Siemens Realize Live 2024 Recap on Shibaura Machine’s Digital Twins and Virtual Reality

ELK GROVE VILLAGE, IL, May 28, 2024 -

At the recent Siemens Realize LIVE 2024 event, Shibaura Machine Company, America presented on the transformative potential of digital twins and virtual reality (VR) to further collaborative user engagement and optimize shop floor operations. The session highlighted key advancements and future directions.

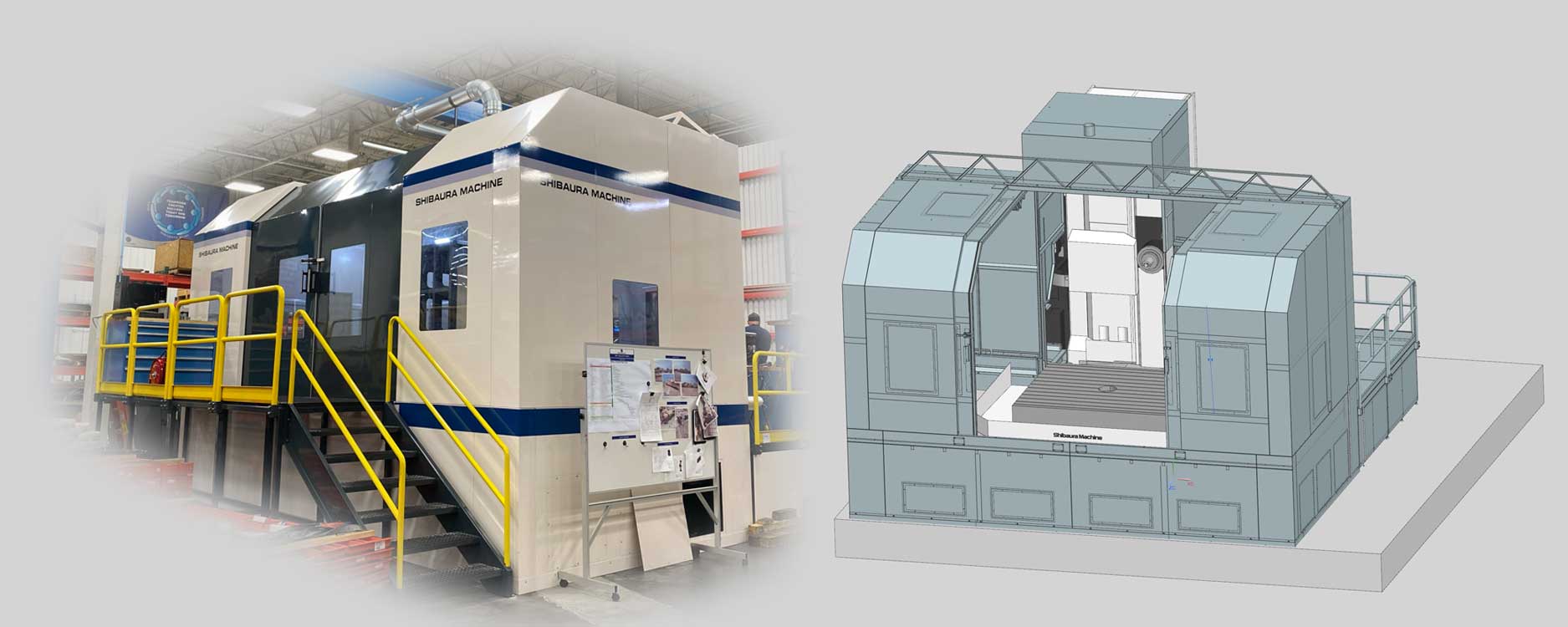

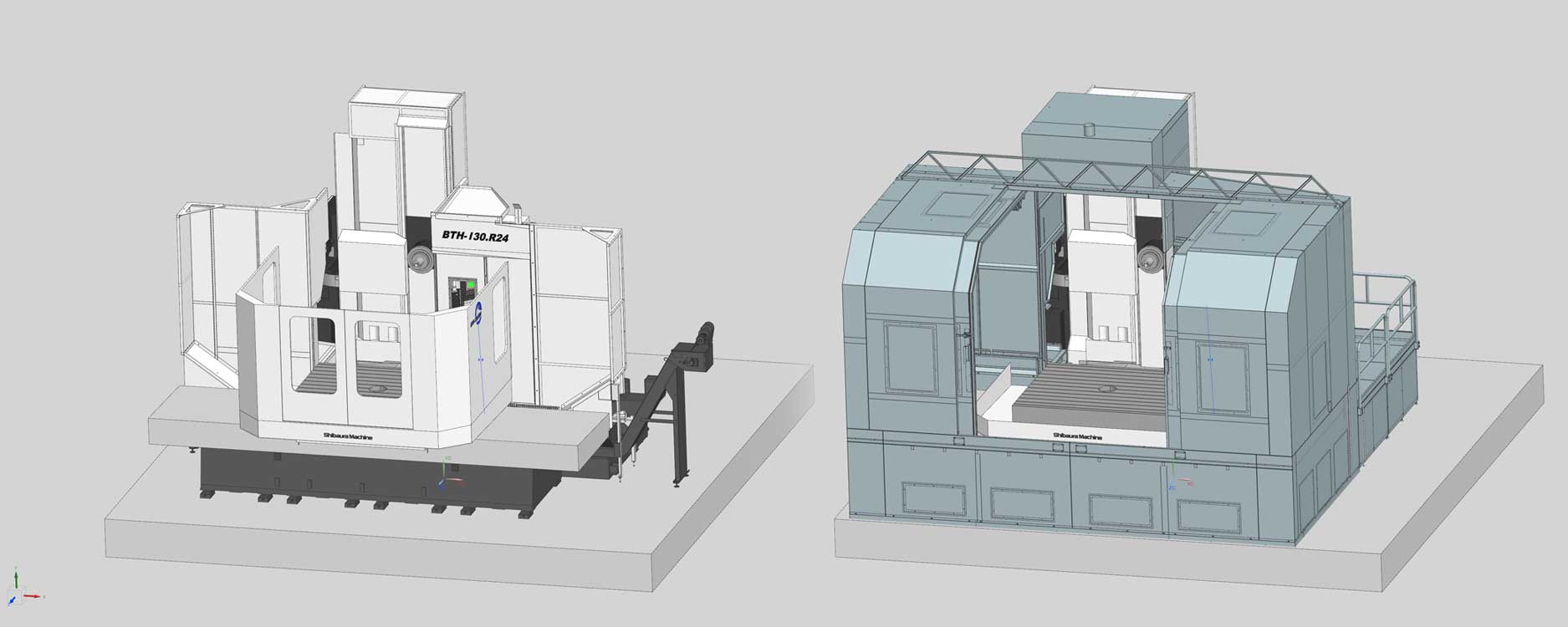

1. Digital Twins: Transforming Manufacturing Processes

Digital twins are virtual replicas of physical devices used to run simulations before actual devices are built and deployed. This technology allows for analysis and diagnostics, significantly reducing system downtime and maintenance costs.

At Shibaura Machine, integrating Siemens PLM technology has enabled us to not only keep pace with industry changes but to drive innovation, creating smarter, more adaptable manufacturing solutions that meet the stringent demands of modern production environments.

The digital twin provides a platform that facilitates strategic decision making that allows proactive, efficiency-focused decisions through accurate models and simulations. This capability reduces the need for physical prototypes, accelerates development cycles, and minimizes costs.

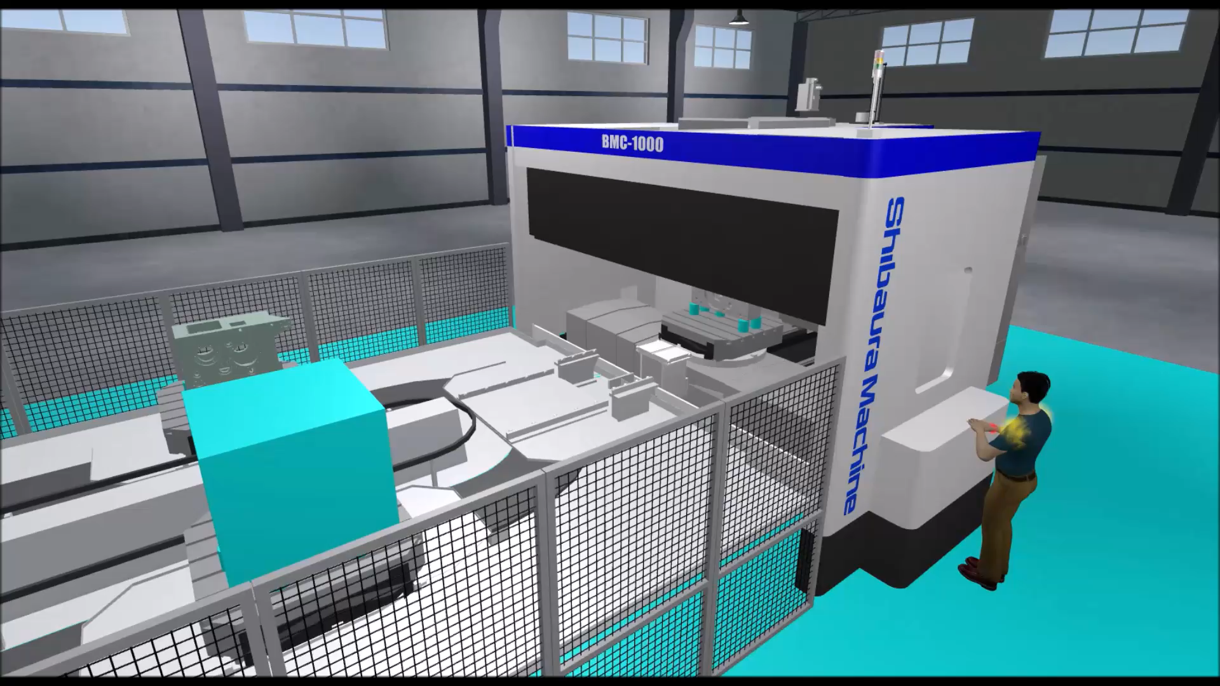

2. Virtual Reality: Enhancing Visualization and Training

Traditional virtual reality has been primarily associated with the entertainment industry, but it is now becoming a valuable engineering solution. Virtual reality enables unprecedented visualization of machinery and production lines, allowing components to be examined in high-resolution 3D. This detailed view makes it easier to discuss and understand even the most complex aspects of manufacturing processes.

Virtual reality also provides a safe, immersive training environment for complex procedures and scenarios, which has been shown to improve employee retention by offering a more engaging and effective learning experience.

3. Improved Global Collaboration: Breaking Down Barriers

Digital twins and virtual reality technologies enable teams from around the world to collaborate in shared virtual spaces, breaking down geographical barriers. This seamless collaboration allows for synchronized work sessions, adjustments, and a unified approach to problem-solving and innovation. VR facilitates flexible environments that adapt to different time zones and cultural contexts, making it easier to manage international projects and tap into diverse expertise.

Advantages of Improved Cooperation:

- Synchronized Work Sessions: Teams can view and interact with the same models simultaneously.

- Global Expertise Access: Collaboration between global teams without physical travel.

- Cultural and Temporal Flexibility: Adapts to different time zones and cultural contexts for effective project management.

Evolving Digitalization in Manufacturing

Shibaura Machine provides manufacturers with unprecedented insights into machine performance and production processes through the use of digital twins and virtual reality. This holistic approach enhances visibility, strategic decision-making, and ensures continuous improvement and excellence in manufacturing operations.

We invite you to explore these innovations and share your perspectives on the impact of digital twins and virtual reality in manufacturing at the upcoming International Manufacturing Technology Show, September 9-14. Reach out to learn more about how the Shibaura Machine Machine Tools team can help you adopt the future of manufacturing digitalization.

Realizing Manufacturing Excellence with VR and Digital Twins

Related Articles View All Machine Tools Articles

Explore Collaborative VR and Digital Twins with Shibaura Machine at Siemens Realize Live 2024

ELK GROVE VILLAGE, IL, April 23, 2024 - Join Shibaura Machine at the much-anticipated Siemens Realize LIVE 2024, held at Mandalay Bay Convention Center, Resort and Casino in Las Vegas, Nevada from May 13-16, where we’ll be showcasing how we’re harnessing S...

Read moreThe Foundation of Manufacturing Excellence: A Strong Machine Tool Factory Presence

ELK GROVE VILLAGE, IL, March 26, 2024 - The machine tool industry is a cornerstone of North American manufacturing. It powers sectors from automotive to aerospace with the precision and efficiency needed to compete on a global scale. In this dynamic landsc...

Read moreA Closer Look: Understanding the Benefits of Full Enclosures for Horizontal Boring Machines

ELK GROVE VILLAGE, IL, March 19, 2024 - Horizontal boring machines are powerhouses in precision machining, known for their ability to handle big, tough jobs with incredible accuracy. As technology evolves, so do the features that make these machine tools s...

Read moreWhat to Consider When Looking at Full Enclosures for Your Horizontal Boring Machine

ELK GROVE VILLAGE, IL, March 5, 2024 - The adoption of horizontal boring machines equipped with full enclosures marks a significant stride in manufacturing towards operational excellence and safety. As businesses strive to enhance their manufacturing capab...

Read moreUnderstanding Chip Management: Selecting the Correct Type of Chip Conveyor for Your Machining Needs

ELK GROVE VILLAGE, IL, February 27, 2024 - In the machining industry, precision and efficiency are key. Chip conveyors play an essential role in this environment, quietly ensuring machine tools stay clean and operational. Choosing the right size of chip co...

Read moreMaximizing Machine Tool Potential with High-Pressure Coolant Technology

ELK GROVE VILLAGE, IL, February 21, 2024 - In the precision-driven world of machine tooling, the pursuit for efficiency, durability, and superior performance is constant. Among the multitude of technological advancements, the application of high-pressure c...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools