Enhance Your Machine Tools Performance With These FANUC CNC Control Options

ELK GROVE VILLAGE, IL, December 06, 2022 -

Shibaura Machine is proud to offer machinists the FANUC CNC control as an option with many of our high performance machine tools. As a world-class technology leader in CNC control designs, the capabilities of today’s FANUC control systems provide a variety of options to improve machine performance and capability. The control systems also have a variety of additional control options offering an array of benefits from increasing accuracy, reducing cycle time, and improving surface finish.

These additional control options offered on the FANUC expand the range of applications in which its machine tool can perform effectively. All of these options will change nothing about the design of the actual machine tool, as the functionality resides generally within the FANUC control.

Achieve More With FANUC Control Options

The FANUC CNC control is a powerful tool for customization, providing machine tool builders the flexibility to choose additional options to meet their customers requirements.

1. Increase Speed and Accuracy

While most machines are designed with either high speed or high accuracy, the high speed machining options provide capabilities such as look ahead, enhance acceleration/deceleration, and automatic feed rate controls to increase both the speed and accuracy in one.

2. Increase Program Storage

With the FANUC registered part programs addition, users will be able to store upwards of 1000 programs. This can be extremely beneficial for those using many small part programs, sub-programs, or macro programs.

3. Expand Part Programming Languages

The Custom Macro/Custom Macro B option makes it easy to create your own custom cycles or parametric family parts programs. With its error-proof processes and data entry, programmers can quickly improve the machining process. This option includes program flow control, math and logic functions, and local and system variables, plus application for probing.

Some more of the most common options include additional part program memory, 999 tool offsets, Advanced AI Contour Control 2, and a wide range of 5-axes options. Contact your Shibaura Machine Tools representative for a complete list of available FANUC control options.

Gain a Competitive Edge with Your FANUC Today

While these options can require additional activation, the competitive edge they provide allows your machine tool to increase quality, efficiency, reliability, and reduce cycle times.

If you are not sure which options are currently available on your control, contact our Machine Tools team and they can help select and integrate the best options for your machine tool.

Related Articles View All Machine Tools Articles

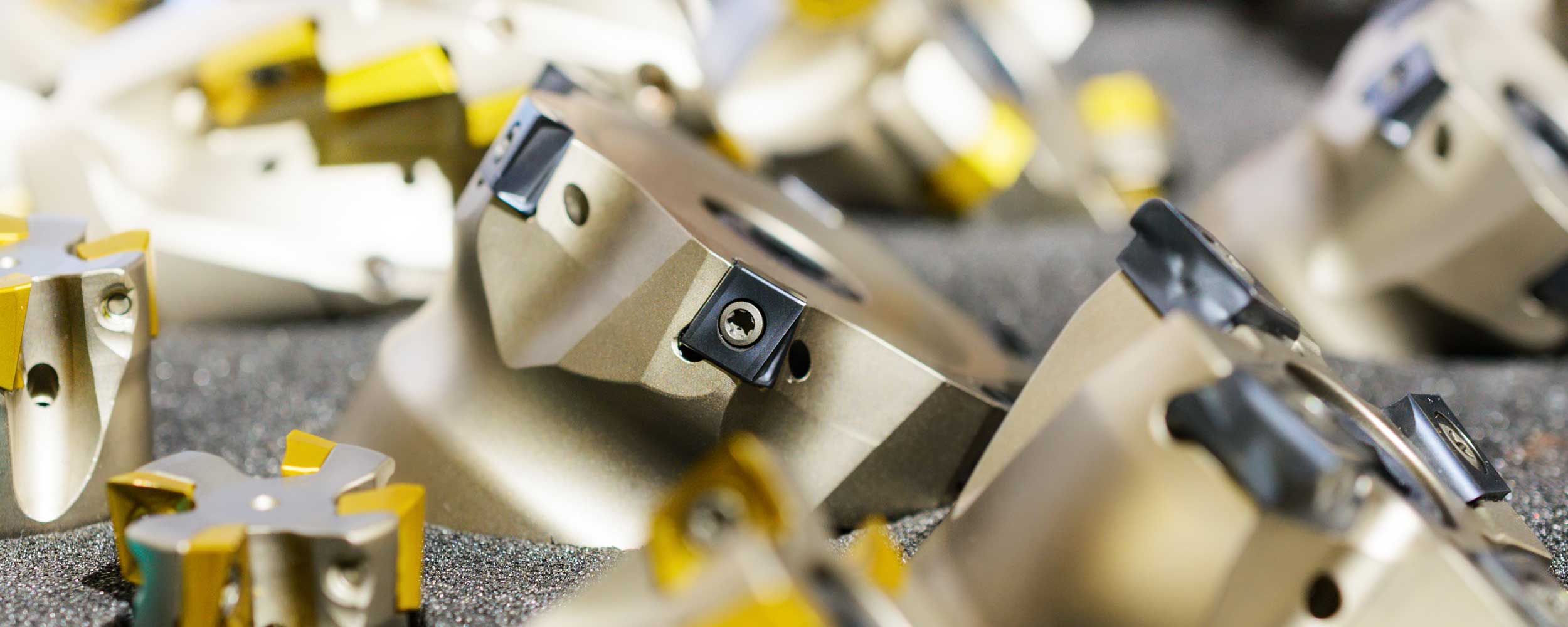

Saving on Perishable Tool Costs Starts with Machine Tool Quality

ELK GROVE VILLAGE, IL, November 30, 2022 - Every shop is challenged with ways to maximize revenue while minimizing costs. That is why when you are looking to make an investment on a new machine tool it goes way beyond the initial price tag. With extensive ...

Read moreTwin Ballscrew Axes Design Offers a High level of Positional Accuracy and Repeatability in Bridge Mill Machine Tool

ELK GROVE VILLAGE, IL, November 22, 2022 - On most milling or turning machine tools, single ballscrew axes designs are used in conjunction with guide surface for table travel, spindle-head travel and column travel. In order to achieve the high repeatabili...

Read moreThree Important Factors to Consider When Choosing a Machine Tool Manufacturer

ELK GROVE VILLAGE, IL, November 15, 2022 - Being able to plan and deliver predictable results is key to maintaining a competitive edge in manufacturing. When it comes to machine tools, the company you choose to purchase from plays a big role in ensuring th...

Read moreThe Shibaura Machine Standard for Tool Holders

ELK GROVE VILLAGE, IL, November 8, 2022 - What to Consider When Choosing a Tool Holder When it comes to machining accuracy of machine tools and product quality, tool holders can be highly influential. Shibaura machine tools are designed to use a high quali...

Read moreImprove Efficiency and Grow Opportunity with a Multi-tasking Machine Tool

ELK GROVE VILLAGE, IL, October 24, 2022 - Being able to combine functions in a single machine tool has long allowed us to save time, save money, and increase efficiency. Everything from smartphones to printers, even gym equipment, has been transformed to p...

Read moreConsiderations when using large cutting tools

ELK GROVE VILLAGE, IL, October 18, 2022 - When searching for the appropriate tooling for your machining application there are many different factors that should be considered. From speeds and feeds to workpiece shape and material, and even how much power d...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools