Machining Excellence: Shibaura Machine's TUE-200(S) Vertical Boring and Turning Mill on Display at IMTS 2024

ELK GROVE VILLAGE, IL, July 9, 2024 -

As the manufacturing industry continuously advances, the demand for versatile, efficient, and precise machinery grows stronger than ever. Shibaura Machine, America is thrilled to announce that the TUE-200(S) Vertical Boring and Turning Mill will be a highlight of our booth located on Level 3 in the South Hall, #339424 at the upcoming International Manufacturing Technology Show (IMTS) 2024. This modern machine tool represents the pinnacle of our engineering excellence and commitment to advancing the capabilities of the manufacturing industry.

Key Features and Benefits

- Superior Rigidity and Stability

The TUE-200(S) features a high-rigidity structure with a robust column and base design. With cast iron components in one-body construction, this ensures exceptional stability during heavy-duty cutting, reducing vibrations and maintaining precision even under the most demanding conditions.

- Advanced Spindle Technology

Equipped with a powerful spindle, the TUE-200(S) delivers high torque and rotational speeds, enabling efficient machining of a wide range of materials. The spindle's thermal stability and precision bearings further enhance its performance, ensuring consistent accuracy and longevity. - Extended Z-Axis Ram Travel

The TUE-200(S) provides the option to be designed with an extended column and Z-axis ram travel, allowing for greater flexibility and reach when machining large and complex workpieces. This feature increases the machine's capability to handle diverse machining tasks with precision. - Versatile Machining Capabilities

The TUE-200(S) can handle a variety of workpieces, from small components to large, heavy parts. Its flexible tooling options and automated tool change system allow for quick and efficient transitions between different machining tasks. - Enhanced User Interface and Control

The machine is equipped with an advanced FANUC CNC system that offers easy programming, real-time monitoring, and diagnostic capabilities. This user-friendly interface minimizes downtime and maximizes operational efficiency. - Precision and Accuracy

Accuracy is paramount in precision machining, and the TUE-200(S) excels in this area. Its high-precision linear guides and ball screws ensure exceptional positioning accuracy, while the machine's thermal compensation system maintains consistency in varying environmental conditions.

The Pinnacle of Machining Innovation

The TUE-200(S) is not just a machine; it is a comprehensive solution for modern machining challenges. It combines turning, milling, and boring capabilities into a single setup, significantly reducing cycle times and improving overall productivity.

Advanced Chip and Coolant Management

The innovative splash cover chip and coolant management system ensures that chips and coolant remain within the machine's workzone, preventing spillage and maintaining a clean working environment. The splash cover is an optional feature that can be added to both new and existing machines, providing an additional layer of protection and management without compromising accessibility.

Enhanced Tool Changeover with Access Door

Efficiency in tool changeover is crucial for maintaining high productivity levels. The machine features a convenient access door that allows operators to change active cutting tools without removing the entire tool holder/block assembly. This feature minimizes production halts and reduces downtime, offering a competitive edge to machining operations.

Versatile Tool Holders for Precision Machining

The TUE-200(S) is equipped with a diverse range of tool holders, from conventional tools to quick-change adapter systems, each designed to maximize functionality and versatility. These tool holders cater to various machining operations, from intricate boring to precision turning. Several key tool holders are listed below.

- Boring Tool Holder (FMS50A-BFP)

- Turning Tool Holder (FMS50A-ST)

- Sandvik CAPTO (C6, C8)

Join Shibaura Machine at IMTS 2024

Don't miss the opportunity to witness the future of precision machining and explore the possibilities that the TUE-200(S) can bring to your manufacturing operations. Visitors to IMTS 2024 will have the opportunity to check out the TUE-200(S) in action.

Event Details:

- Dates: September 9-14, 2024

- Location: McCormick Place, Chicago, IL, South Building, Level 3, 339424- Metal Removal

Registration: Open to the public at IMTS 2024 Registration

Related Articles View All Machine Tools Articles

Siemens Realize Live 2024 Recap on Shibaura Machine’s Digital Twins and Virtual Reality

ELK GROVE VILLAGE, IL, May 28, 2024 - At the recent Siemens Realize LIVE 2024 event, Shibaura Machine Company, America presented on the transformative potential of digital twins and virtual reality (VR) to further collaborative user engagement and optimize...

Read moreExplore Collaborative VR and Digital Twins with Shibaura Machine at Siemens Realize Live 2024

ELK GROVE VILLAGE, IL, April 23, 2024 - Join Shibaura Machine at the much-anticipated Siemens Realize LIVE 2024, held at Mandalay Bay Convention Center, Resort and Casino in Las Vegas, Nevada from May 13-16, where we’ll be showcasing how we’re harnessing S...

Read moreThe Foundation of Manufacturing Excellence: A Strong Machine Tool Factory Presence

ELK GROVE VILLAGE, IL, March 26, 2024 - The machine tool industry is a cornerstone of North American manufacturing. It powers sectors from automotive to aerospace with the precision and efficiency needed to compete on a global scale. In this dynamic landsc...

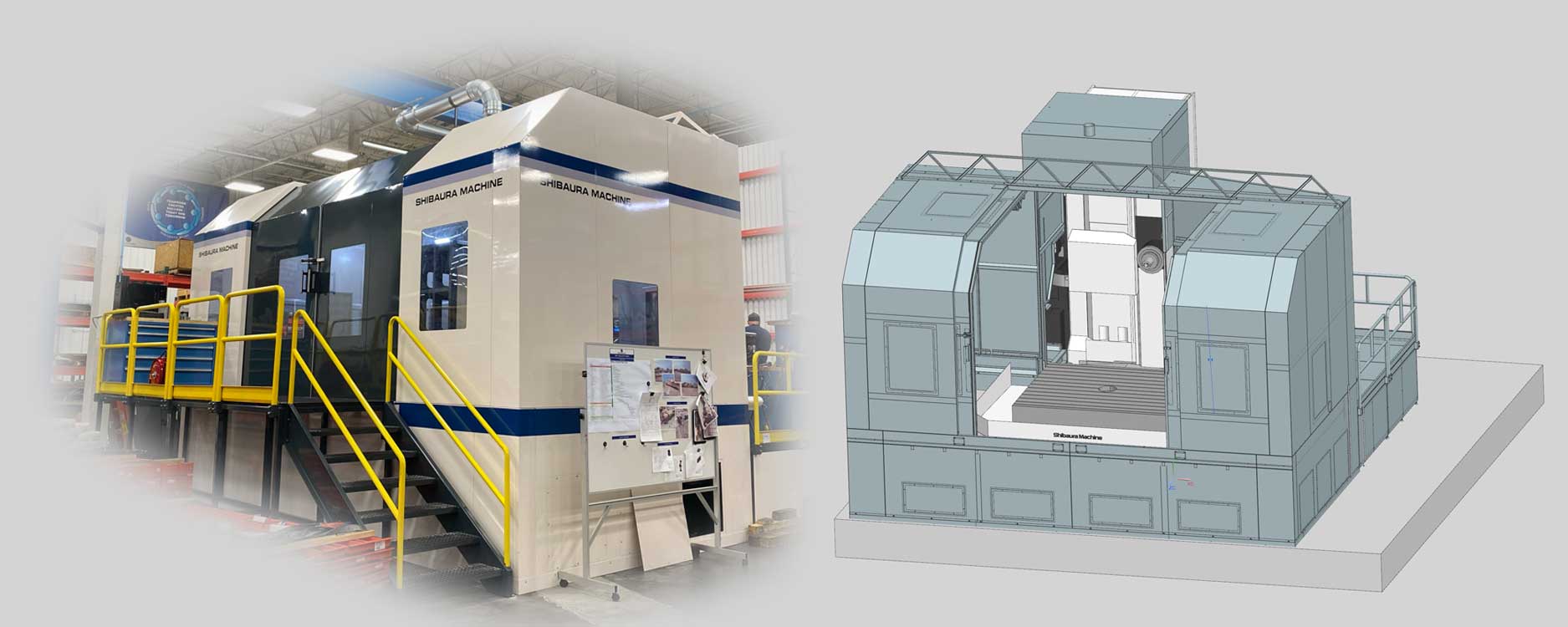

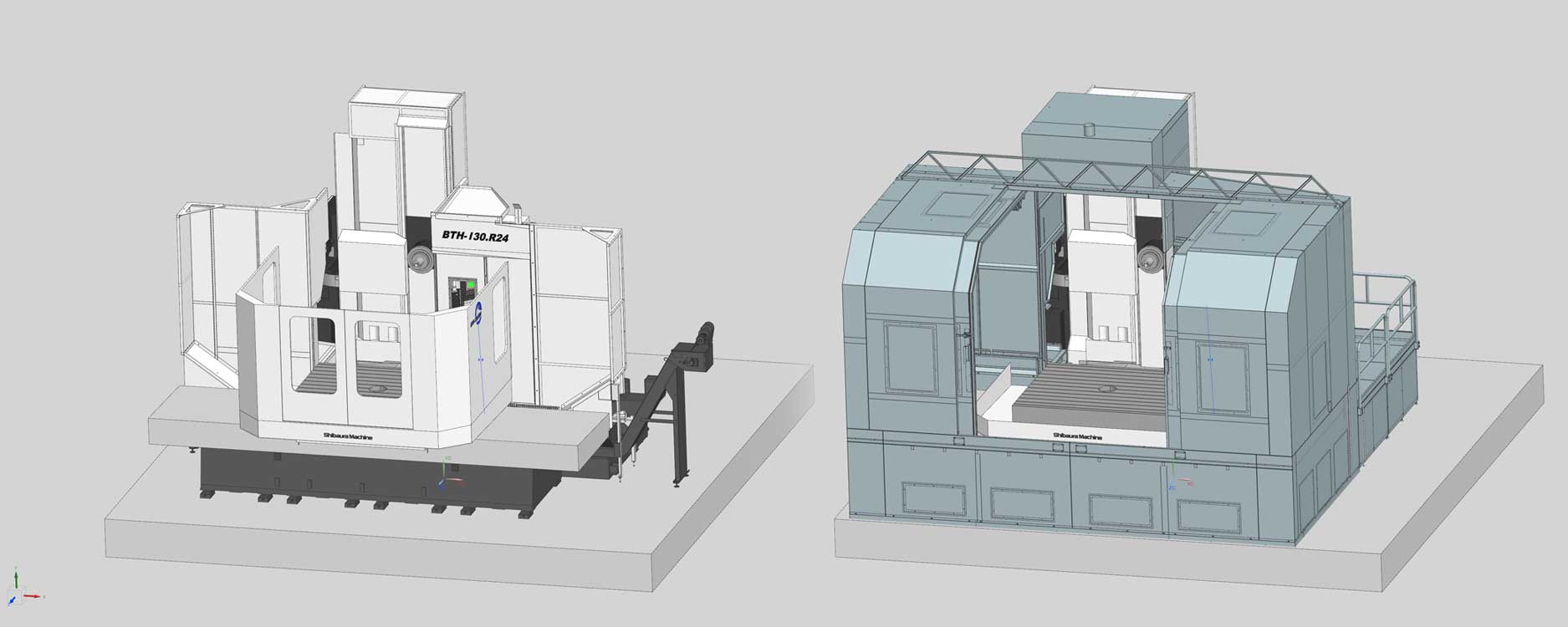

Read moreA Closer Look: Understanding the Benefits of Full Enclosures for Horizontal Boring Machines

ELK GROVE VILLAGE, IL, March 19, 2024 - Horizontal boring machines are powerhouses in precision machining, known for their ability to handle big, tough jobs with incredible accuracy. As technology evolves, so do the features that make these machine tools s...

Read moreWhat to Consider When Looking at Full Enclosures for Your Horizontal Boring Machine

ELK GROVE VILLAGE, IL, March 5, 2024 - The adoption of horizontal boring machines equipped with full enclosures marks a significant stride in manufacturing towards operational excellence and safety. As businesses strive to enhance their manufacturing capab...

Read moreUnderstanding Chip Management: Selecting the Correct Type of Chip Conveyor for Your Machining Needs

ELK GROVE VILLAGE, IL, February 27, 2024 - In the machining industry, precision and efficiency are key. Chip conveyors play an essential role in this environment, quietly ensuring machine tools stay clean and operational. Choosing the right size of chip co...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools