Embracing the Future: Shibaura Machine's Product Innovation in Multi-Tasking Equipment

ELK GROVE VILLAGE, IL, August 8, 2023 -

As manufacturers seek to optimize efficiency and expand capabilities, multi-tasking machining centers have emerged as major innovations in the industry. These advanced machines integrate various machining operations into a single platform, streamlining processes and enhancing productivity. This technology saves time, money, and resources, while improving quality control and accuracy, transforming manufacturers' approach to complex projects.

Transforming Manufacturing with Multitasking Machining Centers

Multi-tasking machine tools are becoming increasingly popular in the manufacturing industry and are expected to be the standard in the future. As industry demands grow more sophisticated, these machines provide the much-needed versatility to navigate challenges with ease. Below are examples of the latest innovations manufacturers can expect with multi-tasking machines and how Shibaura Machine is developing equipment designed to meet modern industry needs.

Integrated Automation for Seamless Operations

One of the key product innovations in Shibaura Machine's multi-tasking machining centers is their integration of advanced automation features. These machines come equipped with pallet loading and unloading systems, and tool changers. Automation ensures continuous unmanned operation, reduces manual labor, and significantly enhances production efficiency. Manufacturers can run their machines around the clock, boosting throughput and productivity.

High Throughput Machining for Faster Cycle Times

With cutting-edge spindle technology, optimized cutting tools, and precision control systems, these machines achieve faster cutting speeds, resulting in reduced cycle times and increased output. For example, Shibaura Machine's MP-2620 (U) mill-turn machining center delivers high throughput machining capabilities whether it's milling, turning, or drilling. The throughput machining feature ensures efficient manufacturing without compromising quality.

Multi-Tasking Machining for Complex Geometries

Another notable product innovation is the MPJ-M double column type machines that can be used as 5-axis machining centers. For example, these multitasking centers incorporate attachments along with the automatic attachment changer to enable simultaneous and complex machining of intricate geometries. As a result, manufacturers can achieve high-precision parts with minimal setup, reducing production time and costs significantly.

User-Friendly Interfaces for Enhanced Efficiency

Understanding the importance of ease-of-use, Shibaura Machine has developed user-friendly interfaces for their multitasking machining centers with both TOSNUC or FANUC CNC controllers; machinists can program and control the machines effortlessly, simplifying complex processes and minimizing the learning curve. The intuitive interface ensures operators can optimize productivity without wasting valuable time on complex setups.

Simplify Modern Manufacturing

Multi-tasking machining centers have the ability to transform manufacturers' approach to complex projects. As industry demands continue to evolve, Shibaura Machine's commitment to innovation ensures that their multitasking machining centers remain at the forefront of cutting-edge technology, providing manufacturers with the tools they need to excel in a competitive global market.

Contact the Machine Tool team to learn more.

Related Articles View All Machine Tools Articles

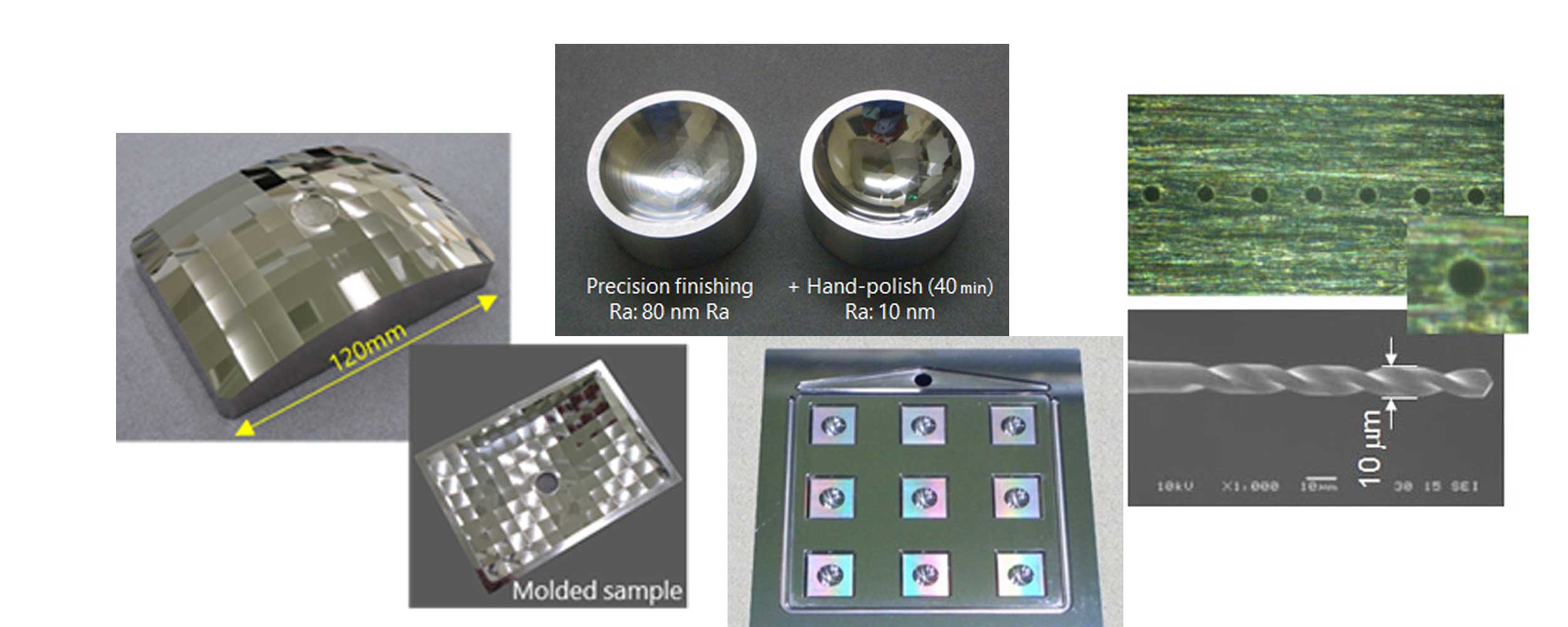

Nano Machines Answer the Demand for High Precision Industrial Equipment Parts Production

ELK GROVE VILLAGE, IL, July 26, 2023 - In the world of industrial equipment manufacturing the importance of product quality cannot be overstated. While parts can vary widely depending on the specific industry and application, the overall quality influences...

Read moreEnabling High Precision Machining with the UVM Series Nano Machines

ELK GROVE VILLAGE, IL, July 19, 2023 - Manufacturers continually seek innovative solutions to satisfy customer demands as industries increasingly require greater levels of precision, reliability, and complexity with their applications. Many are turning to ...

Read moreHow Manufacturers Can Meet the Demands of the Renewable Energy Market

ELK GROVE VILLAGE, IL, July 12, 2023 - As the world prioritizes sustainability and environmental responsibility, the renewable energy sector is undergoing a significant transformation. Countries and industries worldwide are seeking cleaner and more sustain...

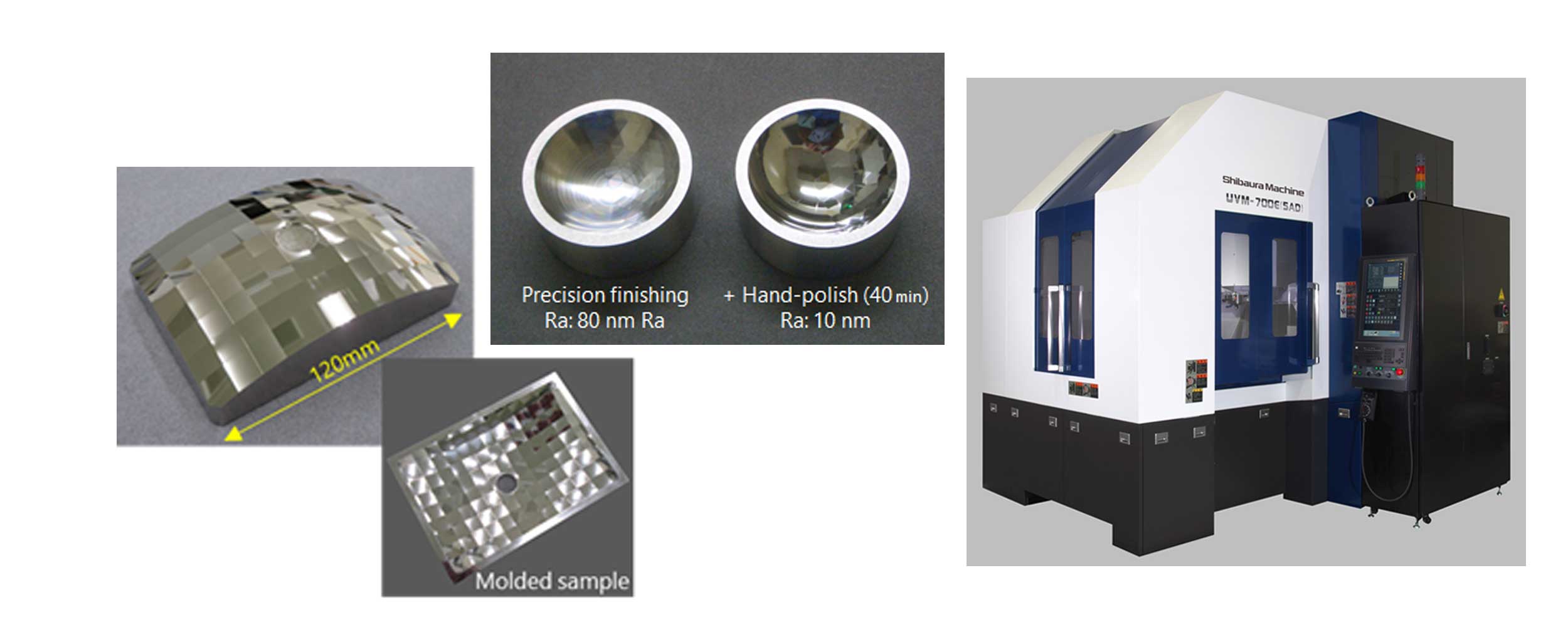

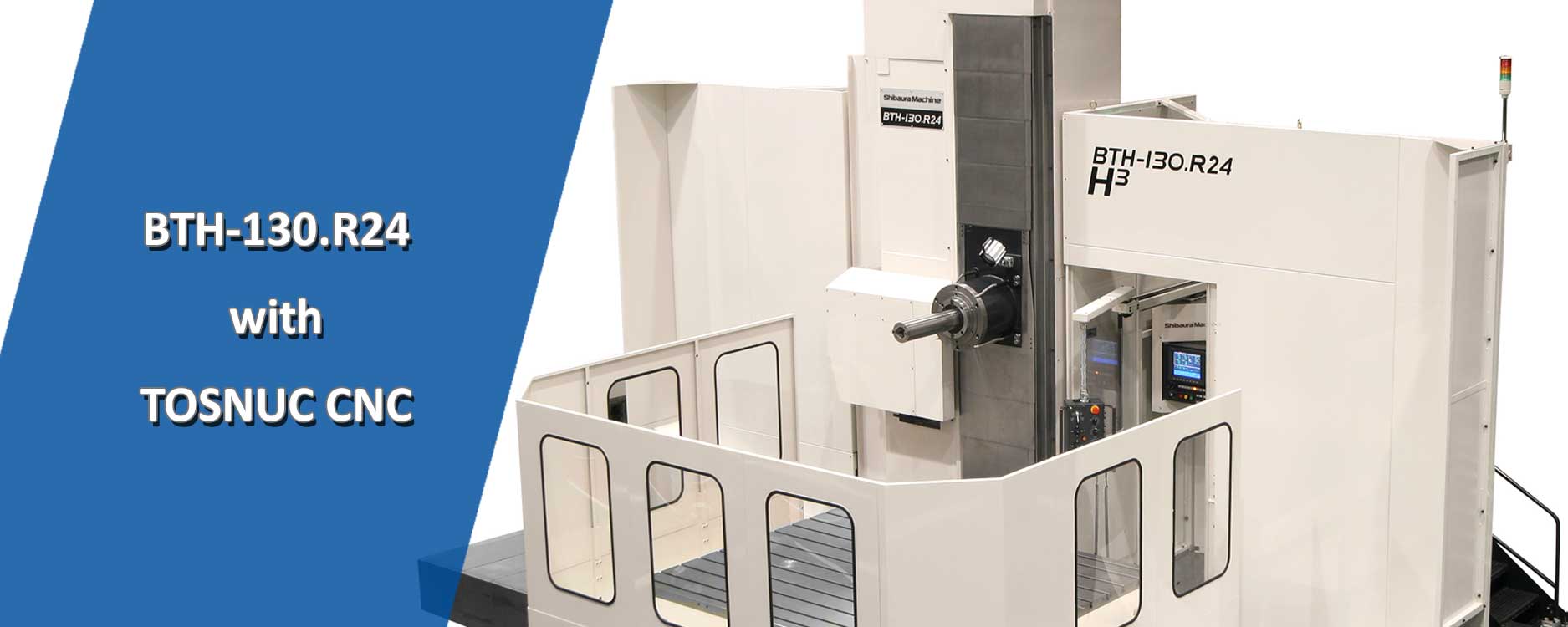

Read moreEmpowering Manufacturers: The BTH-130.R24 and TOSNUC Control System for Precision, Efficiency, and Operational Ease

ELK GROVE VILLAGE, IL, June 27, 2023 - Precision, efficiency, and ease of operation are paramount for manufacturers seeking to gain a competitive edge. Are you taking full advantage of the capabilities of your TOSNUC control system when it comes to your BT...

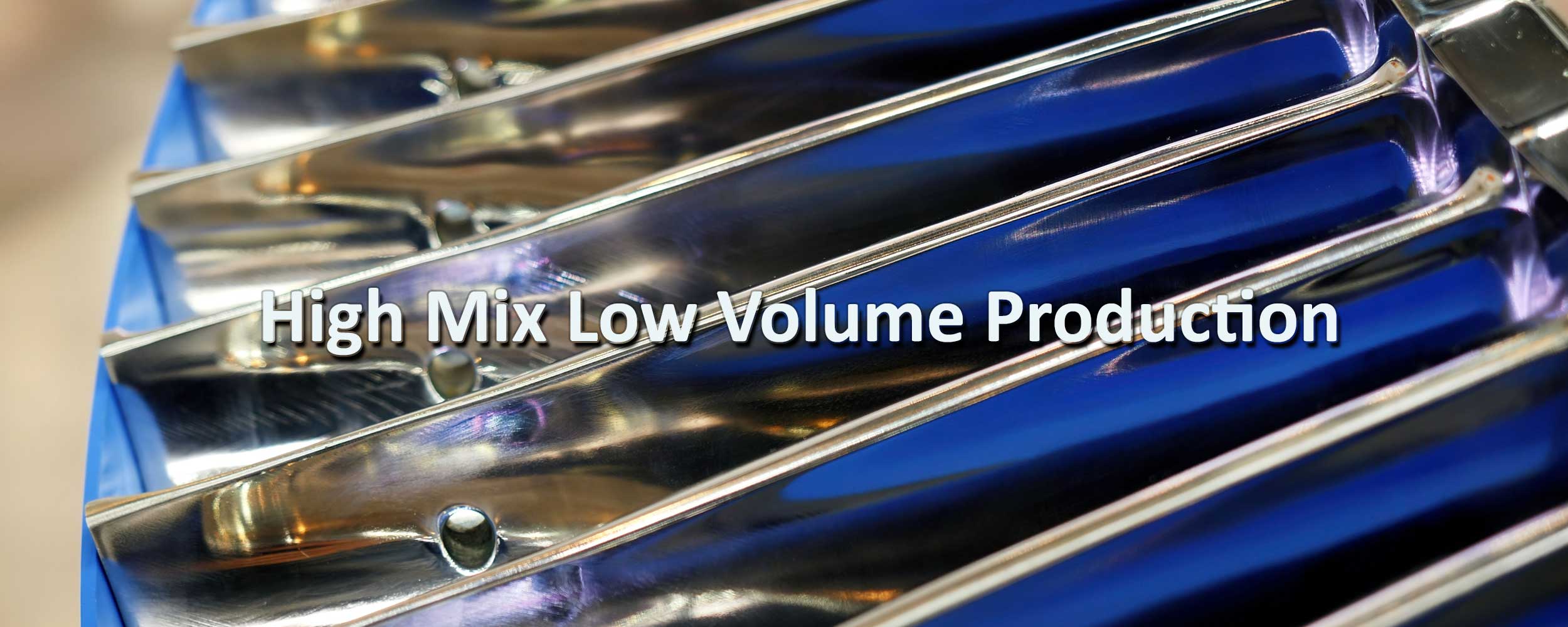

Read moreDriving Success in High Mix Low Volume Production: Multi-Tasking Machines and Attachment Changers as Key Enablers

ELK GROVE VILLAGE, IL, June 19, 2023 - In the ever-changing landscape of manufacturing, businesses face the challenge of adapting to diverse customer demands while maintaining operational efficiency. High mix low volume (HMLV) production has emerged as a g...

Read moreFlexibility as a Competitive Advantage: Embracing the Latest Trends in Machine Tools

ELK GROVE VILLAGE, IL, June 5, 2023 - Global trends in the machine tool industry are leaning towards greater flexibility, driven by the evolving needs and demands of manufacturers across various sectors. Traditionally, machine tools were designed for speci...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools