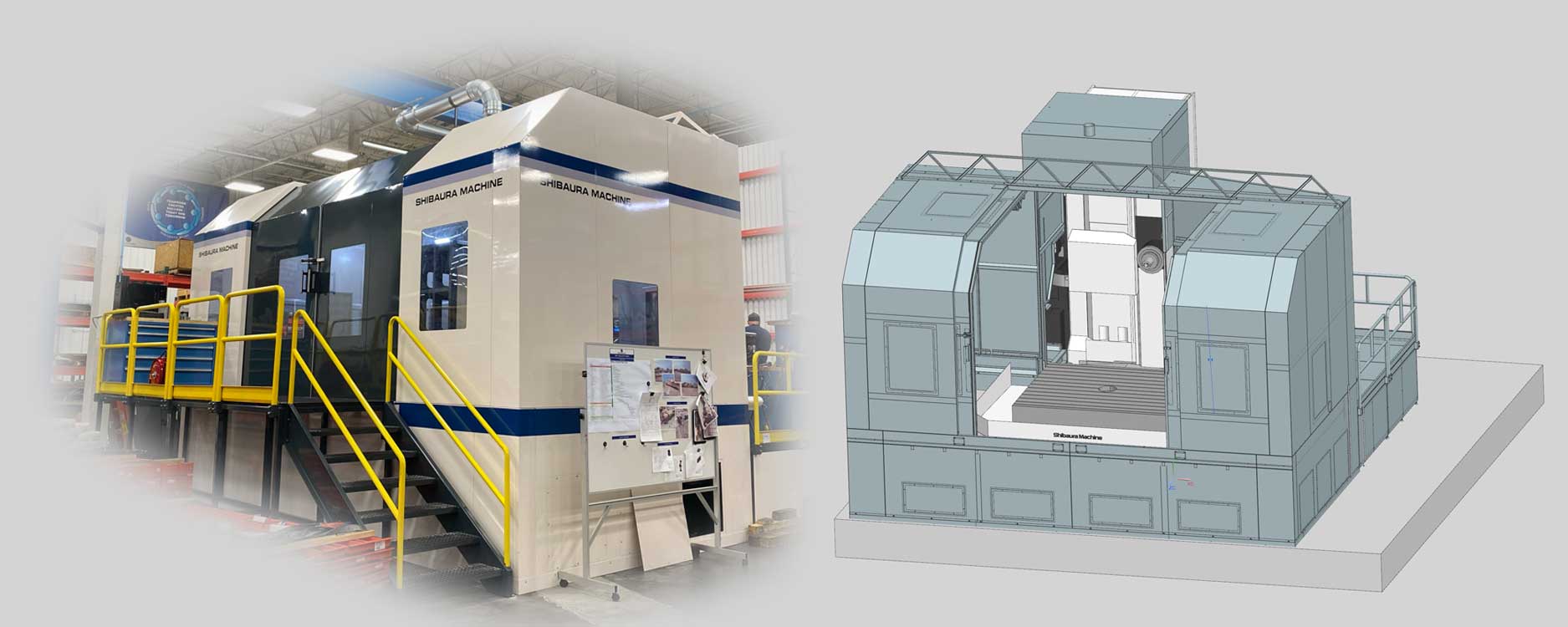

ELK GROVE VILLAGE, IL, March 26, 2024 - The machine tool industry is a cornerstone of North American manufacturing. It powers sectors from automotive to aerospace with the precision and efficiency needed to compete on a global scale. In this dynamic landsc...

Read moreA Closer Look: Understanding the Benefits of Full Enclosures for Horizontal Boring Machines

ELK GROVE VILLAGE, IL, March 19, 2024 - Horizontal boring machines are powerhouses in precision machining, known for their ability to handle big, tough jobs with incredible accuracy. As technology evolves, so do the features that make these machine tools s...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools