K-2025 Media Hub

Shibaura Machine Press Conference Summary

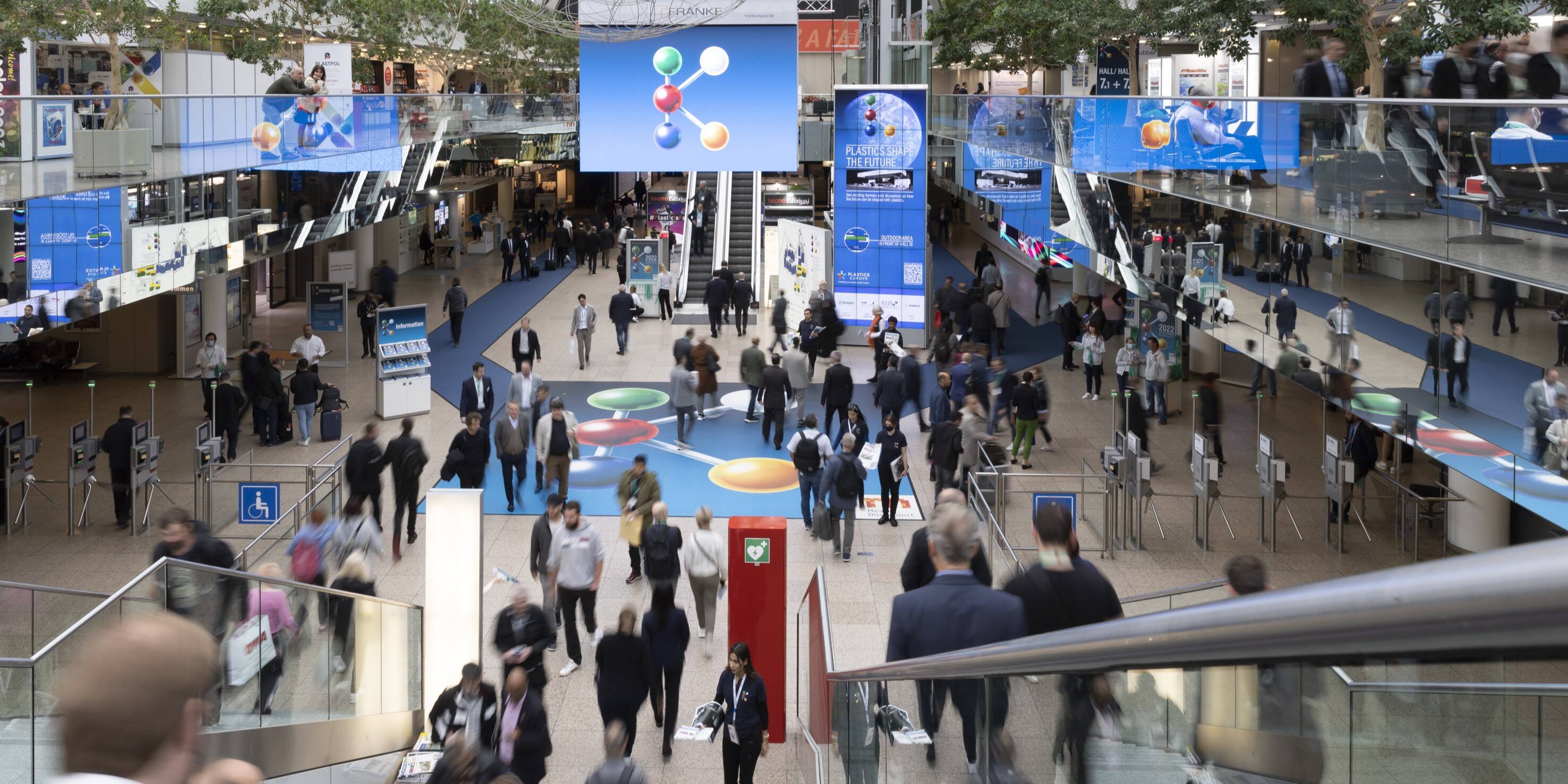

October 9| Messe Düsseldorf, Germany

Shibaura Machine Showcases Smart, Sustainable Turnkey Solutions at K-Show 2025

Shibaura Machine held its official K-Show 2025 press conference on October 9 at 1:30 PM, unveiling its latest advancements in turnkey injection molding solutions, digitalization, and sustainability-driven manufacturing. Under the theme “Transforming Manufacturing: Smarter, More Efficient & Sustainable,” the company highlighted key product launches, digital innovations, and strategic business developments set to shape the future of plastics processing.

Driving Long-Term Growth and Innovation

President Shigetomo Sakamoto opened the event with a forward-looking strategy centered on expanding turnkey system offerings, advancing AI-driven manufacturing, and strengthening Shibaura Machine’s global footprint, particularly in Europe and EMEA.

All-Electric Innovation: EC-SXIII Series

Director and Executive Operating Officer, Jun Koike introduced the EC-SXIII Series, setting new benchmarks in energy efficiency, performance, and precision.

At K-Show, Shibaura Machine demonstrated its EC75SXIII All-Electric Injection Molding Machine, operating in a fully automated production cell manufacturing sleek business card holders from recycled PET (rPET). The system integrates robotics, in-line logo printing, and real-time monitoring via machiNetCloud to maximize Overall Equipment Effectiveness (OEE).

Hydraulic Excellence: S-GenXt Series

Kumar Mathrubootham, Managing Director of Shibaura Machine India, presented the S-GenXt 180-7A Hydraulic Injection Molding Machine, emphasizing its ability to merge hydraulic power with energy efficiency. The machine showcased the production of Polypropylene (PP) food containers using an Indian-built mold and an In-Mold Labeling (IML) system, supported by in-house auxiliary equipment for optimal process control.

Smart Manufacturing with machiNetCloud and LEO

Michael Werner, IIoT Business Development Manager, Shibaura Machine Company, America unveiled the latest machiNetCloud suite, enabling manufacturers to monitor production data, implement predictive maintenance, and improve OEE through data-driven insights. The introduction of LEO (Line Efficiency Optimizer) marked a step forward in AI-assisted operations—predicting potential failure points, assisting operators, and unlocking up to 20% productivity gains.

Strategic Expansion in Europe

Dr. Georg Holzinger, Managing Executive Officer, announced Shibaura Machine’s acquisition of an 80% stake in LWB Steinl GmbH & Co. KG, strengthening its European presence and product portfolio. The Altdorf, Germany facility will serve as Shibaura’s European headquarters and production hub, offering vertical injection machines and automation solutions while retaining both the Shibaura Machine and LWB brands.

A Vision for the Future

Through its focus on automation, digitalization, and sustainability, Shibaura Machine reaffirmed its commitment to empowering global manufacturers with integrated, future-ready solutions. With 87 years of engineering excellence and a strong global presence, the company remains dedicated to building a smarter, greener, and more efficient manufacturing future.

Press Conference Agenda

- 1:00 p.m. to 1:30 p.m. - Registration

- 1:30 p.m. to 1:35 p.m. – Welcome remarks

- 1:35 p.m. to 2:15 p.m. - Presentations

- 2:15 p.m. to 2:30 p.m. - Q&A

Media Assets

Speakers

Shigetomo Sakamoto

President, Shibaura Machine Group

Japan

Georg Holzinger

Managing Executive Officer

Germany

Kumar Mathrubootham

Managing Director, Shibaura Machine India

India

Jun Koike

Director and Executive Operating Officer

Japan

Michael Werner

IIoT Business Development Manager

United States

Smarter Machines. Sharper Performance. Only at Booth B21.

Discover Smart Sustainability in Action: All-Electric Production Cell Producing rPET Card Holders in a Fully Automated Cell

See our EC-SXIII Series All-Electric Injection Molding Machine in action—producing sleek business card holders from recycled PET (rPET) in a fully automated, high-efficiency turnkey production cell. This production cell is designed to manufacture the parts, perform assembly, and complete the process with precise logo printing—all in one seamless workflow.

This advanced manufacturing setup showcases not only the precision and energy efficiency of our EC-SXIII Series but also integrates our latest state-of-the-art auxiliary equipment. The cell is intelligently powered by Virtual Machine Expert, our AI-driven monitoring system that proactively tracks machine performance and alerts operators before issues arise—minimizing downtime and maximizing productivity.

Plus, our machiNetCloud IIoT solution captures real-time machine data to deliver actionable insights that help you optimize operations and improve OEE.

Cleaner, smarter, and more connected—this is the future of injection molding.

Injection Molding Machine:

EC75SXIII All-Electric Machine

Material:

Recycled PET (rPET)

Auxiliary Equipment:

SHIBAURA 6-axis robots (TV1000 & TVM900)

SHIBAURA Compact Dehumidified Air Dryer (HCD50)

SHIBAURA Air-Cooled Chiller (LTAC 3.5)

STAR AUTOMATION Take-Out Robot (IXW-800SVIP)

ROBOPRINT Logo Printer (T-transfer)

CNN 1-cavity rPET mold

IIoT:

machiNetCloud

Smarter Hydraulic Machines for Sustainable Packaging: Fully automated S-GenXt Series Injection Molding Machine Producing Polypropylene (PP) Food Containers

See our S-GenXt series Hydraulic injection molding machine produce Polypropylene (PP) food containers in a fully automated production cell—delivering the performance, precision, and energy efficiency today’s packaging industry demands.

The cell features our proprietary binary injection technology, enabling fast cycle times while reducing costs—without the need for expensive accumulators or additional components. Integrated with our in-house drying system and real-time control of auxiliary equipment directly from the molding machine.

At the heart of the system is our Virtual Machine Expert, an AI-powered monitoring tool that continuously analyzes machine performance and proactively alerts operators to potential issues— it gives real meaning to predictive maintenance, turning data into decisive action.

Our machiNetCloud IIoT platform adds another layer of intelligence by capturing live machine data and turning it into actionable insights.

Injection Molding Machine:

S-GenXt 180-7A Hydraulic machine

Material:

Polypropylene (PP)

Auxiliary Equipment:

WETEC W830X In-Mold Labeling System

SHIBAURA Compact Dehumidified Air Dryer (HCD150)

SHIBAURA Air-Cooled Chiller (LTAC 5)

CNN 2-cavity Polypropylene (PP) mold

IIoT:

machiNetCloud

Revolutionize Your Molding Process with Shibaura Machine’s Auxiliary Solutions

Step into the future of injection molding with Shibaura Machine’s cutting-edge auxiliary equipment—where performance meets innovation. Whether you’re handling materials, managing drying systems, or fine-tuning temperature control, our smart solutions are meticulously engineered to enhance every phase of your electric or hydraulic molding operations.

Expect more than just equipment—experience next-level energy efficiency, low-maintenance reliability, and durability that goes the distance. Our advanced automation and turnkey systems are designed to help you cut downtime, boost part quality, and streamline your entire production line.

Ready to transform your floor into a high-performance powerhouse?

Discover it all at the Shibaura Machine booth.

Transform Your Production with Real-Time Intelligence from machiNetCloud

Smarter Monitoring Across Any Machine

machiNetCloud is Shibaura Machine’s advanced IIoT platform designed to elevate operational efficiency, improve uptime, and unlock measurable ROI across your manufacturing floor. Built to support both all-electric and hydraulic injection molding machines, as well as auxiliary equipment, machiNetCloud provides seamless connectivity and a centralized view of your operations. With features like real-time monitoring, predictive maintenance, energy tracking, and performance analytics, it empowers decision-makers to act proactively reducing unplanned downtime, optimizing cycle times, and lowering total cost of ownership.

At K-2025, we invite you to experience the full capabilities of machiNetCloud firsthand. All machines at our booth will be connected through the platform, offering live data visibility and interactive dashboards in real time. Our experts will be on-site to guide you through one-on-one demos, answer your technical questions, and show how machiNetCloud delivers tangible results from day one. If you're ready to take a smarter, data-driven approach to manufacturing, this is the platform—and the opportunity—you won't want to miss.

Shape a Sustainable Future with rPET and Shibaura Machine

Looking to boost sustainability without sacrificing performance?

rPET (recycled polyethylene terephthalate) is the solution. Sourced from post-consumer plastics like bottles and packaging, rPET delivers the strength, clarity, and reliability manufacturers expect—while significantly reducing environmental impact. Perfect for high-volume applications across packaging, automotive, and more, rPET is leading the charge toward a greener, circular economy.

With Shibaura Machine’s advanced injection molding solutions, you can process rPET with precision, efficiency, and confidence. Discover how our technology helps you mold smarter, cleaner, and more sustainably—without compromise.

Built for Every Task: Shibaura Machine’s Scalable Robotic Solutions

Shibaura Machine offers a comprehensive range of industrial robots ideally suited for high-precision assembly, machine loading/unloading and material-handling applications that can be dust proof, clean room, or IP65/67. The company’s extensive product line starts with a Cartesian solution available in thousands of combinations from single actuators to 4-axis solutions; a complete range of SCARAs from low cost to the industry-leading reach of 1200-mm that can carry up to 20 kgs of payload, and 6-axis solutions that are well suited to general purpose handling applications, working with Injection Molding Machines or downstream automation processes such as inspection, packaging or assembly tasks.

Customer Stories From Around The World

VDI Manufacturing

VDI Manufacturing is a veteran-owned company whose primary mission is Production Injection Molding, Assembly, and Tooling. In addition, offers a full complement of prototyping services including: design assistance, 3D printing, quick-turn aluminum tooling, and prototype molding. VDI also offers an on-site ISO/IEC 17025:2017 Accredited Metrology Lab to certify quality and dimensions on every project. VDI’s collective experience dates back to the 1980s and is backed by state-of-the-art, Shibaura Machine all-electric molding machines, and automated processes.

SPAL Automotive

SPAL Automotive is an Italian company based in Correggio (RE), founded in 1959 and specialized in the production of electromechanical components for the automotive industry. The company works in the design, production and global trade of axial and centrifugal electric fans for cars, motorcycles, buses, off-road vehicles, earthmoving machines, agricultural tractors, trucks and industrial equipment. Starting in 2013, SPAL began its collaboration with EPF, focusing on the fully electric Shibaura Machine injection molding machines. This collaboration has created a real production department consisting of 21 injection molding machines with a capacity from 50 to 1800 tons. The advantages of working with EPF are: a longer cycle time and the possibility of increasing production capacity, a quieter department, lower consumption compared to hydraulic injection molding machines and more streamlined logistics.

INVAT

INVAT is a leading international player in the closures sector for metal, glass, and PET, producing over 500 million pieces annually. In its new factory, the company has adopted Shibaura Machine full electric injection molding machines (II/III series) and has experienced numerous advantages, from repeatability and ease of cleaning to precision in molding and significant reductions in production costs. EPF Plastic compared two injection molding machines of the same tonnage in the INVAT molding department—one fully electric (EC350SXIII) and the other a new generation hydraulic model from a competitor. With the same mold and molding conditions, we observed significant energy savings, all confirmed by a series of measurements conducted on the machines.

Miraial Co., Ltd. in Tokyo & Kumamoto, Japan

Our company manufactures injection-molded products primarily for the semiconductor industry, utilizing a wide range of raw materials, from general-purpose resins to high-performance engineering plastics. Given the stringent requirements for dimensional precision, heat and chemical resistance, and cleanliness in our molded products, the performance of our injection molding machines plays a critical role in ensuring product quality. Since our establishment, we have been using various models of injection molding machines from Shibaura Machine, and they have consistently contributed to meeting increasingly demanding quality standards and improving productivity. We highly value the comprehensive support provided by Shibaura Machine—not only in terms of the latest molding technologies but also in areas such as automation, operational efficiency, and environmental considerations. We look forward to continuing our collaboration and would greatly appreciate your ongoing support as one of our most important technology partners in our pursuit of the highest standards in molding quality.

-Masatoshi Hyobu, President of Miraial Co., Ltd.

Seiko Industries in OSAKA

"Our company primarily uses super engineering plastics as raw materials to produce injection-molded parts for mechanical and electronic components. By using SHIBAURA MACHINE injection molding machines, we have experienced a noticeable reduction in radiant heat, resulting in a cooler factory environment. Since our cycle times (cooling times) tend to be long, the machine's stationary periods are extended, leading to lower power consumption and significant savings on electricity costs. We are extremely satisfied with the results. The high quality of the molding machines is also outstanding, and we feel we have truly benefited from the investment. We also had the opportunity to receive training for our maintenance team from Shibaura Machine’s service personnel, and we recognize them as a strategic partner. If you are considering Shibaura Machine’s products, we highly recommend having a conversation with one of their sales representatives."

-Katsutoshi Hiasa, President of Seiko Industries Co., Ltd.

Maruhachi Corporation in Shizuoka, Japan. – Advancing Manufacturing Excellence with Shibaura Machine

Celebrating its 57th anniversary, Maruhachi Corporation began its journey with metal painting. As motorcycle exterior parts evolved from metal to resin, we were among the first in the region to pioneer resin painting technologies, positioning ourselves as a leader in the field to meet changing customer needs. Building on this foundation, we later expanded into mould design and resin moulding, allowing us to establish a fully integrated production system. This end-to-end capability enables us to deliver high-quality products that meet the sophisticated design requirements of brand-conscious clients.

In recent years, we developed a direct film insert technology in collaboration with major Japanese motorcycle manufacturers. This innovative process eliminates the need for post-painting graphic film application by embedding seamless, peel-resistant graphics directly into the mould. The technology has earned widespread acclaim from users around the world. When we initially launched our moulding operations, cost was our primary consideration, and we utilized machines from another manufacturer. However, as we progressed, it became evident that achieving our desired level of quality required more advanced equipment. This led us to adopt Shibaura Machine's moulding machines.

Following implementation, the machines exceeded our expectations by delivering high-precision, stable moulding quality, significantly enhancing the reliability of our products. Today, all our moulding operations—both in Japan and Indonesia—are conducted using Shibaura Machine’s equipment. Additionally, the introduction of Shibaura Machine’s remote monitoring system, iPAQET, has enabled real-time tracking of machine operations. In the event of a product defect, we can promptly examine moulding conditions on a per-unit basis, allowing us to swiftly identify root causes and implement corrective measures.

We also highly value the responsiveness and professionalism of the Shibaura Machine service team. Their timely support and technical expertise have earned our deep trust. Shibaura Machine’s equipment and support form the backbone of our manufacturing operations. Together, we will continue to deliver high-quality, reliable products to customers around the globe.

- Masaki Alex Ando, President of Maruhachi Corporation

Hoffer Plastics

Founded in 1953, Hoffer Plastics has grown to become an industry leader and innovator in the custom plastic injection molding industry. Located in a 365,000 sq. ft. facility on 24 acres and employing more than 350 people, they produce more than three billion plastic parts annually. Boasting a consistent 99% on-time delivery record, Hoffer Plastics has been honored with numerous awards including Plastic News "Processor of the Year".

http://www.hofferplastics.com