How Manufacturers Can Meet the Demands of the Renewable Energy Market

ELK GROVE VILLAGE, IL, July 12, 2023 -

As the world prioritizes sustainability and environmental responsibility, the renewable energy sector is undergoing a significant transformation. Countries and industries worldwide are seeking cleaner and more sustainable alternatives to traditional energy sources, in line with the United Nations' Sustainable Development Goals. Manufacturers that embrace the shift towards renewable energy and adapt their strategies accordingly stand to gain substantial advantages in this evolving market.

For that reason, Shibaura Machine continues to focus on being at the forefront of this renewable energy revolution, offering innovative solutions to support the transition to a greener future.

Wind Turbine Components: Harnessing Precision & Power

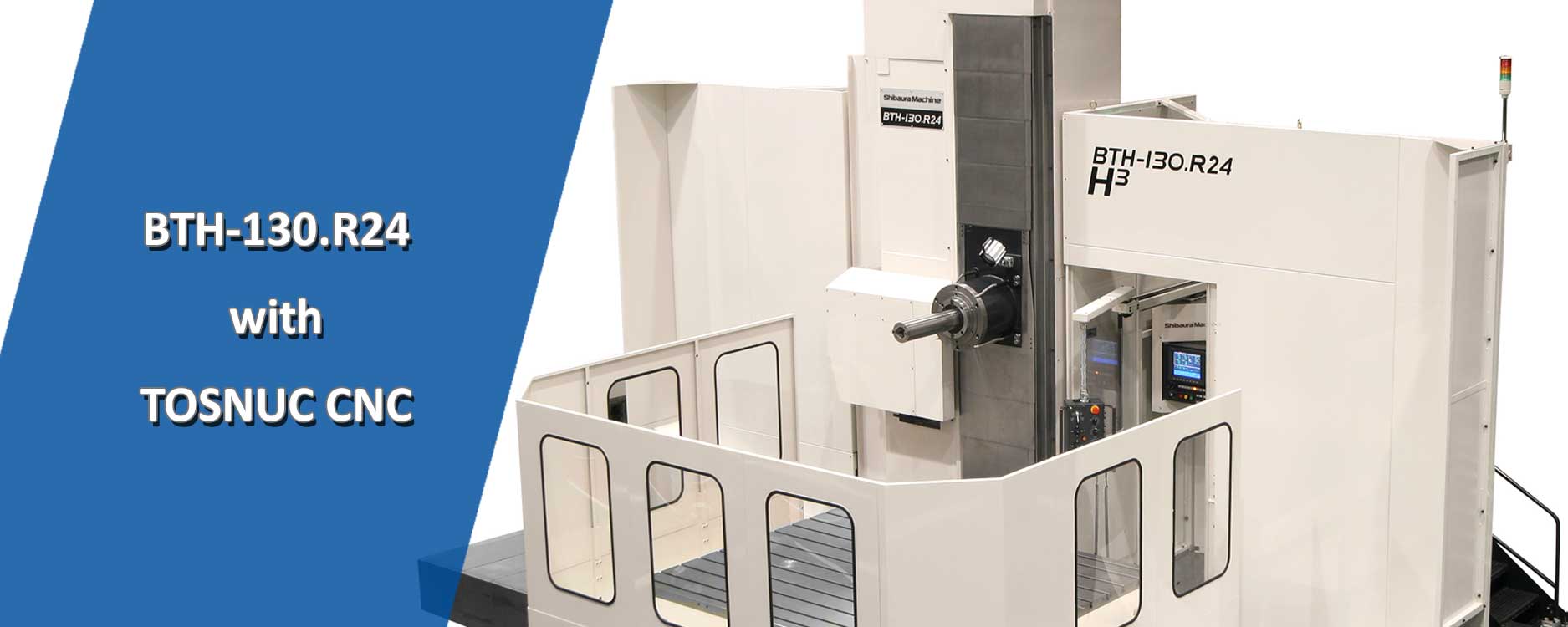

Wind energy is a rapidly growing sector within the renewable energy landscape. In response, many manufacturers are taking on jobs producing wind turbine components. Shibaura Machine's machine tools excel at meeting critical requirements for wind turbine components. For example, the BTH-130.R24 of large horizontal boring machines allows for the efficient production of complex surfaces found in wind turbine components.

These tools are designed to prioritize precision and accuracy, enabling manufacturers to achieve tight tolerances and dimensional control in their production processes. With the robust, rigid design of the machine tools, stability is further enhanced during heavy-duty machining, ensuring the durability and reliability of wind turbine components. With high versatility and flexibility these machine tools accommodate various geometries and complexities required for different wind turbine parts.

Electric Vehicle Powertrain Parts: Driving the Future of Mobility

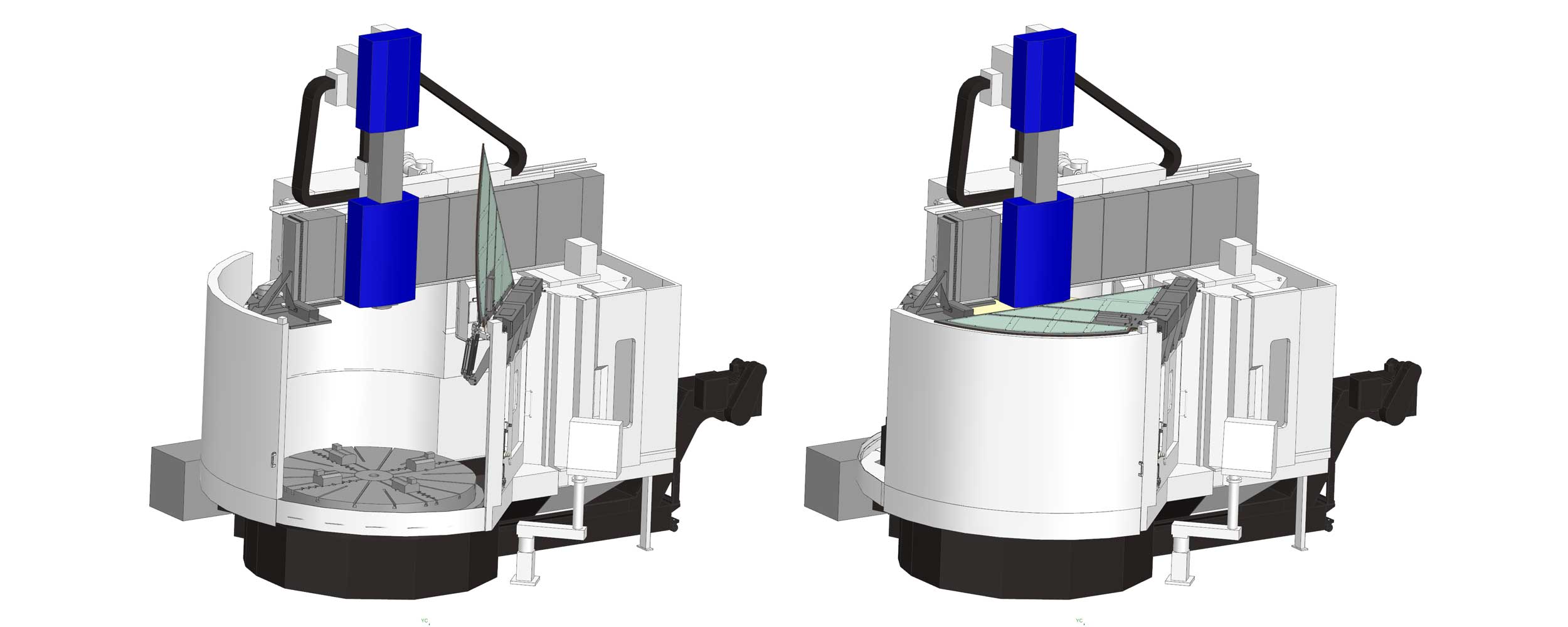

Machine tools continue to play a large role in the automotive industry, particularly as the electric vehicle (EV) market evolves. In response to the growing demand for electric vehicle components, Shibaura Machine has developed multiple machines that will enable 5-sided and 5-axis machining strategies for their production, which is especially useful for battery packs and other critical components. These machines allow automotive manufacturers to adapt quickly to the evolving product cycles required for electric vehicles.

Specifically, Shibaura Machine’s MP-2620(U) double-column type multi-tasking machining center is a high precision tool that can be used for multiple operations. It enhances operating margins on existing workpieces, secures additional work, and improves productivity, empowering manufacturers to meet the requirements for EV part production efficiently.

Adapting to Changing Market Trends

As major players in the energy sector transition away from traditional energy sources towards alternative renewable sources, the industry is undergoing significant changes. These transformations require different components, resulting in new requirements and increased demand for manufacturers. Shibaura Machine recognizes these market trends and actively adapts its strategies to align with emerging opportunities.

By collaborating with Shibaura Machine, manufacturers can harness the potential of the renewable energy market and position themselves as leaders in sustainable manufacturing. To learn more about Shibaura Machine's solutions and the role they play in driving renewable energy transformation, contact the Machine Tool team.

Related Articles View All Machine Tools Articles

Empowering Manufacturers: The BTH-130.R24 and TOSNUC Control System for Precision, Efficiency, and Operational Ease

ELK GROVE VILLAGE, IL, June 27, 2023 - Precision, efficiency, and ease of operation are paramount for manufacturers seeking to gain a competitive edge. Are you taking full advantage of the capabilities of your TOSNUC control system when it comes to your BT...

Read moreDriving Success in High Mix Low Volume Production: Multi-Tasking Machines and Attachment Changers as Key Enablers

ELK GROVE VILLAGE, IL, June 19, 2023 - In the ever-changing landscape of manufacturing, businesses face the challenge of adapting to diverse customer demands while maintaining operational efficiency. High mix low volume (HMLV) production has emerged as a g...

Read moreFlexibility as a Competitive Advantage: Embracing the Latest Trends in Machine Tools

ELK GROVE VILLAGE, IL, June 5, 2023 - Global trends in the machine tool industry are leaning towards greater flexibility, driven by the evolving needs and demands of manufacturers across various sectors. Traditionally, machine tools were designed for speci...

Read moreWhen Size Does Not Determine Accuracy: Breaking Stereotypes with Large Machine Tools

ELK GROVE VILLAGE, IL, May 30, 2023 - In the world of machine tools, precision is often associated with smaller workzone machines or those with limited travel or reach. It's as if the prevailing belief is that accuracy diminishes as the size and scope of t...

Read moreHow the BSF-150C Floor-Type Boring and Milling Machine Enhances Accuracy in Large Workpiece Machining

ELK GROVE VILLAGE, IL, May 23, 2023 - As the demand for high cutting performance, less downtime, and improved productivity increases for machining medium and large-sized parts, floor-type horizontal boring and milling machines have become more popular. Shi...

Read moreThe Smart Choice for Chip and Coolant Management: Introducing the TUE Series Top Cover

ELK GROVE VILLAGE, IL, May 9, 2023 - As technology continues to evolve, so do the challenges that arise in the manufacturing industry. One of the challenges that persist is managing coolant and chips in the machining process. Having a well-designed chip an...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools