How Automatic Load Cell Calibration Helps Prevent Molding Defects

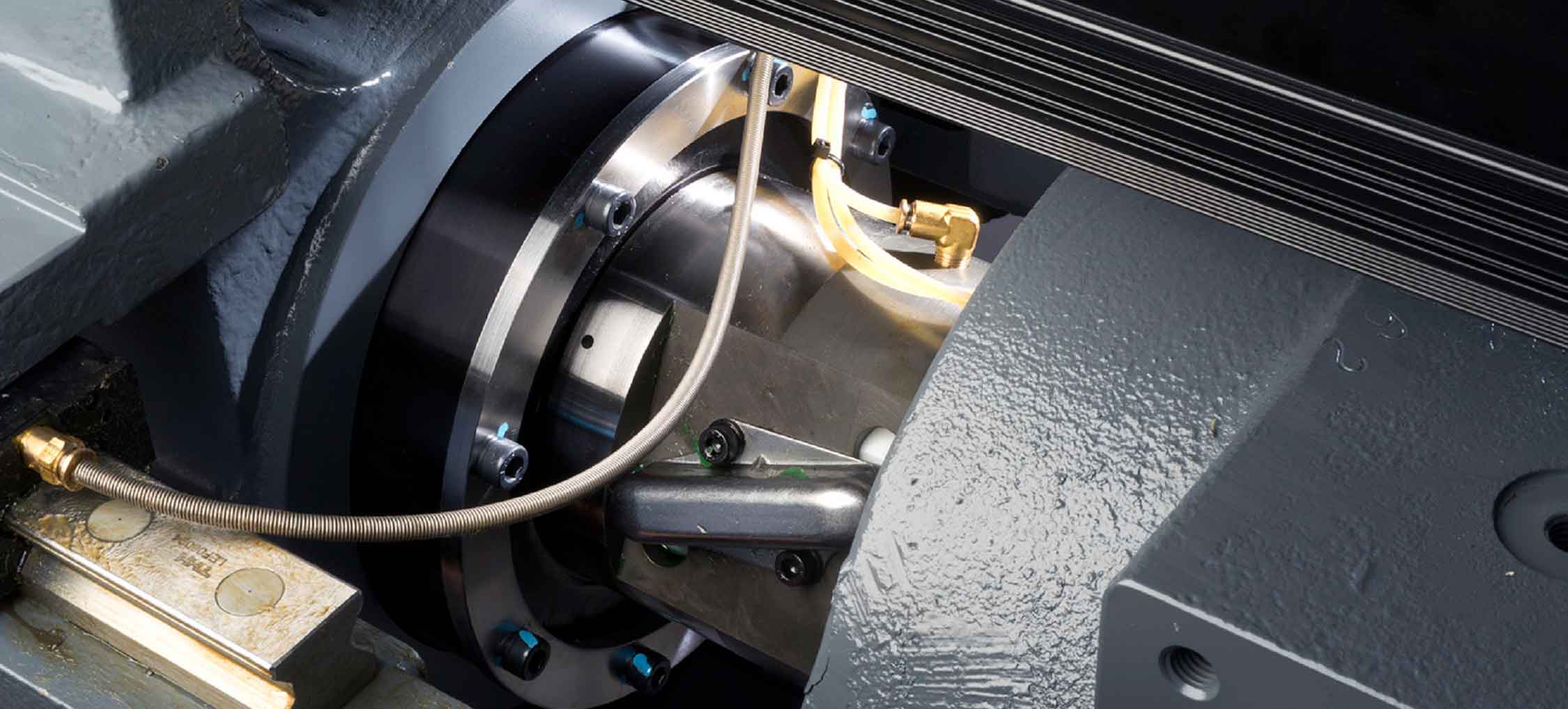

ELK GROVE VILLAGE, IL, December 29, 2021 - One of the key advantages of all-electric injection molding machines is the ability to monitor actual plastic pressure during injection via a load cell behind the screw, without the need for in-mold transducers. Proper calibration of this key component is crucial, yet it is often underrated and misunderstood, making it commonly overlooked. However, if your injection molding machine's load cell is not calibrated properly it cannot provide a true and accurate measure of injection pressure. This can lead to unforeseen molding defects negatively affecting productivity.

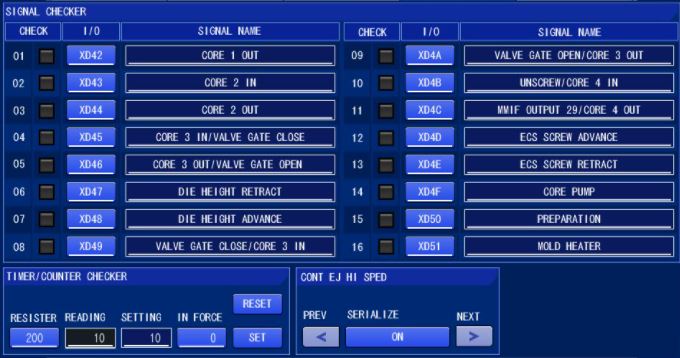

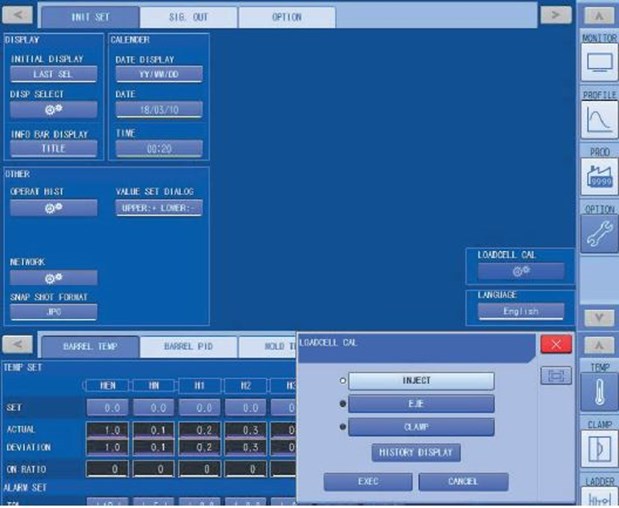

Shibaura Machine provides automatic load cell calibration for the all-electric SXIII series injection molding machines with the Load Cell Automatic Calibration Circuit function on the V70 controller. This function allows the user to automatically calibrate the load cell to detect the injection pressure and shows the history of the past twenty calibrations.

Improving Part Production

One of the main goals in injected molded parts is keeping them identical from run to run. Load cells generally provide precise measurement results and accuracy. Over time, load cells may deteriorate with continuous usage and therefore provide less reliable data. A reading that is out of tolerance indicates that calibration is needed.

With routine calibration you can ensure accurate measurement readings are being taken.

The process of calibrating load cells has long been complicated, leading to loss of time and revenue. Using the Load Cell Automatic Calibration Circuit helps ease the process and improve overall part production. The function automatically calibrates, removing the complexity and allowing plant personnel to focus on other areas of the manufacturing process. By being able to detect the injection pressure and automatically calibrate, the load cell can better maintain its correct zero point which provides more accurate results.

Easily Maintain Load Cells

Learn more about the Load Cell Automatic Calibration Circuit function and all the ways the V70 controller is working to improve maintenance of the SXIII all-electric injection molding machines. Through automatic functions like this, maintenance takes less time away from machine operation and improves overall part production.

Learn More

Contact Shibaura Machine’s injection molding team to learn more about Automatic Load Cell Calibration and all of the V70 controller’s capabilities on our all-electric injection molding machines.

Tel: (888) 593-1616

Email: im-success@shibaura-machine.com.

Contact us today to learn if the Load Cell Automatic Calibration Circuit can help your team minimize machine downtime!

Related Articles View All Articles

How the I/O Checker Minimizes Machine Downtime for Injection Molders

ELK GROVE VILLAGE, IL, December 21, 2021 - Creating injection molded parts not only requires a high level of technical expertise, but also attention to detail. One small mistake can slow down, or even stop production.How many times this year have machine d...

Read moreHow the Mold Guide Makes Set-Up Simple and Efficient

ELK GROVE VILLAGE, IL, December 16, 2021 - Installing a mold in an injection molding machine is a routine process. However, even when tasks are routine, mistakes can be made. Being able to perfect mold change-overs and lessen mistakes can not only help imp...

Read moreShibaura Machine is Making It Simple to Minimize Injection Molding Defects

ELK GROVE VILLAGE, IL, November 30, 2021 - Small mistakes in injection molding can add up to costing companies big money when it comes to time and product lost. Understanding design guidelines and best practices help in preventing defects, but not all mold...

Read moreSupporting Our Southeast Injection Molding Customers: Spotlight on Shibaura Machine’s Charlotte, North Carolina Tech Center & Service Office

ELK GROVE VILLAGE, IL, November 19, 2021 - This is our last week in our Injection Molding Support Series, focusing on our Charlotte, North Carolina facility. While Shibaura Machine operates in a truly global network, these four locations throughout North A...

Read moreSupporting our Canadian Injection Molding Customers: Spotlight on Shibaura Machine’s Markham, ON Tech Center & Service Office

ELK GROVE VILLAGE, IL, November 17, 2021 - If you own a Shibaura injection molding machine or have partnered with our teams then you are familiar with our mission to evolve, through the closest cooperation with our customers, into a value co-creating manuf...

Read moreSupporting our West Coast Injection Molding Customers: Spotlight on Shibaura Machine’s Ontario, California Tech Center & Service Office

ELK GROVE VILLAGE, IL, November 10, 2021 - Having a nearby resource to provide your team with support is crucial to meet business goals and optimize injection molding processes. By having tech centers and service offices throughout North America we are abl...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools