Mold Deflection Causing Problems With Your Injection Molding Process? Read This.

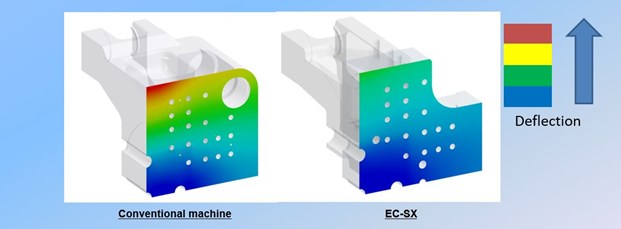

ELK GROVE VILLAGE, IL, September 9, 2021 - When it comes to manufacturing plastic parts to tight tolerances, minimizing mold deflection is essential. Mold deflection is generally caused by clamping and cavity pressures which then cause the mold to deflect and distort significantly from its intended configuration. In order to extend tool life and maximize part quality you need a machine that allows for uniform clamping force distribution.

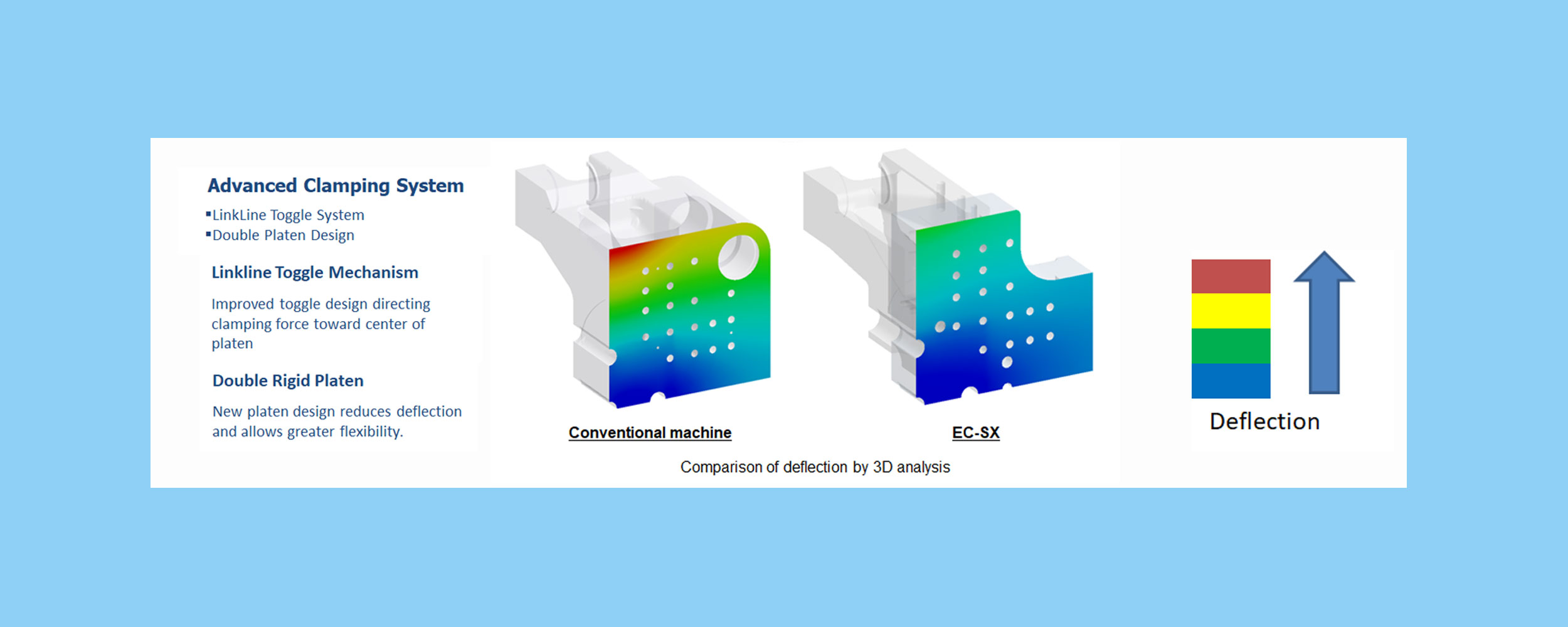

Shibaura Machine’s SXIII series is designed with an advanced clamping system that leverages a 5-point Linkline toggle system and double platen design. This combination offers a uniform clamping force that reduces deflection by 30%, improving mold longevity and preventing flash.

Reduced Deflection in Superior Design

The smart design of the SXIII means that you get a rigid machine structure, with minimum deflection and consistent product accuracy.

Shibaura Machine’s SXIII 5-point Linkline toggle system directs clamping force toward the center of the platen. This improved 5-point toggle mechanism is angled, which distributes force evenly across the platen, increasing quality and minimizing defects. The system also helps to extend mold life and reduces overall machine maintenance.

In combination with the double platen design, this allows the user greater flexibility and productivity. The rigid double platen design is engineered with linear guides on the moving platen instead of tie bar bushings, which ensures a steady and precise movement. This construction ensures uniform clamping force and increased parallelism between the platens.

Combining Power + Flexibility

The 5-point Linkline toggle system and double platen design create a powerful combination for high-performance injection molding. Contact our team to learn more about how the advanced clamping system on the Shibaura Machine SXIII can help your factory achieve its goals, from improving productivity to maximizing machine OEE.

Contact us today to see if our SXIII series can help your molding shop achieve its goals!

Related Articles View All Articles

Optimize Part Weight Consistency with the Shibaura Machine Plastrol Function

ELK GROVE VILLAGE, IL, September 2, 2021 - Part weight variations due to inconsistent check ring response can cause unwanted fluctuations and endanger a stable injection molding process. When we look for ways to stabilize the process and improve shot-to-sh...

Read moreShibaura Machine’s New Smart Factory Highlights IoT Solutions Paired With All-Electric Injection Molding Technology

ELK GROVE VILLAGE, IL, August 27, 2021 - Shibaura Machine will be launching its new Smart Factory with an open house at their Elk Grove Village, Illinois tech center in the Fall, 2021. This manufacturing cell will further support customers to fully leverag...

Read moreTaking LSR Molding to a Higher Level with All-Electric Technology

ELK GROVE VILLAGE, IL, August 20, 2021 -Liquid silicone rubber molding is experiencing demand growth like never before in North America. While many manufacturers are considering whether to invest in a dedicated liquid silicone rubber (LSR) molding machine...

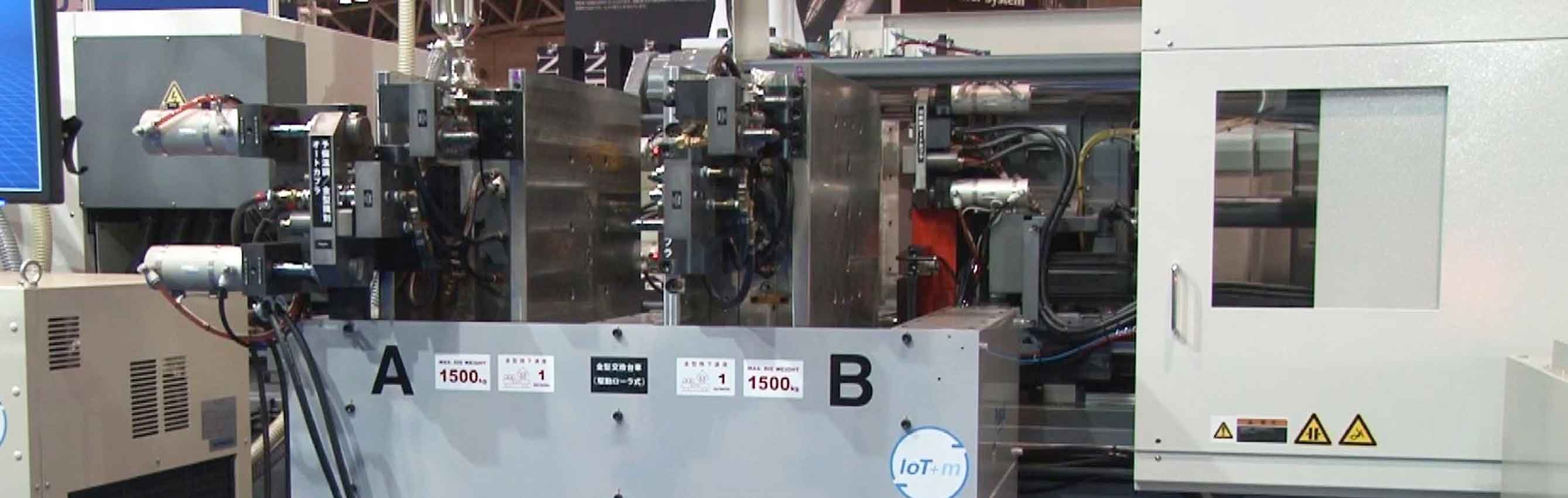

Read moreTwo-Shot Molding: Any Machine, Any Time with Shibaura Machine

ELK GROVE VILLAGE, IL, August 6, 2021 - Two-shot molding is one of the most efficient processes for manufacturers creating products using plastics. By allowing operators to create multi-material or multi-colored parts without adding extra assembly steps it...

Read moreInjection Molding Energy Consumption At a Glance

ELK GROVE VILLAGE, IL, July 28, 2021 - From energy hogs forty years ago to the efficient all-electric options of today, injection molding machines have made quite the evolution. While injection molding is still an energy intensive process, the all-electric...

Read moreFrom One Product to the Next- Improving Set-up Efficiency in Injection Molding with SMED and the SXIII

ELK GROVE VILLAGE, IL, July 7, 2021 - Reducing the changeover time for your operations is critical to maintain a competitive advantage and improve profitability in the manufacturing industry today.That’s where the concept of single-minute exchange of die, ...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools