Shibaura Machine’s New Smart Factory Highlights IoT Solutions Paired With All-Electric Injection Molding Technology

ELK GROVE VILLAGE, IL, August 27, 2021 - Shibaura Machine will be launching its new Smart Factory with an open house at their Elk Grove Village, Illinois tech center in the Fall, 2021. This manufacturing cell will further support customers to fully leverage the potential of their SXIII series all-electric machines and V70 controller while showcasing the latest Internet of Things (IoT) technology. The Smart Factory will highlight not only what is possible today, but also what Shibaura Machine is working towards making possible in collaboration with customers for the future.

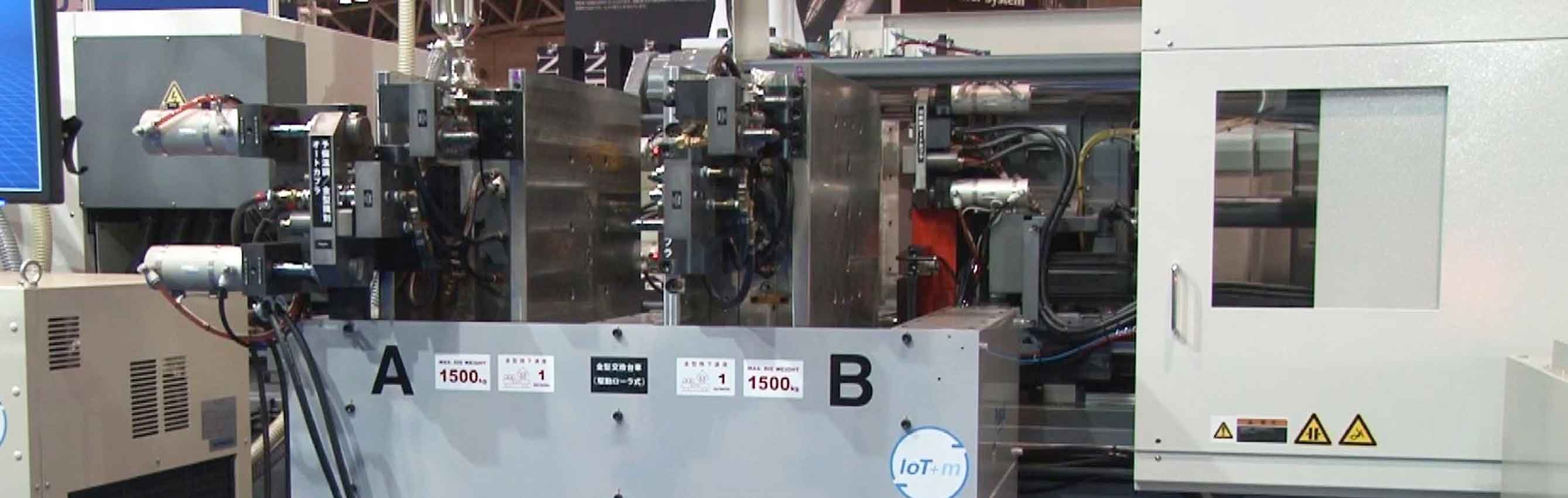

The Smart Factory features a completely automated operation, exhibiting three all-electric machines producing a touch screen stylus, USB stylus holder, and stylus case. The manufacturing cell includes machine mounted take-out robots feeding each component to a central automation system and from there items are assembled and placed within a case. The three machines featured are:

- EC85SXIIIV70-2Y (83 Tons / 5.1oz)

- EC200SXIIIV70-U34-6Y (198 Tons / 7.3oz)

- EC250SXIIIV70-U48-8Y – 2 Shot Machine (254 Tons / Primary 10.3oz, Secondary 2.08oz)

Experience Full Machine Potential

The focus of the Smart Factory is to not only help customers improve efficiency and productivity, but highlight new possibilities of the machines and technology in order to strengthen competitiveness. The entire process of the three machine cell will produce a two-material stylus for touch screens, a USB holder, and a case, all while highlighting several technologies and partnerships. These include:

- SXIII series all-electric machines with V70 controllers (3 models featured)

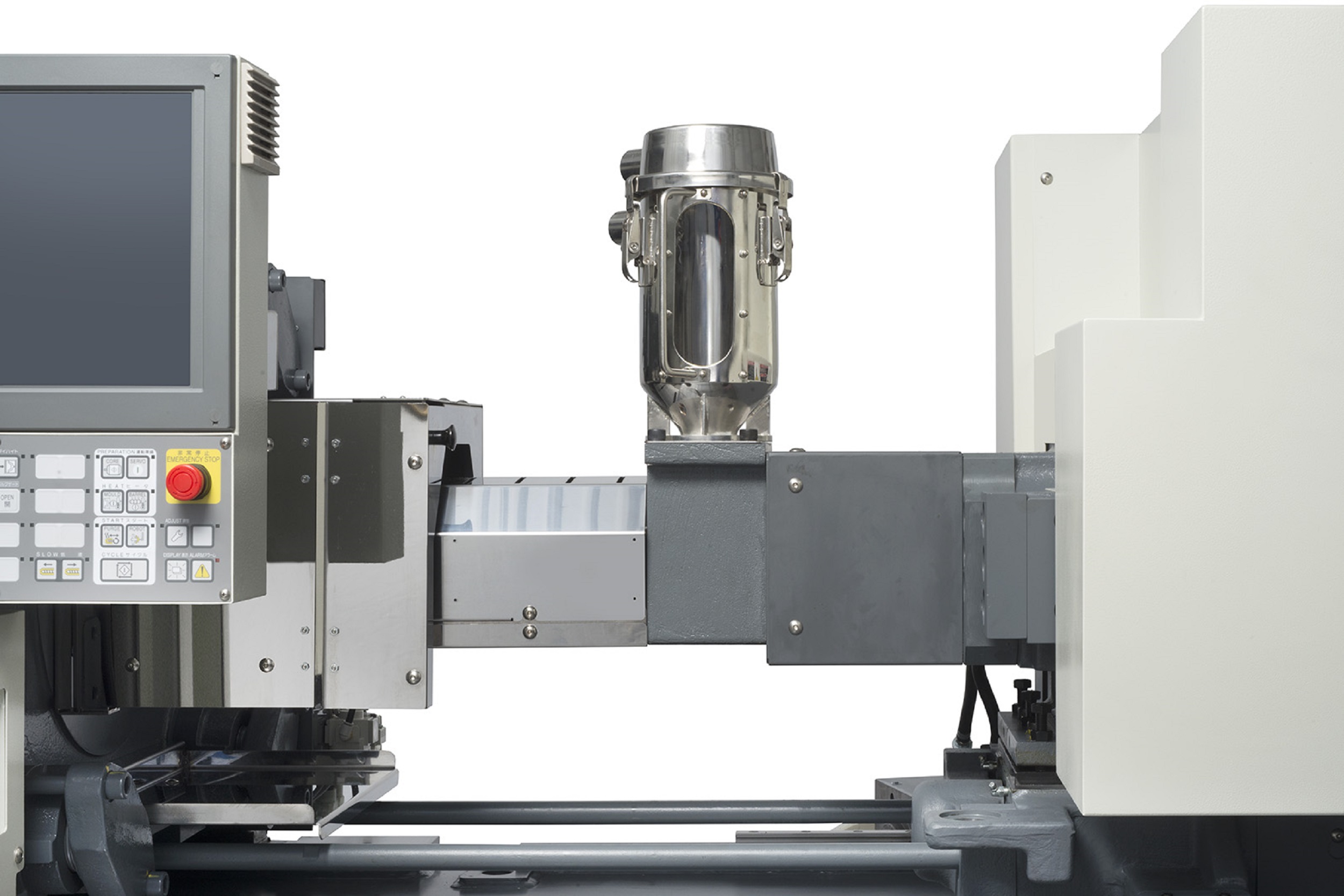

- Two-shot machine configuration on the EC250SXIII, using an E-Multi EM2-80SC-25 secondary injection unit

- Star Automation robots integrated into the V70 controller on all three molding machines

- Matsui mold temperature controllers and dryer integrated into the V70 controller on all three molding machines

- All tooling designed and manufactured by Phoenix Proto Technologies (Centerville, Michigan)

- All assembly automation designed and manufactured by EPF Automation (Milan, Italy)

- 6-axis robot and support provided by TM Robotics (Elk Grove Village, Illinois)

The Future of Injection Molding

Striving to create greater value through co-creation with our customers has brought us to utilize the latest IoT (Internet of Things) Industry 4.0 technology. The Smart Factory will highlight a new cloud based IoT system utilizing analytics to deliver superior manufacturing. This allows for access to machine processing and production data via the cloud, along with remote services, diagnostics, predictive maintenance, and access to the machine controller from anywhere, anytime. With these capabilities, shops can track OEE to make better data-driven decisions to minimize unplanned downtime and increase efficiency.

Contact us today at im-success@shibaura-machine.com to schedule your visit to our new Smart Factory to leverage your machine’s full potential and look towards the future of manufacturing with IoT.

Contact us today to learn more about our all-electric technology and IoT solutions!

Related Articles View All Articles

Taking LSR Molding to a Higher Level with All-Electric Technology

ELK GROVE VILLAGE, IL, August 20, 2021 -Liquid silicone rubber molding is experiencing demand growth like never before in North America. While many manufacturers are considering whether to invest in a dedicated liquid silicone rubber (LSR) molding machine...

Read moreTwo-Shot Molding: Any Machine, Any Time with Shibaura Machine

ELK GROVE VILLAGE, IL, August 6, 2021 - Two-shot molding is one of the most efficient processes for manufacturers creating products using plastics. By allowing operators to create multi-material or multi-colored parts without adding extra assembly steps it...

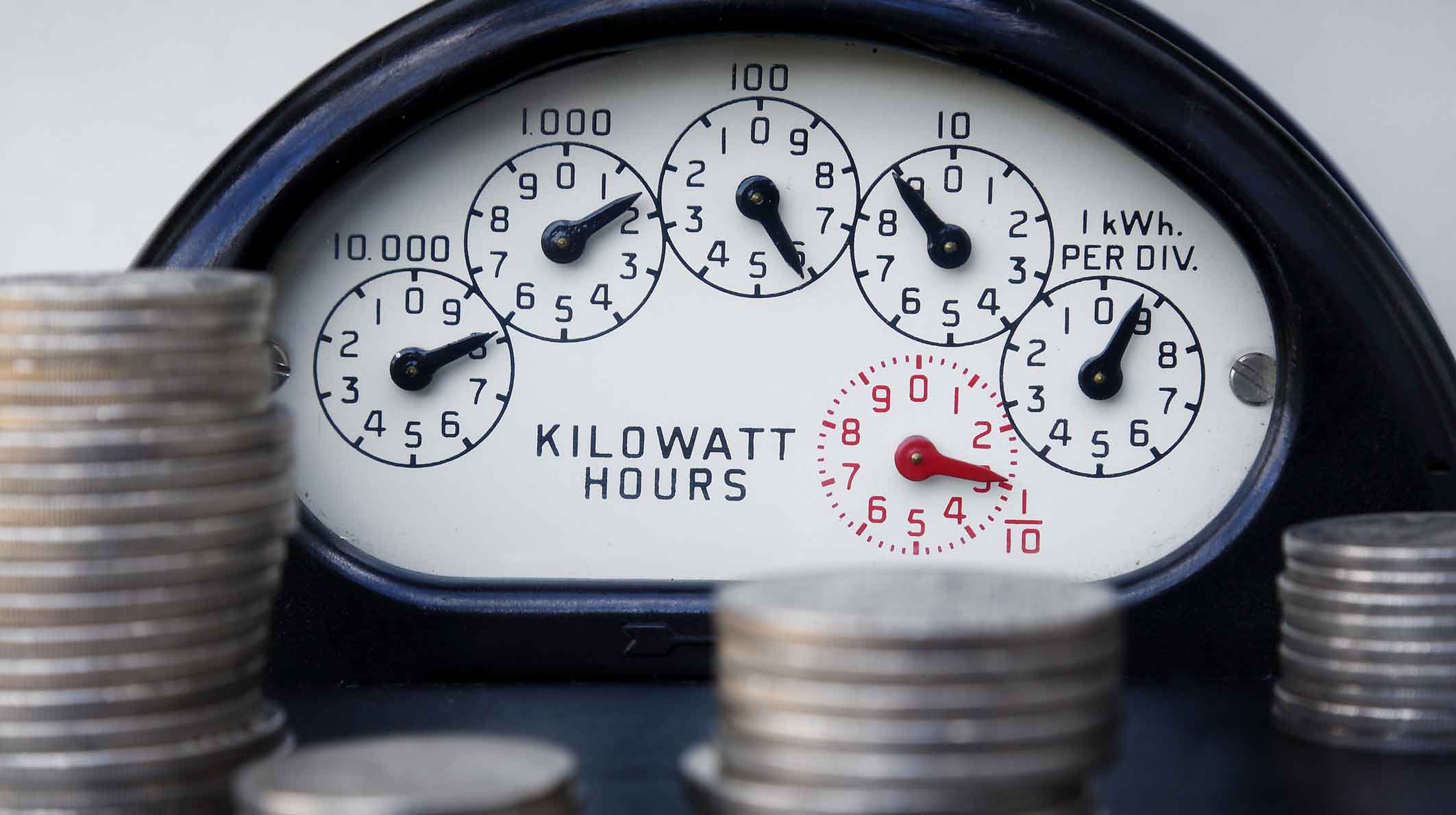

Read moreInjection Molding Energy Consumption At a Glance

ELK GROVE VILLAGE, IL, July 28, 2021 - From energy hogs forty years ago to the efficient all-electric options of today, injection molding machines have made quite the evolution. While injection molding is still an energy intensive process, the all-electric...

Read moreFrom One Product to the Next- Improving Set-up Efficiency in Injection Molding with SMED and the SXIII

ELK GROVE VILLAGE, IL, July 7, 2021 - Reducing the changeover time for your operations is critical to maintain a competitive advantage and improve profitability in the manufacturing industry today.That’s where the concept of single-minute exchange of die, ...

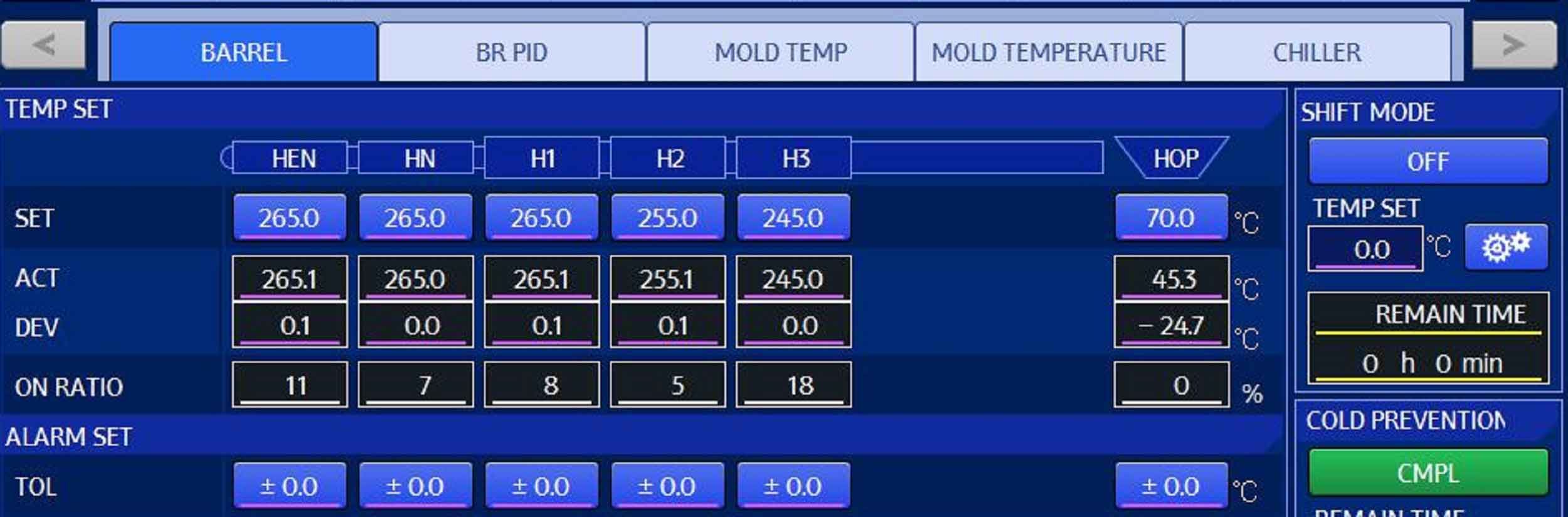

Read moreGain Control Over Your Barrel Temperature with Shibaura Machine’s V70 Controller

ELK GROVE VILLAGE, IL, June 25, 2021 - Errors in temperature control result in a large part of rejects in the injection molding world. If a molder wants to ensure a stable molding cycle and high quality product, having a temperature control process is esse...

Read moreUsing Auto-Purge to Improve Injection Molding Efficiency

ELK GROVE VILLAGE, IL, June 23, 2021 - Molders today are always looking for a way to minimize their losses. So while purging is often necessary, it makes many molders cringe because this process often means costly waste and lost production time- defeating...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools