Driving Success in High Mix Low Volume Production: Multi-Tasking Machines and Attachment Changers as Key Enablers

ELK GROVE VILLAGE, IL, June 19, 2023 -

In the ever-changing landscape of manufacturing, businesses face the challenge of adapting to diverse customer demands while maintaining operational efficiency. High mix low volume (HMLV) production has emerged as a game-changing strategy for companies seeking to strike the right balance between customization and cost-effectiveness. This approach allows manufacturers to thrive in an era where customers increasingly expect customized products and shorter lead times.

Unlocking Effective High Mix Low Volume Batch Production

The challenge many manufacturers face is efficiently producing a wide variety of products in smaller quantities while maintaining productivity, flexibility, and cost-effectiveness. To meet these demands, advanced technologies such as multi-tasking machine tools and attachment changers have become invaluable assets.

Increased Productivity

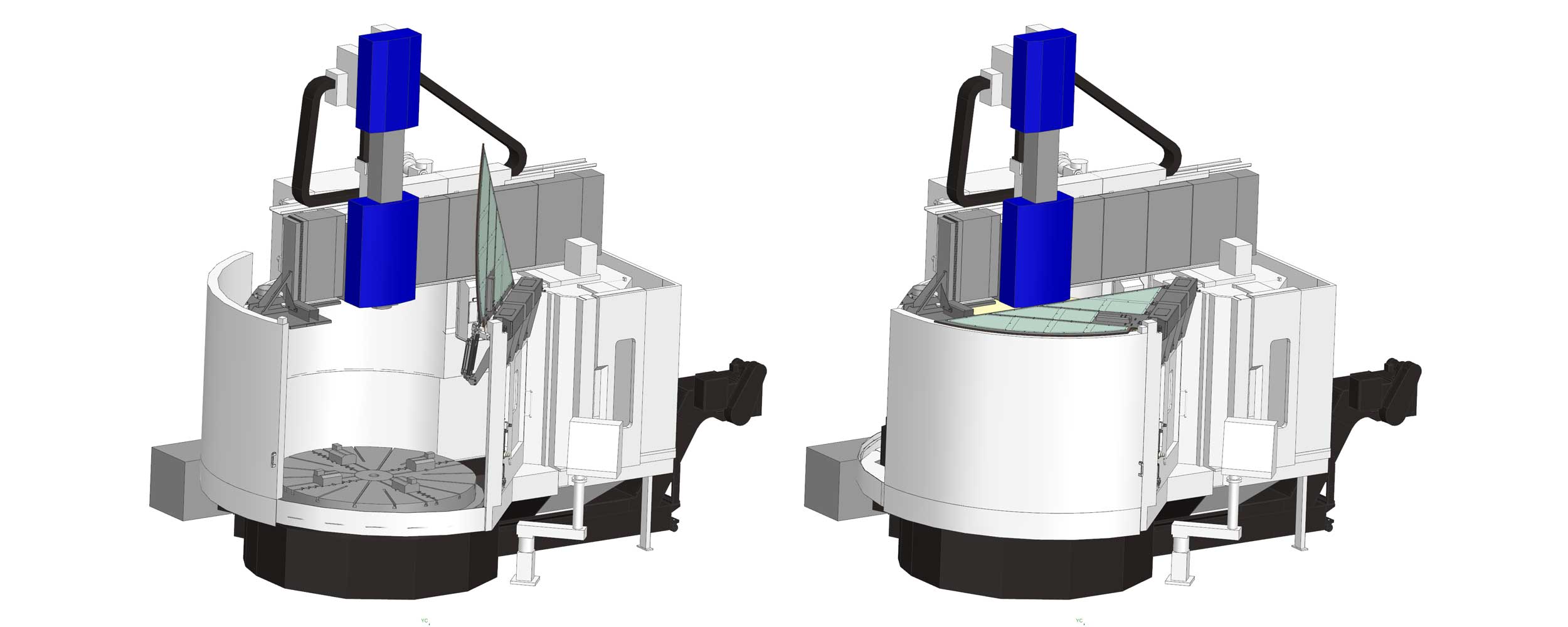

Multi-tasking machine tools combine multiple operations into a single setup, enabling simultaneous machining processes. This eliminates the need for manual transfers between different machines which improves workpiece quality while reducing cycle times. The MP-U Series from Shibaura Machine, for example, offers a wide range of machining capabilities, including horizontal boring, lathe machining, and 5-axis machining in a single machine.

Improved Flexibility

HMLV production requires frequent changes in product specifications. Multi-tasking machines excel in their ability to adapt to various part geometries and accommodate diverse production requirements. With their ability to perform multiple operations, these machines provide manufacturers with the flexibility to handle different product variants efficiently and quickly.

Streamlined Workflow

Attachment changers play a critical role in optimizing the workflow of HMLV batch production. These systems allow for the machine to quickly adapt to different machining tasks by switching the attachment, allowing for a change in orientation without manual intervention to suit the specific application. This allows for rapid tool changes and uninterrupted production flow, enabling operators to focus on other value-added tasks.

Precision and Accuracy

Maintaining consistent quality across various product variants is paramount in HMLV production. The MP-U Series with the addition of an attachment changer incorporates an advanced control system with high-quality design to deliver exceptional machining accuracy and repeatability, ensuring that every part meets stringent specifications.

Improved Resource Utilization

Multi-tasking machine tools optimize resource utilization by consolidating multiple operations into a single machine. This eliminates the need for multiple machinists and equipment. Additionally, attachment changers minimize idle time during tool changes, maximizing machine uptime and enhancing overall production efficiency.

Meet Your Customer Demands

As the demand for high mix, low volume batch production continues to grow, manufacturers are turning to solutions that can automate and optimize to address the associated challenges. Shibaura Machine's MP-U Series multi-tasking machine tools and attachment changer play a pivotal role in enabling efficient and cost-effective production of diverse product variants in smaller quantities.

Contact the Machine Tool team to learn more about how we are providing solutions to meet the evolving needs of the HMLV manufacturing landscape.

Related Articles View All Machine Tools Articles

Flexibility as a Competitive Advantage: Embracing the Latest Trends in Machine Tools

ELK GROVE VILLAGE, IL, June 5, 2023 - Global trends in the machine tool industry are leaning towards greater flexibility, driven by the evolving needs and demands of manufacturers across various sectors. Traditionally, machine tools were designed for speci...

Read moreWhen Size Does Not Determine Accuracy: Breaking Stereotypes with Large Machine Tools

ELK GROVE VILLAGE, IL, May 30, 2023 - In the world of machine tools, precision is often associated with smaller workzone machines or those with limited travel or reach. It's as if the prevailing belief is that accuracy diminishes as the size and scope of t...

Read moreHow the BSF-150C Floor-Type Boring and Milling Machine Enhances Accuracy in Large Workpiece Machining

ELK GROVE VILLAGE, IL, May 23, 2023 - As the demand for high cutting performance, less downtime, and improved productivity increases for machining medium and large-sized parts, floor-type horizontal boring and milling machines have become more popular. Shi...

Read moreThe Smart Choice for Chip and Coolant Management: Introducing the TUE Series Top Cover

ELK GROVE VILLAGE, IL, May 9, 2023 - As technology continues to evolve, so do the challenges that arise in the manufacturing industry. One of the challenges that persist is managing coolant and chips in the machining process. Having a well-designed chip an...

Read moreThe Multi-tasking Capabilities of the Mill-Turn Machine Tool

ELK GROVE VILLAGE, IL, April 25, 2023 - Transitioning between machine tools is one of the biggest challenges for machinists. This can result in human errors during setup and the accumulation of processing errors. As a solution, multi-tasking tools are beco...

Read moreExploring the Versatility of Dynamic Part Probing for CNC Machine Tools

ELK GROVE VILLAGE, IL, April 19, 2023 - Dynamic part probing is a powerful tool that has transformed the way CNC machine tools operate in manufacturing. By using sensors and software to collect and analyze data in real-time during the machining process, dy...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools