Faster Cycle Times with All-Electric Injection Molding

ELK GROVE VILLAGE, IL, January 6, 2022 - Considering changing out from hydraulic to all-electric machines in the new year, but trying to justify the change? Look no further than the improvements these machines can make to your cycle time. Being able to reduce cycle times means a significant improvement in efficiency of your process- from both a time and cost standpoint.

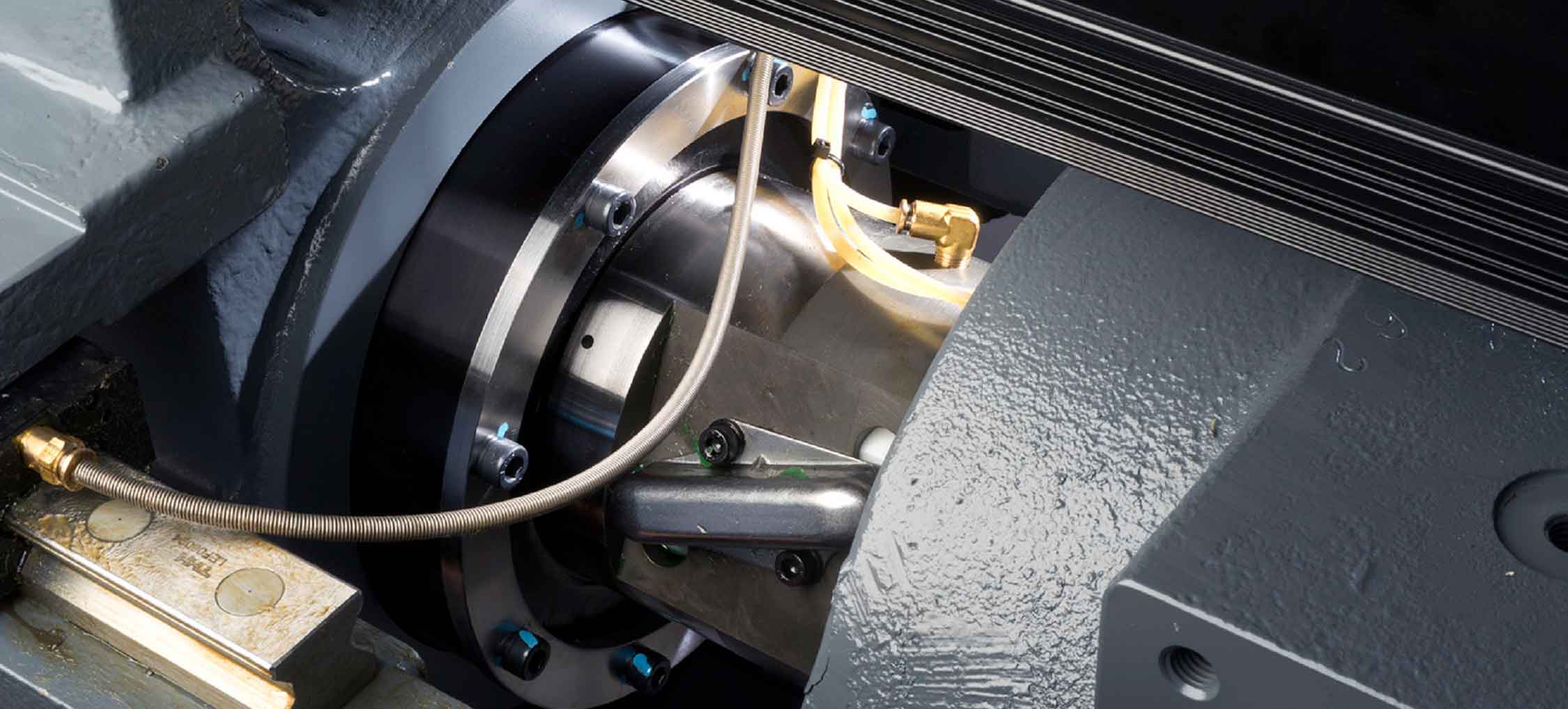

When you have to slow down you lose cycle time, bottom line. For hydraulic machines that happens for a slew of different reasons from avoiding slamming the mold to screw recovery. Hydraulic machines also come with more components and fluids which translates to a slower response time. And while these machines can run fast, they don’t consistently run fast like their all-electric counterparts which have no chance of leakage and have independent motors controlling the entire process from injection to screw recovery to clamping and ejection.

How Electric Machines Improve Cycle Time

The productivity advantages of the all-electric machines are a game changer. The Shibaura Machine SXIII series provides precise control and faster cycle times allowing for a reduction in operating costs year after year. With a combination of simultaneous motion and high speed movement, the all-electric SXIII series creates a more repeatable, faster process.

Several standout features with all-electric machines when it comes to improving cycle times include:

- Enabling eject on the fly, which in most cases allows the mold to open and close without a pause for ejection

- LAP sequencing allows injection to start as soon as the mold halves touch, but before lock up, also improving tool venting

- Ability to relax the clamp prior to cooling time expiring, saving time on mold open

The SXIII series also provides other simultaneous motions that improve cycle times since these machines feature independent servo motors on each axis. Opening the mold while charging and pulling the core in and out on the fly are also beneficial.

Learn More

Improved cycle times paired with superior performance, lower energy costs, and a better overall molding environment means manufacturers can expect a quicker return on investment. Contact the injection molding team to learn more about the SXIII series all-electric machines.

Tel: (888) 593-1616

Contact us today to learn how our all-electric technology can help your team minimize cycle times!

Related Articles View All Articles

How Automatic Load Cell Calibration Helps Prevent Molding Defects

ELK GROVE VILLAGE, IL, December 29, 2021 - One of the key advantages of all-electric injection molding machines is the ability to monitor actual plastic pressure during injection via a load cell behind the screw, without the need for in-mold transducers. ...

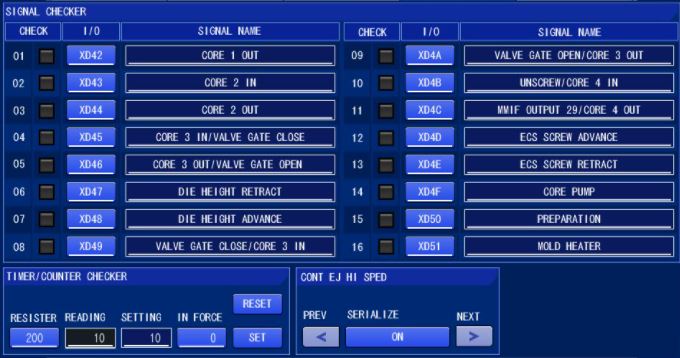

Read moreHow the I/O Checker Minimizes Machine Downtime for Injection Molders

ELK GROVE VILLAGE, IL, December 21, 2021 - Creating injection molded parts not only requires a high level of technical expertise, but also attention to detail. One small mistake can slow down, or even stop production.How many times this year have machine d...

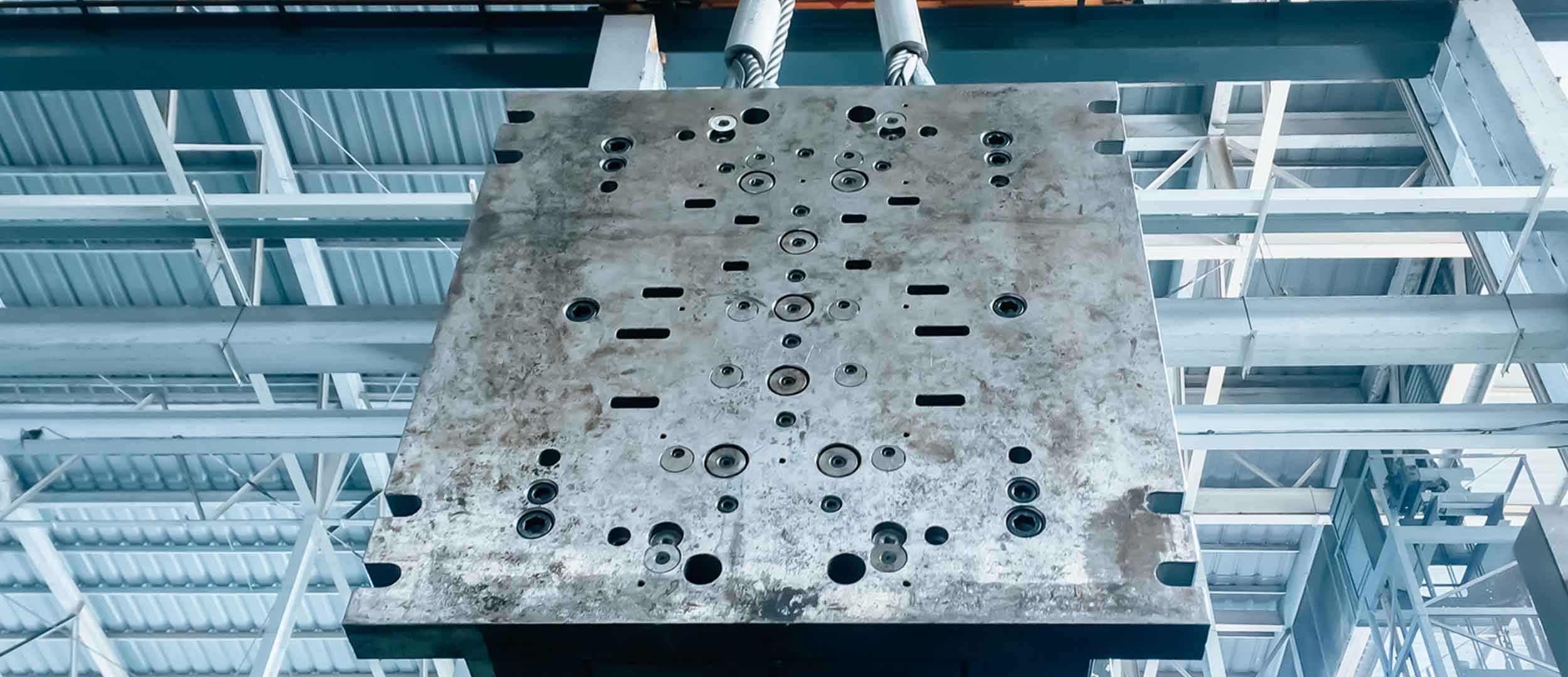

Read moreHow the Mold Guide Makes Set-Up Simple and Efficient

ELK GROVE VILLAGE, IL, December 16, 2021 - Installing a mold in an injection molding machine is a routine process. However, even when tasks are routine, mistakes can be made. Being able to perfect mold change-overs and lessen mistakes can not only help imp...

Read moreShibaura Machine is Making It Simple to Minimize Injection Molding Defects

ELK GROVE VILLAGE, IL, November 30, 2021 - Small mistakes in injection molding can add up to costing companies big money when it comes to time and product lost. Understanding design guidelines and best practices help in preventing defects, but not all mold...

Read moreSupporting Our Southeast Injection Molding Customers: Spotlight on Shibaura Machine’s Charlotte, North Carolina Tech Center & Service Office

ELK GROVE VILLAGE, IL, November 19, 2021 - This is our last week in our Injection Molding Support Series, focusing on our Charlotte, North Carolina facility. While Shibaura Machine operates in a truly global network, these four locations throughout North A...

Read moreSupporting our Canadian Injection Molding Customers: Spotlight on Shibaura Machine’s Markham, ON Tech Center & Service Office

ELK GROVE VILLAGE, IL, November 17, 2021 - If you own a Shibaura injection molding machine or have partnered with our teams then you are familiar with our mission to evolve, through the closest cooperation with our customers, into a value co-creating manuf...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools