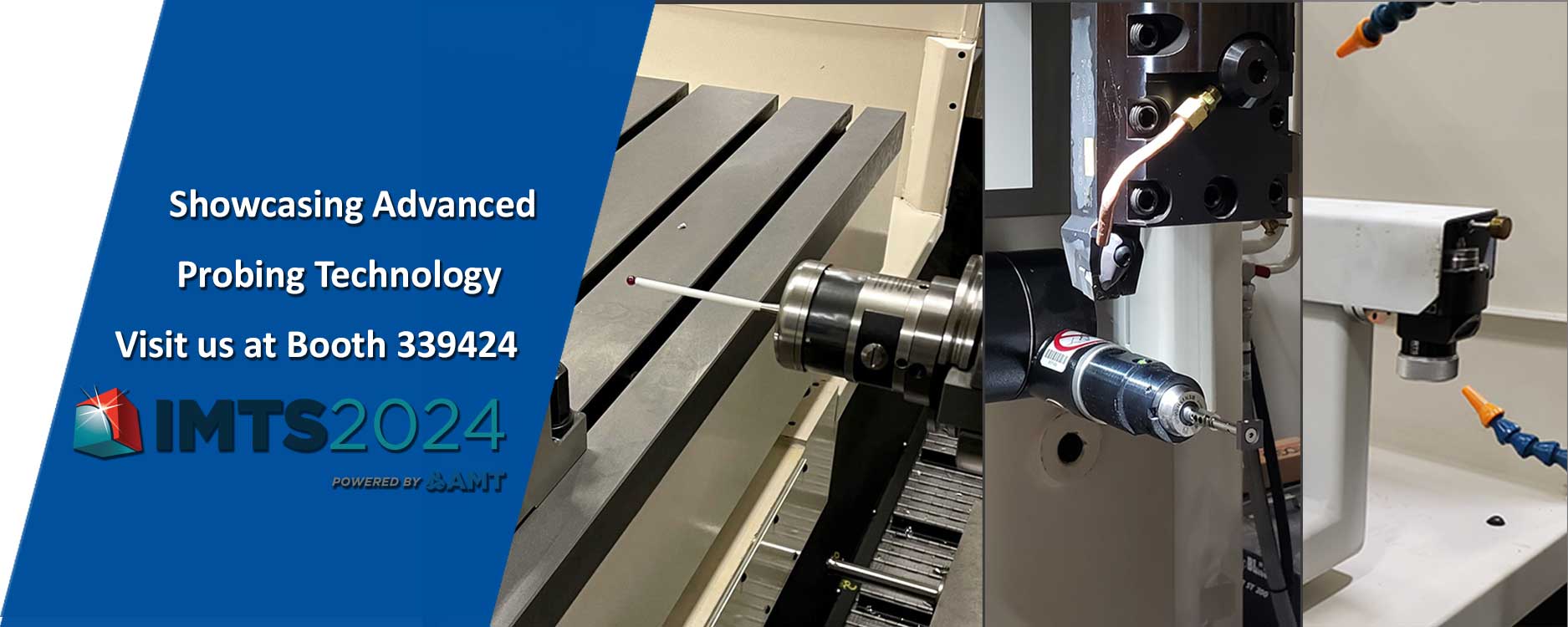

Showcasing Advanced Probing Technology: Metrology Resource Group and Shibaura Machine at IMTS 2024

ELK GROVE VILLAGE, IL, August 13, 2024 -

Dynamic part probing technology is revolutionizing CNC machine tools by providing data that enhances accuracy, efficiency, and productivity. By integrating sensors and software, this technology collects and analyzes data throughout the machining process, significantly improving precision and reducing the need for operator intervention.

Shibaura Machine has partnered with Metrology Resource Group to develop and implement these advanced probing solutions. From radio probe systems for the vertical boring and turning mills to part measurement solutions on the horizontal boring mill machines, this collaboration has continually pushed the boundaries of machining technology.

At the International Manufacturing Technology Show (IMTS), Shibaura Machine will showcase the vertical boring and turning mill TUE-200(S) and horizontal boring mill BTD-110S.R16 machine with these probing technologies at Booth #339424 in the South Hall. Join us to see live demonstrations and learn how these solutions can elevate your manufacturing capabilities.

Discover the Shibaura Motorized Tool Setting Innovation at IMTS

One of Metrology Resource Group’s most significant innovations is the HPMA motorized tool setting solution for the VTL series. This advanced solution allows users to quickly and easily set tools on large VTL machines using the JOG feature, automatically updating the control tool offsets. This eliminates the need for experienced operators with macro programming skills, streamlining the process and enhancing operational efficiency. Key benefits of the HPMA motorized tool setting solution include:

- Ease of Use: Simplifies tool setting on large VTL machines.

- Increased Efficiency: Reduces the time required for tool setting and adjustments.

- Automatic Updates: Automatically updates control tool offsets.

- Operator Independence: Eliminates the need for experienced operators with macro programming skills.

- Enhanced Precision: Improves the accuracy of tool settings.

Partnering for Excellence: Renishaw Probing Systems

Shibaura Machine’s collaboration with Metrology Resource Group and Renishaw brings the Renishaw RPM-60 inspection probe system to vertical turning lathes, horizontal boring mills, and bridge-style/double-column machines. These systems automate processes, reduce downtime and rework, and lower calibration and maintenance costs. They also improve safety and productivity by reducing manual input errors and allowing operators to focus on proactive engineering roles.

Join Shibaura Machine at IMTS 2024

Shibaura Machine invites all industry professionals to explore the advanced probing technology developed in collaboration with the Metrology Resource Group at IMTS 2024. Visit our booth to see live demonstrations of these innovative solutions and learn how they can enhance your manufacturing capabilities.

Event Details:

- Dates: September 9-14, 2024

- Location: McCormick Place, Chicago, IL, South Building, Level 3, 339424- Metal Removal

Registration: Open to the public at IMTS 2024 Registration

Related Articles View All Machine Tools Articles

Transforming Manufacturing with Virtual Reality and Digital Twin Technology: Shibaura Machine at IMTS 2024

ELK GROVE VILLAGE, IL, August 6, 2024 - Shibaura Machine is transforming the manufacturing landscape with its innovative use of digital twin and virtual reality (VR) technologies. These cutting-edge tools are setting new standards in manufacturing excellen...

Read moreDiscover the Future of Smart Manufacturing with Shibaura Machine’s IIoT machiNetCloud at IMTS 2024

ELK GROVE VILLAGE, IL, July 30, 2024 - As the manufacturing industry moves towards digital transformation, the integration of Industrial Internet of Things (IIoT) solutions has become increasingly important. At the forefront of this industry shift, Shibaur...

Read moreShibaura Machine's Space-Saving BTD-110S.R16 HBM with FANUC and TOSNUC Control Options at IMTS 2024

ELK GROVE VILLAGE, IL, July 23, 2024 - In today’s competitive manufacturing landscape, facilities need compact yet powerful solutions to enhance their machining capabilities without expanding their footprint. Shibaura Machine’s BTD-110S.R16 Horizontal Bori...

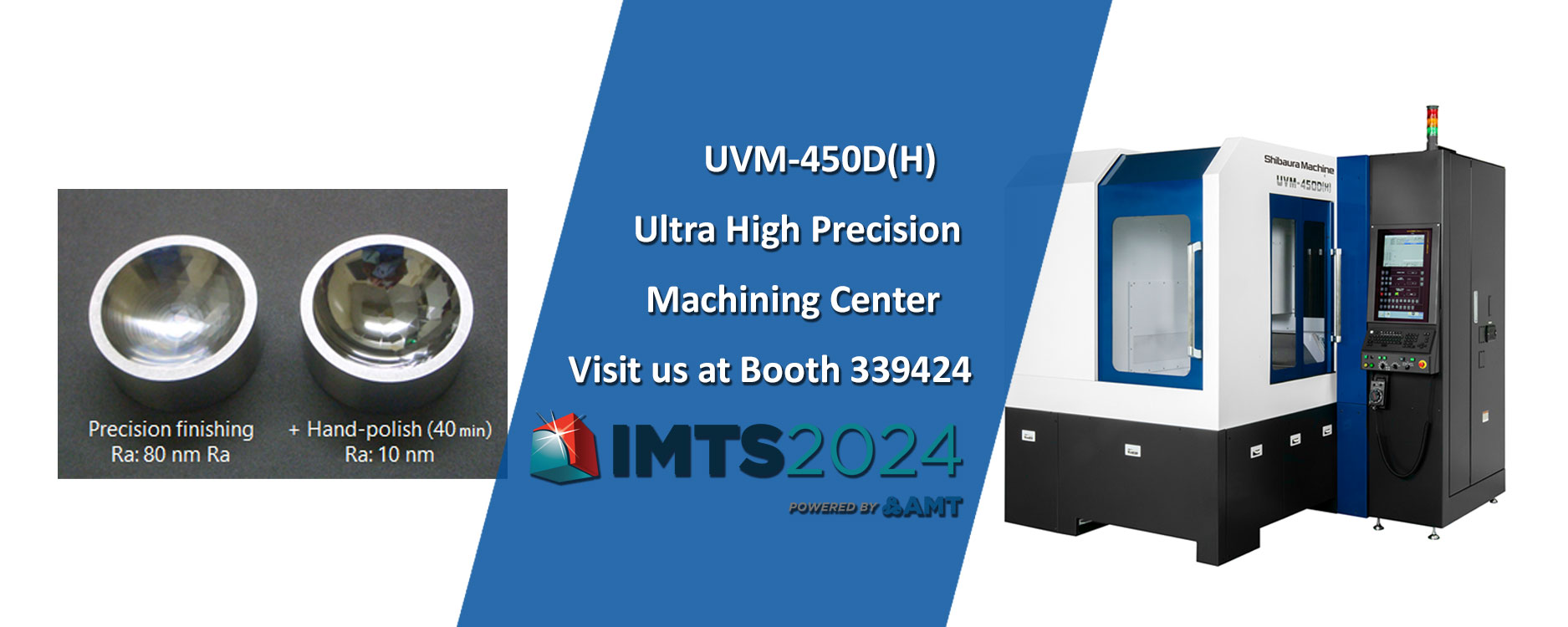

Read moreMeet the Future of Nano Machining: Shibaura Machine's UVM-450D(H) High Precision Machining Center at IMTS 2024

ELK GROVE VILLAGE, IL, July 16, 2024 - As industries evolve, the demand for precision at the nano level has become increasingly vital. Micro machining, characterized by its ability to deliver exceptional accuracy and intricate detailing, is revolutionizing...

Read moreMachining Excellence: Shibaura Machine's TUE-200(S) Vertical Boring and Turning Mill on Display at IMTS 2024

ELK GROVE VILLAGE, IL, July 9, 2024 - As the manufacturing industry continuously advances, the demand for versatile, efficient, and precise machinery grows stronger than ever. Shibaura Machine, America is thrilled to announce that the TUE-200(S) Vertical B...

Read moreSiemens Realize Live 2024 Recap on Shibaura Machine’s Digital Twins and Virtual Reality

ELK GROVE VILLAGE, IL, May 28, 2024 - At the recent Siemens Realize LIVE 2024 event, Shibaura Machine Company, America presented on the transformative potential of digital twins and virtual reality (VR) to further collaborative user engagement and optimize...

Read moreExplore Collaborative VR and Digital Twins with Shibaura Machine at Siemens Realize Live 2024

ELK GROVE VILLAGE, IL, April 23, 2024 - Join Shibaura Machine at the much-anticipated Siemens Realize LIVE 2024, held at Mandalay Bay Convention Center, Resort and Casino in Las Vegas, Nevada from May 13-16, where we’ll be showcasing how we’re harnessing S...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools