Enabling High Precision Machining with the UVM Series Nano Machines

ELK GROVE VILLAGE, IL, July 19, 2023 -

Manufacturers continually seek innovative solutions to satisfy customer demands as industries increasingly require greater levels of precision, reliability, and complexity with their applications. Many are turning to nano processing capabilities for navigating this market requiring sophisticated manufacturing technologies.

Although many machine tools provide high-quality components individually, nano processing is unique in that the entire machine is of the highest quality. It is possible for machinists not only to maintain tight profile tolerances and exceed surface finish requirements, but also to increase speeds and feed rates. Supporting high-speed machining with superior accuracy, this technology is ideal for production of parts such as medical implants, aerospace components, and automotive components. It is also capable of machining multiple features in one set up, making it a more cost-effective solution for complex parts.

Shibaura Machine’s UVM series of nano machines combines the power of nano technology with exceptional high precision and efficiency.

Advanced Technology for Maximum Precision and Performance

The machine's high precision and quick production capabilities are made possible by its carefully engineered components. For instance, the machine incorporates an air bearing spindle capable of rotating at 60,000 RPM and a thermal stabilizing system that provides temperature stability. This unique combination of high spindle speed and low heat generation significantly improves machining efficiency while ensuring exceptional surface quality. UVM series machines also feature linear motor axes instead of traditional mechanical axes further contributing to faster acceleration, greater accuracy, and higher throughput.

Additionally, the UVM series is equipped with multiple automation features. For example, a versatile in-house software tool called UVM-TSA facilitates high precision machining and automation, and FormEye® accurately measures cutter contours even during high-speed rotations. An imaging-type workpiece measuring system, called "ShapeEye," allows for precise tailoring of fine shapes that cannot be reached using touch probes and with the help of "VectPath" the machine is equipped to compensate for machining errors, reducing the need for re-modeling and re-generation of the tool path, ultimately reducing the number of tools needed.

Optimizing Performance and Cost

Compared to conventional machines, the UVM series is designed to lower running costs while offering significant improvements in quality. This is achieved by incorporating a variety of technologies, such as high-speed spindles, advanced motion control, and a high-precision rotary table into the system. By combining these innovations into a single machine, manufacturers benefit from accelerated and more precise machining operations, along with improved energy efficiency and cost savings.

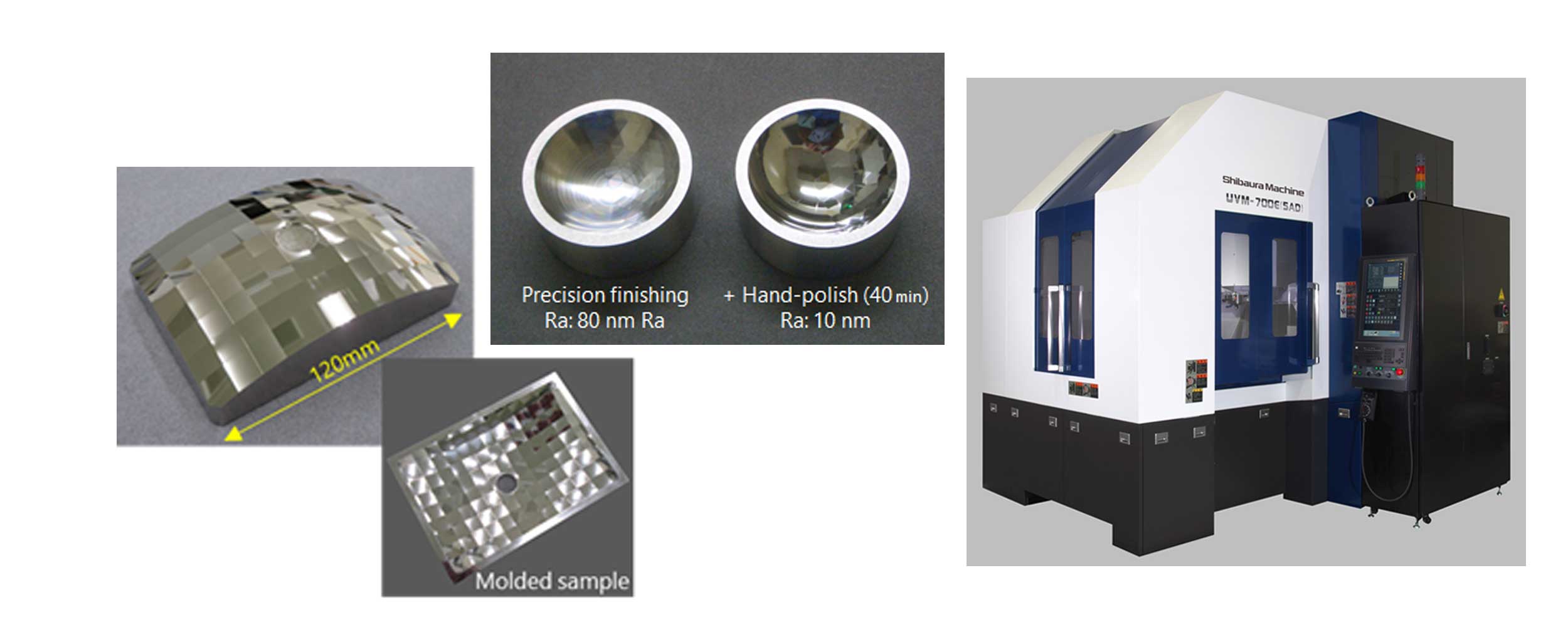

An excellent example of the UVM series' capabilities lies in its application to optical lens molds and medical equipment. Through its high-speed micro-pattern machining system, manufacturers can achieve intricate patterns and superior surface finishes with exceptional accuracy, surpassing conventional machines' limitations. This technology opens up new avenues for manufacturers to produce complex components cost effectively with unparalleled precision.

Driving Manufacturing Excellence

Shibaura Machine is dedicated to ensuring our customers can meet the unique challenges of manufacturing, providing appropriate machining systems to support growth. Recognized as a respected manufacturer of "mother machines" for over a century, the UVM series exemplifies our commitment to world-class engineering, empowering manufacturers across diverse industries to achieve remarkable results at the polar opposite “nano” level machining.

Take on the future of high precision manufacturing with confidence by harnessing the power of Shibaura Machine's nano machines. Contact the Machine Tool team to learn more.

Related Articles View All Machine Tools Articles

How Manufacturers Can Meet the Demands of the Renewable Energy Market

ELK GROVE VILLAGE, IL, July 12, 2023 - As the world prioritizes sustainability and environmental responsibility, the renewable energy sector is undergoing a significant transformation. Countries and industries worldwide are seeking cleaner and more sustain...

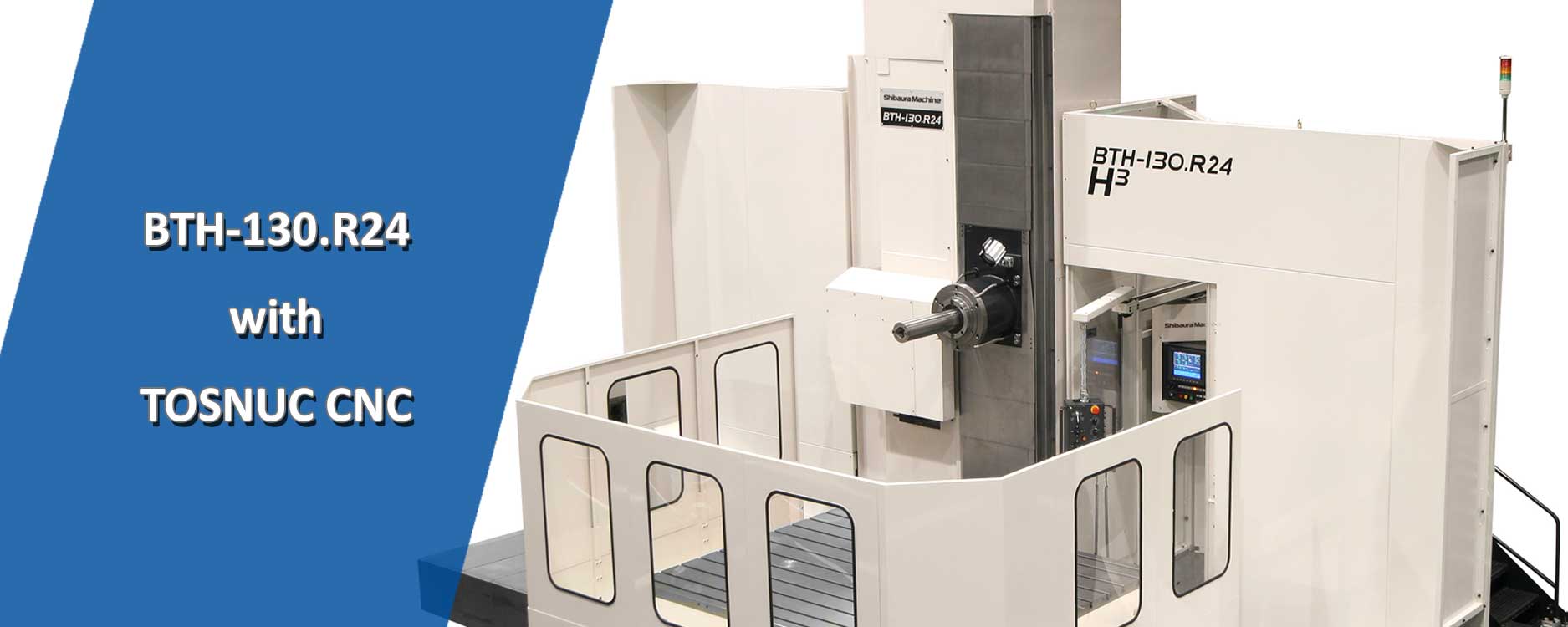

Read moreEmpowering Manufacturers: The BTH-130.R24 and TOSNUC Control System for Precision, Efficiency, and Operational Ease

ELK GROVE VILLAGE, IL, June 27, 2023 - Precision, efficiency, and ease of operation are paramount for manufacturers seeking to gain a competitive edge. Are you taking full advantage of the capabilities of your TOSNUC control system when it comes to your BT...

Read moreDriving Success in High Mix Low Volume Production: Multi-Tasking Machines and Attachment Changers as Key Enablers

ELK GROVE VILLAGE, IL, June 19, 2023 - In the ever-changing landscape of manufacturing, businesses face the challenge of adapting to diverse customer demands while maintaining operational efficiency. High mix low volume (HMLV) production has emerged as a g...

Read moreFlexibility as a Competitive Advantage: Embracing the Latest Trends in Machine Tools

ELK GROVE VILLAGE, IL, June 5, 2023 - Global trends in the machine tool industry are leaning towards greater flexibility, driven by the evolving needs and demands of manufacturers across various sectors. Traditionally, machine tools were designed for speci...

Read moreWhen Size Does Not Determine Accuracy: Breaking Stereotypes with Large Machine Tools

ELK GROVE VILLAGE, IL, May 30, 2023 - In the world of machine tools, precision is often associated with smaller workzone machines or those with limited travel or reach. It's as if the prevailing belief is that accuracy diminishes as the size and scope of t...

Read moreHow the BSF-150C Floor-Type Boring and Milling Machine Enhances Accuracy in Large Workpiece Machining

ELK GROVE VILLAGE, IL, May 23, 2023 - As the demand for high cutting performance, less downtime, and improved productivity increases for machining medium and large-sized parts, floor-type horizontal boring and milling machines have become more popular. Shi...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools