A Closer Look: Understanding the Benefits of Full Enclosures for Horizontal Boring Machines

ELK GROVE VILLAGE, IL, March 19, 2024 -

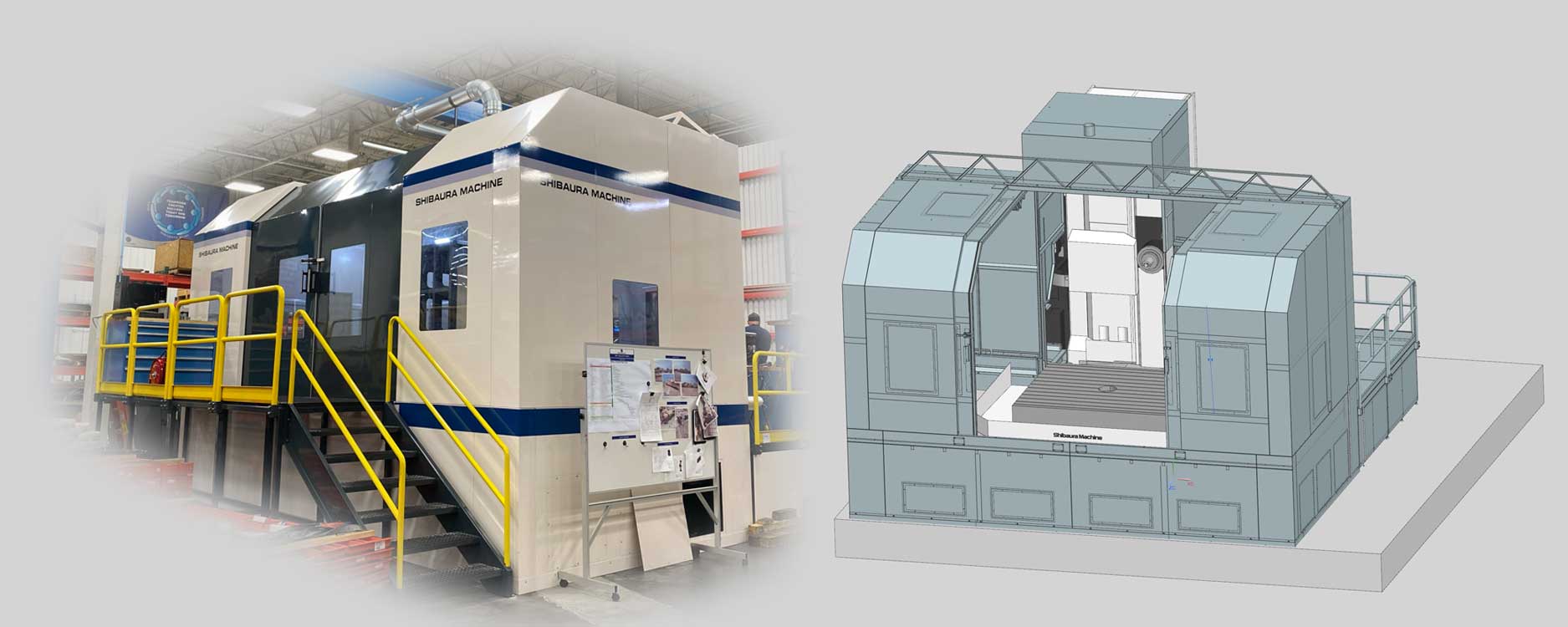

Horizontal boring machines are powerhouses in precision machining, known for their ability to handle big, tough jobs with incredible accuracy. As technology evolves, so do the features that make these machine tools safer, more efficient, and easier to use. One feature that's making a big difference is the full enclosure.

With manufacturers always looking for ways to work smarter, cut costs, and keep their operations safe a full enclosure is becoming a common choice in the industry. As we navigate through the advancements in technology, the shift towards fully enclosed horizontal boring machines (HBMs) signifies a broader commitment to pushing the boundaries of innovation, prioritizing safety, and embracing environmental stewardship.

The Advantages of Full Enclosures on Horizontal Boring Machines

1. Enhanced Safety

The use of full enclosures on horizontal boring machines significantly reduces injury and accident risks. Protecting the operator from flying chips and coolant splash, they provide a physical barrier between the operator and the machine's moving parts. This not only ensures the well-being of the machine operators but also contributes to a safer overall work environment.

2. Improved Precision and Quality

Full enclosures create a controlled environment that contributes to machining precision and quality. By managing chips and mist, enclosures ensure that the machining process runs smoothly and the finished product is of the highest quality possible.

3. Sound Reduction

A great deal of sound can be generated during machining operations, especially when heavy and large workpieces are involved. During operations, full enclosures act as sound barriers, reducing noise levels. As a result, operators are able to work in a more comfortable and less distracting environment.

4. Enhanced Cleanliness and Maintenance

Full enclosures help in maintaining cleanliness within the shop by containing the chips, coolant, and mist within the machine. With this containment, cleaning is easier and more efficient, reducing maintenance and cleaning downtime.

5. Aesthetic and Organizational Benefits

Adding a full enclosure to the shop can give it a sleek, modern look. They can also contribute to a more organized and professional appearance, which can be helpful during client visits or audits. In addition, having a clean and orderly workplace can have a positive psychological impact on employee morale and productivity.

Embracing the Future with Full Enclosures

Adopting fully enclosed horizontal boring machines is more than just an upgrade; it's a strategic move towards creating safer, more sustainable, and more productive manufacturing environments. As we look ahead, the adoption of such advanced features is set to redefine industry standards, ensuring that manufacturers not only keep pace with technological advancements but also lead the way in operational excellence and environmental stewardship.

Contact the Machine Tools team to learn more.

Related Articles View All Machine Tools Articles

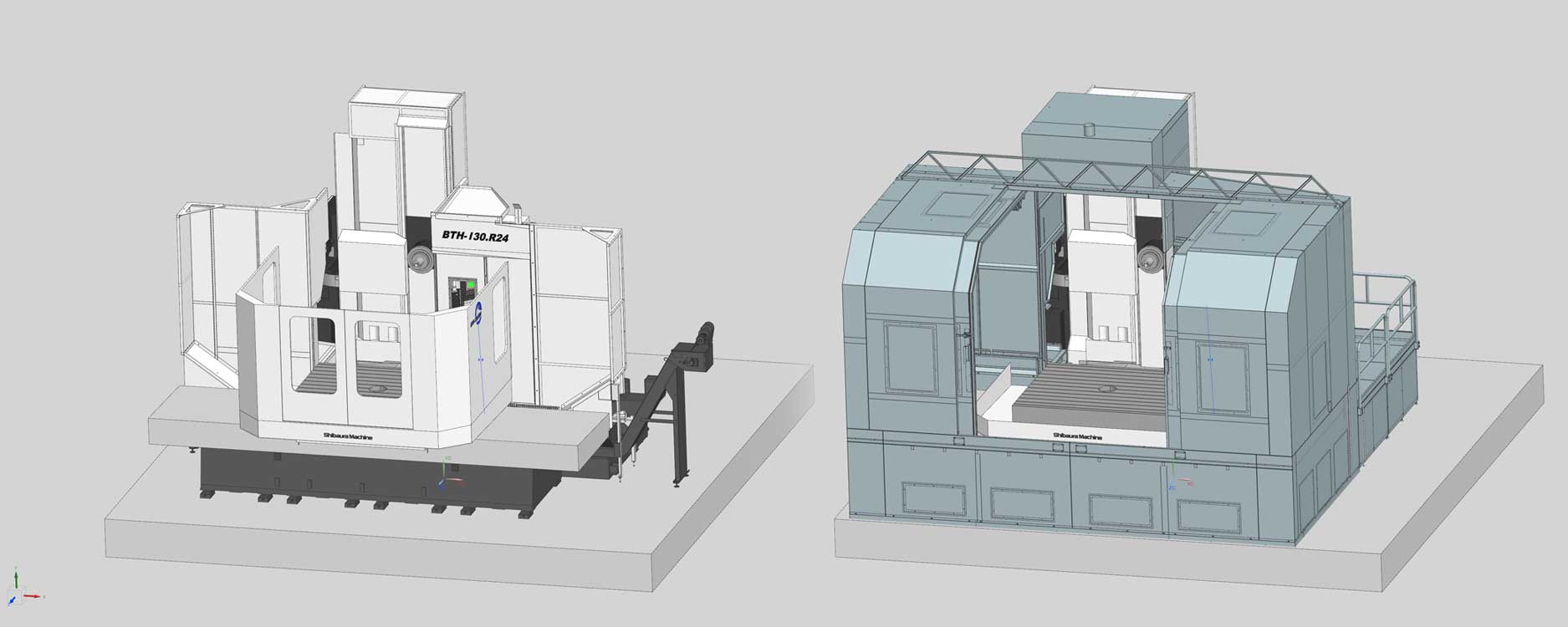

What to Consider When Looking at Full Enclosures for Your Horizontal Boring Machine

ELK GROVE VILLAGE, IL, March 5, 2024 - The adoption of horizontal boring machines equipped with full enclosures marks a significant stride in manufacturing towards operational excellence and safety. As businesses strive to enhance their manufacturing capab...

Read moreUnderstanding Chip Management: Selecting the Correct Type of Chip Conveyor for Your Machining Needs

ELK GROVE VILLAGE, IL, February 27, 2024 - In the machining industry, precision and efficiency are key. Chip conveyors play an essential role in this environment, quietly ensuring machine tools stay clean and operational. Choosing the right size of chip co...

Read moreMaximizing Machine Tool Potential with High-Pressure Coolant Technology

ELK GROVE VILLAGE, IL, February 21, 2024 - In the precision-driven world of machine tooling, the pursuit for efficiency, durability, and superior performance is constant. Among the multitude of technological advancements, the application of high-pressure c...

Read moreEngineering Excellence: A Closer Look at Shibaura Machine's TUE Series Tool Holders

ELK GROVE VILLAGE, IL, February 6, 2024 - Shibaura Machine's TUE series machines are equipped with a diverse range of tool holders, each designed to maximize functionality and versatility. These tool holders are integral to the TUE series catering to a wid...

Read moreThe Future of Machine Tool Support: Introducing Shibaura Machine's Customer Portal

ELK GROVE VILLAGE, IL, January 30, 2024 - As we get ready to launch our new Customer Service Portal for Machine Tool customers later this year, Shibaura Machine Company, America is leading the way in transforming how you access information and receive supp...

Read moreElevating Customer Support in Machine Tools: Shibaura Machine's Integration of CRM and Smart Glasses

ELK GROVE VILLAGE, IL, January 23, 2024 - In an era where digital transformation is not just a trend but a business imperative, Shibaura Machine Company, America continues to grow our virtual customer support options in the machine tool industry. Building ...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools