Unleashing Production Potential with Multi-Pallet Integration in BTH-Series Horizontal Boring Machines

ELK GROVE VILLAGE, IL, August 29, 2023 -

In modern manufacturing, efficiency and adaptability are not just buzzwords; they're a cornerstone of success. As factories expand production mix and volume, new opportunities bring fresh challenges. A particular pain point for many is the increasing time required to construct multiple setups. This growth, while a sign of success, often reveals a bottleneck that hinders scalability and responsiveness.

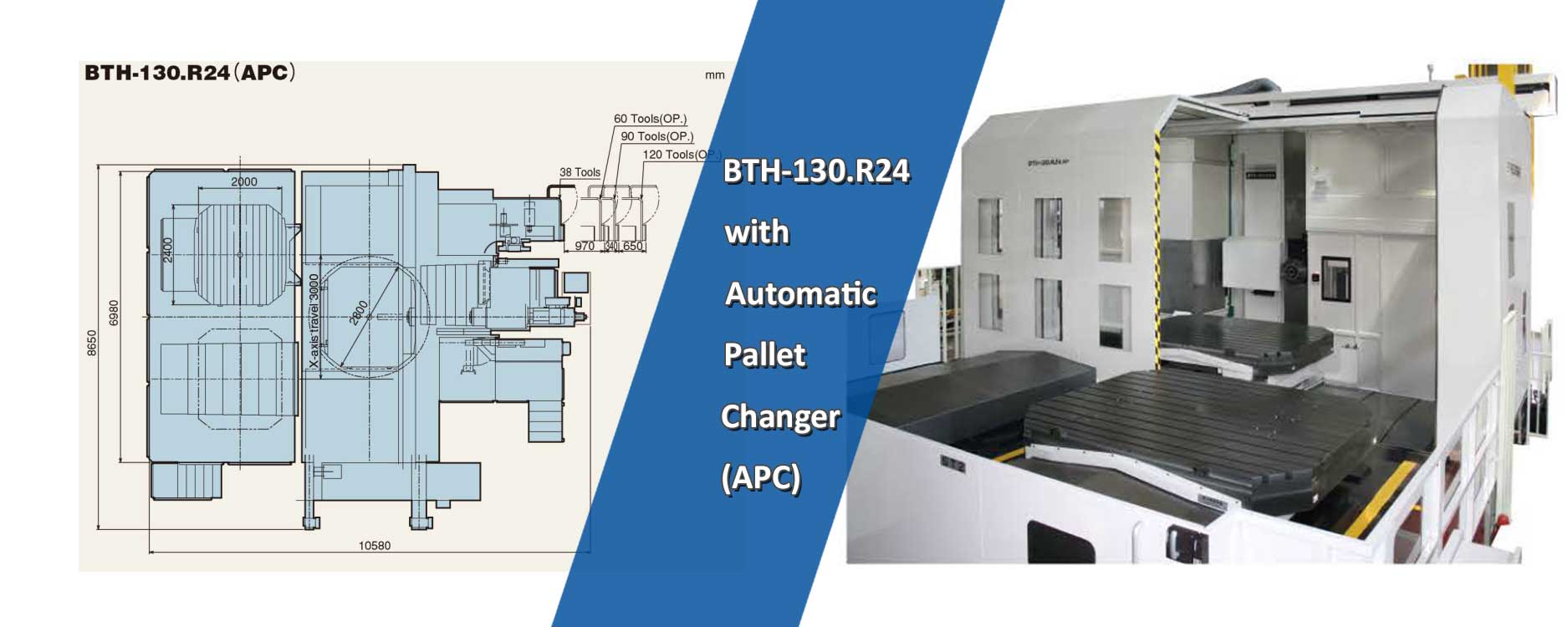

When it comes to producing large components with unmatched precision, Shibaura Machine’s BTH-Series horizontal boring machines coupled with an integrated multi-pallet system provides a combination that addresses this challenge. By alleviating the time-consuming nature of multiple setups, this combination not only elevates the capabilities of these machines but also tackles growth challenges, allowing for reduced manual handling, increased efficiency, and unprecedented flexibility.

Seamless Transition to Continuous Production

With a conventional horizontal boring machine (HBM), the workflow might be interrupted, waiting for manual loading and unloading of each workpiece. Now, picture a multi-pallet system integrated into that same HBM.

For example, the BTH-Series with a multi-pallet system ensures uninterrupted production. Managed by the machine controller, it allows the next workpiece to be staged while the current one is machined, thereby significantly boosting overall throughput.

Adaptability in a Fast-Changing World

The flexibility provided by a multi-pallet system is critical in industries such as aerospace, energy, and automotive where various components require precise machining. Different part sizes and shapes can be handled in succession without extensive setup changes.

The BTH-Series equipped with a multi-pallet system becomes a versatile tool, ready to adapt to different production demands. It's no longer just a specialized machine; it's a flexible solution capable of meeting today's manufacturer's diverse needs. This adaptability is crucial for handling varied production demands.

Redefining Efficiency and Quality

Automated pallet changing allows for HBMs to operate continuously without needing to be manually reset or reloaded. This eliminates the need for additional labor costs and increases efficiency by allowing for an uninterrupted production process.

Moreover, this automation ensures that each workpiece is handled with consistent precision, resulting in uniform quality across all products. In fields like medical equipment manufacturing, where exact tolerances are essential, this consistent handling ensures every part meets stringent standards.

Overcome Modern Manufacturing Challenges

Shibaura Machine's BTH-Series integrated with multi-pallet systems are an innovative stride in the manufacturing world. The blend of technology, design, and practical application offers a glimpse into the future of horizontal boring, where efficiency, precision, and adaptability reign supreme.

Learn how the multi-pallet system available for the BTH-Series horizontal boring machines can redefine your production capabilities.

Contact the Machine Tool team to learn more.

Related Articles View All Machine Tools Articles

5 Value Adds to Increasing Automation with the Multi-Pallet Magazine on the TMD Series

ELK GROVE VILLAGE, IL, August 22, 2023 - In manufacturing, staying ahead requires more than just meeting current demands – it requires a proactive anticipation of tomorrow's challenges. As the drive towards automation gains momentum, manufacturers are real...

Read moreEmbracing the Future: Shibaura Machine's Product Innovation in Multi-Tasking Equipment

ELK GROVE VILLAGE, IL, August 8, 2023 - As manufacturers seek to optimize efficiency and expand capabilities, multi-tasking machining centers have emerged as major innovations in the industry. These advanced machines integrate various machining operations ...

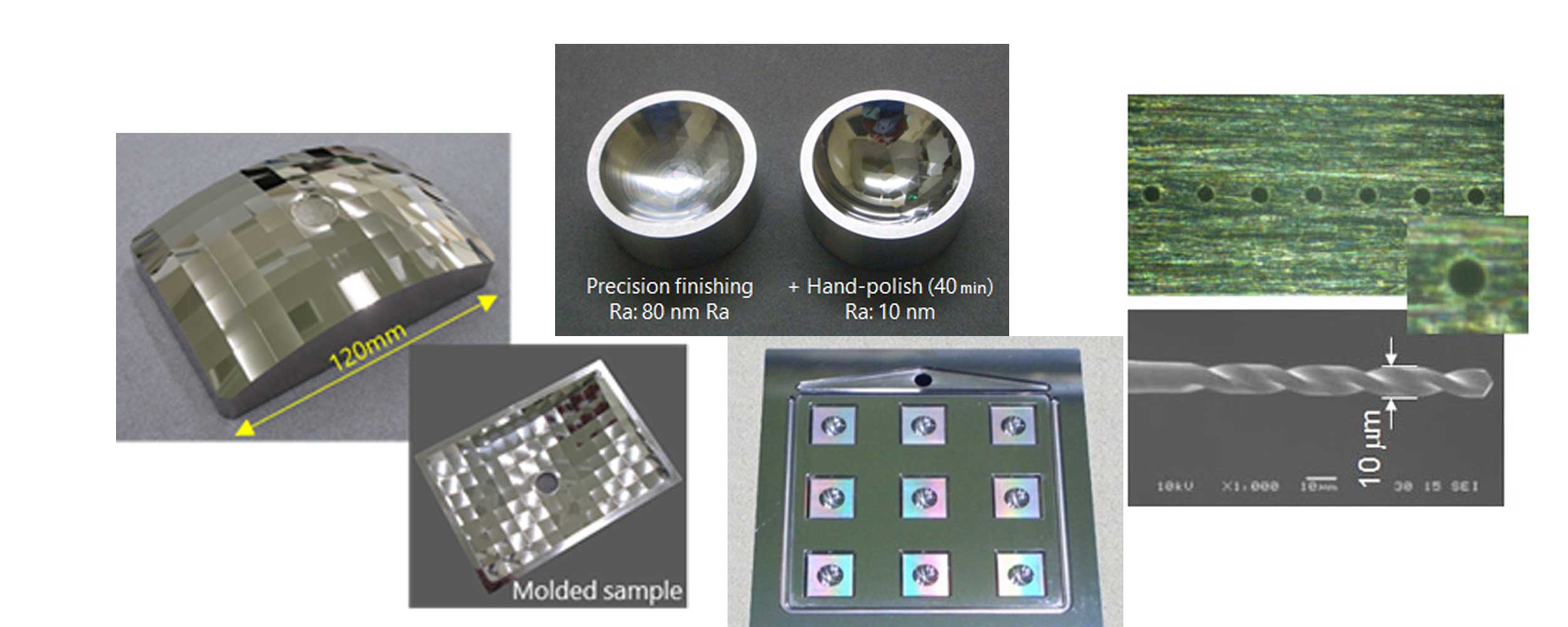

Read moreNano Machines Answer the Demand for High Precision Industrial Equipment Parts Production

ELK GROVE VILLAGE, IL, July 26, 2023 - In the world of industrial equipment manufacturing the importance of product quality cannot be overstated. While parts can vary widely depending on the specific industry and application, the overall quality influences...

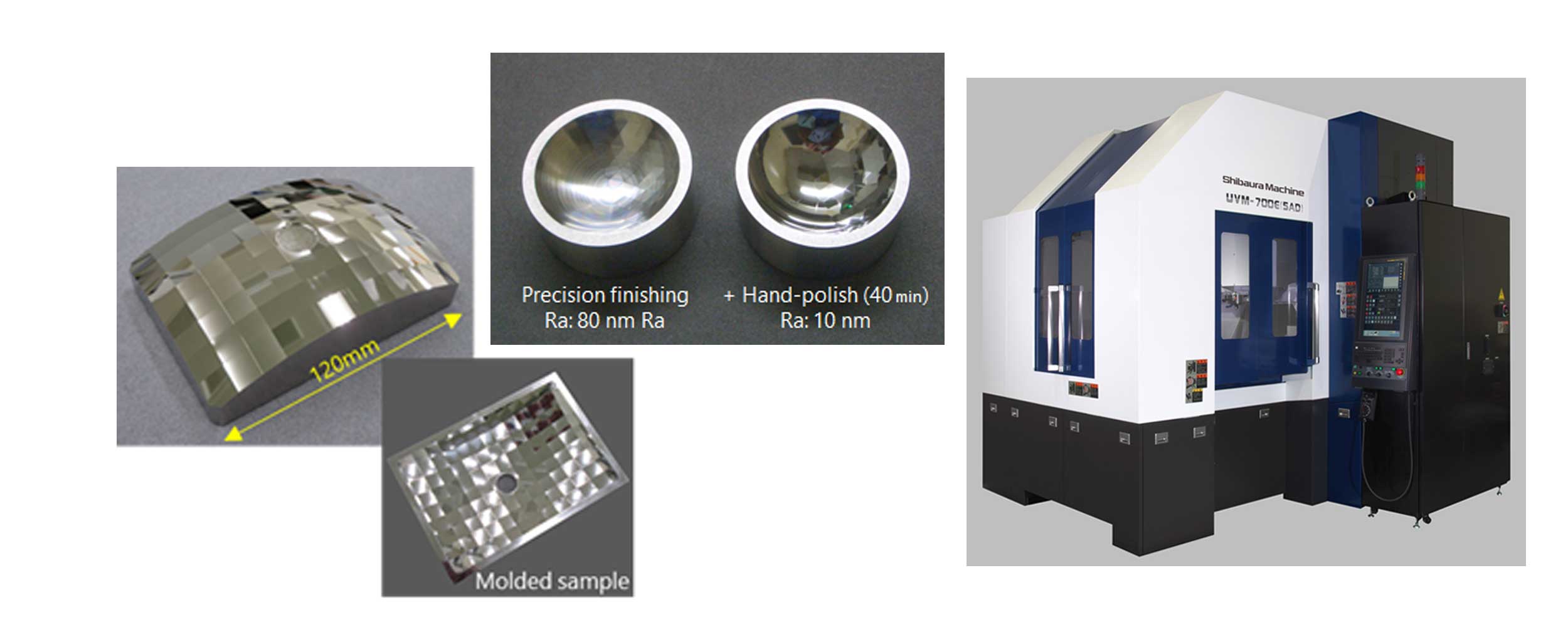

Read moreEnabling High Precision Machining with the UVM Series Nano Machines

ELK GROVE VILLAGE, IL, July 19, 2023 - Manufacturers continually seek innovative solutions to satisfy customer demands as industries increasingly require greater levels of precision, reliability, and complexity with their applications. Many are turning to ...

Read moreHow Manufacturers Can Meet the Demands of the Renewable Energy Market

ELK GROVE VILLAGE, IL, July 12, 2023 - As the world prioritizes sustainability and environmental responsibility, the renewable energy sector is undergoing a significant transformation. Countries and industries worldwide are seeking cleaner and more sustain...

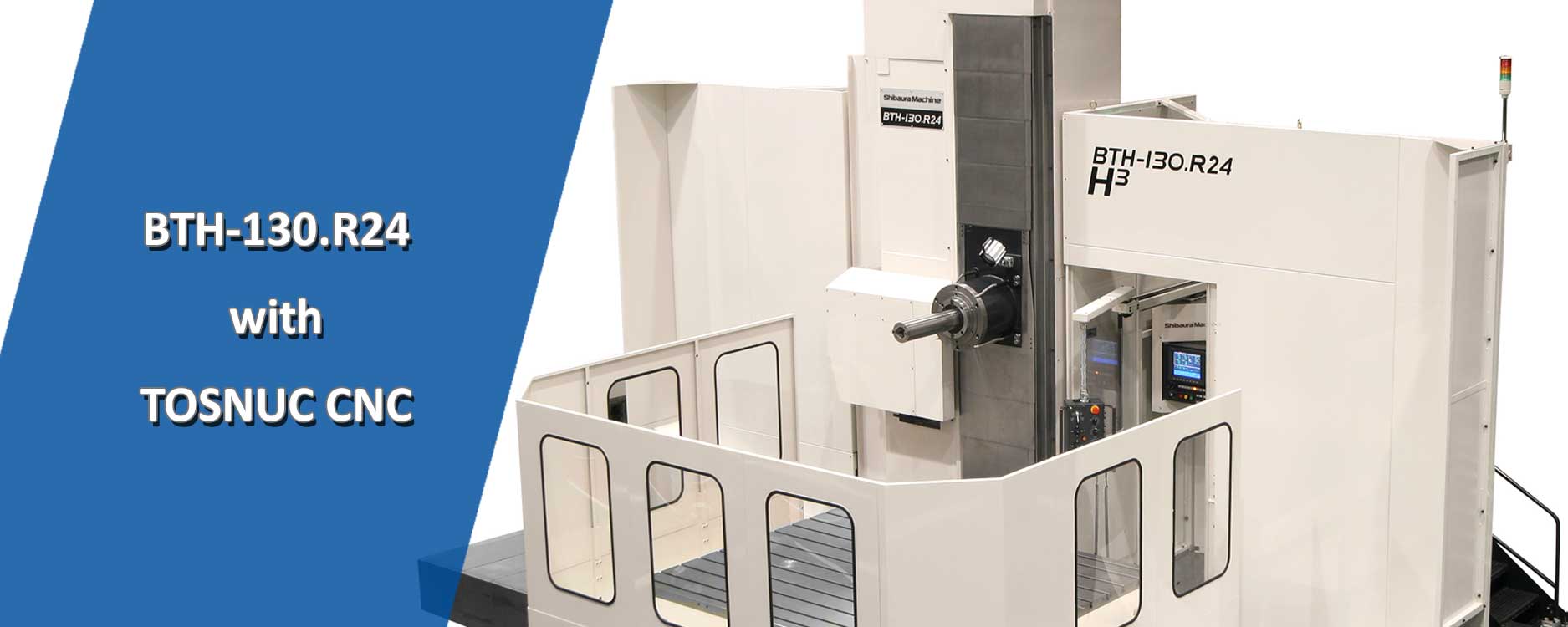

Read moreEmpowering Manufacturers: The BTH-130.R24 and TOSNUC Control System for Precision, Efficiency, and Operational Ease

ELK GROVE VILLAGE, IL, June 27, 2023 - Precision, efficiency, and ease of operation are paramount for manufacturers seeking to gain a competitive edge. Are you taking full advantage of the capabilities of your TOSNUC control system when it comes to your BT...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools