Shibaura's BTD-130S.R22: High Capacity, Compact Design for Modern Manufacturing

ELK GROVE VILLAGE, IL, October 8, 2024 -

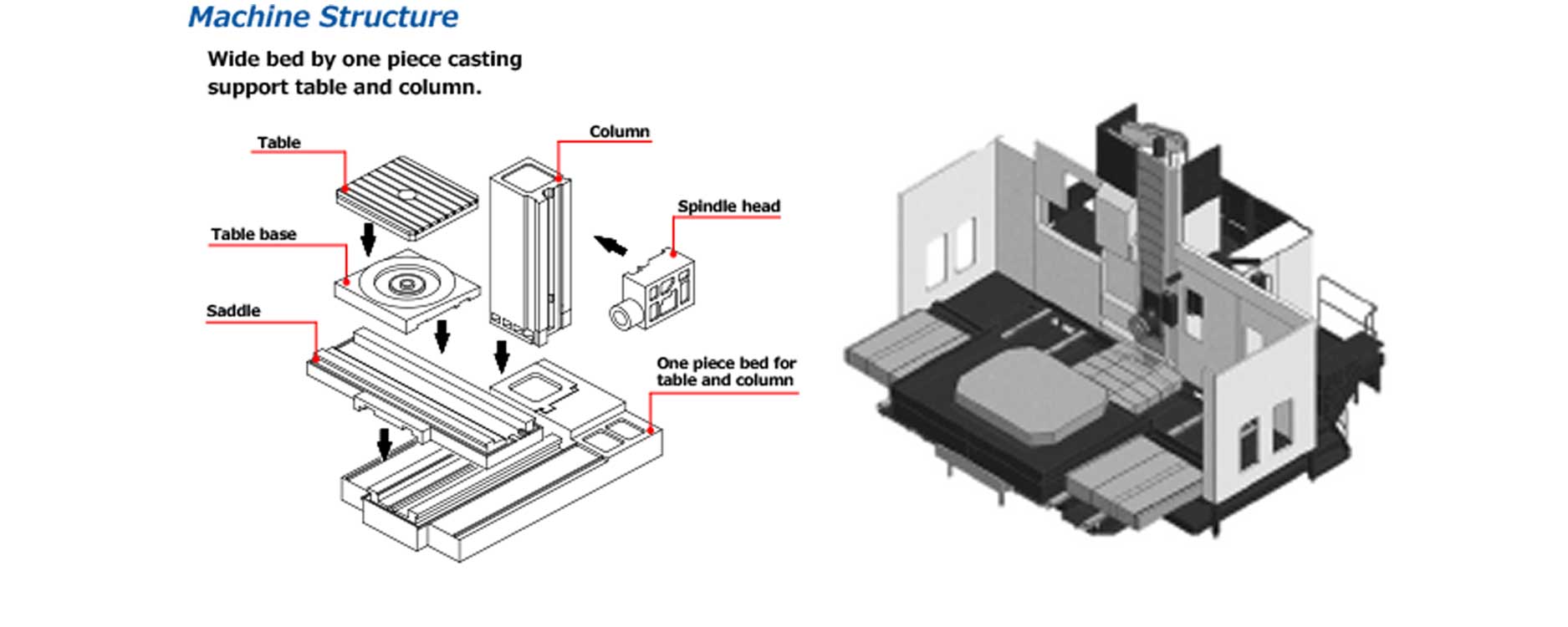

The Shibaura Machine BTD-130S.R22 Table-Type Horizontal Boring Machine represents the next era in precision machining, developed as the successor to the BTD-130H.R22.

Building on decades of expertise in machine manufacturing, this machine offers cutting-edge features like spindle cooling, rotary milling, and automated systems. Shibaura Machine’s legacy of producing high-quality machine castings at its in-house foundry further sets it apart. With the BTD-130S.R22, manufacturers benefit from a modern, compact design, high capacity, and flexibility—boosting productivity while maintaining a lean footprint.

Compact Machine with Big Capabilities

In today’s fast-paced manufacturing environment, increasing output without sacrificing valuable floor space is key. The BTD-130S.R22 answers this challenge with its 5.1 inches (130mm) spindle diameter and impressive X stroke of 118 inches (3000mm) and Y stroke of 90.5 inches (2300mm), allowing manufacturers to handle larger, more complex workpieces. This compact yet powerful design eliminates the need for additional space, making it an ideal solution for operations looking to improve capacity and precision while providing an efficient, small footprint.

Boost Efficiency with Advanced Features

Maximizing productivity while minimizing downtime is crucial in modern manufacturing. The BTD-130S.R22’s portable handwheel feed unit facilitates smooth transitions between manual and CNC operations, reducing setup time and errors. Its rotary milling function eliminates the need for additional rotary tables, allowing for seamless cylindrical and end surface machining—saving both time and simplifying programming.

For those needing higher precision, the scale feedback system on X, Y, Z, and B axes further improves accuracy, designed with servo drive mechanisms to achieve high rigidity during operations.

Built to Handle the Most Demanding Jobs

Meeting high capacity and load requirements is a challenge for many industries. The BTD-130S.R22 addresses this with its advanced dual pinion drive system and robust table features, making it ideal for machining heavy, complex parts.

At the core of its precision is the highly rigid double pinion drive system on the B-axis, ensuring stabilized table indexing. This advanced mechanism guarantees smooth, precise rotary movements even under heavy loads, enhancing both accuracy and consistency during machining operations.

With a table load capacity of up to 44,000 lbs (20,000 kgs) and optional air lift functionality, the BTD-130S.R22 effortlessly handles massive workpieces. The optional Automatic Pallet Changer (APC), supporting two pallets, further streamlines production for increased efficiency.

Optimizing Machine Utilization

Maintaining peak productivity and precise quality control is crucial in today’s competitive environment. The BTD-130S.R22 addresses this challenge with optional workpiece probing and tool setting features that support efficient operations.

- Renishaw Automatic Measuring Probe: Enables tool calibration and offset adjustments, reducing errors and downtime.

- Automatic Tool Setting with Renishaw RTS Probe: Improves productivity by automating tool length measurement and compensation, improving overall machining efficiency.

Future-Proof Your Operations

For those seeking to enhance their production capabilities, the BTD-130S.R22 Table-Type Horizontal Boring Machine offers a future-focused solution, designed to help manufacturers stay at the forefront of innovation. Reach out to Shibaura Machine Company, America today to learn more about how this advanced table-type horizontal boring mill can optimize your production process.

Related Articles View All Machine Tools Articles

Final Days at IMTS 2024—Visit Shibaura Machine’s Booth Today!

ELK GROVE VILLAGE, IL, September 11, 2024 - What a fantastic start to IMTS 2024! Over the past two days, our booth in the South Hall, Level 3, #339424, has been filled with activity as we showcase the latest in machining technology. It’s been a pleasure co...

Read moreShibaura Machine Welcomes You to IMTS 2024: A Showcase of Innovation and Excellence

ELK GROVE VILLAGE, IL, September 9, 2024 - Shibaura Machine Company, America is thrilled to welcome you to the opening day of the International Manufacturing Technology Show (IMTS) 2024 at McCormick Place in Chicago! The past two years have brought incredi...

Read moreShowcasing Advanced Probing Technology: Metrology Resource Group and Shibaura Machine at IMTS 2024

ELK GROVE VILLAGE, IL, August 13, 2024 - Dynamic part probing technology is revolutionizing CNC machine tools by providing data that enhances accuracy, efficiency, and productivity. By integrating sensors and software, this technology collects and analyzes...

Read moreTransforming Manufacturing with Virtual Reality and Digital Twin Technology: Shibaura Machine at IMTS 2024

ELK GROVE VILLAGE, IL, August 6, 2024 - Shibaura Machine is transforming the manufacturing landscape with its innovative use of digital twin and virtual reality (VR) technologies. These cutting-edge tools are setting new standards in manufacturing excellen...

Read moreDiscover the Future of Smart Manufacturing with Shibaura Machine’s IIoT machiNetCloud at IMTS 2024

ELK GROVE VILLAGE, IL, July 30, 2024 - As the manufacturing industry moves towards digital transformation, the integration of Industrial Internet of Things (IIoT) solutions has become increasingly important. At the forefront of this industry shift, Shibaur...

Read moreShibaura Machine's Space-Saving BTD-110S.R16 HBM with FANUC and TOSNUC Control Options at IMTS 2024

ELK GROVE VILLAGE, IL, July 23, 2024 - In today’s competitive manufacturing landscape, facilities need compact yet powerful solutions to enhance their machining capabilities without expanding their footprint. Shibaura Machine’s BTD-110S.R16 Horizontal Bori...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools