How the Mold Guide Makes Set-Up Simple and Efficient

ELK GROVE VILLAGE, IL, December 16, 2021 - Installing a mold in an injection molding machine is a routine process. However, even when tasks are routine, mistakes can be made. Being able to perfect mold change-overs and lessen mistakes can not only help improve productivity, but decrease scrap rates and the need for rework.

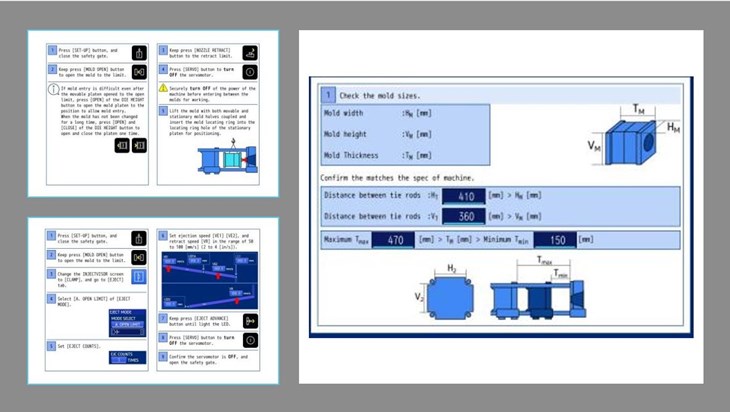

Shibaura Machine’s V70 controller features a Mold Guide to provide molders preparation of molds with step-by-step guidelines. The Mold Guide is extremely useful for those new to injection molding and it can help to keep procedures top of mind for experienced molders. The guide provides molders direction on each step to take and what to look for before setting up a mold in the all-electric SXIII. Utilizing the guide can result in fewer mold set-up mistakes and speeding up changeover, which ultimately leads to cost savings.

Making Mold Set-Up Simple

The Mold Guide at its most basic is showing what a molder needs to know before setting up a mold in the machine. The user interface is easy to navigate, with steps clearly marked and relevant instructions for each process located within the tabs.

The three main tabs displayed are for set-up preparation, ejector set-up, and mold set-up. The tabs can be clicked on to further display detailed instructions to ensure the mold and ejectors are properly set up. From selecting the correct ejector rods, position set points, standard bolt depth, and outlining the proper mold protect procedure this straightforward instruction allows molders to efficiently prepare the mold knowing it is done right the first time.

Start Improving Production

Mold set-up will always be part of the injection molding process, but that doesn’t mean the machine has to sit idle for longer than it needs to. The Mold Guide on the V70 controller ensures that steps are properly completed and helps avoid unnecessary shut downs.

Using the Mold Guide gives molders the ability to reduce set-up preparation and more efficiently prepare molds. Especially for new molders, this can result in improved production and profit margin. To learn more about using the Mold Guide on the Shibaura Machine V70 controller, contact our Injection Molding team today.

Learn More

Contact Shibaura Machine’s injection molding team to learn more about the Mold Guide and all of the V70 controller’s capabilities on our all-electric injection molding machines.

Tel: (888) 593-1616

Email: im-success@shibaura-machine.com.

Contact us today to learn how our SXIII series can help your team minimize mold set-up time!

Related Articles View All Articles

Shibaura Machine is Making It Simple to Minimize Injection Molding Defects

ELK GROVE VILLAGE, IL, November 30, 2021 - Small mistakes in injection molding can add up to costing companies big money when it comes to time and product lost. Understanding design guidelines and best practices help in preventing defects, but not all mold...

Read moreSupporting Our Southeast Injection Molding Customers: Spotlight on Shibaura Machine’s Charlotte, North Carolina Tech Center & Service Office

ELK GROVE VILLAGE, IL, November 19, 2021 - This is our last week in our Injection Molding Support Series, focusing on our Charlotte, North Carolina facility. While Shibaura Machine operates in a truly global network, these four locations throughout North A...

Read moreSupporting our Canadian Injection Molding Customers: Spotlight on Shibaura Machine’s Markham, ON Tech Center & Service Office

ELK GROVE VILLAGE, IL, November 17, 2021 - If you own a Shibaura injection molding machine or have partnered with our teams then you are familiar with our mission to evolve, through the closest cooperation with our customers, into a value co-creating manuf...

Read moreSupporting our West Coast Injection Molding Customers: Spotlight on Shibaura Machine’s Ontario, California Tech Center & Service Office

ELK GROVE VILLAGE, IL, November 10, 2021 - Having a nearby resource to provide your team with support is crucial to meet business goals and optimize injection molding processes. By having tech centers and service offices throughout North America we are abl...

Read moreSupporting our Midwest Injection Molding Customers: Spotlight on Shibaura Machine’s Elk Grove Village, IL Tech Center & Service Office

ELK GROVE VILLAGE, IL, November 4, 2021 - Delivering customers a great experience every step of the way has continually been a goal for the Shibaura Machine team. We realize that while purchasing a reliable, high quality injection molding machine is import...

Read moreKeep Your Injection Molding Process Stable and Repeatable with Laminar Control

ELK GROVE VILLAGE, IL, October 29, 2021 - One of the best ways a molder can ensure quality parts consistently is by understanding and improving upon the injection speed process.Shibaura Machine’s all-electric injection molding machines offer a Laminar Cont...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools