Exploring the Natural Pack Feature on the V70 Controller to Improve Injection Molding Processing

ELK GROVE VILLAGE, IL, November 9, 2022 - Manufacturers molding thin and/or long flow length parts are always looking for ways to reduce part defects. With high peak cavity pressure these applications can be particularly challenging. By being able to maximize part quality it not only impacts the performance and success of the end product but can shave time off production and overall cost. Being able to perform less rework also brings a quicker time to the customer, a true competitive advantage in today’s market.

One of the best ways to maintain a high level of part quality while also reducing mold wear is to look at the filling, packing, and holding stages of the injection molding process. With Shibaura Machine’s Natural Pack processing feature on the V70 controller, molders can produce more repeatable parts, faster while reducing tool maintenance.

Better Process Control

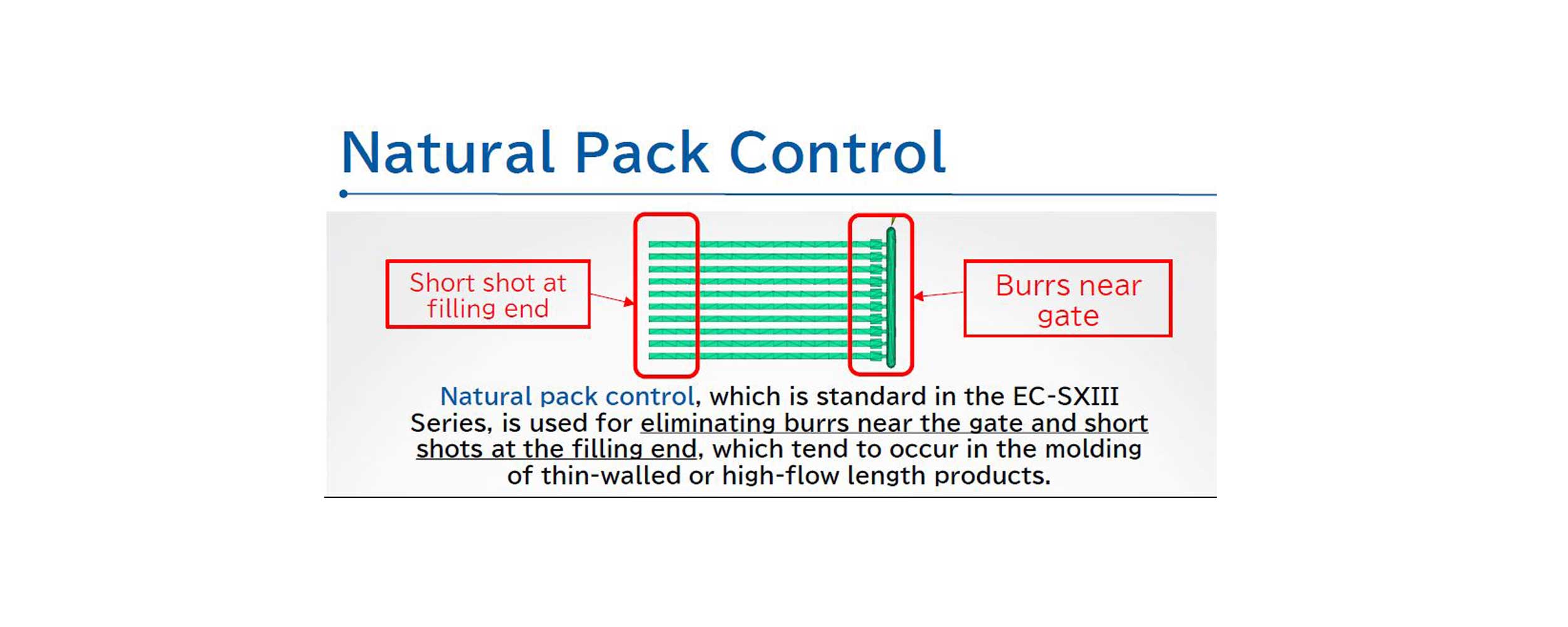

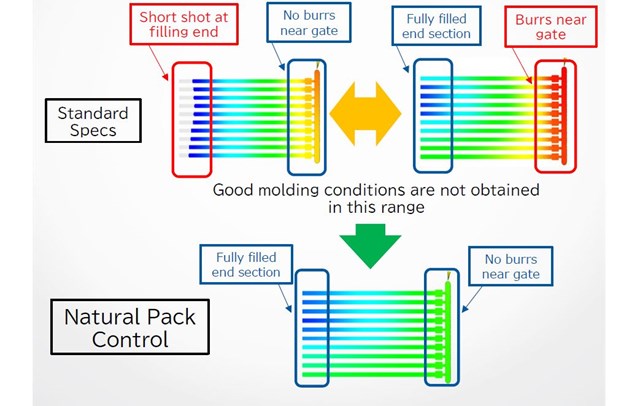

The Natural Pack processing feature slows the injection just before the transfer to holding. This allows the melted plastic to “naturally” fill out the part cavity. By stopping the screw for a set amount of time at the transfer position, the resin flows from the screw tip in the fill area due to the remaining pressure compressed between the cavity gates so it can be completely filled at a lower pressure below the peak pressure.

For example, consider when flashing is at the head of a part such as a nylon cable tie. As the cavity pressure increases in the nylon cable tie, the Natural Pack feature releases energy, reducing the overall peak pressure. This action decompresses the material and allows the flow front to move forward naturally, reducing cavity pressure and possible flash.

This feature helps to improve several common issues:

- Cavity balance

- Flash/burrs at the gate

- Short shots at the end of fill

- Reducing the clamp force

- Less wear on the tool

Ready to Learn More?

Natural Pack Control is easy to use and readily available on the V70 controller. Contact the Injection Molding team to learn more about the benefits of this feature and get started reducing part rework while improving productivity today.

Tel: (888)593-1616

Email: im-success@shibaura-machine.com

Related Articles View All Articles

Bring Real-Time Quality Monitoring to the Injection Molding Floor with Shibaura Machine

ELK GROVE VILLAGE, IL, November 2, 2022 - How efficiently and effectively are you able to control your quality processes? When quality management is running smoothly it not only maintains quality but is focused on maximizing productivity creating the best ...

Read moreNow Enrolling for In-Person Injection Molding Training Courses

ELK GROVE VILLAGE, IL, August 3, 2022 - Shibaura Machine is pleased to announce our popular in-person injection molding training courses are resuming for the remainder of 2022. Customers can join us at our tech centers in Elk Grove Village, IL, Charlotte, ...

Read moreRobot Integration Simplified With Shibaura Machine

ELK GROVE VILLAGE, IL, June 29, 2022 - Automating tasks with robots has become an increasingly popular option for injection molding manufacturers. From placing inserts into molds to moving parts through post-mold processes, robots provide process stability...

Read moremachiNetCloud Industrial IoT Now Included on New Injection Molding Machines

ELK GROVE VILLAGE, IL, June 22, 2022 - As the landscape in manufacturing continues to rapidly change due to digitalization, the Industrial Internet of Things (IIoT) brings a great opportunity to gain a competitive advantage in every form of production, inc...

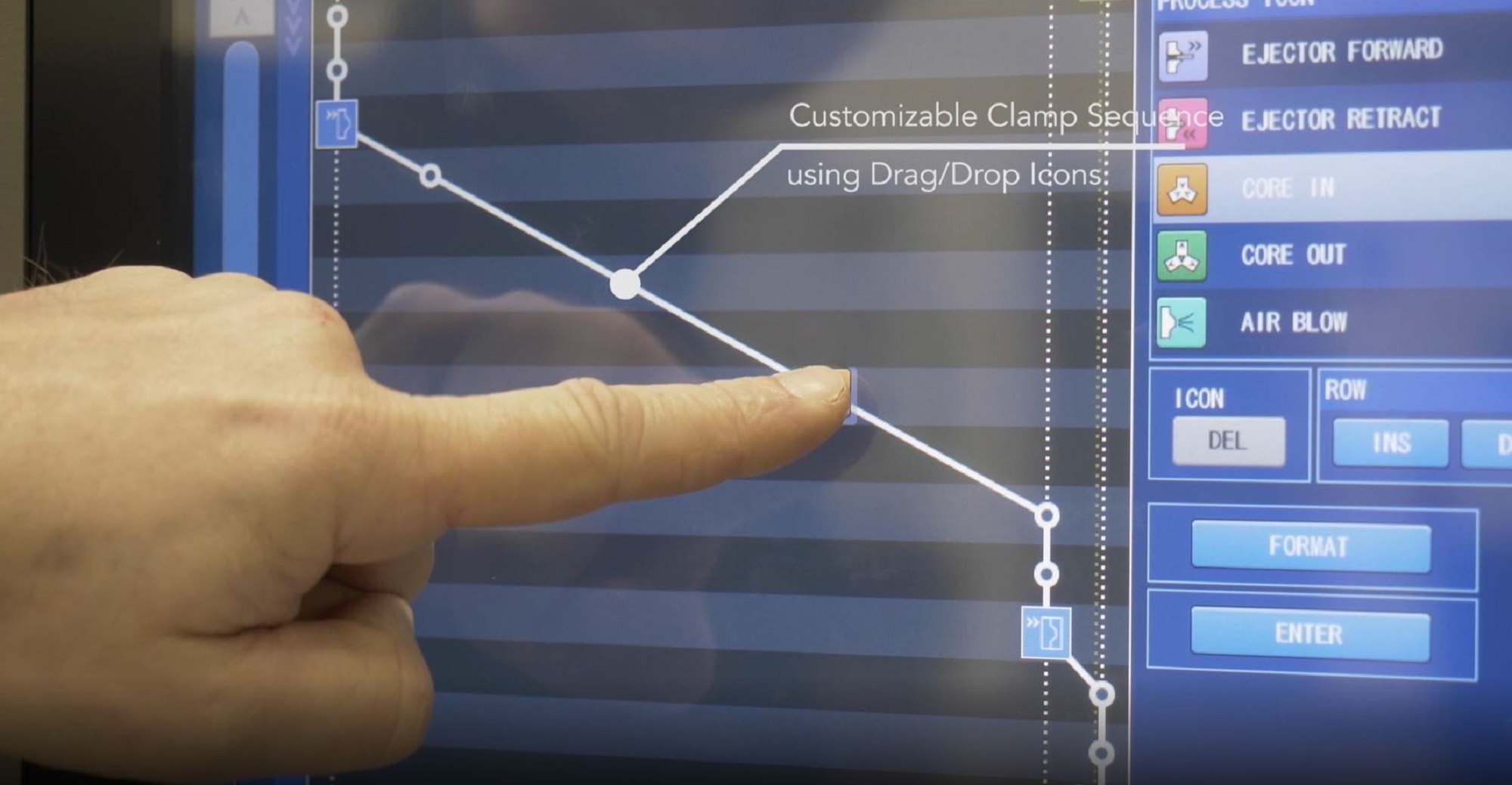

Read moreCustomize Your Clamping Sequence at a Touch

ELK GROVE VILLAGE, IL, June 17, 2022 - One of the steps to get the best results from injection molding requires the operator to properly set up the clamping sequence. Without an intuitive and visual experience, setting this up can be a time-consuming and d...

Read moreRegistration is Open For Our Injection Molding Smart Factory Open House

ELK GROVE VILLAGE, IL, April 28, 2022 - Merging existing technologies with new innovations can be challenging for manufacturers. To help injection molding factories envision the future of manufacturing, Shibaura Machine has partnered with key industry part...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools