Three-Stage Mold Protection Saves Time and Money

ELK GROVE VILLAGE, IL, March 24, 2021 – Mold protection often goes overlooked, but mold damage and downtime can be prevented by utilizing this feature properly.

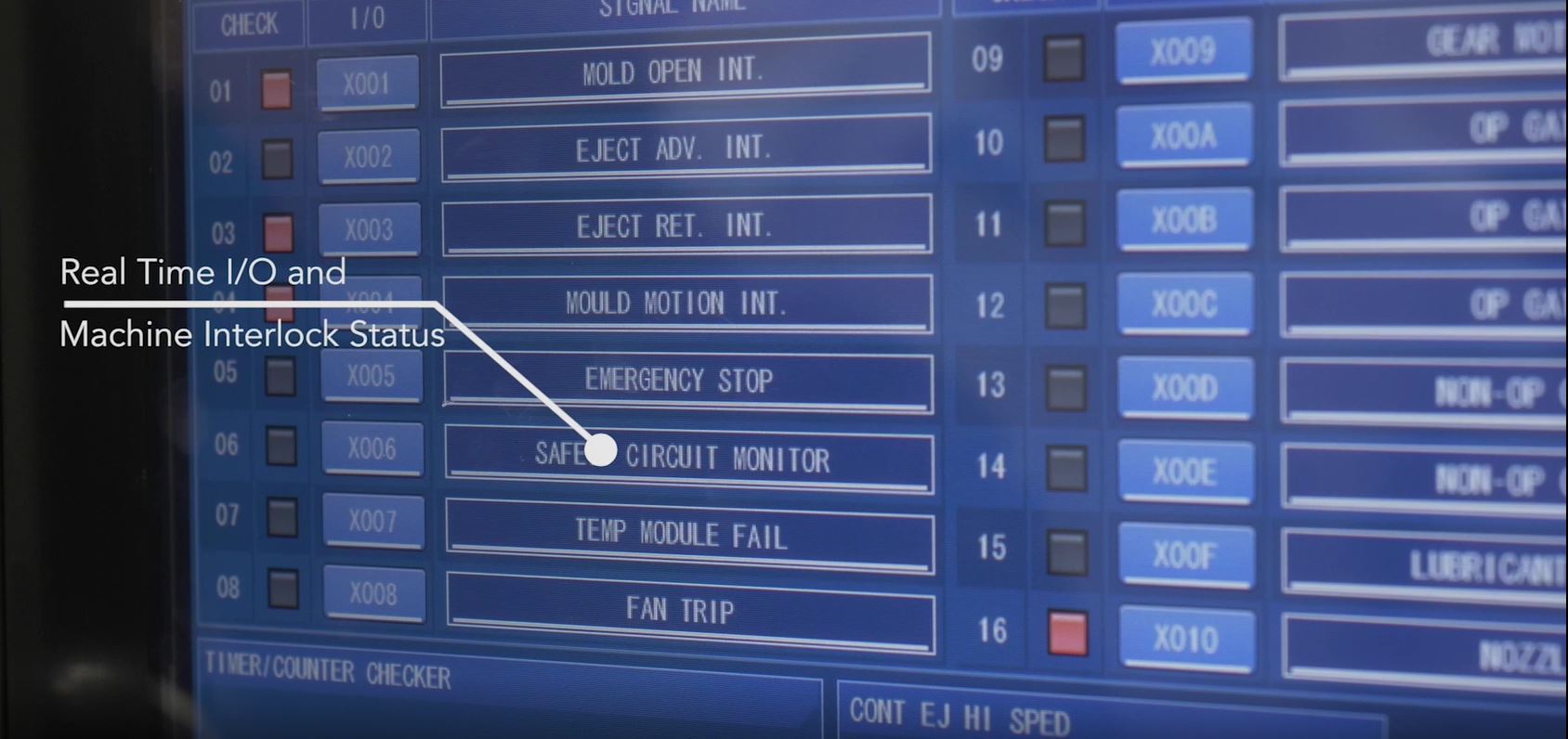

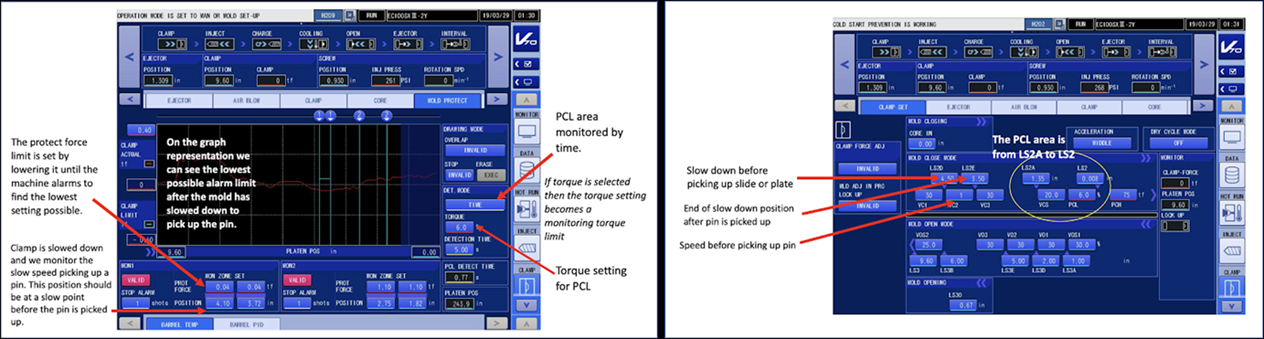

Each mold has its own requirements, so having a machine that makes input and monitoring easy is important so that it can be executed quickly and correctly. Shibaura Machine’s three stage mold protection feature on the V70 controller breaks the closing sequence of the machine into (three) separate segments. This feature allows for not only monitoring torque required for each segment, but assigns tolerances around required torque and also allows for the machine to stop and alarm if the torque goes out of tolerance.

Monitoring Mold Protection Made Easy

While the time and attention required to monitor the mold protection more than pays for itself, many find it hard to set up and execute on their machines. This means that mold protection is often neglected. When designing the V70 controller our team took this into consideration and made the three stage mold protect feature easier to utilize and monitor.

The goal of input and monitoring of the molds is to protect them from obstruction. The three stage mold protection that the V70 controller features helps to protect slides in the mold or plates, whether a part or delicate mold detail that could prevent a smooth mold closing. Settings can be sensitive enough to detect lack of grease on leader pins and help prevent galling of the tool, which saves money on repairs.

It is important to be proactive when it comes to protecting your molds. Preventing issues before they occur can save costly downtime and expensive repairs. The V70 controller three stage mold protection feature was created specifically with injection molders in mind. By integrating directly into the main control it is easy to set-up and monitor, allowing you to protect your mold investment.

Contact the Shibaura Machine injection molding team to learn more about the three stage mold protection feature on our V70 controller.

Contact our processing experts today to discuss how 3-stage mold protection can help protect your tooling investment!

Related Articles View All Articles

Comparing Injection Molding Ejector Systems - All-Electric vs. Hydraulic

ELK GROVE VILLAGE, IL, March 17, 2021 – Hearing the manufacturing line is down and a mold has been damaged because of an ejector issue is the last thing an operations manager wants to hear. Unfortunately, if you can’t maintain tight control over how and wh...

Read moreWhy Screw Design is Critical to Your Injection Molding Success

ELK GROVE VILLAGE, IL, March 9, 2021 – The proper selection of your screw for any given injection molding application is critical to successful processing. In fact, changing to an optimized screw design has been shown to improve cycle times and reduce part...

Read moreWhat to Know When Deciding Between All-Electric and Servo-Hydraulic Injection Molding Machines

ELK GROVE VILLAGE, IL, March 2, 2021 – Precision and repeatability. These are two things that all shop floors are looking to continually achieve. When considering what type of injection molding machine you want to help you achieve these things there are se...

Read moreDoes Your Injection Molding Machine Offer Easy Visibility into Diagnostics and History?

ELK GROVE VILLAGE, IL, February 23, 2021 – Troubleshooting and maintenance can become tedious and time-consuming tasks on the manufacturing floor. What would it mean to your business if you were able to more efficiently understand your machine and have qui...

Read moreWhy Injection Molding Machine Design Matters - And What to Look For

ELK GROVE VILLAGE, IL, February 19, 2021 – When you have a well-designed injection molding machine there are no limits to what types of molded parts you can create. Whether it's automotive, packaging, medical, or custom plastics - an injection molding mach...

Read moreMinimizing Injection Molding Complexity without Compromising Capability

ELK GROVE VILLAGE, IL, February 10, 2021 – The convenience of your injection molding machine controller correlates directly with your factory production efficiency. A controller that is not only powerful but offers intuitive operation, simple navigation, ...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools