What to Know When Deciding Between All-Electric and Servo-Hydraulic Injection Molding Machines

ELK GROVE VILLAGE, IL, March 2, 2021 – Precision and repeatability. These are two things that all shop floors are looking to continually achieve. When considering what type of injection molding machine you want to help you achieve these things there are several options.

Many shops find themselves comparing all-electric machines to servo-hydraulic machines. In this article, we will be investigating the differences between them and offering insight into which offers higher precision and repeatability, and why.

Improving Precision & Repeatability

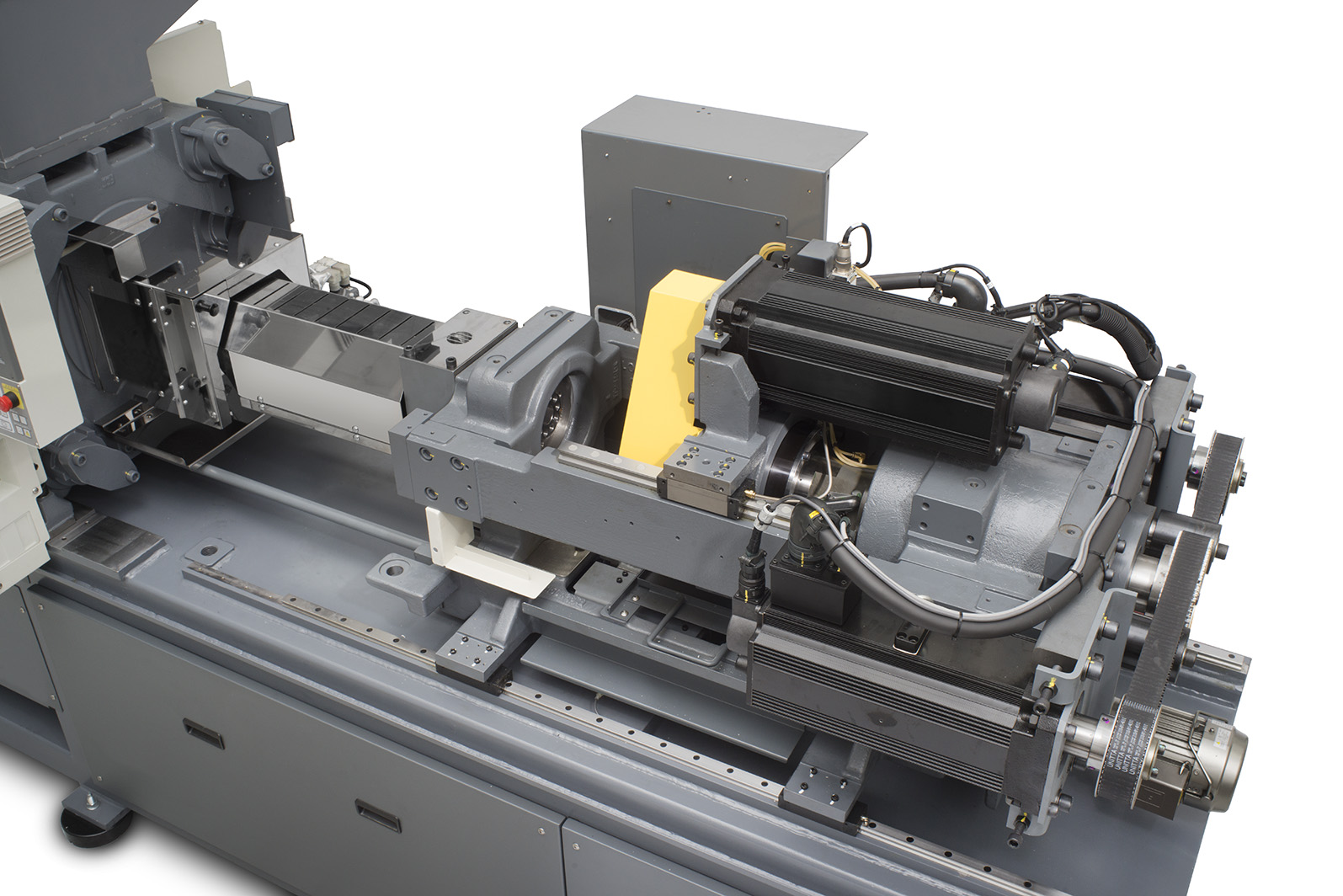

Of all molding machines on the market, all-electric injection molding machines have the highest accuracy and repeatability. But why is that? Several reasons to consider specific to our Shibaura Machine all-electric ECSXIII series include:

- The optical rotary encoders in our ECSXIII series offer position sensing with a control resolution of .00005 mm ensuring complete precision and repeatability.

- In combination with the V70 controller, the advanced load cell used in the ECSXIII can help achieve scientific molding without the requirement of internal transducers.

- The control of acceleration and deceleration on our all-electric machines is smoother because the force is controlled through the current to the servo motor. Force is instantaneous, which is a huge advantage.

- The heavy weight of the ECSXIII injection unit is supported on linear guides, greatly reducing the drag of injection and back pressure allowing for a more precise process. The friction-free drive system also ensures more accurate injection speed and backpressure control, improving shot-to-shot repeatability throughout the processing cycle. This results in accurate and repeatable control of the force output at the work point. On the other hand, hydraulic machine cylinders are slower and not as responsive resulting in less shot-to-shot precision.

It’s clear the future of the industry is the all-electric machine. Shibaura’s all-electric injection molding machine offers improved accuracy and repeatability compared to its servo-hydraulic counterparts. Contact our team to learn more about how the features of the ECSXIII series can give your shop a competitive advantage.

Contact our team today to learn how Shibaura Machine all-electric technology can give your shop a competitive advantage!

Related Articles View All Articles

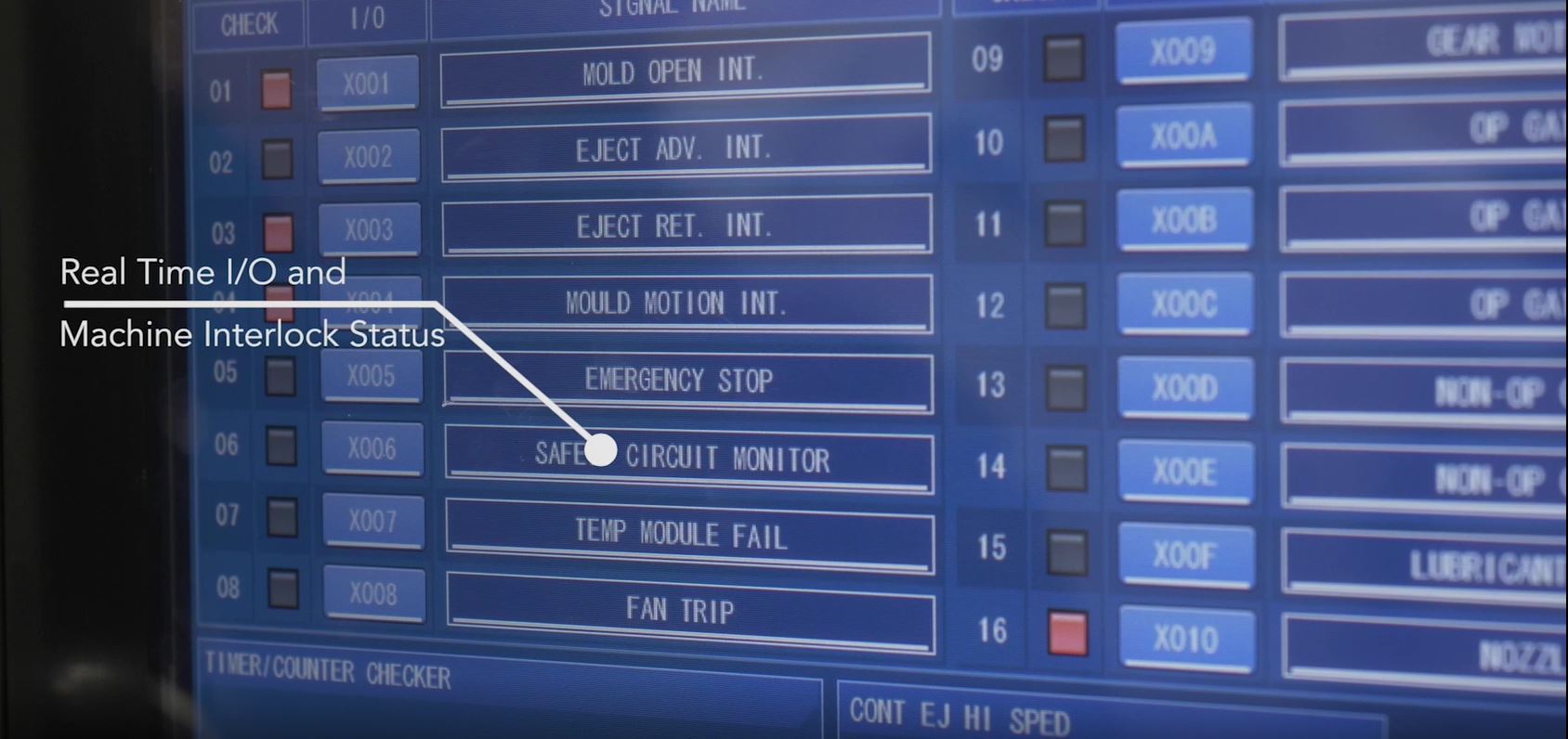

Does Your Injection Molding Machine Offer Easy Visibility into Diagnostics and History?

ELK GROVE VILLAGE, IL, February 23, 2021 – Troubleshooting and maintenance can become tedious and time-consuming tasks on the manufacturing floor. What would it mean to your business if you were able to more efficiently understand your machine and have qui...

Read moreWhy Injection Molding Machine Design Matters - And What to Look For

ELK GROVE VILLAGE, IL, February 19, 2021 – When you have a well-designed injection molding machine there are no limits to what types of molded parts you can create. Whether it's automotive, packaging, medical, or custom plastics - an injection molding mach...

Read moreMinimizing Injection Molding Complexity without Compromising Capability

ELK GROVE VILLAGE, IL, February 10, 2021 – The convenience of your injection molding machine controller correlates directly with your factory production efficiency. A controller that is not only powerful but offers intuitive operation, simple navigation, ...

Read moreAll-Electric Injection Molding Machines Offer More Than Energy Savings

ELK GROVE VILLAGE, IL, February 3, 2021 – Did you know energy spending in most injection molding plants is one of the highest costs month after month? At the end of the day, it is often costing more to run old machines then it would to invest in new, energ...

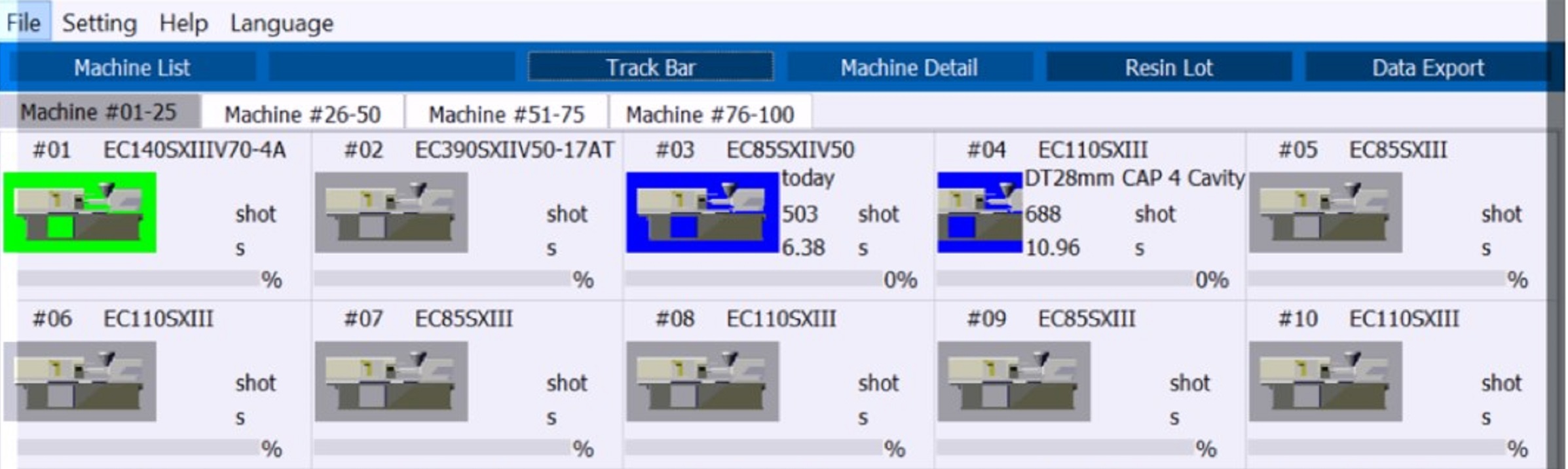

Read moreImprove Quality Control and Productivity with the iPAQET Remote Data Management System

ELK GROVE VILLAGE, IL, January 27, 2021 – Not all monitoring and data management systems are created equal. Many systems are prone to errors, have less than easy to use interfaces, or require someone to be in front of the machine- oftentimes collecting dat...

Read moreHow to Minimize Injection Molding Machine Downtime

ELK GROVE VILLAGE, IL, January 19, 2021 – Whether planned or unplanned, machine downtime is very costly. Aside from directly impacting production and labor, machine downtime extends to other areas of operation and can affect the organization as a whole. An...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools