Find Your Ideal Chip Conveyor Set Up

ELK GROVE VILLAGE, IL, January 10, 2023 -

One way manufacturers can work to maximize machine tool output is with the use of a chip conveyor. Not only does it keep the workspace clean and clear of chips, but makes it easier for operators to access the machine tool allowing for improved efficiency and productivity. Back in 2021, we even wrote an entire article on the topic of improving chip filtration and the benefits of a chip conveyor that you can check out.

To ensure optimal operating performance, it is important to choose the appropriate type of conveyor or conveyor system for your specific chip/application. Making sure you have a properly sized chip conveyor that works for your application will not only help achieve desired operating efficiency, but improve output accuracy.

Setting Your Chip Conveyor Up For Success

Defining your application and its requirements will help guide your decision on the most suitable conveyor for your company's needs.

The type of conveyor you choose will depend on your application. Hinge belt conveyors are still the most common chip conveyor, largely because they can be modified to handle everything from heavy parts to tough scrap. This proven solution is suitable for a variety of materials, chip types, and chip loads.

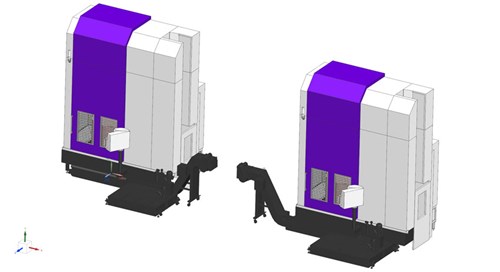

Having the right size conveyor on a machine tool will help ensure the efficiency and effectiveness of the machining process. A chip conveyor that is too small, may not be able to handle the volume of chips being produced, leading to a build-up of chips in the workspace. For example, a large horizontal boring machine requires a large space for installation and will produce high amounts of chips, so selecting a chip conveyor that can meet its workload is key to maximize the benefits. On the other hand, if the chip conveyor is too large for the machine tool, it may take up more space on the shop floor and also require more upkeep than needed for the job.

Additionally, consider if your conveyor offers added options and controls. Some conveyors are able to allow operators to regulate speeds for their application to help with chip load capacity and coolant carry-out. These types of features can extend conveyor service life, reduce wear, and improve the overall machining process.

Find Your Ideal Chip Conveyor Set-Up

By choosing the right chip conveyor for your job it is possible to improve output by effectively removing chips from the machining process and maintain a clean and safe workspace.

Contact the Machine Tool Tech Team to find your ideal chip conveyor arrangement.

Related Articles View All Machine Tools Articles

Get the Most Out of Your TOSNUC 999 CNC Controller

ELK GROVE VILLAGE, IL, January 04, 2023 - Going into 2023 are you taking advantage of everything your CNC control can do for you? The TOSNUC 999 provides plenty of manufacturing advantages with its user-friendly interface and functions. Designed with the m...

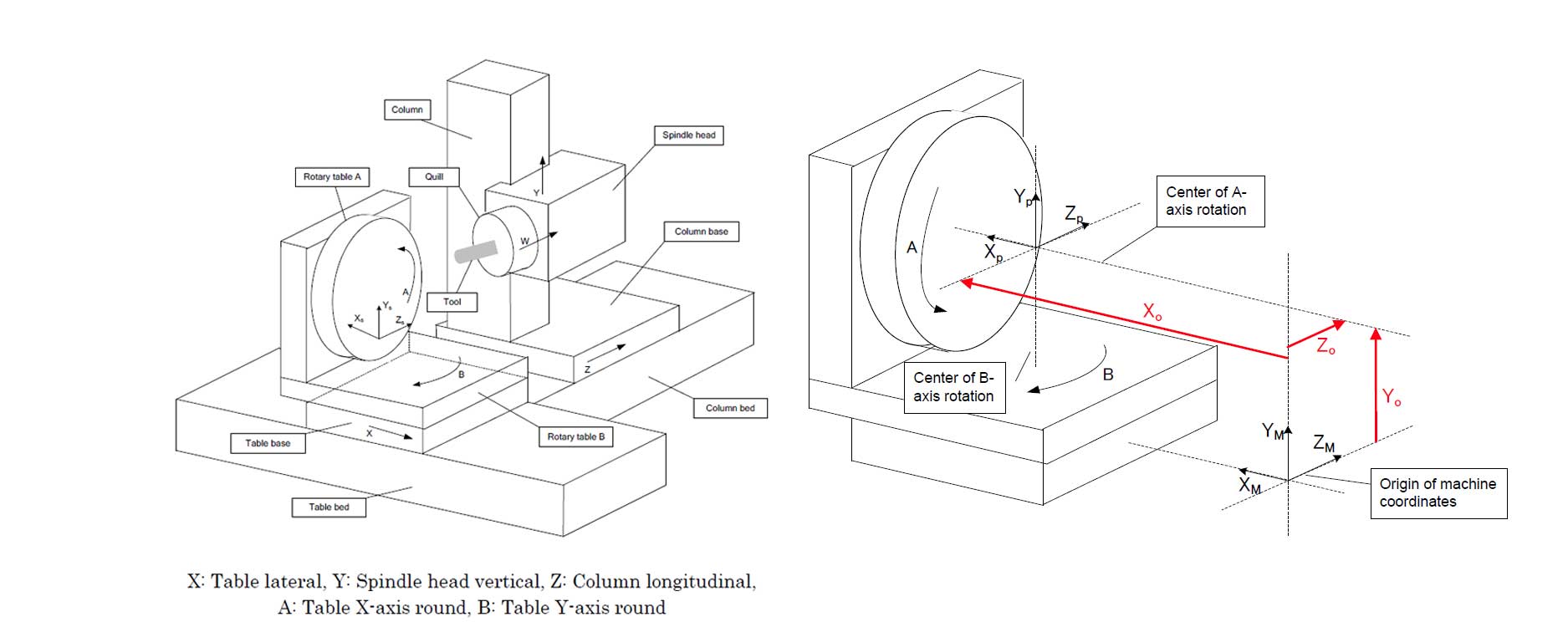

Read moreExpand your Horizontal Boring Machine Capabilities with Additional Axis Control

ELK GROVE VILLAGE, IL, December 14, 2022 - Depending on a parts’ geometry, having 5-axis machining can have a major impact on your productivity and quality. Being able to move the cutting tool along five axes allows for a high degree of flexibility and pre...

Read moreEnhance Your Machine Tools Performance With These FANUC CNC Control Options

ELK GROVE VILLAGE, IL, December 06, 2022 - Shibaura Machine is proud to offer machinists the FANUC CNC control as an option with many of our high performance machine tools. As a world-class technology leader in CNC control designs, the capabilities of toda...

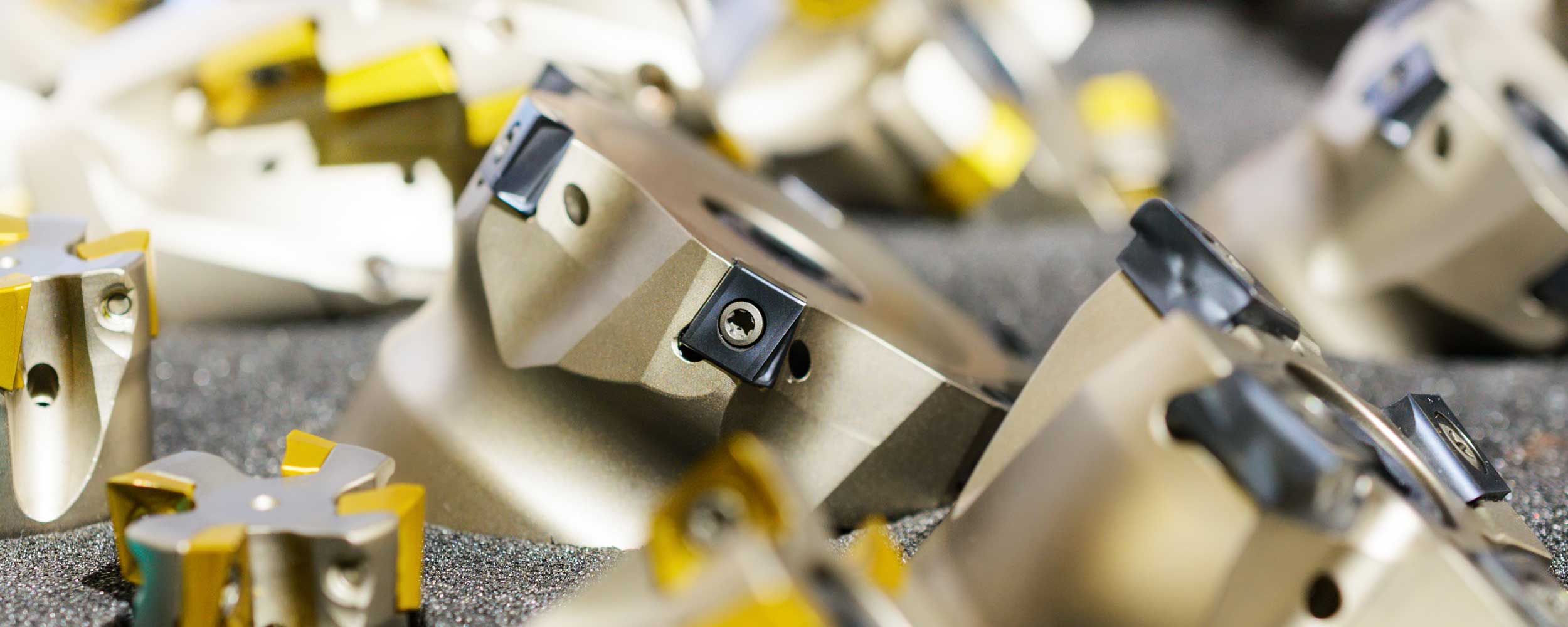

Read moreSaving on Perishable Tool Costs Starts with Machine Tool Quality

ELK GROVE VILLAGE, IL, November 30, 2022 - Every shop is challenged with ways to maximize revenue while minimizing costs. That is why when you are looking to make an investment on a new machine tool it goes way beyond the initial price tag. With extensive ...

Read moreTwin Ballscrew Axes Design Offers a High level of Positional Accuracy and Repeatability in Bridge Mill Machine Tool

ELK GROVE VILLAGE, IL, November 22, 2022 - On most milling or turning machine tools, single ballscrew axes designs are used in conjunction with guide surface for table travel, spindle-head travel and column travel. In order to achieve the high repeatabili...

Read moreThree Important Factors to Consider When Choosing a Machine Tool Manufacturer

ELK GROVE VILLAGE, IL, November 15, 2022 - Being able to plan and deliver predictable results is key to maintaining a competitive edge in manufacturing. When it comes to machine tools, the company you choose to purchase from plays a big role in ensuring th...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools