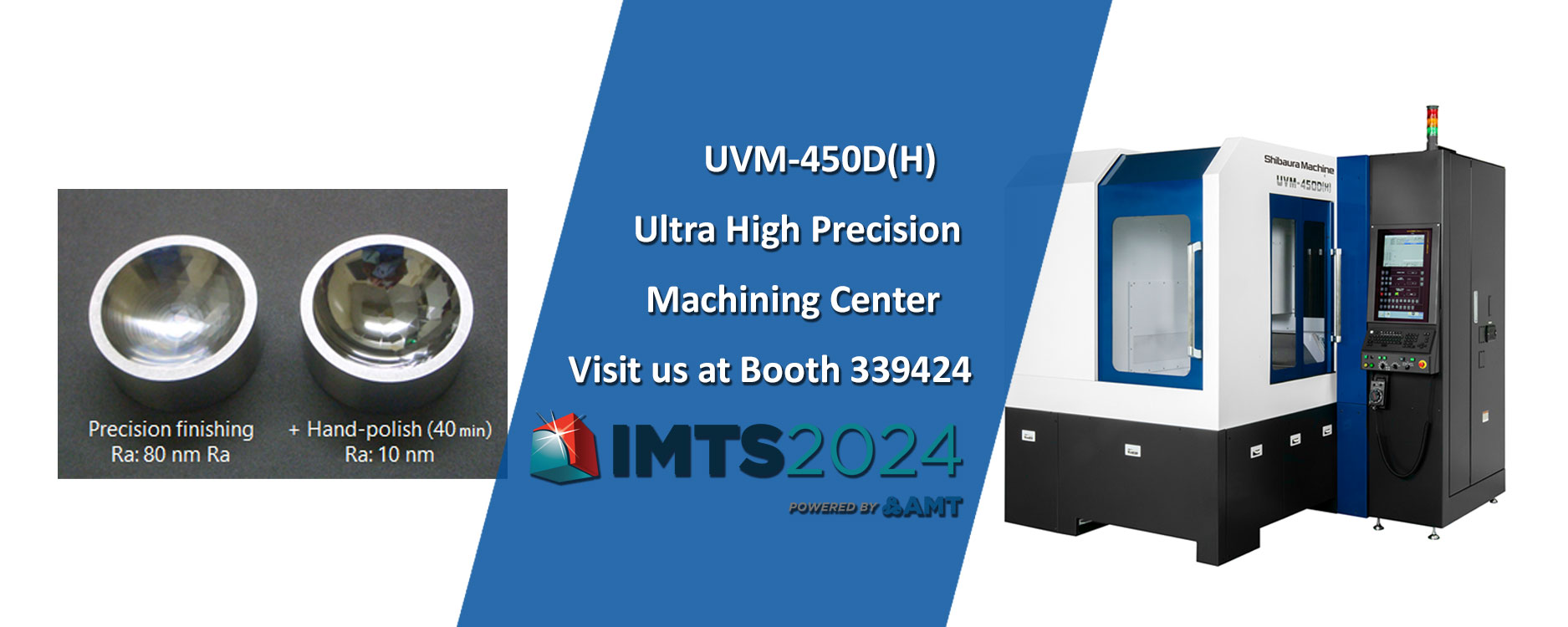

Meet the Future of Nano Machining: Shibaura Machine's UVM-450D(H) High Precision Machining Center at IMTS 2024

ELK GROVE VILLAGE, IL, July 16, 2024 -

As industries evolve, the demand for precision at the nano level has become increasingly vital. Micro machining, characterized by its ability to deliver exceptional accuracy and intricate detailing, is revolutionizing fields from medical devices to aerospace engineering.

Recognizing this critical shift, Shibaura Machine is proud to show the UVM-450D(H) High Precision Machining Center at the upcoming International Manufacturing Technology Show (IMTS) 2024. This state-of-the-art machine embodies the future of manufacturing, designed to meet the exacting standards of modern industry with unmatched precision and efficiency. Discover how the UVM-450D(H) can elevate your manufacturing capabilities and keep you at the cutting edge of technology.

Key Features and Applications

1. Advanced Spindle Technology

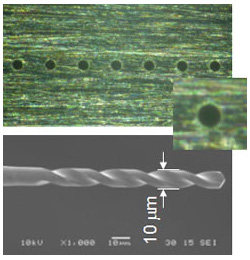

At the heart of the UVM-450D(H) is its high-speed aerostatic bearing spindle, capable of rotating at an impressive 60,000 RPM. This high rotational speed not only ensures reduced machining time but also provides exceptional accuracy and surface finish. The virtually unlimited lifespan of the aerostatic bearing spindle translates to lower maintenance costs and increased machine uptime.

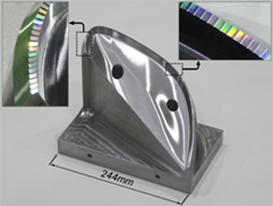

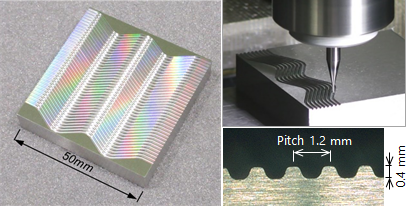

For example, the UVM-450D(H) excels in producing intricate and accurate components to meet stringent standards in various industries. Its ability to maintain tight profile tolerances and achieve superior surface finishes is critical for applications such as surgical instruments and implantable devices, ensuring each part is manufactured to the highest quality.

2. Thermal Stability

The UVM-450D(H) is equipped with a sophisticated thermal stabilizing system that circulates temperature-controlled liquid through the machine's structure. This feature ensures consistent thermal stability, minimizing distortion and maintaining high precision throughout extended operations.

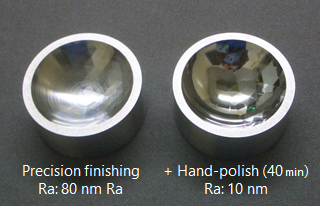

For instance, in the auto industry components must withstand extreme conditions and meet rigorous safety standards. The UVM-450D(H) advanced thermal stability system ensures that even during long production runs, high-precision molds for refractive lenses remain consistent and precise. This system offers superior accuracy and reliability essential for producing these high-quality molds that enhance vehicle safety and driver visibility.

3. Linear Motor Axes

The UVM-450D(H) utilizes linear motor axes instead of traditional mechanical axes. This results in faster acceleration, greater accuracy, and higher throughput, making it ideal for high-speed, high-precision machining tasks.

4. Automation and Precision Support

The UVM-450D(H) is equipped with automation features that enhance precision and efficiency. The UVM-TSA software facilitates high-precision machining and automation, while the FormEye® tool contour measuring system ensures accurate cutter shapes during high-speed rotation. Additionally, the ShapeEye imaging-type workpiece measuring system allows for precise tailoring of fine shapes, reducing the need for re-modeling and re-generation of tool paths.

For instance, producing optical lens molds requires careful attention to detail and surface quality. The UVM-450D(H)’s advanced automation and precision support systems ensure that each lens mold is produced to exact specifications, significantly reducing errors and improving production efficiency.

Join Shibaura Machine at IMTS 2024

Shibaura Machine invites all industry professionals to witness the innovative capabilities of the UVM-450(H) at IMTS 2024. Attendees will have the opportunity to see this advanced high precision machining center in action and understand how it can transform their manufacturing processes.

Event Details:

- Dates: September 9-14, 2024

- Location: McCormick Place, Chicago, IL, South Building, Level 3, 339424- Metal Removal

Registration: Open to the public at IMTS 2024 Registration

Related Articles View All Machine Tools Articles

Machining Excellence: Shibaura Machine's TUE-200(S) Vertical Boring and Turning Mill on Display at IMTS 2024

ELK GROVE VILLAGE, IL, July 9, 2024 - As the manufacturing industry continuously advances, the demand for versatile, efficient, and precise machinery grows stronger than ever. Shibaura Machine, America is thrilled to announce that the TUE-200(S) Vertical B...

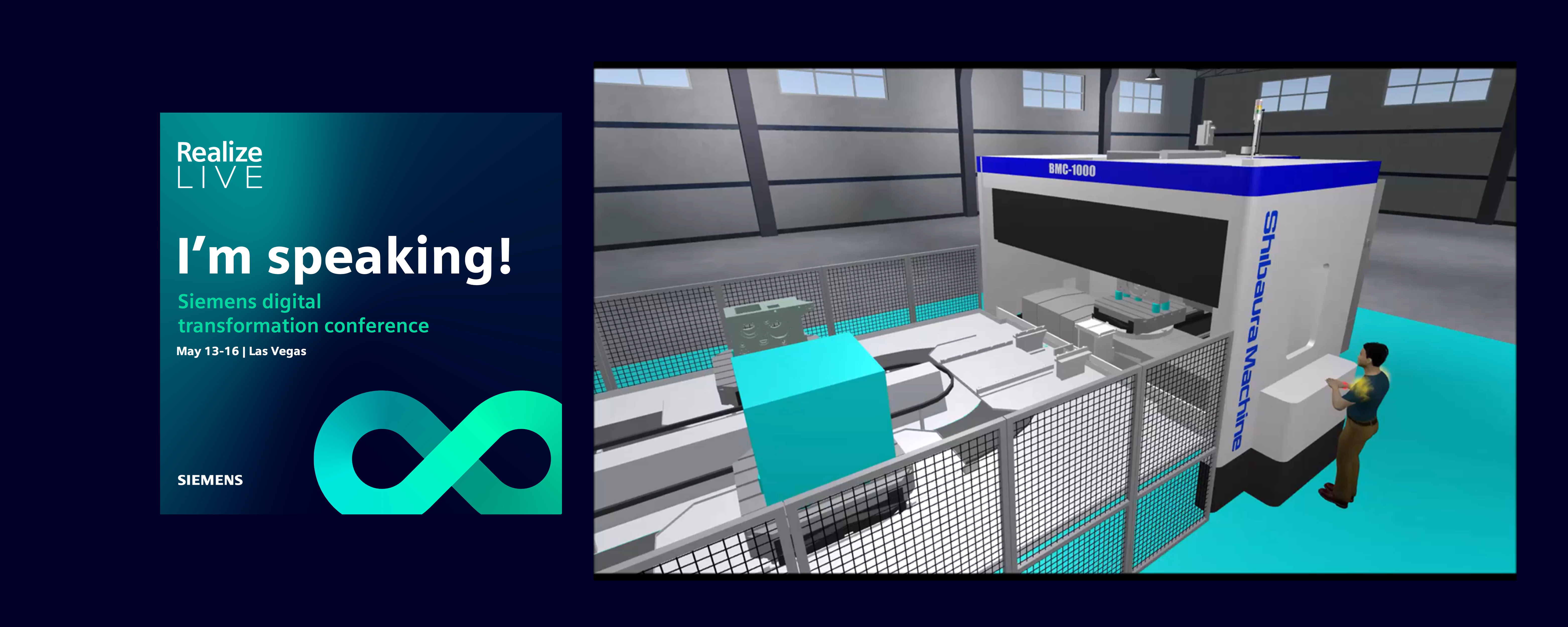

Read moreSiemens Realize Live 2024 Recap on Shibaura Machine’s Digital Twins and Virtual Reality

ELK GROVE VILLAGE, IL, May 28, 2024 - At the recent Siemens Realize LIVE 2024 event, Shibaura Machine Company, America presented on the transformative potential of digital twins and virtual reality (VR) to further collaborative user engagement and optimize...

Read moreExplore Collaborative VR and Digital Twins with Shibaura Machine at Siemens Realize Live 2024

ELK GROVE VILLAGE, IL, April 23, 2024 - Join Shibaura Machine at the much-anticipated Siemens Realize LIVE 2024, held at Mandalay Bay Convention Center, Resort and Casino in Las Vegas, Nevada from May 13-16, where we’ll be showcasing how we’re harnessing S...

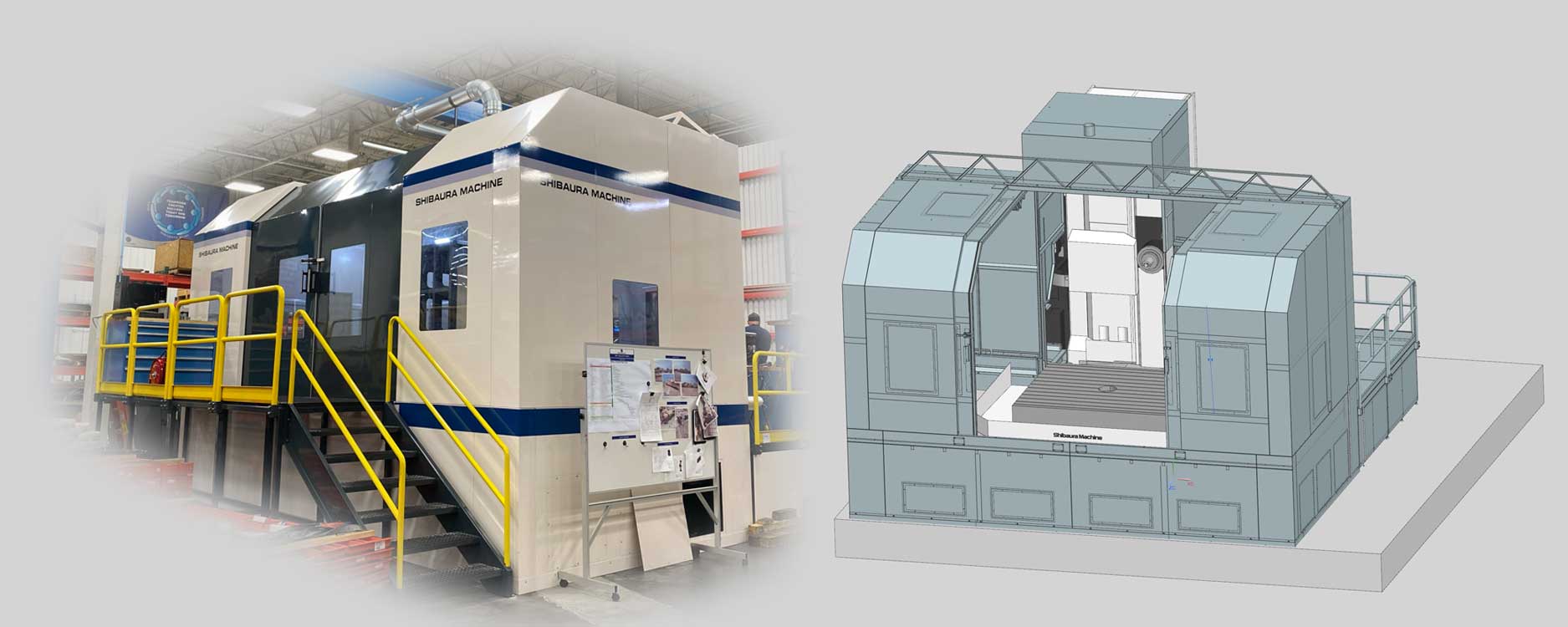

Read moreThe Foundation of Manufacturing Excellence: A Strong Machine Tool Factory Presence

ELK GROVE VILLAGE, IL, March 26, 2024 - The machine tool industry is a cornerstone of North American manufacturing. It powers sectors from automotive to aerospace with the precision and efficiency needed to compete on a global scale. In this dynamic landsc...

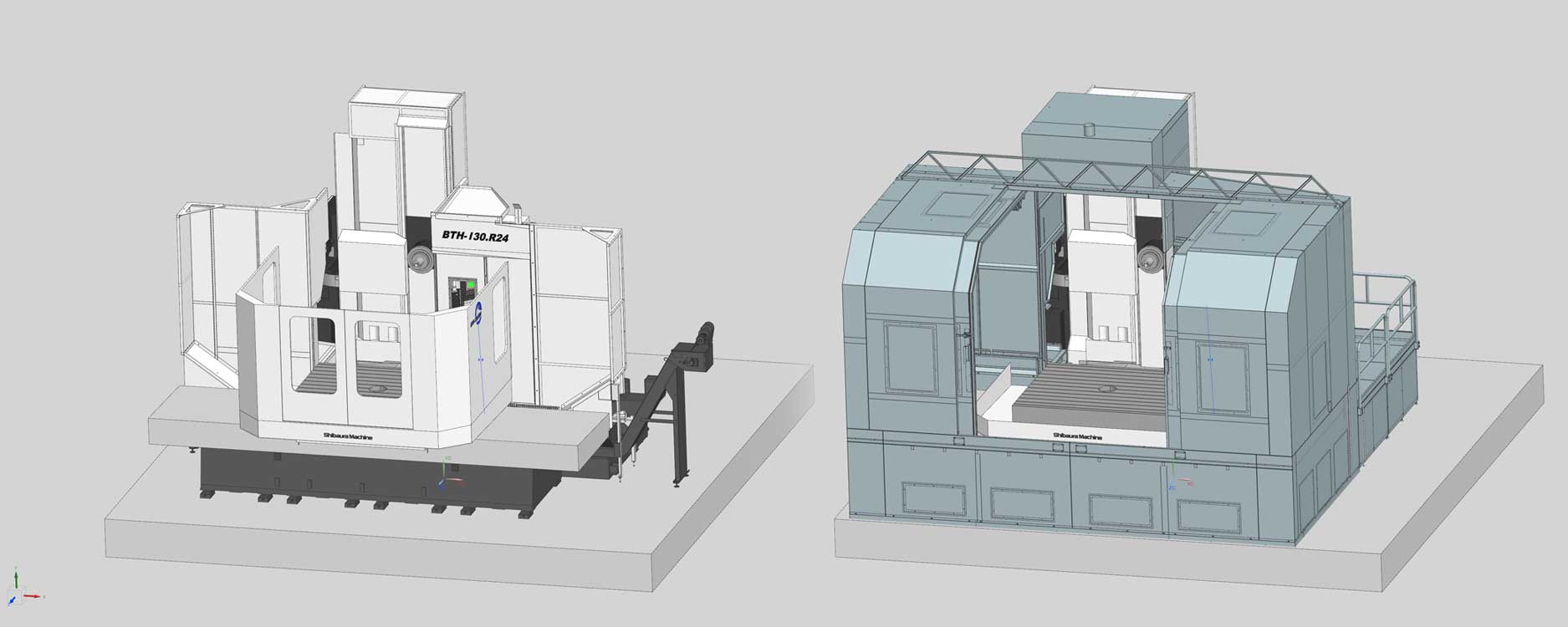

Read moreA Closer Look: Understanding the Benefits of Full Enclosures for Horizontal Boring Machines

ELK GROVE VILLAGE, IL, March 19, 2024 - Horizontal boring machines are powerhouses in precision machining, known for their ability to handle big, tough jobs with incredible accuracy. As technology evolves, so do the features that make these machine tools s...

Read moreWhat to Consider When Looking at Full Enclosures for Your Horizontal Boring Machine

ELK GROVE VILLAGE, IL, March 5, 2024 - The adoption of horizontal boring machines equipped with full enclosures marks a significant stride in manufacturing towards operational excellence and safety. As businesses strive to enhance their manufacturing capab...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools