Shibaura Machine Combines the Power of Turning/Milling and Boring Into One

ELK GROVE VILLAGE, IL, July 28, 2021 -

The American manufacturing industry is changing. Automation and the ability to multi-task is quickly becoming a valuable tool for factories to achieve growth due to a declining workforce and remain competitive with the overseas market. Adopting a multitasking machine that provides both turn/mill and boring technology not only enables the user to complete a workpiece in a single handling, improving productivity, but makes it easier to hold tight tolerances.

When Should My Factory Use a Turn/Mill Boring Machine?

The answer to this question is simple- when you want to reduce your manufacturing cycle time, reduce the handling of the workpiece, and produce higher quality parts. These multitask machines stabilize the manufacturing process by offering a single setup, making it easier to hold tight tolerances and in some cases increase MRR (Metal Removal Rate). Most manufacturers see overwhelming benefits of using a multitasking turn/mill boring machine and use them in a number of manufacturing scenarios, including:

- Highly accurate workpieces are excellent candidates

- Workpieces that are too heavy to continually move

- High surface finish requirements

- Limited machine shop floor space

- Machining operations that require both turning milling and boring operations

- Workpiece surfaces that have interrupted cutting requirements can be better suited to milling processes versus turning.

What Turn/Mill Boring Machine is Right For You?

As an industry leader in the design and manufacturing of conventional vertical turning machines and horizontal boring machines, Shibaura Machine took on the challenge to design and build a machine series that combined these conventional machining processes.

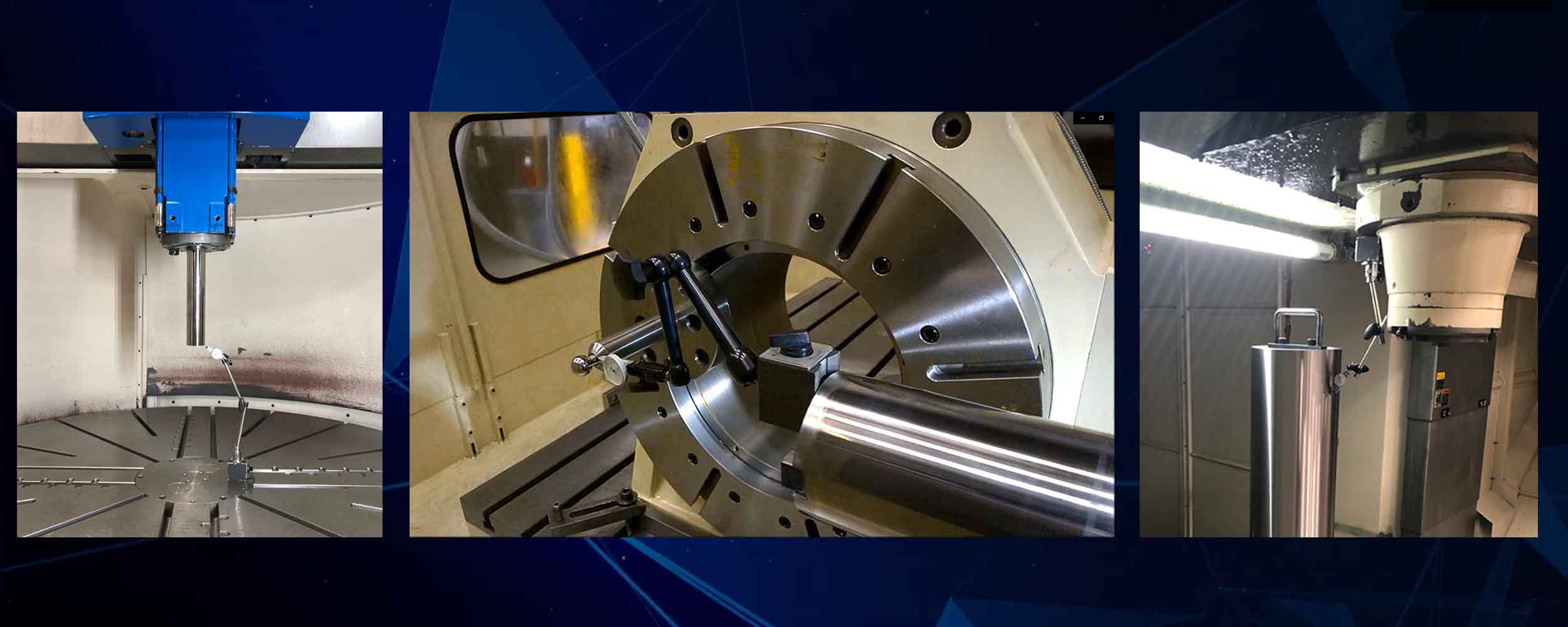

Through well-funded engineering efforts, Shibaura Machine designed a full series of turning milling and boring machines: TUE, TMD, TSS and TDS. This series streamlines the process of CNC machining offering both turning tables and milling/boring spindle capabilities in a single machine.

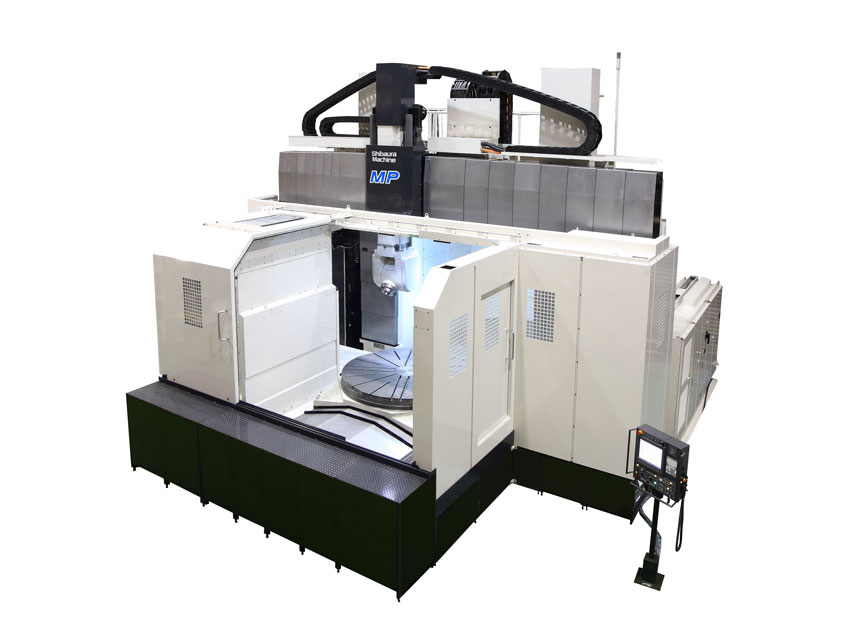

The Shibaura Machine factory also took machine development a step further to combine a double column machine and a 5 axes angular machining attachment, paired with a 2000mm (78.8") full contour milling turning table. The result was the MP-U, one of the first 5 axes turning/milling machines on a milling machine structure.

For larger work zone requirements, Shibaura Machine has developed a turn/milling and boring double column “Mother Machine”. These robust machines combine these machining processes with tables up to 8000mm (315") in diameter for very large work zone machining.

Whether your factory is working towards lower costs, tighter tolerances, or improved throughput a combined turn/mill and boring machine can help you achieve your goals. Contact the CNC Machine Tool team at Shibaura Machine to learn more about what solution is best suited for your factory.

Contact us MT-Sales@shibaura-machine.com.

Related Articles View All Machine Tools Articles

Multi-Surface Machining Improves Efficiency and Productivity

ELK GROVE VILLAGE, IL, July 20, 2021 - Shibaura Machine is making it simple to adopt a 5 (face) sided and/or 5-axis positioning machining strategy with our double column/bridge machines. Switching to 5-Sided or 5-Axis Machining While traditional vertical 3...

Read moreShibaura Machine Horizontal Spindle Quill Machines Bring Power and Versatility to Shop Floors

ELK GROVE VILLAGE, IL, July 12, 2021 - Spindles continue to play an important role in a fast production space. Horizontal spindle quill machines allow shops to take on complex cutting jobs and also combine the structural stability and geometric precision f...

Read moreAviation Industry Post Pandemic Update for Manufacturers

ELK GROVE VILLAGE, IL, July 6, 2021 - The modern aviation industry is slowly seeing positive growth for the first time since the COVID-19 pandemic hit. United Airlines announced in late June they will post a positive income for the first time since January...

Read moreThe Benefits of 5 axis 3+2 Machining with Shibaura Machine

ELK GROVE VILLAGE, IL, June 29, 2021 - Looking into 5 axis machining? It’s gaining a lot of attention today and for good reason. However, if your shop is considering a move to a 5 axis machine you should also read up on 3+2 machining. Most machining applic...

Read moreShibaura Machine Inspection Testing Checklist for Machine Tools

ELK GROVE VILLAGE, IL, June 22, 2021 - Whether your goal is to produce small or large parts, you will want to make sure you are purchasing a machine tool from a builder that has a strong quality initiative and can meet your customers requirements whether t...

Read moreExperience High Precision Machining with Shibaura Machine Nano “Micro Machining”

ELK GROVE VILLAGE, IL, June 14, 2021 - How are you keeping your customers coming back? These are just some questions our customers are faced with everyday. New challenges are emerging as customer demands and innovative technology continues to grow. High pr...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools